Professional Documents

Culture Documents

Filling Valve

Uploaded by

alguna540 ratings0% found this document useful (0 votes)

15 views4 pagesSTOCCHI + US 2003 106 606 A1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSTOCCHI + US 2003 106 606 A1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views4 pagesFilling Valve

Uploaded by

alguna54STOCCHI + US 2003 106 606 A1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

US 20030106606A1

ay United States

«2 Patent Application Publication co) Pub. No.: US 2003/0106606 AL

Stocchi 3) Pub. Date: Jun. 12, 2003

(54) FILLING VALVE OF BOTTLING PLANT. Publication Classification

(76) Inventor: Gabriele Stocehi, Parma (IT)

61) Incl? BOSB $7/14; BOSB 57,06;

Conrespondence Addeess: OSB 3/28; BOTC 300; BOSB 1/30

OBLON, SPIVAK, MCCL

NEUSTADT, Pc.

1940 DUKE STREET .

ALEXANDRIA, VA 22314 (US) 6n ABSTRACT

LAND, MAIER &

141/198

Appl. No: 103312,875

Improvements to filing valves of bottling plants ia which

PCT Filed: Jul 5, 2001 the interruption of the processing uids’ flow happens

oc sripout automatically when the level of the liquid inside the filled

een ey bottle reaches the lower edge of the vent tube and the air

30) Foreign Application Priority Data trapped! in the filling valve prevents the coming out of the

. meen . liquid feom the tank even ifthe external membrane (6) stil

Jul. 7,200 (11) 1802000000409 in the open position

Patent Application Publication Jun. 12, 2003 Sheet 1 of 2 US 2003/0106606 Al

Tire

Patent Application Publication Jun. 12,2003 Sheet 2 of 2 US 2003/0106606 AL

FIG. 2

US 2003/0106606 AL

FILLING VALVE OF BOTTLING PLANT

FIELD OF THE ART

[0001] ‘The prescat invention is related tothe technologies

Of the boting processes, and it specifically pertains to

improved filling valves of turret filling machines. Such

technologies are included in the International Classification

Bore

STATE OF THE ART

[0002] _In he previous technology are known several kinds

Of filling valves that are set up peripherally around filling

[0003] All kinds of known filling valves have intercepting

‘organs inside the bodies of the filling valve that constitute an

‘obstacle for the flow of the filling fluid and forthe cleansing

‘options. In fact, said intercepting organs inside the down-

flow conduits create retention zones or interstices, where the

residual particles of the processing uid often are gathered,

[0004] ‘The problem to be solved is to eliminate such

intercepting organs inside the filing valve in order to

eliminate all the related problems of the traditional filling

valves.

DESCRIPTION

[0005] The invention is now disclosed with reference to

the schematic figures of the attached drawings as a not

limiting example

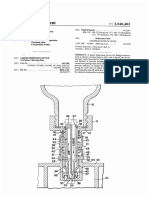

[0006] FIG. 1 represents schematically 4 fling valve at

the end of filing phase of a bottle. One ean notice thatthe

filing valve does not have intercepting organs inside of the

downflow conduits. Nonetheless, he downtlow of the liquid

is stopped by the air trapped inside the filling valve,

[0007] This phenomenon allows the optimization of the

Shape of the dowaflow conxluits, thus solving all the prob-

ems of the traditional filing valves,

[0008] The filing valves made according the improve-

‘meois object of the present inveation will be cheaper in the

realization and more celiable during the filling and cleansing

‘operations.

[0009] FIG. 2 represents schematically a Gilling valve

‘uring the removal phase of the filled bottle. One can notice

that, during this phase, the filling valve without inner

intercepting organs is closed by a membrane 6 external to

the enbloc body of the filling valve; sai) membrane is

deformed by an extemal synchronized electrovalve 7.

[0010] One can notice that there are aot intercepting and

sealing organs inside the filling Valve and that said mem-

brane 6; hermetically sealed, is constantly held upon the

eenbloc body of te filling valve and that it keeps closed from

the outside the dawnflow conduit

[0011] Inthe figures of the attached drawings, each single

‘detail is marked as follows:

[0012] 1 is the filled bottle

[0013] 2 indicates the lower edge of the venting tube

that sets the filling level ofthe liquid in the bottle

Jun. 12, 2003

[0014] 3 is the air venting tube inside the empty

botile

[0015] 4 bortle’s hand!

[0016] Sis the zone where the aie is tapped when the

Tiguid’s level teaches the lower edge of the venting

tube

(0017)

[0018]

(0019)

(0020)

[0021] 9 is the genera tank of the tguid

[0022] The evidence ofthe figures highlighis the operation

Of the filling valve is extremely simple and automatic. In

fact, even though the filling valve does not internal inter-

cepting organs, the stopping of the filling process happens

by siphon effect, I is the residual air that being, tapped

inside the flowing conduits interrupts the downflow of the

iquid when inside the bottle is reached the level set by the

position of the lower edge of the venting tube.

[0023] ‘The absence of intercepting onsans inside the fill-

ing valve allows to realize flowing conduits with optimized

profile, that is without retention zones and interstices that

disturb the laminar motion of the filling anc doo’t obstruct

the cleansing operation.

[0024] The invention of course allows for several varia-

lions of practical realization as far as the proportional

structuring and the technological choice are concerned, that

‘will adjusted to the different needs of bottling plants

[0025] 1 is therefore evident that all. improvements 10

filling valves that will be based on the inventive principles

‘of the present invention, as substantially described, illus-

tated and hercinafier claimed, will be considered part of the

protection sphere of the present invention.

1) Improvements to filling valves of bottling plants

(CHARACTERIZED BY THE FACT THAT the iatereeption

‘of the downllow of the process fluids happens automatically

‘when the Jevel of the liquid inside the filled bottle reaches

the lower edge of the venting tube and that the air trapped

inside the fling valve prevents the coming out ofthe liquid

from the tank even ifthe external membrane 6 is sil in the

‘opening position,

2) Improvements to filling valves of botling plants, asin

claim 1, CHARACTERIZED BY THE FACT THAT since

the internal organs of interception and sealing have been

eliminated, the shape of downflow conduit is optimized

‘because it does not present retention zones or interstices that

clistucb the laminar filling downflow and obstruct the cleans-

ing operations of the botling plant

3) Improvements to filling valves of botling plants asin

previous claims, CHARACTERIZED BY ‘THE FACT.

‘THAT during the removal operations ofthe filled bottle, the

filling valve is kept closed by the clastic membrane 6

cexternal to the enbloe body of the filling valve and it is

actuated by a synchronized electro-valve 7,

device

6 is the external membrane in opening posi-

6 is the external membrane in closing position

Tis the external synchronized electro-valve

8 is the liquid phase of the bottling process

You might also like

- Aiset N 5000Document2 pagesAiset N 5000alguna54No ratings yet

- Abb Nema Explosion Proof Ac & DCDocument56 pagesAbb Nema Explosion Proof Ac & DCCarlos Alvarez L.No ratings yet

- Agilent - ICP MS 7500Document659 pagesAgilent - ICP MS 7500alguna54No ratings yet

- Bottle Filling Machine + US 4 967 813 ADocument15 pagesBottle Filling Machine + US 4 967 813 Aalguna54No ratings yet

- Pressureless Multi-Lane Dividing ApparatusDocument11 pagesPressureless Multi-Lane Dividing Apparatusalguna54No ratings yet

- Weight Measuring Type Filling MachineDocument19 pagesWeight Measuring Type Filling Machinealguna54No ratings yet

- Filling Valve + US 4 794 959 ADocument4 pagesFilling Valve + US 4 794 959 Aalguna54No ratings yet

- 7500ceICP MShardwaremanualenDocument334 pages7500ceICP MShardwaremanualenbahram adimiNo ratings yet

- Liquid Dispensing DeviceDocument4 pagesLiquid Dispensing Devicealguna54No ratings yet

- Clamp Gripper For Container Transport SystemDocument16 pagesClamp Gripper For Container Transport Systemalguna54No ratings yet

- Vehicle fuse and relay guideDocument17 pagesVehicle fuse and relay guidealguna54No ratings yet

- 2SC2655 Y (F) ToshibaDocument2 pages2SC2655 Y (F) Toshibaalguna54No ratings yet

- Weight Control Filling ApparatusDocument11 pagesWeight Control Filling Apparatusalguna54No ratings yet

- Bottle Filling DevicesDocument5 pagesBottle Filling Devicesalguna54No ratings yet

- Apparatus For Widening and Slowing Down A Stream of Upright BottlesDocument6 pagesApparatus For Widening and Slowing Down A Stream of Upright Bottlesalguna54No ratings yet

- Aquence LG 75-EnDocument1 pageAquence LG 75-Enalguna54No ratings yet

- Sell Sheet Optal XP en FinalDocument2 pagesSell Sheet Optal XP en Finalalguna54No ratings yet

- Aquence LG 75S-EnDocument1 pageAquence LG 75S-Enalguna54No ratings yet

- MRM Elgin SMPP135v2 Filler ManualDocument90 pagesMRM Elgin SMPP135v2 Filler Manualalguna54No ratings yet

- 00 05manual PDFDocument129 pages00 05manual PDFNevsaint MartinezNo ratings yet

- 00 05manual PDFDocument129 pages00 05manual PDFNevsaint MartinezNo ratings yet

- Accumax Va Fa Instruction ManualDocument2 pagesAccumax Va Fa Instruction Manualalguna54No ratings yet

- HYPRO, Pocket Guide 2010 Nozzle TablesDocument8 pagesHYPRO, Pocket Guide 2010 Nozzle Tablesalguna54No ratings yet

- 5BH TiDocument16 pages5BH Tialguna54No ratings yet

- Science Direct + Biochemical System A Tics and Ecology - A Comparative Study of Flavonoids in Some Members of The PapaveraceaeDocument3 pagesScience Direct + Biochemical System A Tics and Ecology - A Comparative Study of Flavonoids in Some Members of The Papaveraceaealguna54No ratings yet

- AlloyingElements enDocument24 pagesAlloyingElements enhsemargNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)