Professional Documents

Culture Documents

Filling Valve + US 4 794 959 A

Uploaded by

alguna540 ratings0% found this document useful (0 votes)

7 views4 pagesJORDAN + US 4 794 959 A

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJORDAN + US 4 794 959 A

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views4 pagesFilling Valve + US 4 794 959 A

Uploaded by

alguna54JORDAN + US 4 794 959 A

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

United States Patent 1:9

Jordan et al.

[54] FILLING VALVE FOR COUNTERPRESSURE

FILLING MACHINES

(75] Inventors: “Heinrich Jordan; Rolf Sishardt, both,

of Dortmund, Fed. Rep. of Germany

[73] Assignee: Holstein und Kappert GmbH

[21] Appl. No: 926,805

[2] Filed: Oct. 30, 1986

Related U.S. Application Data

[65] _ Contiuation of er No. 104,747, Feb. 25, 1985, aban

[30] Foreign Application Priority Data

Feb, 25, 1984 [DE] Fed. Rep. of Germany nn 3406922

[51] At, OLS coarse B6SB 31/04

2] us.a, : “144/141; 141/6

(58) Field of Search 1417/6, 140, 141, 142,

141/143, 147, 192, 193, 207, 276, 290

[6 References Cited

US. PATENT DOCUMENTS

2057,538 10/1936 Petersen uav216

2.617575 11/1952 Majonnier 41/6

3.589610 6/1971 Manas waa x,

‘$031,930 6/1977 SutliMe et wai207

Primary Examiner—Mark J. Thronson.

(11) Patent Number:

l4s]_Date of Patent:

4,794,959

Jan. 3, 1989

Attorney, Agent, or Firm—Toren, McGeady &

‘Associates

(7 ABSTRACT

Ina filling valve for a counterpressure filling machine

for filling containers, such as bottles, cans and the like,

comprising a filing valve body including a filing chan-

nel, a centering tulip for positioning a container below

the filling channel in sealed connection therewith, sec-

‘ond channels in said valve body coueting with said

filling channel for at least one of evacuating, pressuri2-

ing and relieving a container located within said second

channels, wherein the improvement comprises each

said auxiliary valve includes an axially elongated con-

trol bolt located in said filling valve body for opening

one of said second channels, said control bolt having a

first end located within said filling valve body and a

second end located on the outside of said filling valve

ody, a cam plate located opposite the second end of

said control bolt outside of said filling valve body and

selectively engageable by the second end of said control

bolt, and means associated with said centering tulip for

cooperating with said control bolt and said cam plate

‘when a container is present in the centering tulip for

properly axially displacing said control bolt and open-

ing the respective said second channel by axial displace-

‘ment of said second end of said control bolt by said cam

plate

4 Claims, 1 Drawing Sheet

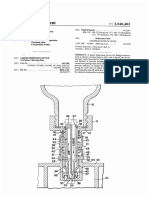

| 7

root

US. Patent

Jan, 3, 1989

4,794,959

[ 9 | Fig.1

° TT T

5

7

i 7

1

5 5 )

roo

be

8

|

5 fl

8 g

3

4,794,959

1

FILLING VALVE FOR COUNTERPRESSURE

FILLING MACHINES

‘This isa continuation of application Ser. No. 704,747,

filed Feb. 25, 1985, now abandoned.

‘The invention is directed to a filing valve for filling

of containers such as bottles, cans and such like, consist-

ing of a filling valve body and coacting with it channels

for evacuation, pressurizing and releasing as well as,

valves associated with the channels, which are control-

lable separately and/or collectively from the exterior.

Here one deals with rotating filling machines into

which the bottles to be filled are fed spaced from each

other, then revolve in the filling machine rotating circle

and are subsequently discharged out of the filling ma-

‘chine. Hereby the bottles are centered by means of

centering tulips immediately after transfer onto the

filling machine rotation circle, they are lifted from

below and moved against the filling valves, The func-

tions of this filling element go on automatically pro-

vided a bottle is applied below the filling element,

‘meaning the bottle is evacuated then is pressurized by

‘means of pressurizing gas onto the kettle internal pres-

sure and subsequently filled. In particular for a vacuum

supply the filling valve comprises an additional auxil-

iary valve, whose control bolt protrudes towards the

outside and is actuated by fixed or pivotable cam plates.

‘These cam plates do not react to missing or damaged

bottles, so that the applicable valves are actuated also in

such cases, without their function being required.

Hereby occasionally losses occur with filing machines

of this sort depending upon their throughput perfor-

‘mance, which must be avoided within the framework of

the present invention. The invention has therefore set

itself the goal to allow the valve to function only when

a flawless bottle is located under the filling valve for the

purpose of being filled.

This task is solved in accordance with the novelty by

supporting auxiliary control segments interswitchably

atthe valve parts between the control bolt of the valves

and the cam plate provided for the control operation.

Hereby it has shown itself to be advisable, that an

auxiliary control segment is pivotably supported at the

centering tulip and displaceable by same into the range

of the principal cam plate between it and the control

bolt.

It is also conceivable, that the control bolt can be

designed to be divided and an auxiliary control element

is interswitchable between its outer and its inner portion

pointing towards the vaive.

This auxiliary control element can be constituted

within the framework of the invention by a sphere inter-

switchable by bolts actuatable by the centering tulip.

is already known in the state of the-art to directly

iate the function of certain valves by means of con-

trol levers attached at the centering tulip, as for instance

as is shown in the DE-OS No. 1 632 014. Hereby one

deals with the unloading of certain areas or with the

‘control functions which are accomplished directly by

the centering tulip.

‘Counter to this, the present invention has the advan-

tage that fixed control paths exist in correspondingly

stable construction, which are" generally suited for the

switching and control of the valves concerned, but can

only function when the bottle in question is applied at

the desired level below the filling element. The embodi-

‘ment proposed in the present invention has the addi-

1s

25

38

*

4s

©

2

tional advantage, that normal valves can also be subse-

‘quently equipped with such a safety switching, without

that special modification work has to be accomplished

at the valve itself. This is important inasmuch as the

filling valves concerned are extremely complicated and

fabricated from high grade material.

In the following the invention is described with par-

ticularity with the help of embodiment examples de-

picted in the drawings.

‘The drawings show:

FIG. 1 the filling valve in cross-section with inter-

switchable control part, and

FIG. 2 a design of the filing valve with a divided

‘control bolt.

The filling valve shown in FIG. 1 consists of a main

valve body 1 and a channel 2 for the filing liquid. In this

cchannel 2a valve shutoff body, not further shown here,

is supported. The main valve body 1 additionally com:

prises auxiliary valves, which can be provided for evac-

uation of the bottle as well as for its release. Addition-

ally, a centering tulip 3 which can be moved up and

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 7500ceICP MShardwaremanualenDocument334 pages7500ceICP MShardwaremanualenbahram adimiNo ratings yet

- Aiset N 5000Document2 pagesAiset N 5000alguna54100% (1)

- Agilent - ICP MS 7500Document659 pagesAgilent - ICP MS 7500alguna54No ratings yet

- Abb Nema Explosion Proof Ac & DCDocument56 pagesAbb Nema Explosion Proof Ac & DCCarlos Alvarez L.No ratings yet

- Liquid Dispensing DeviceDocument4 pagesLiquid Dispensing Devicealguna54No ratings yet

- Weight Control Filling ApparatusDocument11 pagesWeight Control Filling Apparatusalguna54No ratings yet

- Bottle Filling Machine + US 4 967 813 ADocument15 pagesBottle Filling Machine + US 4 967 813 Aalguna54No ratings yet

- Clamp Gripper For Container Transport SystemDocument16 pagesClamp Gripper For Container Transport Systemalguna54No ratings yet

- Bottle Filling DevicesDocument5 pagesBottle Filling Devicesalguna54No ratings yet

- Filling ValveDocument4 pagesFilling Valvealguna54No ratings yet

- Pressureless Multi-Lane Dividing ApparatusDocument11 pagesPressureless Multi-Lane Dividing Apparatusalguna54No ratings yet

- Weight Measuring Type Filling MachineDocument19 pagesWeight Measuring Type Filling Machinealguna54No ratings yet

- Apparatus For Widening and Slowing Down A Stream of Upright BottlesDocument6 pagesApparatus For Widening and Slowing Down A Stream of Upright Bottlesalguna54No ratings yet

- Aquence LG 75S-EnDocument1 pageAquence LG 75S-Enalguna54No ratings yet

- 2SC2655 Y (F) ToshibaDocument2 pages2SC2655 Y (F) Toshibaalguna54No ratings yet

- Vehicle fuse and relay guideDocument17 pagesVehicle fuse and relay guidealguna54No ratings yet

- AlloyingElements enDocument24 pagesAlloyingElements enhsemargNo ratings yet

- Aquence LG 75-EnDocument1 pageAquence LG 75-Enalguna54No ratings yet

- 00 05manual PDFDocument129 pages00 05manual PDFNevsaint MartinezNo ratings yet

- MRM Elgin SMPP135v2 Filler ManualDocument90 pagesMRM Elgin SMPP135v2 Filler Manualalguna54No ratings yet

- Sell Sheet Optal XP en FinalDocument2 pagesSell Sheet Optal XP en Finalalguna54No ratings yet

- HYPRO, Pocket Guide 2010 Nozzle TablesDocument8 pagesHYPRO, Pocket Guide 2010 Nozzle Tablesalguna54No ratings yet

- 5BH TiDocument16 pages5BH Tialguna54No ratings yet

- Accumax Va Fa Instruction ManualDocument2 pagesAccumax Va Fa Instruction Manualalguna54No ratings yet

- 00 05manual PDFDocument129 pages00 05manual PDFNevsaint MartinezNo ratings yet

- Science Direct + Biochemical System A Tics and Ecology - A Comparative Study of Flavonoids in Some Members of The PapaveraceaeDocument3 pagesScience Direct + Biochemical System A Tics and Ecology - A Comparative Study of Flavonoids in Some Members of The Papaveraceaealguna54No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)