Professional Documents

Culture Documents

Repeater Comba R-9110AC

Uploaded by

JohnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Repeater Comba R-9110AC

Uploaded by

JohnCopyright:

Available Formats

EQUIPMENT MANUAL FOR R-9110AC

R-9110AC

GSM 900 BAND SELECTIVE REPEATER

EQUIPMENT MANUAL

The information contained herein is the

responsibility of and is approved by the

following, to whom all enquiries should be

directed in the first instance:

Nicole Au/David Shiu

International Documentation Centre

Comba Telecom

This is an unpublished work the copyright in which vests in Comba International ("Comba"). All rights reserved.

The information contained herein is confidential and the property of Comba and is supplied without liability for errors or omissions. No part

may be reproduced, disclosed or used except as authorised by contract or other written permission. The copyright and the foregoing

restriction on reproduction and use extend to all media in which the information may be embodied.

R-9110AC QE Copyright - refer to title page Page 1

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

0.2 CONTENTS

Section Page

0.2 CONTENTS ...........................................................................................................................2

0.3 INDEX TO FIGURES AND TABLES .....................................................................................4

0.4 HISTORY...............................................................................................................................5

0.5 ISSUE CONTROL .................................................................................................................6

0.6 REFERENCES ......................................................................................................................7

0.7 GLOSSARY OF TERMS .......................................................................................................8

0.8 SAFETY NOTICES AND ADMONISHMENTS......................................................................9

0.9 SERVICING POLICY AND RETURN OF EQUIPMENT .....................................................10

0.10 READERS COMMENTS .....................................................................................................11

1 GENERAL INFORMATION .................................................................................................12

2 EQUIPMENT DESCRIPTION..............................................................................................13

2.1 GENERAL............................................................................................................................13

2.2 EQUIPMENT LAYOUT ........................................................................................................13

2.3 R-9110AC BLOCK DIAGRAM.............................................................................................14

2.4 MANUFACTURING ENTITIES............................................................................................14

2.5 KIT OF PARTS ....................................................................................................................15

2.6 TECHNICAL SPECIFICATIONS .........................................................................................16

2.6.1 ELECTRICAL AND POWER ...............................................................................................16

2.6.2 MECHANICAL, ENVIRONMENTAL ....................................................................................16

2.6.3 OPERATION & MAINTENANCE.........................................................................................17

3 INSTALLATION ...................................................................................................................18

3.1 WARNINGS AND ALERTS .................................................................................................18

3.2 SITE PLANNING CONSIDERATIONS................................................................................19

3.2.1 REPEATER INSTALLATION CHECKLIST .........................................................................20

3.2.2 ANTENNA INSTALLATION CONSIDERATION..................................................................20

3.3 INSTALLATION PROCEDURES.........................................................................................21

3.3.1 GOODS INWARDS INSPECTION ......................................................................................21

3.3.2 TOOLS.................................................................................................................................21

3.3.3 PREPARATION ...................................................................................................................21

3.3.4 WALL MOUNTING DETAILS ..............................................................................................22

3.3.5 POLE MOUNTING DETAILS ..............................................................................................23

3.3.6 DRIP-LOOP .........................................................................................................................23

3.3.7 EQUIPMENT CONNECTIONS............................................................................................23

4 COMMISSIONING...............................................................................................................25

4.1 MCU LED INDICATORS .....................................................................................................25

4.2 EQUIPMENT POWER-UP ..................................................................................................25

4.3 OMT .....................................................................................................................................26

4.4 NON-VOLATILE MEMORY .................................................................................................26

4.4.1 OMT SOFTWARE VERSION ..............................................................................................27

4.4.2 OMT SOFTWARE INSTALLATION.....................................................................................27

4.4.3 PREPARATION FOR REMOTE CONNECTION OF OMT USING WIRELESS

MODEM ...............................................................................................................................27

4.4.4 CONNECTING OMT TO EQUIPMENT ...............................................................................28

4.5 LOCAL COMMISSIONING..................................................................................................29

4.5.1 DESCRIPTION OF PARAMETERS ....................................................................................30

4.6 COMMISSIONING PROCEDURES ....................................................................................34

4.7 REMOTE MONITORING USING OMC ...............................................................................36

5 OPERATION........................................................................................................................37

R-9110AC QE Copyright - refer to title page Page 2

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

6 MAINTENANCE...................................................................................................................38

7 APPENDICES......................................................................................................................39

7.1 APPENDIX A: TOOLS AND EQUIPMENT FOR INSTALLATION ......................................39

7.2 APPENDIX B: VSWR – RETURN LOSS TABLE ................................................................39

7.3 APPENDIX C: UPLINK ATT AND NOISE LEVEL...............................................................39

7.4 APPENDIX D: RMA (RETURN MATERIAL AUTHORIZATION) FORM .............................40

R-9110AC QE Copyright - refer to title page Page 3

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

0.3 INDEX TO FIGURES AND TABLES

Fig 1: Front view of equipped product .............................................................................................13

Fig 2: R-9110AC block diagram ......................................................................................................14

Fig 3: Mounting rack dimension ......................................................................................................22

Fig 4: Wall mounting overview.........................................................................................................22

Fig 5: Pole mounting overview ........................................................................................................23

Fig 6: Location of MCU and LED.....................................................................................................25

Fig 7: Wireless modem....................................................................................................................27

Fig 8: OMT screenshot - communication setup ..............................................................................28

Fig 9: OMT screenshot - Main window............................................................................................29

Table 1: R-9110 variants ..................................................................................................................13

Table 2: R-9110AC Manufacturing Entities ......................................................................................14

Table 3: R-9110AC KOP ..................................................................................................................15

Table 4: Electrical specifications ......................................................................................................16

Table 5: Mechanical and environmental specifications....................................................................16

Table 6: Management of R-9110AC.................................................................................................17

Table 7: Repeater Installation checklist............................................................................................20

Table 8: Antenna installation checklist .............................................................................................20

Table 9: MCU LED............................................................................................................................25

Table 10: Management - Network Parameters ..............................................................................30

Table 11: Management - RF parameters .........................................................................................31

Table 12: Management - Alarm list...................................................................................................32

Table 13: Commissioning procedures..............................................................................................35

Table 14: Alarms diagnosis ..............................................................................................................37

R-9110AC QE Copyright - refer to title page Page 4

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

0.4 HISTORY

Change No. Issue/ENU Details Of Change

1 V 2.1 Issued on March 2003 and revised on Oct 2004

2 1-0-0 Re-write and issued in March 2005, Author D Shiu

R-9110AC QE Copyright - refer to title page Page 5

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

0.5 ISSUE CONTROL

Date 02

03

05

Section

All all

R-9110AC QE Copyright - refer to title page Page 6

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

0.6 REFERENCES

0.6.1 OMT Installation guide for R-9110AC ENU 1-0-0 prepared by Nicole Au Mar 2005

R-9110AC QE Copyright - refer to title page Page 7

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

0.7 GLOSSARY OF TERMS

Abbreviation Definition

ALC Automatic Level Control

ATT Attenuation

BS Base Station

BTS Base Transceiver Station

dB Decibel

dBm Decibels relative to 1 milliwatt

DL Downlink

DT Donor Terminal

DPX Duplexer

EEPROM Electrically Erasable Programmable Read Only

Memory

FS Frequency Selector

GSM Groupe Speciale Mobile or Global Standard for Mobile

Communication

Hz Hertz

ID Identification

LNA Low Noise Amplifier

MCU Main Control Unit

MHz Megahertz

MT Mobile Terminal

MTBF Mean Time Between Failures

NC Normally Closed

NF Noise Figure

NO Normally Open

OMC Operation & Maintenance Center

OMT Operation & Maintenance Terminal

PLL Phase Locked Loop

PSU Power Supply Unit

RF Radio Frequency

SMA Sub-Miniature A Connector (coaxial cable connector

type)

SMS Short Message System

UL Uplink

VAC Volts Alternating Current

VSWR Voltage Standing Wave Radio

R-9110AC QE Copyright - refer to title page Page 8

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

0.8 SAFETY NOTICES AND ADMONISHMENTS

This document contains safety notices in accordance with appropriate standards. In the interests of

conformity with the territory standards for the country concerned, the equivalent territorial

admonishments are also shown.

Any installation, adjustment, maintenance and repair of the equipment must only be carried out by

trained, authorised personnel. At all times, personnel must comply with any safety notices and

instructions.

Specific hazards are indicated by symbol labels on or near the affected parts of the equipment. The

labels conform to international standards, are triangular in shape, and are coloured black on a yellow

background. An informative text label may accompany the symbol label.

Hazard labelling is supplemented by safety notices in the appropriate equipment manual. These

notices contain additional information on the nature of the hazard and may also specify precautions.

Warning:

These draw the attention of personnel to hazards which may cause death or injury to the operator or

others. Examples of use are cases of high voltage, laser emission, toxic substances, point of high

temperature, etc.

Alert:

These draw the attention of personnel to hazards which may cause damage to the equipment. An

example of use is the case of static electricity hazard.

Caution notices may also be used in the handbook to draw attention to matters that do not constitute

a risk of causing damage to the equipment but where there is a possibility of seriously impairing its

performance, e.g. by mishandling or gross maladjustment. Warnings and Cautions within themain

text do not incorporate labels and may be in shortened form.

R-9110AC QE Copyright - refer to title page Page 9

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

0.9 SERVICING POLICY AND RETURN OF EQUIPMENT

The repair of individual units and modules of this equipment is not considered practicable without

factory facilities. It is, therefore, the policy of Comba whereby faulty units or modules are returned to

the local agent for repair.

To enable an efficient, prompt after sales service to be provided for the diagnosis, repair and return

of any faulty equipment, please comply with the following requirements.

Items to be sent for repair should be packaged so as to provide both electrostatic and physical

protection and a Repair Material Authorization (a sample of this form is in appendix D) completed

giving the required information

This request must be included with the item for repair, items for repair should be sent to the nearest

Comba office:

COMBA TELECOM SYSTEMS, LTD.

Hong Kong Office

Address: Room 1503-10 Delta House, 3 On Yiu Street, Shatin, Hong Kong.

Tel: + 852 2636 6861

Fax: + 852 2637 0966

Email: combahk@comba-telecom.com

Singapore office

Address: 865 Mountbatten Road #05-43, Katong Shopping Centre, Singapore 449408

Tel: + 65 6345 4908

Fax: + 65 6345 1186

Email: combasg@comba-telecom.com

Sweden Office

Address: Comba Telecom Systems AB, Gustavslundsvagen 147, S- 167 51 Bromma,

Stockholm, Sweden

Tel: +46 8 25 38 70

Fax: +46 8 25 38 69

Email: info@comba-telecom.se

China R&D and Manufacturing Base

Address: No.6, Jinbi Road, Guangzhou Economic and Technological Development

District, Guangzhou, China.

Tel: + 86 20 8222 5788

Fax: + 86 20 8222 6121

Email: combagz@comba-telecom.com

R-9110AC QE Copyright - refer to title page Page 10

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

0.10 READERS COMMENTS

Whilst every endeavour is made to ensure the accuracy of this and all Comba documents, there is

always the possibility that an inaccuracy or omission could occur.

In order that any amendment/remedial action can be carried out promptly, we would appreciate your

co–operation in filling out and returning a photocopy of this customer reply sheet as soon as

possible.

Customer Information:

Name

Title

Company

Date

Address

Telephone Number

Customer Comments:

Equipment title

ENU 1-0-0

Page number

Paragraph number

Line number

Figure number

Details of inaccuracies

Other comments

End of section

R-9110AC QE Copyright - refer to title page Page 11

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

1 GENERAL INFORMATION

R-9110AC system is a GSM 900 MHz band-selective RF repeater. The system is used in outdoor

locations where signal coverage for dead zone is desired (e.g. villages, highways, rural area, etc.)

Band-specific linear amplifier and filtering effectively amplifies the desired BTS carrier and provides

superior out-of-band rejection. Typical units incorporate up to 15MHz, 19MHz and 24.6MHz filter

bandwidth with frequencies programmed to specific requirements of the network. Remote

configuration and surveillance is possible through Comba’s remote control and monitoring system,

via laptop or wireless modem to the OMC. Li-ion battery backup built in enclosure ensures alarm

signals are sent out in the event of power failure, and optional external battery backup ensures

operation in conditions of non-ideal power supply or unstable supply voltages. The R-9110AC

comes in a completely sealed, well-ventilated cast aluminum chassis, suitable for all weather

conditions.

Main features of R-9110AC:

z High output power of 10W.

z Band selective with variable bandwidth from 2 to 15MHz (19MHz or 24.6MHz) in full band

of GSM 900MHz.

z Integrated GSM modem for remote configuration, monitoring and control.

z Automatic gain stabilization prevents self oscillation caused by a low isolation between

DT and MT antennas.

z Internal backup battery keeps the alarm unit running for up to 3 hours after power loss.

z Optional OMC is available for remote operation and maintenance of repeaters.

z Designed for all weather outdoor – waterproof, damp-proof and omni-sealed (IP65).

End of section

R-9110AC QE Copyright - refer to title page Page 12

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

2 EQUIPMENT DESCRIPTION

2.1 GENERAL

The R-9110AC repeater consists of:

z Frequency Selector (FS): can select the demand signal band and reject the other

unwanted signals effectively.

z Power Amplifier (PA): fulfils power amplification in both of uplink and downlink branches.

z Couplers: Located towards the DT and MT connections, these provide coupling signal to

the modem and as a point for testing the DL input and UL output power levels.

z Duplexer (DPX): Located towards the DT and MT connections, their function is to

combine/divide the uplink and downlink signals.

z One Low Noise Amplifier (LNA) is installed in each UL/DL branch. The repeater UL/DL

ATT value corresponds individually to UL/DL LNA gain.

z Main Control Unit (MCU): is used to monitor and control the operation parameters of the

repeater and provides telecommunication interface for remote control, indicator LEDs

(L1~L4) on which display the respective operation status.

z Located on the distribution board (backplane) the following connections: connectivities to

function modules, MCU, RS232 port (D5) for local control.

The following variant exists under the R-9110 naming structure:

R-9110AC Band selective repeater

R-9110AS Solar powered GSM repeater

R-9110DB Dual Cell (Two Band Selective)

R-9110H Hybrid repeater Hybrid (Band and Channel Selective)

Table 1: R-9110 variants

2.2 EQUIPMENT LAYOUT

Fig 1: Front view of equipped product

R-9110AC QE Copyright - refer to title page Page 13

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

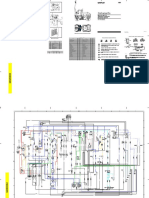

2.3 R-9110AC BLOCK DIAGRAM

ALC

M-ATT

DL Band Selective

LNA1 Module PA1

Downlink

Donor Mobile

Ant Ant

DT MT

ALC

M-ATT

UL Band Selective

PA2 Module LNA2

Mobile

Uplink

Alarm Power Li-ion

Main Control Unit

OMT Indicator Supply BATT

Computer with Modem

Data card

Wireless

Modem

External

Power

OMT

OMC

Fig 2: R-9110AC block diagram

2.4 MANUFACTURING ENTITIES

R-9110AC is composed of modules with the following identifiers.

Identification Code Description

PA-4250CSS00D Downlink broadband power amplifier

PA-4250CSS00U Uplink broadband power amplifier

FB-C942B27SS06 Downlink broadband frequency selector

FB-C897B24SS06 Uplink broadband frequency selector

LA-1439C1SS01 Low noise amplifier

FD-U897D942B25SS03 Duplexer

RC-5SK/SK/SK-30C DT coupler

RC-5SK/SK/SK-20C MT coupler

R-9110AC1-M1 Main control unit

R-9110AC1-BB Distribution board

WM02-G900 Wireless modem

PC222435A-1 (26V) Power supply unit

3.6V/1300mAh ×6 Li-on battery assembly

V20-C/2 Lightning arrester

Table 2: R-9110AC Manufacturing Entities

R-9110AC QE Copyright - refer to title page Page 14

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

2.5 KIT OF PARTS

Product identifier Description

R-9122C8-5140/1 Mounting rack (kit)

M10×110 Masonry bolt

M10×85×110 U expansion bolt

5.5 Allen key

R-9122C/R-9122AC Field commission cable

Label “9122” Key

6.3A Delay Fuse

R-9110AC QE 1-0-0 This equipment manual

V1.03 OMT software

Table 3: R-9110AC KOP

R-9110AC QE Copyright - refer to title page Page 15

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

2.6 TECHNICAL SPECIFICATIONS

2.6.1 ELECTRICAL AND POWER

Frequency Range, UL – [MHz] 890 – 915

Frequency Range, DL – [MHz] 935 – 960

Max. Filter Bandwidth (FBW) – [MHz] *1 15, 19, 24.6

Operating bandwidth (BW) – [MHz] 2 – FBW

(Adjustable in GSM900MHz Full

Band)

System Gain Adjustable Range– [dB] (1dB Step) 60–92 ± 2

3rd Order Intercept, OIP3 – [dBm] 55 (10W), 58 (1W, 2W)

Output Power (with ALC) – [dBm] 30, 33, 40 ± 1

Pass Band Ripple @ FBW, p-p – [dB] ≤4

System Noise Figure – [dB] ≤5

@ Max. System Gain

Group Delay – [µsec] ≤6

Out-of-band Gain @System Gain ≤ 80 – [dB] *2

- at Offset ≥ 400KHz < 50

- at Offset ≥ 600KHz < 40

- at Offset ≥ 1MHz < 35

- at Offset ≥ 5MHz < 25

Spurious – [dBm]

- 9kHz to 1GHz ≤ -36

- 1GHz to 12.75GHz ≤ -30

Intermodulation @ 2x22dBm – [dBm] ≤ -36 (10W output power)

Intermodulation @ 2x27dBm – [dBm] ≤ -36 (1W, 2W output power)

Max. Non-destructive RF Input Power – [dBm] +10

VSWR ≤ 1.5

Impedance – [Ω] 50

Power Supply – [VAC] 155–285 / 45-55Hz

Power Consumption – [W] 150 (10W output power, approx.)

130 (1W, 2W output power, approx.)

MCU Battery Backup Time – [hr] 3 (approx.)

Power Up Waiting Time – [sec] 60 (approx.)

Table 4: Electrical specifications

2.6.2 MECHANICAL, ENVIRONMENTAL

Dimensions, L x W x H – [mm] 600 x 450 x 195

Housing Material Aluminum

Housing Color Grey Anodized, RAL877U

Weight – [kg] 37 (approx.)

Connector Type N-Female

Operating Temperature – [°C] -40 to +55

Operating Humidity – [%] ≤ 95

Cooling Convection

MTBF – [hrs] > 50,000

Environmental Class IP65

Table 5: Mechanical and environmental specifications

R-9110AC QE Copyright - refer to title page Page 16

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

2.6.3 OPERATION & MAINTENANCE

Local Monitoring Feature PC via RS232

Remote Data Transfer Built-in wireless GSM modem

(data or SMS), OMC (optional)

Local and Remote Controlled Parameters Channel No., ATT, Soft

ON/OFF, Oscillation Elimination

ON/OFF, Over-Temp Threshold,

DL Output Power Threshold, DL

Input Power Threshold, Alarm

Report Enable

Local and Remote Monitored Parameters Alarms (LNA, PA, PLL unlock,

Power Down, PSU Fault, Door

Open, Self oscillation, DL Input

Power Low, Over Temp,

VSWR, DL Output Power Low),

UL/DL Output Power, DL Input

Power

Table 6: Management of R-9110AC

End of section

R-9110AC QE Copyright - refer to title page Page 17

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

3 INSTALLATION

3.1 WARNINGS AND ALERTS

Radio Frequency energies

There may be situations, particularly workplace environments near high- powered RF sources,

where recommended limits for safe exposure of human beings to RF energy could be exceeded. In

such cases, restrictive measures or actions may be necessary to ensure the safe use of RF energy.

High voltage

The equipment have been designed and constructed as to prevent as far as reasonably practicable

danger. Any work activity on or near equipment involving installation, operation or maintenance must

be as far as reasonably free from danger.

Where there is a risk of damage to electrical systems involving adverse weather, extreme

temperatures, wet, corrosive or dirty conditions, flammable or explosive atmospheres than the

system must be suitably installed to prevent danger.

Protective Earthing

Equipment provided for the purpose of protecting individuals from electrical risk must be suitable for

the purpose and properly maintained and used.

Handling Percautions

This covers a range of activities including lifting, lowering, pushing, pulling, carrying, moving, holding

or restraining an object, animal or person. It also covers activities which require the use of force or

effort such as pulling a lever, or operating power tools.

ESD

Observe standard precautions for handling ESD-sensitive devices. Assume that all solid-state

electronic devices are ESD-sensitive. Ensure use of a grounded wriststrap or equivalent while

working with ESD-sensitive devices. Transport, store, and handle ESD-sensitive devices in static-

safe environments.

R-9110AC QE Copyright - refer to title page Page 18

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

3.2 SITE PLANNING CONSIDERATIONS

Site considerations

The repeater is designed to be waterproof, rainproof, and with snow protection. Temporary

protection should be taken when the equipment chassis is opened for installation or maintenance in

an outdoor environment. The equipment must not be opened for installation or maintenance in bad

weather (e.g. gale, storm rainfall, extreme temperatures and high humidity)

Installation location

Mounting surface shall be suitable to support weight pf the equipment: for R-9110AC, this is about

37 kg (82 lb.).

Environmental

Humidity has an effect on the reliability of the equipment. It is recommended to install the equipment

in location having stable temperature and un-restricted air-flow.

R-9110AC equipment has been designed to operate in the ambient air temperature range of -40°to

+55℃/-40°to 131℉ (class I) or -25°to +55℃/-13°to 131℉ (class II) at <95% relative humidity.

Should the direct day light temperature exceeds 40°C (104°F), then barrier device should be

installed in to protect the equipment to limit sunlight exposure.

Powering

The power supply unit (PSU) provides power to all modules within the chassis. The PSU accepts

155~285VAC/50Hz. It is recommended that the PSU operate on a dedicated AC circuit breaker or

fused circuit.

In order to avoid electromagnetic interference, select the R-9110AC mounting location to minimize

interference from electromagnetic sources such as: large electricity powered equipment.

Grounding requirement

Verify the equipment has been well grounded, this includes antennas and all cables connected.

Ensure lightning protection for the antennas is properly grounded.

Cable routing

Four cables entries to the equipment: Two co-axial, mains-power and 1x RS-232

Manual handling

During transportation and installation, take necessary handling precautions to avoid potential

physical injury to the installation personnel and the equipment.

R-9110AC QE Copyright - refer to title page Page 19

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

3.2.1 REPEATER INSTALLATION CHECKLIST

Installation Location Requirement Considerations

Working Space available Ample space on mounting pole or wall surface

AC power supply at each installation Power cord length is 2m (6.5 ft), use a dedicated

location: 155~285VAC 50Hz AC breaker or fuse circuit, and with good access to

an earthing point.

EMC and interference Do not locate near large transformers or motors

that may cause electromagnetic interference.

Maintain distance from chassis to DT, MT Reduce of signal loss in feeder cable

antennas

Suitable operating environment -40° to 55°C(-40° to 131°F) (class I) -25°to 55°C (-

13° to 131°F) (class II) Maximum 95% relative

humidity.

Table 7: Repeater Installation checklist

3.2.2 ANTENNA INSTALLATION CONSIDERATION

Installation Location Requirement Considerations

Locate donor antenna in a site to receive Field intensity of receiving site: Typical mobile

the maximum signals from the desired BTS phone test field intensity ≥-70dBm

and to shield the other signals at the same

time.

Locate the mobile antenna in the center of

signal coverage area

Isolation of donor antenna and mobile I > Gmax+ 10dB

antenna (I) must be larger than the

maximum gain of the repeater in operation

Table 8: Antenna installation checklist

R-9110AC QE Copyright - refer to title page Page 20

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

3.3 INSTALLATION PROCEDURES

3.3.1 GOODS INWARDS INSPECTION

z Verify the number of packages received against the packing list.

z Check all packages for external damage; report any external damage to the shipping carrier. If

there is damage, a shipping agent should be present before unpacking and inspecting the

contents because damage caused during transit is the responsibility of the agent.

z Open and check each package against the packing list. If any items are missing. Contact

Comba Telecom Systems.

z Do not remove items from antistatic packing until installation. If damage is discovered at the

time of installation, contact the shipping agent.

3.3.2 TOOLS

See appendix 7.1 for a full list of tools required for installation.

3.3.3 PREPARATION

Repeater:

z Mounting surface or pole capable of support chassis’ weight: < 37 kg (82 lb.)

z Power outlet within 2m / 6.5 ft.

z Terminate unused antenna ports with a 50 ohm terminator.

z Earthing point/Safety ground within 2m / 6.5 ft.

Antenna:

z Antenna installation is covered by their respective manuals. Take normal precautions when

preparing and handling feeder cables to ensure they are not damaged.

R-9110AC QE Copyright - refer to title page Page 21

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

3.3.4 WALL MOUNTING DETAILS

z Fix the mounting rack to a wall with four masonary bolts (M10×100). If the mounting surface is

not strong enough, insert two more masonary bolts to the upper mounting rack.

z Raise the chassis and position it over the mounting rack, hook the equipment chassis onto the

mounting rack from the upper corners.

z Unlock and open the chassis door and to remove four socket-head bolts on each corners of the

cover.

z Four bolts (M8×80) secure the chassis to the mounting rack, these are accessed from the rear

rack.

z Close the chassis cover, tighten the socket-head bolts on four corners and lock the chassis

door.

Fig 3: Mounting rack dimension

Fig 4: Wall mounting overview

R-9110AC QE Copyright - refer to title page Page 22

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

3.3.5 POLE MOUNTING DETAILS

z The equipment can be mounted on customer-located poles of about 75mm in diameter.

z Insert and tighten the U bolts to secure the mounting frame onto the pole.

z The remainder of the installation are identical to wall-mounting.

Fig 5: Pole mounting overview

3.3.6 DRIP-LOOP

Comba recommends that every horizontal cable entry to the equipment forms a 'U' before its entry to

the equipment. Any accumulated water on the cable will drip down at the bottom of the loop and will

not climb up to the equipment.

3.3.7 EQUIPMENT CONNECTIONS

The equipment has been designed for all cable entries from the bottom of the chassis. The only

exception is the RS232 connection where it a temporary connection for equipment commissioning.

Ground connection

The chassis must be grounded securely. Connect a copper wire (resistance <2.5 Ω) to the

grounding terminal on the equipment chassis, and connect the other end to a protective ground (i.e.

building earth point). An internationally acceptable coloring code of the ground connection wire is

green/yellow.

Service voltage connection

The repeater accepts single phase 220V AC 50Hz power. The recommected AC connection is rated

at AC 220V, 10A and has three connections to include earth. This connection is labelled ‘AC in’

R-9110AC QE Copyright - refer to title page Page 23

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

Optional: Equipment back-up battery connectivity

External batteries provides DC voltage at 24V 100Ah to the equipment. Comba recommends

sealed lead-acid batteries to be used. DC connection is made with wires constructed on-site,

wires of AVR 1.2mm2 are used, select red for ‘+’ and black for the ‘-‘ connection.

Take red and black wires from the terminals within the chassis; feed them through the cable

gland to the battery pack. This connection is labeled “DC in”.

24V is derived by two 12v battery cells connected in series, connect the red and black wires to

the battery terminals securely and tightening the cable gland.

RF signal connection

Connectection to donor antenna and mobile antenna is below:

z Donor antenna cable → DT port

z Mobile antenna cable → MT port

Li-ion battery connection

The lithium-ion battery-pack provides back-up supply to the MCU board; an in-line connector

close to the battery pack is ‘disconnected’ before shipping. During installation, re-connect the in-

line connector to ensure proper function of the MCU.

OMT connection for commission and local management

This cable is supplied with the equipment, it connects between the serial port of the PC to the ‘D5’

on the distribution board within the chassis. Note: temporary break the the Li-ion battery connection

before making the OMT connection.

End of section

R-9110AC QE Copyright - refer to title page Page 24

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

4 COMMISSIONING

4.1 MCU LED INDICATORS

Four diagnostic LED are located on the distribution board, each indicates the status of a particular

function:

Identifier Colour Indication

L1 Red Online programming.

L2 Red Alarm.

L3 Green MCU operation.

L4 Red Wireless modem status.

Table 9: MCU LED

- MCU resumes operation mode

Following initialization, L2, L3 & L4 will flash for 60sec then remain ON. At this point, the MCU is

under normal operation mode.

- Whilst MCU is in normal operation, the following mode

z Operation is indicated by L3 (Green LED) flashing at a rate of 1 flash/sec. Any other flashing

rate indicates MCU is faulty.

z Warning LED L2 (Red LED) is ON to indicate alarm.

z L4 (Red LED) indicates the status of the wireless modem. During normal operation, it is

OFF, while ON, it’s indicating faulty wireless modem and no communication will take place.

z L1 LED indicator will flash when users read, set or download files via OMT

Note: Faulty MCU is indicated by LED (L2, L3 or L4) flashing at any other rate than 1 flash/sec. MCU

will have to be replaced.

Fig 6: Location of MCU and LED

4.2 EQUIPMENT POWER-UP

Before applying power, check that the expected voltage, current, and power levels do not violate any

ratings. Double check all connections before applying power. Do not manipulate circuits or make

changes with power applied.

R-9110AC QE Copyright - refer to title page Page 25

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

4.3 OMT

The equipment can be monitored and controlled by one or two means.

z OMT software running on a local PC with serial connection the equipment

z OMC software with remote connection to the equipment over wire/wireless telecommunication

network.

OMT software is based on Windows operation system, and is designed for monitoring and

maintaining of Comba repeaters and boosters.

For R-9110AC repeater, the OMT software can accomplish the following functions:

z To configure and adjust the repeater’s operating parameters

z Display the repeater’s internal operation status

z Display the input field level and output power

z To configure and commission the software network parameters

4.4 NON-VOLATILE MEMORY

A non-volatile storage device on the MCU holds the configuration of the equipment, the following

information are preserved in the event of power-loss:

Repeater configuration

Repeater number

Device number

SMS center number

Alarm dial-up number

OMC inquiry number

Remote communication mode

Operating parameters

Master ATT

Assistant ATT

PA soft on/off

Oscillation elimination on/off

Output power

Gain

Channel field

Alarm thresholds

R-9110AC QE Copyright - refer to title page Page 26

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

4.4.1 OMT SOFTWARE VERSION

The version number of OMT for this equipment is 1.03, this is compatible for both 5W and 10W

version of the repeater.

4.4.2 OMT SOFTWARE INSTALLATION

This is documented separately by the OMT Installation manual. (Ref: 0.6.1)

After installing OMT software on the PC, connection to the equipment can be done directly or

remotely.

4.4.3 PREPARATION FOR REMOTE CONNECTION OF OMT USING WIRELESS

MODEM

A factory installed wireless modem with the equipment provides the option of remote connection of

the equipment by OMT. The wireless modem implements the link for data and SMS.

The power cable and data wire has already been connected to the wireless modem, customer only

need to insert the SIM card into the wireless modem.

Fig 7: Wireless modem

R-9110AC QE Copyright - refer to title page Page 27

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

4.4.4 CONNECTING OMT TO EQUIPMENT

OMT communicates to the equipment by either a direct serial link or remotely by a wireless modem.

1. Connect the local PC to the equipment by the RS232 cable supplied, one end connects to the

‘D5’ connector within the equipment, the other to the serial port of PC.

2. Power-up the equipment, and it will go through the initialization process (duration about

60~120s).

3. After initialization, select ‘Choose Connection Type’ -> “Local connection” -> ‘OK’

4. Select ‘Com-Setting’ -> ‘Serial Port Setting’ to enter communication port configuration.

Note, the default settings are: baud rate (9600), check bit (None), data bits (8 bits), and stop bit (1

digit).

Fig 8: OMT screenshot - communication setup

The aboves enable communication between OMT and the equipment. The OMT main-window will

appear automatically, and is followed by a pop-up message ‘Online OK’

For remote connection, selecting ‘online’ should bring up the main-window.

In the event of connection failure, a connection prompt will appear on the screen, proceed to verify

the following and re-try the connection:

z Check the power connection

z Check serial port selection

z Check speed setting for the port

z Check whether the mains voltage is normal, and whether the repeater is switched on.

z Check whether the site ID is correct.

R-9110AC QE Copyright - refer to title page Page 28

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

4.5 LOCAL COMMISSIONING

With OMT executing on the local PC and connected to the equipment, select ‘online’ from the main

window to enter the screen for equipment configuration and data inquiry.

The ‘R-9110AC band Selective Repeater’ window will appear, and ‘Online OK!’ message will

appear.

Fig 9: OMT screenshot - Main window

R-9110AC QE Copyright - refer to title page Page 29

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

4.5.1 DESCRIPTION OF PARAMETERS

The parameters being described are applicable throughout the R-9110AC variants having power

1W, 2W and 10W.

4.5.1.1 NETWORK PARAMETERS

The following parameters are located on the left of the main screen, these include: Site ID, SMS and

data link parameters, all of enables communication with the OMC located in a Network Operation

Centre.

SITE ID The identification of each site to the OMC (see section ‘Remote

Monitoring using OMC’)

SMS REPORT ALARM Specifies the SMS centre the system dial when alarms are to be

sent as SMS.

The ‘OMC report number’ specifies a number the MCU to dial for

alarm reporting.

DATALINK REPORT In the datalink mode, alarms can be sent over the PSTN to a

ALARM maximum of four numbers.

Table 10: Management - Network Parameters

Note 1: Only one communication mode is available at one time. Green indicates active and red

indicates disable.

Note 2: If the alarm message has been acknowledged using OMT, then it would not be reported

again.

R-9110AC QE Copyright - refer to title page Page 30

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

4.5.1.2 RF PARAMETERS

Occupuing the middle of the main window are the RF parameters:

Identifier Application Setting 1 Setting 2 Initial setting

Soft On/Off To avoid the electro- ‘On' = DC power ‘Off’= no DC supply to ON

Switch magnetic emission from the supply enabled, and frequency selecting and

repeater in operation, by the frequency amplifying module. their

enable/disable the DC power selecting and parameters (frequency

supply to the frequency amplifying module is band, ATT, power, and

selecting and amplifying enabled, parameters alarm) can not be read

module. The repeater gives of which can be set or set.

out no power in this case, but and read.

other parameters are not

affected.

‘On' = enable the

function to eliminate

the self-excited

oscillation, this is

Oscillation To enable/disable the ‘Off' = disable the

done automatically by

Elimination function that eliminates self- function to eliminate the ON

stepping down the

On/off excited oscillation self-excited oscillation.

gain when while

isolation value is

lower than the

configured value.

Uplink freq chn

Channel To configur channel number, Uplink channel Down channel high edge =

number and allow fine tuning of numbers: High edge numbers: High edge 88, Downlink

setting frequency in steps of 25KHz. and low edge and low edge freq chn high

edge = 66

ATT setting Adjustment to the operation Master uplink / Assistant uplink / 0dB for master

gain for: Master uplink ATT, downlink ATT is downlink ATT is ATT, 0~3dB

master downlink ATT, 0~30dB 0~15dB. for Assistant

assistant uplink ATT and ATT

assistant downlink ATT.

Setting the upper- Shoule the measured

Temperature temperature threshold within temperature reach the

+75c

threshold the chassis. A measured threahold, the alarm is

temperature is shown. generated.

For uplink and downlink Should the measured

power threshold setting power value is lower

ranging from +10 to +40dBm. than the setting, the

Power

A measures power level is appropriate +12dBm

threshold

shown, and customer can set uplink/downlink power

power threshold according to alarm will be

situation. generated.

Field Intensity threshold,

valid range is from –40 to – Should the measured

80dBm. The measured value field value is lower

Field

is shown (DT port downlink than field threshold, a -55dBm

threshold

input power), Customer can field-low alarm is

set field threshold according generated.

to situation.

Table 11: Management - RF parameters

R-9110AC QE Copyright - refer to title page Page 31

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

4.5.1.3 EQUIPMENT RESET

In the unlikely events of false alarms being reported or software appear to run abnormally, the

customer has the option to reset the equipment. Observing the read-only fields should indicate

equipment reset had completed.

Select ‘System’ -> ‘Device Reset’ followed by ‘Yes’ or ‘No’

4.5.1.4 ALARM LIST

The Alarm list for the R-9110AC is shown below, these are enabled/disabled with OMT/OMC by

placing a ‘tick’ in the adjacent box against the required alarm condition and select ‘Set’:

Alarm name Observations

Uplink/downlink LNA alarm monitor whether uplink/downlink LNA is

normal

Power down alarm check whether the AC power supply is down

Power fault alarm check whether the power supply is at fault

Door open alarm check whether the chassis door is closed

Oscillation alarm check whether the system is in the status of

self-excited oscillation

Uplink/downlink PA alarm check whether uplink/downlink power

amplification is normal

Field low alarm check whether DT field intensity is too low

Over temperature alarm check whether the temperature in chassis is

too high

Uplink/downlink VSWR alarm check whether DT/MT antenna VSWR is

normal

Uplink/downlink high/low edge PLL alarm check whether local PLL is normal

Uplink/downlink power low alarm check whether uplink/downlink power is too

low

Table 12: Management - Alarm list

On the OMT/OMC screen, the alarm is colour coded to indicate its status:

z Red indicates failure, and an alarm condition is generated.

z Green indicates normal, and no alarm is generared.

z Gray indicates null, meaning alarm can not be read (i.e. Soft ON/OFF set to ‘ON’)

4.5.1.5 ALARM ACKNOWLEDGEMENT

As and when the designated Alarm occurs, it will be visible on OMT and/or reported to OMC.

If OMC does not acknowledging after a time-out of three minutes, the same alarm will be reported to

OMC.

After each the time-out, the un-acknowledged alarm will be reported again with a total of with five

attempts.

Should the alarm is acknowledged within the time-out period, the alarm is acknowledged, and

reported stops.

Alarm is cleared after the necessary diagnosis and rectification has been carried out, the on-scree

colour indicator for the designator should turn to green.

Every twenty-four hours, the equipment will be resetted automatically, any alarm messages held

within the equipment would be cleared.

R-9110AC QE Copyright - refer to title page Page 32

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

For every five dial-up attempts, the equipment will be resetted automatically, any alarm messages

held within the equipment would be cleared.

Should the ‘Soft on/off’ function is ‘ON’, then the no alarm will be generated for the following

conditions: Power down, power failed, chassis lock and over temp alarms.

4.5.1.6 SOFTWARE DOWNLOAD

This deals with the firmware held on the MCU, download is initiated by selecting ‘Download’.

Firmware update is carried out when a new version is released, the current formware is at releae

“V4.9.07”.

4.5.1.7 SOFTWARE VERSION

OMT software are designed to be backward compatible, to view the OMT software version, select

‘Help’ → ‘About System’ in the OMT software main window.

The MCU firmware has its own version number. This version number is shown on the upper right of

the ‘equipment configuration’ window.

4.5.1.8 EXIT OMT

Click ‘Exit’ sub-menu under ‘System’ command of OMT main window, select ‘Yes’, the OMT

software will stop executing.

R-9110AC QE Copyright - refer to title page Page 33

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

4.6 COMMISSIONING PROCEDURES

System commission can commence after the monitoring system has initialized. (e.g. when MCU

LED L4 is off and L3 begin to flash). The commission procedure is as follow:

Commissioning Tasks Observation

1. Verify RF uplink and z Locate the DT coupler at the inside left side of chassis.

downlink power Measure signal from the –30dB coupling port to verify

downlink signals from BS or uplink signals retransmitted

by the repeater.

z Measure signal from the –20dB coupling port to verify

GSM modem signal level to transmit remote control

signals.

z Locate the MT coupler at the right side of chassis.

Measure signal from the –30dB coupling port to verify

uplink signals from mobile antenna or downlink signals

retransmitted by the repeater.

2. On-line & inquiry status z Enter into R-9110AC Main window. Initialization of

monitoring system will be up in about 2 minutes, at that

time, on MCU L4 is off and L3 begins to flash. Click

‘online’ button and inquiry the repeater’s status. Go to

next step if there is no alarm. Else or, check the point of

failure and handle the alarm.

z Set site ID and telephone number

3. Set On/off Status / z Click ‘ON’ of power supply and set high edge and low

operating band/ gain edge of the repeater’s operating frequency,

uplink/downlink master ATT (user can set initial value to

30~40dB) and uplink/downlink assistant ATT (factory

set value is 0dB).

4. Set monitoring system

parameters

5. Test DL input power and z Observe DL input power from ‘Field (dBm)’. Align the

align donor antenna direction of donor antenna till the DL input power

reading is maximized.

6. Set monitoring system

parameters

7. Measuring power

8. Test DL output power and z Set the DL ATT to the optimal level to avoid saturating

adjust DL ATT level the DL PA or to satisfy designing requirement.

9. Test coverage area field z Use test-handset to verify field intensity within the

intensity and adjust mobile coverage area. If needed, re-align the mobile antenna to

antenna . achieve the coverage as per customer requirement.

z Note 1: If during operation, the equipment gain could

not be set to maximum or the output power is not high

enough due to influence of donor antenna and mobile

antenna isolation, the value of ‘I’ should be re-

calculated. If the output power has been high enough

and ALC is enables, then adjust gain for the downlink

branch to achieve ALC to operate within 4~7 dB.

z Note 2: Output power may be variable due to TDMA

technology employed in GSM devices. Take the

maximum value when reading parameters.

R-9110AC QE Copyright - refer to title page Page 34

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

10. Verify uplink gain and z Adjust uplink gain and carryout test-call. Set the uplink

ensure test-call is proper gain slightly lower than downlink gain. Then carryout

and there’re no interfering test call in the coverage area while adjusting uplink gain

BS if required. Note: If the repeater locates near the BTS

and the test-call performance is poor, this may be due

to uplink noise interfere the BTS. Customers can

calculate whether the repeater uplink noise interfere the

BTS according to the table in appendix C.

z Verify again there’s no unacceptable interference to

BTS and Isolation meets the need after test-call.

Table 13: Commissioning procedures

R-9110AC QE Copyright - refer to title page Page 35

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

4.7 REMOTE MONITORING USING OMC

OMC offers flexibility to manager a network of equipment, all the tasks carried out by the OMT can

performed centrally from the OMC terminal.

In order for OMC to communicate to each equipment, an unique equipment identification must be

referred to, and it is entered using OMT after local commission has been completed. The identifier is

known as ‘Site ID’, and is an alpha-numeric string composed of of six characters.

z Enter the unique ‘Site ID’ value into the ‘Site Address’ field and select ‘Set’

End of section

R-9110AC QE Copyright - refer to title page Page 36

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

5 OPERATION

Following installation and commissioning, occasional operation tasks to handling alarms may be

required:

Alarm condition Diagnosis

Power down / power Check AC power cable and verify AC mains supply is normal. During

fault alarm power fault alarm, DC power supply has no output. Check if DC

output power is overload or short-circuitd. The PSU could be faulty.

Uplink / downlink LNA, Check power and signal connections of respective modules. If the

uplink / downlink PA, power and signal wire connections are OK, then the respective

uplink / downlink modules may be faulty. Replace the fault modules and return it to

high/low edge PLL the factory for repair.

alarms handling

Uplink / downlink power Eliminate alarm by correct setting of uplink/downlink power threshold

low alarm The recommended power threshold is within the range of

10~40dBm. If alarm can not be cleared, check the equipment.

Field low alarm Eliminate alarm by correct setting of field threshold. The

recommended field threshold is within the range of –40~-80dBm. If

alarm can not be cleared, check the DT antenna system.

Oscillation alarm Check whether the Isolation between donor antenna and mobile

antenna is large enough. Adjustment to RX/TX antennas can

eliminate self-excited oscillation. Verify the (I) is 10dB larger than

Gmax.

Uplink / downlink VSWR Check DT antenna system if there is uplink VSWR alarm. Check MT

alarm antenna system if there is downlink VSWR alarm.

Over temperature alarm Eliminate alarm by correct setting of temperature threshold. If alarm

can not be cleared, apply climatic protection to the equipment

Door open alarm Close the chassis door

Table 14: Alarms diagnosis

End of section

R-9110AC QE Copyright - refer to title page Page 37

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

6 MAINTENANCE

The R-9110AC repeater offers trouble free operation and generally does not need maintenance.

The equipment operation status can be observed remotely through OMC.

Periodic inspection of the repeater equipment(s) is recommended, the recommended tasks includes:

z Inspect and record operation status and output power of the repeater from OMC or OMT.

z Verify the direction and position of antennas. Re-align if necessary.

z Make sure the cable gland and sealing on the RF cable connectors are not damaged.

z Verify lightning and grounding protection are in good condition.

z For both Li-ion and the optional equipment back-up battery, verify their state. Deeply

discharged battery shall be return to Comba for replacement.

A simple procedure to check Li-ion battery: after operating for 24-hours, switch off AC

power supply. Measure and if the voltage of Li-on battery drops below 16V within one

hour, the Li-on battery has been over-discharged.

A simple procedure to check the back-up battery: after operating for 24-hours, switch off

AC power. Measure and if the voltage of backup battery drops below 23.5V within one

hour, the backup battery has been over-discharged.

R-9110AC QE Copyright - refer to title page Page 38

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

7 APPENDICES

7.1 APPENDIX A: TOOLS AND EQUIPMENT FOR INSTALLATION

Description

Slotted screwdriver

Phillips screwdriver

Adjustable spanner (up to 20mm opening)

Electrically operated drill and masonry drill bits

Anti-static wrist strap

Allen key

7.2 APPENDIX B: VSWR – RETURN LOSS TABLE

VSWR - Return VSWR - Return VSWR - Return Loss

Loss (dB) (VSWR - Loss (dB) (dB) (VSWR - RL)

RL) (VSWR - RL)

1.4 -- -15.5 1.8 -- -10.9 2.2 -- -8.5

1.5 -- -14 1.9 -- -10.2 2.3 -- -8.1

1.6 -- -12.8 2.0 -- -9.6 2.4 -- -7.7

1.7 -- -11.8 2.1 -- -9 2.5 -- -7.4

7.3 APPENDIX C: UPLINK ATT AND NOISE LEVEL

Uplink Uplink 200KHz Noise

Master ATT Channel ATT Level (dBm)

(dB) (dB)

0 0 -21

-10 0 -30

-20 0 -37

-30~-40 0 -40

-30~-40 -10 -47

-30~-40 -20 -50

R-9110AC QE Copyright - refer to title page Page 39

ENU Status : 1-0-0

EQUIPMENT MANUAL FOR R-9110AC

7.4 APPENDIX D: RMA (RETURN MATERIAL AUTHORIZATION) FORM

End of section

End of Document

R-9110AC QE Copyright - refer to title page Page 40

ENU Status : 1-0-0

You might also like

- RD-9120 Qi 1-0-0Document52 pagesRD-9120 Qi 1-0-0aminshamsNo ratings yet

- OMT Explorer V2 20 QU 1 0 0Document24 pagesOMT Explorer V2 20 QU 1 0 0Radit TidarNo ratings yet

- Omt V4.00 Software User'S ManualDocument70 pagesOmt V4.00 Software User'S ManualmaurichipNo ratings yet

- Capacity Monitoring Guide - R18Document62 pagesCapacity Monitoring Guide - R18didin mansyurNo ratings yet

- SP-2110 Ii2 Qe 1-0-0Document35 pagesSP-2110 Ii2 Qe 1-0-0Duval FortesNo ratings yet

- PC 3000 Flash Brochure - 2016Document8 pagesPC 3000 Flash Brochure - 2016zinhofeNo ratings yet

- GSM Architecture: A Summer Training ReportDocument32 pagesGSM Architecture: A Summer Training Reportrite2ankur100% (1)

- LTE RF PlanningDocument2 pagesLTE RF PlanningSham DegiggsyNo ratings yet

- Huawei GSM DBS3900Document74 pagesHuawei GSM DBS3900إدريس طاهيريNo ratings yet

- Comba OMC - HW&SW - RequirementsDocument3 pagesComba OMC - HW&SW - Requirementsbricks007No ratings yet

- RTWP Explained: What is Received Total Wideband PowerDocument4 pagesRTWP Explained: What is Received Total Wideband PowerYogesh KumarNo ratings yet

- Commscope In-Building Wireless SolutionsDocument16 pagesCommscope In-Building Wireless SolutionsAdrian ParalescuNo ratings yet

- OMT v4.0 QU 3-0-0 PDFDocument70 pagesOMT v4.0 QU 3-0-0 PDFCarlos EduardoNo ratings yet

- Huawei PICO Link Budget - ADocument3 pagesHuawei PICO Link Budget - AMita HeidyaniNo ratings yet

- RF Interference PDFDocument64 pagesRF Interference PDFtoolwaveNo ratings yet

- L3SDR FDD BS8900A Product DescriptionDocument39 pagesL3SDR FDD BS8900A Product DescriptionglocallNo ratings yet

- VAPEL Power Supply System Technical DocumentDocument24 pagesVAPEL Power Supply System Technical Documenteddywidjaya9No ratings yet

- Azenqos Installation Guide For Oneplus 6Document6 pagesAzenqos Installation Guide For Oneplus 6emilson cruzNo ratings yet

- Lte OverviewDocument3 pagesLte Overviewrahulyadav243No ratings yet

- Instruction For Selecting GSM BTS Antenna Models-20021024-A-2.0Document41 pagesInstruction For Selecting GSM BTS Antenna Models-20021024-A-2.0Bagoes MardanieNo ratings yet

- WCDMA Link Budget 384 DataDocument27 pagesWCDMA Link Budget 384 DataAnjit RajkarnikarNo ratings yet

- First Steps & 1G: Archaic Mobile Communication" Electronic Communications: Fixed Networks"Document16 pagesFirst Steps & 1G: Archaic Mobile Communication" Electronic Communications: Fixed Networks"Bassem AbouamerNo ratings yet

- Edge Through Put EnhancementDocument8 pagesEdge Through Put Enhancementjoseph boikanyoNo ratings yet

- 3G Optimization ReferanceDocument205 pages3G Optimization ReferanceNaransinhNo ratings yet

- Tems ParametersDocument15 pagesTems Parametersganeshtomar880% (5)

- Technical Information TSMW-Z8Document7 pagesTechnical Information TSMW-Z8Santosh SinhaNo ratings yet

- Frequency Hopping Benefits and ImplementationDocument27 pagesFrequency Hopping Benefits and Implementationsardar87No ratings yet

- 5060 Wireless Call Server (WCS) Release 5.1.6 Alarms and Events Troubleshooting GuideDocument1,618 pages5060 Wireless Call Server (WCS) Release 5.1.6 Alarms and Events Troubleshooting GuideShiv BindNo ratings yet

- NSN HW NotesDocument12 pagesNSN HW Noteseduardo_pl8256No ratings yet

- GBSS9.0 BSC6900 Basic Feature Description V1.4Document189 pagesGBSS9.0 BSC6900 Basic Feature Description V1.4Dhananjay ShrivastavNo ratings yet

- Overlaid Underlaid Subcells in GSMDocument2 pagesOverlaid Underlaid Subcells in GSMSamehTareshNo ratings yet

- ZXUR 9000 UMTS Radio Parameter ReferenceDocument955 pagesZXUR 9000 UMTS Radio Parameter ReferencePantheraLeoSkTauNo ratings yet

- 3G Project Script PreparationDocument20 pages3G Project Script PreparationSangwani NyirendaNo ratings yet

- ZXC 10 BTSDocument55 pagesZXC 10 BTSDurga Pinninti100% (1)

- M0139ACDDocument60 pagesM0139ACDydvideoNo ratings yet

- TCH & SD Drops AnalysisDocument20 pagesTCH & SD Drops AnalysisnileshNo ratings yet

- HUAWEI E392u-12 User Manual (V100R001 01)Document2 pagesHUAWEI E392u-12 User Manual (V100R001 01)sam2976No ratings yet

- What Is The Function of SDCCHDocument12 pagesWhat Is The Function of SDCCHjabi_shaik_1No ratings yet

- RF Optimization and PlanningDocument12 pagesRF Optimization and PlanningVikash JhaNo ratings yet

- Csdap DeletionDocument17 pagesCsdap DeletionkarthikNo ratings yet

- Presentation RF Optimization and PlanningDocument12 pagesPresentation RF Optimization and PlanningMohammad AshrafNo ratings yet

- TEMS Investigation 15.0 Release NoteDocument22 pagesTEMS Investigation 15.0 Release NotelahyouhNo ratings yet

- 3 Interface Protocol and Signaling Flow 50Document48 pages3 Interface Protocol and Signaling Flow 50Chidhuro OwenNo ratings yet

- 2GDocument7 pages2Gjitu_rfNo ratings yet

- Cell Barring (RAN15.0 02)Document104 pagesCell Barring (RAN15.0 02)Jonathan RuizNo ratings yet

- 03 Tm2201eu04tm 0002 Umts EvolutionDocument5 pages03 Tm2201eu04tm 0002 Umts EvolutionBassem AbouamerNo ratings yet

- Frequency HoppingDocument24 pagesFrequency HoppingKamil KocNo ratings yet

- Basic 3G ParametersDocument5 pagesBasic 3G ParametersUmair SiddiqueNo ratings yet

- GSM-To-UMTS Training Series 02 - WCDMA Radio Network Coverage Planning - V1.0Document86 pagesGSM-To-UMTS Training Series 02 - WCDMA Radio Network Coverage Planning - V1.0AliKaiserNo ratings yet

- 15 - 30!48!2. GSM Handover AlgorithmDocument75 pages15 - 30!48!2. GSM Handover AlgorithmAnonymous ofwB20r0sNo ratings yet

- Cross-Layer Resource Allocation in Wireless Communications: Techniques and Models from PHY and MAC Layer InteractionFrom EverandCross-Layer Resource Allocation in Wireless Communications: Techniques and Models from PHY and MAC Layer InteractionNo ratings yet

- VoLTE and ViLTE: Voice and Conversational Video Services over the 4G Mobile NetworkFrom EverandVoLTE and ViLTE: Voice and Conversational Video Services over the 4G Mobile NetworkNo ratings yet

- Understanding UMTS Radio Network Modelling, Planning and Automated Optimisation: Theory and PracticeFrom EverandUnderstanding UMTS Radio Network Modelling, Planning and Automated Optimisation: Theory and PracticeMaciej NawrockiNo ratings yet

- Fundamentals of Cellular Network Planning and Optimisation: 2G/2.5G/3G... Evolution to 4GFrom EverandFundamentals of Cellular Network Planning and Optimisation: 2G/2.5G/3G... Evolution to 4GNo ratings yet

- CSR Installation GuideDocument38 pagesCSR Installation GuideTshering WangdiNo ratings yet

- User Manual For RX-8123 - CombaDocument34 pagesUser Manual For RX-8123 - CombaEduardo Tamariz100% (1)

- Nemo BTS FileformatDocument23 pagesNemo BTS Fileformatpeanut!100% (1)

- 7760.00A Dual High Broadband Cross Polarized: Powerwave Single Broadband AntennasDocument1 page7760.00A Dual High Broadband Cross Polarized: Powerwave Single Broadband AntennasAnnBlissNo ratings yet

- 7721.00 High Broadband Cross Polarized: Powerwave Single Broadband AntennasDocument1 page7721.00 High Broadband Cross Polarized: Powerwave Single Broadband AntennasAnnBlissNo ratings yet

- Manual - QualiPoc SW - Freerider v10.6Document22 pagesManual - QualiPoc SW - Freerider v10.6JohnNo ratings yet

- Manual - QualiPoc SW - Active Engine v10.6Document42 pagesManual - QualiPoc SW - Active Engine v10.6JohnNo ratings yet

- NQView - 16.1 - Manual - Backup and RestoreDocument38 pagesNQView - 16.1 - Manual - Backup and RestoreJohnNo ratings yet

- User Manual: R&S Tsme Ultra Compact Drive Test ScannerDocument69 pagesUser Manual: R&S Tsme Ultra Compact Drive Test ScannerJohnNo ratings yet

- Nokia Siemens Networks: LTE Transmission Planning (RL30)Document6 pagesNokia Siemens Networks: LTE Transmission Planning (RL30)JohnNo ratings yet

- LTE Radio Access System OverviewDocument27 pagesLTE Radio Access System OverviewJohnNo ratings yet

- 00 CT11400EN05GLA0rtc Doc PDFDocument6 pages00 CT11400EN05GLA0rtc Doc PDFJohnNo ratings yet

- Quick Start Guide - Diversity OptimizerDocument39 pagesQuick Start Guide - Diversity OptimizerJohnNo ratings yet

- Diversity and QualiPoc - Supported Devices PDFDocument34 pagesDiversity and QualiPoc - Supported Devices PDFJose LuisNo ratings yet

- TOR Admin Assistant SC - 4Document1 pageTOR Admin Assistant SC - 4newarakanNo ratings yet

- Aoc Le32w136 TVDocument82 pagesAoc Le32w136 TVMarcos Jara100% (4)

- High-Temperature Quad 2-Inputs OR Gate DatasheetDocument6 pagesHigh-Temperature Quad 2-Inputs OR Gate DatasheetSalim Abdul Rahman Sa'dyNo ratings yet

- Aiwa NSX-VC58Document41 pagesAiwa NSX-VC580000AbdielNo ratings yet

- Practice PLSQL SEC 4Document19 pagesPractice PLSQL SEC 4annonymous100% (1)

- Geh 6130Document132 pagesGeh 6130Sergio FurutaNo ratings yet

- Railway Signaling Concepts and DefinitionsDocument92 pagesRailway Signaling Concepts and DefinitionsGopipavanNo ratings yet

- Millau Viaduct Case Study: World's Tallest BridgeDocument14 pagesMillau Viaduct Case Study: World's Tallest BridgeDevendra Kumar KumarNo ratings yet

- Article 5 - How To Purge Husqvarna Hydrostatic TransmissionDocument3 pagesArticle 5 - How To Purge Husqvarna Hydrostatic TransmissionSofia AlyaNo ratings yet

- VW T-Cross 2019+ - Connector ViewsDocument220 pagesVW T-Cross 2019+ - Connector ViewsMucowera AshaNo ratings yet

- NACA Report 184 The Aerodynamic Forces On Airship HullsDocument16 pagesNACA Report 184 The Aerodynamic Forces On Airship Hullsshatal16No ratings yet

- MAP Demo ExercisesDocument34 pagesMAP Demo ExercisesNancy HernandezNo ratings yet

- EC6302 - Digital ElectronicsDocument6 pagesEC6302 - Digital ElectronicsAdal ArasuNo ratings yet

- Electric Schematic CB113 114 QENR2003 PDFDocument2 pagesElectric Schematic CB113 114 QENR2003 PDFHipac TapicuNo ratings yet

- An Experimental Comparative Review - PK NanavatiDocument9 pagesAn Experimental Comparative Review - PK NanavatiPurvesh NanavatiNo ratings yet

- ch19 Validation VerificationDocument43 pagesch19 Validation VerificationKarthikeya HsNo ratings yet

- Friction in OrthodonticsDocument9 pagesFriction in Orthodonticsaa bbNo ratings yet

- UOP046-85 Wax Content in Petroleum OilsDocument6 pagesUOP046-85 Wax Content in Petroleum OilsZiauddeen Noor100% (1)

- Blueendo MorcellatorDocument7 pagesBlueendo MorcellatorLia GuslianiNo ratings yet

- General Principles - Mathes Vol 1Document1,155 pagesGeneral Principles - Mathes Vol 1Nanna de Vengerberg75% (4)

- History Spring08Document7 pagesHistory Spring08Anonymous 9VcxlFErfNo ratings yet

- 2 Hinged ArchDocument19 pages2 Hinged ArchSaeed_HassaniurscorpNo ratings yet

- TPF 5-165 Task 1 Final ReportDocument112 pagesTPF 5-165 Task 1 Final ReportLohith Kumar H PNo ratings yet

- Refresher Day 3Document4 pagesRefresher Day 3Jevan A. CalaqueNo ratings yet

- Tufail MaboodDocument3 pagesTufail MaboodMickey DalbeheraNo ratings yet

- Re 29037Document12 pagesRe 29037BorisNo ratings yet

- EI 6702-Logic and Distributed Control SystemDocument2 pagesEI 6702-Logic and Distributed Control SystemMnskSaro50% (2)

- ABB MNS System GuideDocument34 pagesABB MNS System GuideLeslie HallNo ratings yet

- SIPROTEC 5 - Configuration: Technical DataDocument10 pagesSIPROTEC 5 - Configuration: Technical DatasuadNo ratings yet

- Notification ACF One Range Officer RajasthanDocument2 pagesNotification ACF One Range Officer RajasthanAshok SainiNo ratings yet