Professional Documents

Culture Documents

6060 Properties

Uploaded by

interpon07Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6060 Properties

Uploaded by

interpon07Copyright:

Available Formats

1° PART*

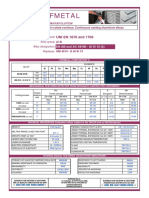

TECHNICAL DATA SHEET OF ALLOY 6060 AND ALUMINIUM PROFILE.

6060 T5 9006/1 EX UNI 3569

Corrispondence to normative laws

USA Italy Germany - France Great Britain Switzerland

A.A. UNI DIN W.N. Afnor B.S. S.N.

6060 9006/1 EX UNI 3569 AlMgSiO,5 3.3206 6060 6060 AlMgSi0.5

Chemical composition

Specification

- Impurity

number

A.A. Si Fe Cu Mn Mg Cr Zn Zr Ti Each Total

0.3 0.1 0.35

6060 0.10 0.10 0.05 0.15 - 0.10 0.05 0.15

0.6 0.3 0.6

Mechanical characteristics

Phisical Phisical

Tensile

Specification condition condition Yield point Stretching

strength Hardness

number according according Rp 0.2 to break point

at break HB

A.A. to UNI to UNI N/mm2 %

Rm (N/mm)

3565 8278

R O 140 max 80 max 20 40 max

TaN T1 120 50 16 35

6060

TaA T5 185 145 11 55

TA T6 205 165 10 60

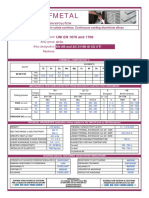

PHYSICAL PROPERTIES:

VOLUMIC MASS: ≈2,70 kg/dm³

INFERIOR MELTING POINT: ≈605 °C

SPECIFIC HEAT: ≈0,92 J/(g · K)

THERMAL STATE STATE Ω ≈2,09 W/(cm · K)

CONDUCTIVITY 20°C: STATE T6 ≈1,75 W/(cm · K)

from 20° to 100° 23 · 10-6 · K-1

THERMICAL LINEAR

EXPANSION COEFFICIENT: from 20° to 200° 24 · 10-6 · K-1

from 20° to 300° 25 · 10-6 · K-1

STATE Ω ≈3,14 µO · cm

RESISTIVITY AT 20°C

STATE T6 ≈3,25 µO · cm

ELASTIC MODULUS: ≈66000 N/mm2

HEAT TREATMENTS

Temper at the press following to artificial

T5 (standard)

ageing from 170 to 185°C for 6 - 10 h to regime.

TECHNOLOGICAL PROPRETIES

PROCESSING AND BEHAVIOUR SPECIFICATION APPRAISAL

for states O,T1,T4 good

cold plastic forming

for states T5,T6,T8 T10 scarce

with arc in inert gas (MIG e TIG)

and with added metal good

weldability in alloy Al-Si o Al-Mg

electrical resistance good

for states O T1,T4 redoubt

machinability

for states T5,T6,T8 T10 from sufficient to good

for states O T1,T4 sufficient

polishibility

for states T5,T6,T8 T10 good

marine and industrial good

corrosion proofness

urban and rural good

in environment

internal and dry optimal

aptitude at anodizing as protection and decorative use optimal

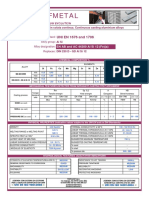

INERTIA MOMENTS AND STRENGTH

PROFILES Jxcm 3

Jxcm 4

Wx3 Wy3 PROFILES Jxcm3 Jxcm4 Wx3 Wy3

P120/10 1,93 1,93 1,29 1,29 P170/50 45,53 45,53 10,76 10,76

P120/18 1,28 1,28 0,91 0,91 P270/50 26,86 51,50 12,33 12,33

P220/18 0,80 2,16 0,67 0,67 P170/50bas 389,09 85,14 42,52 16,37

P130/25 4,10 4,10 1,90 1,90 Bas 40 7,87 9,07 3,75 4,53

P231/25 3,74 5,21 1,85 1,85 Bas 60 30,37 22,10 12,12 8,18

P232/25 4,54 4,54 3,26 3,26 Bas 80 94,78 88,80 23,69 22,20

P130/25bas 6,29 6,72 10,39 10,39 Bas 80/110 202,07 117,74 36,74 29,43

P140/20 8,90 8,90 3,54 3,54 Bas 100/40 79,80 17,91 15,96 8,95

P240/20 2,64 11,86 1,88 1,88 Bas 100/50 243,29 22,50 48,66 16,37

P242/20 2,15 9,50 1,75 1,75 Bas 150/50 241,19 31,66 32,16 10,92

P140/25 9,25 9,25 3,27 3,27 Bas 151/50 25,33 31,72 6,66 5,02

P240/25 3,97 14,25 2,87 2,87 S 1400/25I 8,15 8,15 3,05 3,05

P242/25 3,61 11,07 0 0 S 2400/25 3,97 14,25 2,87 2,87

P140/25bas 187,30 18,78 22,84 22,84 S 2401/25 3,51 11,07 0 0

P141/25 15,25 15,25 5,03 5,03 S 1400/35 9,11 9,11 3,40 3,40

P241/25 15,30 15,30 5,47 5,47 S 2400/35 8,36 13,60 3,48 3,40

P241/25bas 197,50 25,4 27,32 32,00 S 1500/25 14,01 14,01 4,80 4,80

P150/25 15,57 15,57 4,82 4,82 S 2500/25 4,55 20,18 2,76 2,76

P250/25 4,55 20,18 2,76 2,76 S 1501/45 17,05 17,05 5,10 5,10

P252/25 4,28 16,53 5,56 0 S 1700/50 43,53 43,53 9,80 9,80

P150/25bas 226,15 25,84 4,44 25,48 S 2700/50 26,86 51,50 12,33 12,33

P151/25 126,30 17,29 4,02 4,02 S 1700/50b. 389,09 85,14 42,52 16,37

P251/25 19,67 21,13 3,91 3,91 P160/45 40,05 40,05 9,60 9,60

P151/25bas 5,09 25,96 25,51 25,51 P160/45/IR 41,00 41,00 9,62 9,62

P150/45 19,83 19,83 5,67 5,67 P260/45 34,20 67,20 8,60 2,80

P250/45 17,53 23,16 5,97 5,97 P126 1,30 33,60 1,70 0

P252/45 16,24 22,57 0 0 P127 1,50 67,70 0,80 0,80

P151/45bas 16,47 30,97 5,15 30,02 P118 4,60 123,00 2,10 0

P170/25 45,16 45,16 22,54 22,54 P128 5,00 130,00 2,50 0

P170/25bas 379,53 84,59 16,26 41,47

P270/25 6,11 39,82 7,24 4,73

You might also like

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Cialis Case PDFDocument4 pagesCialis Case PDFinterpon07No ratings yet

- Material Alloy KHR32CDocument2 pagesMaterial Alloy KHR32CKHNo ratings yet

- CERTIFICATE OF QUALITY FOR STAINLESS STEEL SHEETDocument1 pageCERTIFICATE OF QUALITY FOR STAINLESS STEEL SHEETCarlos RomeroNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Brazil UnileverDocument5 pagesBrazil Unileverinterpon07100% (1)

- Potential Application of Nanotechnology in Transportation SeminarDocument20 pagesPotential Application of Nanotechnology in Transportation SeminarAvinash SugathanNo ratings yet

- The Determination of The Composition of Complex Ions in Solution by A Spectrophotometric MethodDocument5 pagesThe Determination of The Composition of Complex Ions in Solution by A Spectrophotometric Methodcassiopeia*TVXQ100% (14)

- Experiment 4 PostlabDocument3 pagesExperiment 4 PostlabArmiee InfiniteNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- En 44100Document2 pagesEn 44100hiren_mistry55No ratings yet

- Raffmetal aluminium alloy guideDocument2 pagesRaffmetal aluminium alloy guideDhamodaran RNo ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- Raffmetal: UNI EN 1676 and 1706Document1 pageRaffmetal: UNI EN 1676 and 1706swaroop NalamNo ratings yet

- Product Catalog AluminiuDocument32 pagesProduct Catalog AluminiusnoofsnoofNo ratings yet

- Alloy 6082 - Rev2012Document2 pagesAlloy 6082 - Rev2012Ysraels Santisteban DurandNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Jonas AnderssonNo ratings yet

- Cosmos Alminium-Technical - Specifications PDFDocument2 pagesCosmos Alminium-Technical - Specifications PDFmindsopenNo ratings yet

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Krzysztof WrzeszczNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Tehnicke Karakteristike Asistal Alu OkapnicaDocument2 pagesTehnicke Karakteristike Asistal Alu OkapnicaDARKO RADICEVICNo ratings yet

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNo ratings yet

- Datasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Document6 pagesDatasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Mohammed Saleem Syed KhaderNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Autrod 1264Document2 pagesAutrod 1264Anonymous yL7oldKNo ratings yet

- Jis C3771Document2 pagesJis C3771bkprodhNo ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- EN47100Document2 pagesEN47100tsonjayaNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Heat Resistant Alloy HN Data SheetDocument2 pagesHeat Resistant Alloy HN Data SheetAzize RazamNo ratings yet

- AbcDocument2 pagesAbcsurendarNo ratings yet

- Astm A-297 HPDocument2 pagesAstm A-297 HPeduardo_exsys100% (1)

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- Sandvik 254 SMO Datasheet for Seamless Tube and PipeDocument9 pagesSandvik 254 SMO Datasheet for Seamless Tube and PipeReadersmoNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Product Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Cem DufourNo ratings yet

- Special Steels A320 L43: American Standards AstmDocument1 pageSpecial Steels A320 L43: American Standards Astmsamirfun2006No ratings yet

- CDA110 Specifaction SheetDocument5 pagesCDA110 Specifaction SheetGendakensNo ratings yet

- En Aw 6082 Rev 2 Final PDFDocument3 pagesEn Aw 6082 Rev 2 Final PDFtechspawNo ratings yet

- RAFFMETAL: THE ALUMINIUM EVOLUTIONDocument2 pagesRAFFMETAL: THE ALUMINIUM EVOLUTIONAmandeep SinghNo ratings yet

- The Aluminium Evolution: Continuous Casting Aluminium AlloysDocument2 pagesThe Aluminium Evolution: Continuous Casting Aluminium AlloysHareth MRAIDINo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Datasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1Document13 pagesDatasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1mauferesNo ratings yet

- kme_STOL76_C19010_enDocument1 pagekme_STOL76_C19010_enMattia Terri TerrandoNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- En 1706 Aluminum and Aluminum Alloys Castings en 1676 Aluminum Alloyed Ingots For RemeltingDocument1 pageEn 1706 Aluminum and Aluminum Alloys Castings en 1676 Aluminum Alloyed Ingots For RemeltingBahar ÇolakNo ratings yet

- Product Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Filipe CordeiroNo ratings yet

- Join & Repair High-Carbon Steels with NiCr HLSDocument1 pageJoin & Repair High-Carbon Steels with NiCr HLSwalter091011No ratings yet

- 34 CR Ni Mo 6Document2 pages34 CR Ni Mo 6hp_vijaykNo ratings yet

- MS SHEETS MTCDocument6 pagesMS SHEETS MTCAmit Kumar OjhaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Jonathan Getial CruzNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6InaamNo ratings yet

- PressedDocument46 pagesPressedsameh aboulsoudNo ratings yet

- Al 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSADocument2 pagesAl 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSAAlex GăuruşNo ratings yet

- Alloy 360 Data SheetDocument4 pagesAlloy 360 Data SheetImags GamiNo ratings yet

- Contact Material Beryllium Nickel Be NiStrip360 PDFDocument4 pagesContact Material Beryllium Nickel Be NiStrip360 PDFImags GamiNo ratings yet

- Rifeng PAP 2Document37 pagesRifeng PAP 2Sota KarunaNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Unilever Marketing Strategy For Brazil Low Income ConsumersDocument13 pagesUnilever Marketing Strategy For Brazil Low Income Consumerscoolvidhs3817No ratings yet

- X 062 Chemical Resistance of PUR (Polyurethane)Document1 pageX 062 Chemical Resistance of PUR (Polyurethane)interpon07No ratings yet

- Macro Tim Harford ArticleDocument14 pagesMacro Tim Harford Articleinterpon07No ratings yet

- Global Recovery Brings Opportunities For Emerging MarketsDocument6 pagesGlobal Recovery Brings Opportunities For Emerging Marketsinterpon07No ratings yet

- Battery Comparison Graphs PDFDocument7 pagesBattery Comparison Graphs PDFinterpon07No ratings yet

- The Goal SummaryDocument14 pagesThe Goal Summaryinterpon07No ratings yet

- Mountain ManDocument7 pagesMountain Maninterpon07No ratings yet

- Decision CasesDocument1 pageDecision Casesinterpon07No ratings yet

- The Effectiveness of The Dove Campaign For Real Beauty in Terms oDocument74 pagesThe Effectiveness of The Dove Campaign For Real Beauty in Terms ointerpon07No ratings yet

- Air Plasma Spray.: (Click Here For Materials)Document2 pagesAir Plasma Spray.: (Click Here For Materials)interpon07No ratings yet

- The Effectiveness of The Dove Campaign For Real Beauty in Terms oDocument74 pagesThe Effectiveness of The Dove Campaign For Real Beauty in Terms ointerpon07No ratings yet

- SEO-Optimized Title for Document on Consumer Choice with Composite GoodsDocument19 pagesSEO-Optimized Title for Document on Consumer Choice with Composite Goodsinterpon07No ratings yet

- 8-The GoalDocument7 pages8-The Goalinterpon07No ratings yet

- Argonne Li-Ion ReportDocument73 pagesArgonne Li-Ion ReportDuke LeaheyNo ratings yet

- 420 HSB Recommended Practice For Electrical Preventive Maintenance - 2Document10 pages420 HSB Recommended Practice For Electrical Preventive Maintenance - 2WaqasMumtaz100% (1)

- Advances in Thermal Spray TechnologyDocument3 pagesAdvances in Thermal Spray Technologyinterpon07No ratings yet

- Install09 - BusbarDocument2 pagesInstall09 - Busbarinterpon07100% (1)

- Pu PDFDocument5 pagesPu PDFinterpon07No ratings yet

- Vol3-3 Elec Conn For Power CircuitsDocument20 pagesVol3-3 Elec Conn For Power CircuitsmichellerejanoNo ratings yet

- Vol3-3 Elec Conn For Power CircuitsDocument20 pagesVol3-3 Elec Conn For Power CircuitsmichellerejanoNo ratings yet

- Through Hole PCB Plating with BaytronDocument2 pagesThrough Hole PCB Plating with Baytroninterpon07No ratings yet

- Aluminum Vs CopperDocument7 pagesAluminum Vs Copperc.a.g.p.No ratings yet

- Galvanized Steel Inspection GuideDocument20 pagesGalvanized Steel Inspection GuidePham Ngoc Khan100% (2)

- Battery ComparisonDocument7 pagesBattery Comparisoninterpon07No ratings yet

- ReVolt Zn-air Batteries for MobilityDocument9 pagesReVolt Zn-air Batteries for Mobilityinterpon07No ratings yet

- Bachelor of Pharmacy: Aks University, SatnaDocument93 pagesBachelor of Pharmacy: Aks University, SatnaPrathiNo ratings yet

- UNIT: Total and Direct BilirubinDocument10 pagesUNIT: Total and Direct BilirubinbiddyusmcNo ratings yet

- Fly Ash. Use of Secondary Additives in Fly Ash Based Soil Stabilization For Soft SubgradesDocument34 pagesFly Ash. Use of Secondary Additives in Fly Ash Based Soil Stabilization For Soft SubgradesjyjiaNo ratings yet

- Discover the functions and properties of lipids through experimentsDocument8 pagesDiscover the functions and properties of lipids through experimentsJasper Ian Tan JumalaNo ratings yet

- 2701 Downstream ProcessingDocument16 pages2701 Downstream Processingdadang71No ratings yet

- Battery AdvancementsDocument7 pagesBattery Advancementsabhishek gowdaNo ratings yet

- Objective: Write A Formula Equation, Complete Ionic Equation, and Net Ionic Equation That Represent A ReactionDocument8 pagesObjective: Write A Formula Equation, Complete Ionic Equation, and Net Ionic Equation That Represent A Reactionp bergerNo ratings yet

- Graphene PropertiesDocument6 pagesGraphene PropertiesAwais BodlaNo ratings yet

- 28093.formicary Corrosion - Cu TubesDocument1 page28093.formicary Corrosion - Cu TubesRomie CubalNo ratings yet

- Biscuit Baking and Industries in IndiaDocument27 pagesBiscuit Baking and Industries in IndiaSam BoykaNo ratings yet

- 12 Chemistry NcertSolutions Chapter 12 IntextDocument9 pages12 Chemistry NcertSolutions Chapter 12 IntextAkhil KrishnaNo ratings yet

- Chemical Engineering JournalDocument3 pagesChemical Engineering Journalelsa merryNo ratings yet

- Full Download Test Bank For Foundations of Maternal Newborn and Womens Health Nursing 6th Edition by Murray PDF FreeDocument32 pagesFull Download Test Bank For Foundations of Maternal Newborn and Womens Health Nursing 6th Edition by Murray PDF FreeMichael Taylor100% (12)

- Smart Tools For Smart ApplicationsDocument208 pagesSmart Tools For Smart ApplicationsTaha AbdouNo ratings yet

- CHE 203 Thermodynamics Final ExamDocument5 pagesCHE 203 Thermodynamics Final ExamcessareNo ratings yet

- Quiz - 1 Part - ADocument6 pagesQuiz - 1 Part - ATarang AgrawalNo ratings yet

- Heats of Formation and Chemical CompositionsDocument18 pagesHeats of Formation and Chemical Compositionshermas67No ratings yet

- Alkyd Resin Soucek2015Document83 pagesAlkyd Resin Soucek2015Anchit GhoshNo ratings yet

- Calvin CycleDocument6 pagesCalvin CycleAtika ZulfiqarNo ratings yet

- SínteseDocument2 pagesSínteseDaniel Viana RodriguesNo ratings yet

- CH 10 and 11 Acid-Base QuestionsDocument8 pagesCH 10 and 11 Acid-Base QuestionsNap DoNo ratings yet

- High Temperature CorrosionDocument2 pagesHigh Temperature CorrosionIlhamChaniefNo ratings yet

- Glycerol Acetylation 1Document224 pagesGlycerol Acetylation 1Matheus ZimermannNo ratings yet

- 5 Boiler OperationDocument12 pages5 Boiler OperationAllen AnyayahanNo ratings yet

- B. Q. Vaccine Medium (Thioglycollate Broth W - Liver Extract)Document3 pagesB. Q. Vaccine Medium (Thioglycollate Broth W - Liver Extract)Kunal VermaNo ratings yet

- Ficha Técnica Heparina PDFDocument4 pagesFicha Técnica Heparina PDFArthur CordeiroNo ratings yet

- Paper FerrocenoDocument5 pagesPaper FerrocenoEmily Coromoto Gonzalez MarcanoNo ratings yet