Professional Documents

Culture Documents

XH200 Spec Sheet USLETTER Print

Uploaded by

Tiago HenriquesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XH200 Spec Sheet USLETTER Print

Uploaded by

Tiago HenriquesCopyright:

Available Formats

WATER

XH

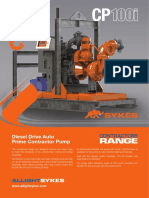

Diesel Drive Auto Prime

XTRA High Head Pump

As Mines and Quarries go deeper the Xtra Primax engineers have ensured that the

High Head automatic priming solids handling enormous pressures and heads associated

pumpset is designed to dewater more with such performance do not compromise

efficiently and effectively. seal integrity through shaft flexing.

Boasting one of the best shaft stiffness ratio’s Primax Xtra High Head Pump range caters

of any automatic priming pump on the market to the demands of the global mining industry

the Primax Xtra High Head range provides the and all models have the ability to operate

reliability to meet the market expectations. unattended at high discharge heads.

www.allightprimax.com LIGHT WATER

Features • Diesel, electric or hydraulic drive

Application

• Solids handling

• Low fuel usage • Construction • Solids laden

• Simple maintenance

• Reduced engine sizes • Environmental liquids

• Replaceable wear parts

• Lower maintenance costs • Industrial • Ground

• Chassis - skid, road tow,

• Dry self prime and reprime • Mining Dewatering

wheeled, caged

• Close coupled SAE Bearing Frames • Clean Water • Pipeline &

• Powered by Perkins or Cat Engines.

• Suction lifts to 9m • Sludge Drilling

• Other engines available on request

• Operates in ‘snore’ conditions • Slimes • Jetting

• Custom build available

• Vacuum Priming option available for • Sewage • Quarries

ground dewatering. • Sykes purpose built Control panel

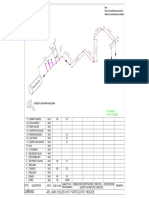

Technical Data

625 190

materials of construction

XH200

600

180 1600RPM 340

Pump Casing: S.G. IRON 370/17

KW Suction Cover: S.G. IRON 370/17

550 170 220 /4

KW 280 56H 38 Air Separation Tank: S.G. IRON 400/12

/2 KW P 0K

160

1500RPM

95H / W Bearing Bracket: S.G. IRON 400/12

500 P 375 /5

150 18 HP 09 Pump Shaft: 431 Stainless Steel

0K HP

W Impeller: 316 Stainless Steel

/2

140 41

450 1400RPM HP Wearplates: 316 Stainless Steel

130 Mechanical Seal: Silicon Carbide cartridge

400 seal c/w pumping ring

120 1300RPM

and Glycol Quench

350

110 N.R.V. (Ball Type): S.G. IRON 370/17

TOTAL HEAD

100

300 B.E.P. design details

90

PUMP SPEEDS FOR Single Stage, End Suction type, 5 vane

80 IMPELLER Ø 636MM

250 closed impeller, centrifugal pump

70 Suction Flange (in/mm): 10/250

= RECOMMENDED PUMP

OPERATING RANGE Delivery Flange (in/mm): 8/200

200 60

Solids Handling Size (in/mm): 1.2/31

50 NOTE: Maximum Head (ft/m): 564/172

150 POWER CURVES INCLUDES PUMP

40

SELF PRIMING DEVICE POWER CONSUMPTION Maximum Capacity: 3108 US gal/min

100

fuel usage (us gal /hr) @ bep

30 3FT 30FT

SUCTION LIFT

8FT 2M 8M 25FT

1600RPM

NPSHR

13FT 4M 6M 20FT

FEET

METRES

18FT

6M 4M 15FT Speed POWER FUEL RUN TIME

23FT 10FT

28FT 8M 2M 5FT (rpm) USAGE RATE (hrs - 660 US gal

(kW/HP) (US gal/hr) fuel tank)

L/S 20 40 60 80 100 120 140 160 180 200 220 1300 212/284 13.84 47.7

US GPM 300 600 900 1200 1500 1800 2100 2400 2700 3000 3300

1400 256/343 16.70 39.5

1500 326/437 21.27 31.0

M3/HR 100 150 200 250 300 350 400 450 500 550 600 650 700 750

1600 368/493 24.01 27.5

FLOW - CLEAR WATER PERFORMANCE

CALCULATIONS BASED ON 210 g/kw.hr

Dry Weight: 20,811 lb

Fuel Capacity: 660 US gal CL

CL CL

CL

XH200 x CAT C-18 ENGINE

Final weight and dimensions will depend on completed specifications

ON A 2500L CHASSIS

All this information in this document is substantially correct at the time of printing

and may be altered subsequently

APPROX. DRY WEIGHT = 9440KG

APPROX. WET WEIGHT = 11500KG

www.allightprimax.com LIGHT WATER

You might also like

- Diesel Drive Auto Prime XTRA High Head PumpDocument2 pagesDiesel Drive Auto Prime XTRA High Head Pumpekho_febryNo ratings yet

- Sykes XH200-1750Document2 pagesSykes XH200-1750hendrynNo ratings yet

- Boomer T1D PDFDocument4 pagesBoomer T1D PDFArturo Pedro Salgado MedinaNo ratings yet

- Cat - D8T Dozer Specs, Videos & 360 Views - D8 Dozer - CaterpillarDocument17 pagesCat - D8T Dozer Specs, Videos & 360 Views - D8 Dozer - CaterpillarDavisson9No ratings yet

- D25KS D245S Blasthole Drill PDFDocument4 pagesD25KS D245S Blasthole Drill PDFlorenzo henerNo ratings yet

- Bucket Teeth For Excavator BucketsDocument2 pagesBucket Teeth For Excavator BucketsMiguel Angel Ojeda OreNo ratings yet

- Cont MinerDocument28 pagesCont MinerSunilNo ratings yet

- LT 650 Specification SheetDocument2 pagesLT 650 Specification Sheetolaff jardinez moreno100% (1)

- Technical Specification Boomer m2 C With Cop 3038 9851 2774 01 Web tcm821-1533267 PDFDocument4 pagesTechnical Specification Boomer m2 C With Cop 3038 9851 2774 01 Web tcm821-1533267 PDFTamara Monsalve100% (1)

- Sandvik LH307 (TORO 6) (6 - 7t)Document2 pagesSandvik LH307 (TORO 6) (6 - 7t)Дмитрий АсташонокNo ratings yet

- Imt International Drilling Rigs Spec F3f1a4Document16 pagesImt International Drilling Rigs Spec F3f1a4Phinto YuliandraNo ratings yet

- Charmec SF 605 DA (V) : Technical Data SheetDocument10 pagesCharmec SF 605 DA (V) : Technical Data SheetJohn VergaraNo ratings yet

- HPP Products PT - SmsDocument13 pagesHPP Products PT - SmsChank GeographicNo ratings yet

- Datos Tecnicos LH202Document8 pagesDatos Tecnicos LH202Roel Aroni CuaresmaNo ratings yet

- Meter Hours / Meter Lengths (KM) / Machine Present (1 or 0Document2 pagesMeter Hours / Meter Lengths (KM) / Machine Present (1 or 0Anushke HennayakeNo ratings yet

- Production Drilling Rig Range PresentationDocument31 pagesProduction Drilling Rig Range Presentationdan roy wouters sarabiaNo ratings yet

- Catalog Mining Truck 793f CaterpillarDocument28 pagesCatalog Mining Truck 793f CaterpillardiegoNo ratings yet

- Chieftain 1800Document16 pagesChieftain 1800José Luis OrellanaNo ratings yet

- Sandvik RH550r DTH hammer replacement partsDocument1 pageSandvik RH550r DTH hammer replacement partsEnrique MurgiaNo ratings yet

- Scooptram St2D: Atlas Copco Underground LoadersDocument4 pagesScooptram St2D: Atlas Copco Underground LoadersMiguel Flores100% (1)

- DL420 15c SpecificationsDocument4 pagesDL420 15c Specificationsesteban muñozNo ratings yet

- Catalog Altivar Process ATV600 Variable Speed DrivesDocument136 pagesCatalog Altivar Process ATV600 Variable Speed DrivesBarney RossNo ratings yet

- Powerroc T35 E: Surface Drill Rig For Construction, Road Construction and Urban DevelopmentDocument5 pagesPowerroc T35 E: Surface Drill Rig For Construction, Road Construction and Urban DevelopmentElgi Alam PangestuNo ratings yet

- DE712 Spec Sheet 02 2018Document5 pagesDE712 Spec Sheet 02 2018Zeus ChillopaNo ratings yet

- Underground Drill Models and SpecificationsDocument10 pagesUnderground Drill Models and SpecificationsDiogo Cordova100% (1)

- General Arrangement Up-Series (80 Gal.) 22431829 G: R.Redmond W.SorahDocument3 pagesGeneral Arrangement Up-Series (80 Gal.) 22431829 G: R.Redmond W.SorahRogerNo ratings yet

- 993K Specalog Aehq5922 PDFDocument32 pages993K Specalog Aehq5922 PDFpercyNo ratings yet

- AARD 5.5 LP LHD Underground LoaderDocument4 pagesAARD 5.5 LP LHD Underground LoaderEric CNo ratings yet

- ACEROS ROCKMORE-Full CatalogDocument154 pagesACEROS ROCKMORE-Full CatalogYsraels Santisteban DurandNo ratings yet

- Commando 300 Spec SheetDocument3 pagesCommando 300 Spec SheetgzapasNo ratings yet

- RC19 - IDC T450WS Shramm Exploration Drilling RC19Document2 pagesRC19 - IDC T450WS Shramm Exploration Drilling RC19Philippe Dumont100% (1)

- Ds311 Specification Sheet EnglishDocument4 pagesDs311 Specification Sheet EnglishYonatan Tarazona HilarioNo ratings yet

- KL 900 Details SpecsDocument4 pagesKL 900 Details SpecsbenNo ratings yet

- Toolrec SurfaceDocument7 pagesToolrec Surfacedefiunikasungti100% (1)

- 6000 Spa PDFDocument51 pages6000 Spa PDFLmf DanielNo ratings yet

- Undercarriage Measurement Appraisal FormDocument2 pagesUndercarriage Measurement Appraisal FormFrancisco AlmeidaNo ratings yet

- Flexiroc D60 and D65: Atlas Copco Surface Drill RigsDocument4 pagesFlexiroc D60 and D65: Atlas Copco Surface Drill RigsFernando Pérez SarriaNo ratings yet

- DCM CatalogDocument116 pagesDCM CatalogHussin LempoyangNo ratings yet

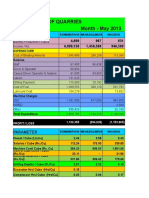

- Production of QuarriesDocument114 pagesProduction of QuarriesSarinNo ratings yet

- 9851 2980 01 - L - tcm835 3544379Document4 pages9851 2980 01 - L - tcm835 3544379Jimmy Gonzalo Veliz QuispeNo ratings yet

- TSR KuDocument16 pagesTSR KuAngsaNo ratings yet

- Cost Calculation of Jamtara-Dumka ProjectDocument24 pagesCost Calculation of Jamtara-Dumka ProjectnsureshbabuNo ratings yet

- Horizontal Pump Curve for 420EXHV Pump with 150mm DischargeDocument1 pageHorizontal Pump Curve for 420EXHV Pump with 150mm Dischargeachmadj1405No ratings yet

- Applications and Planning Guide: WIRTGEN Surface Mining ManualDocument17 pagesApplications and Planning Guide: WIRTGEN Surface Mining ManualYunweiNo ratings yet

- Sandvik Rotary Tools: Drill String Components by RigDocument40 pagesSandvik Rotary Tools: Drill String Components by Rigwalther alcocer100% (1)

- Th430 Specification Sheet EnglishDocument8 pagesTh430 Specification Sheet EnglishAmanda TaylorNo ratings yet

- ZirconDocument12 pagesZirconMohamed KarakacheNo ratings yet

- 31050862Document11 pages31050862farukNo ratings yet

- Technical Data Earthmover TyresDocument1 pageTechnical Data Earthmover TyresThiago Lisboa GuimarãesNo ratings yet

- Multiflo rf85mv Dewatering Pump Spec SheetDocument2 pagesMultiflo rf85mv Dewatering Pump Spec SheetAjyNo ratings yet

- Spraymec 6050 WPCDocument3 pagesSpraymec 6050 WPCPatop CofréNo ratings yet

- Spek Alat Di TAL Dan BangkoDocument8 pagesSpek Alat Di TAL Dan BangkoZinedin Zidan AkbarNo ratings yet

- T11M408 I1 Takraf 03910 Vdcme02 P1me01 004Document42 pagesT11M408 I1 Takraf 03910 Vdcme02 P1me01 004manuelarranoNo ratings yet

- New Matching A ShovelDocument25 pagesNew Matching A ShovelStephy MaryNo ratings yet

- MT42 Specification Sheet 9851 2697 01dDocument4 pagesMT42 Specification Sheet 9851 2697 01dJovanyNo ratings yet

- DD310-26 6232sfDocument4 pagesDD310-26 6232sfRoger TrujilloNo ratings yet

- PV351 Upgrades 2018Document6 pagesPV351 Upgrades 2018Francisco GonzalezNo ratings yet

- AS SpecSheet - CP100iDocument2 pagesAS SpecSheet - CP100iFrank RodriguezNo ratings yet

- Self-Priming Pump Automatically ReprimesDocument2 pagesSelf-Priming Pump Automatically Reprimesekho_febryNo ratings yet

- Atlas Copco RH 656 PartsDocument16 pagesAtlas Copco RH 656 PartsTiago HenriquesNo ratings yet

- EM P 02 Assignment 1 Example SlidesDocument11 pagesEM P 02 Assignment 1 Example SlidesTiago HenriquesNo ratings yet

- QLT m10 Asl Parts Book 2012Document46 pagesQLT m10 Asl Parts Book 2012Tiago Henriques100% (1)

- 2935 0724 30 - tcm30-1628027Document54 pages2935 0724 30 - tcm30-1628027Hossam Mohi EldinNo ratings yet

- EM P 01 Energy Statistics & Emergy Prices SlidesDocument49 pagesEM P 01 Energy Statistics & Emergy Prices SlidesTiago HenriquesNo ratings yet

- EM P 06 Energy Systems Analysis SlidesDocument14 pagesEM P 06 Energy Systems Analysis SlidesTiago HenriquesNo ratings yet

- EM P 09 Process Input-Output Analysis SlidesDocument12 pagesEM P 09 Process Input-Output Analysis SlidesTiago HenriquesNo ratings yet

- Applied Thermal Engineering: Minje Park, Daebong Jung, Minjae Kim, Kyoungdoug MinDocument9 pagesApplied Thermal Engineering: Minje Park, Daebong Jung, Minjae Kim, Kyoungdoug MinTiago HenriquesNo ratings yet

- EM P 12 MicrogenerationDocument7 pagesEM P 12 MicrogenerationTiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- EM P 08 Process Input-Output Analysis SlidesDocument16 pagesEM P 08 Process Input-Output Analysis SlidesTiago HenriquesNo ratings yet

- Energy Management Diagrams and AnalysisDocument4 pagesEnergy Management Diagrams and AnalysisTiago HenriquesNo ratings yet

- EM P 08 IOT Energy Systems Analysis SlidesDocument18 pagesEM P 08 IOT Energy Systems Analysis SlidesTiago HenriquesNo ratings yet

- EM P 06 Energy Systems Analysis SlidesDocument14 pagesEM P 06 Energy Systems Analysis SlidesTiago HenriquesNo ratings yet

- EM P 05 Energy Systems Analysis SlidesDocument14 pagesEM P 05 Energy Systems Analysis SlidesTiago HenriquesNo ratings yet

- EM P 03 Energy Prices SlidesDocument14 pagesEM P 03 Energy Prices SlidesTiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- S Intermediate Input Final Demand: 0 #Value! #Value!Document2 pagesS Intermediate Input Final Demand: 0 #Value! #Value!Tiago HenriquesNo ratings yet

- EM P 01 Energy Statistics SlidesDocument40 pagesEM P 01 Energy Statistics SlidesTiago HenriquesNo ratings yet

- EM P 06 Energy Systems Analysis SlidesDocument14 pagesEM P 06 Energy Systems Analysis SlidesTiago HenriquesNo ratings yet

- EM Ass 04 Annex 2 DataDocument3 pagesEM Ass 04 Annex 2 DataTiago HenriquesNo ratings yet

- EM Ass 04Document1 pageEM Ass 04Tiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- S Intermediate Input Final DemandDocument2 pagesS Intermediate Input Final DemandTiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- High Pressure Turbine Governing System PDFDocument28 pagesHigh Pressure Turbine Governing System PDFAnonymous ZnuMEWN1100% (4)

- Trojan Type A - 3Document2 pagesTrojan Type A - 3Cairo Oil Refining Co.No ratings yet

- 2-1. Structure and FunctionDocument86 pages2-1. Structure and FunctionBreyner Romero SantosNo ratings yet

- JSA For CT OperationsDocument39 pagesJSA For CT OperationsAniekan AkpaidiokNo ratings yet

- At Alo GueDocument40 pagesAt Alo GueSK100% (1)

- Novel Subsea Boosting Solutions To Increase IORDocument25 pagesNovel Subsea Boosting Solutions To Increase IORxiaoyi123No ratings yet

- Reliable Hot Water Piping SystemDocument6 pagesReliable Hot Water Piping SystemAzher ANo ratings yet

- The Water Supply RegulationsDocument13 pagesThe Water Supply RegulationsBalaji NaikNo ratings yet

- INTERMEDIATED HYDRAULIC SYSTEM COMPONENTSDocument153 pagesINTERMEDIATED HYDRAULIC SYSTEM COMPONENTSBalikpapan CityNo ratings yet

- Close-Coupled Centrifugal PumpsDocument12 pagesClose-Coupled Centrifugal PumpsIan RidzuanNo ratings yet

- Helicopter Transmission SystemsDocument113 pagesHelicopter Transmission SystemsAlaye AkpanaNo ratings yet

- PATUAKHALIDocument46 pagesPATUAKHALIAbir AhmedNo ratings yet

- YGSL-120R Operation ManualDocument54 pagesYGSL-120R Operation ManualzebarsNo ratings yet

- SP70Y EnglishDocument2 pagesSP70Y EnglishGarcia CruzNo ratings yet

- Almex SVP Brochure 106Document4 pagesAlmex SVP Brochure 106Enrique GutierrezNo ratings yet

- Dd422ie Specification Sheet English 5Document4 pagesDd422ie Specification Sheet English 5P. Morales EdgarNo ratings yet

- DX340LCA: Crawler ExcavatorDocument26 pagesDX340LCA: Crawler ExcavatorGloria CaicedoNo ratings yet

- PERIMATIC GP Operator ManualDocument22 pagesPERIMATIC GP Operator ManualssalahNo ratings yet

- 854F-Disassembly and AssemblyDocument204 pages854F-Disassembly and AssemblyZIBA KHADIBI100% (2)

- Type Description NO. Price Total Prices Split & Ventilation FanDocument3 pagesType Description NO. Price Total Prices Split & Ventilation FanHemn Rafiq TofiqNo ratings yet

- Dewatering Pump: Instruction, Installation, Operation and Maintenance ManualDocument5 pagesDewatering Pump: Instruction, Installation, Operation and Maintenance ManualDeepNo ratings yet

- N2000 Spec SheetDocument2 pagesN2000 Spec SheetJavier GarciaNo ratings yet

- RT Series Lobe Pump Catalogue PDFDocument15 pagesRT Series Lobe Pump Catalogue PDFvj4249100% (1)

- Product Leaflet S 928-988 Separator and System enDocument4 pagesProduct Leaflet S 928-988 Separator and System enCaet GamingNo ratings yet

- Module 3 - Pump Configuration Specific Speed and Affinity Laws - No AnsDocument17 pagesModule 3 - Pump Configuration Specific Speed and Affinity Laws - No AnsRoi Vincent AnitNo ratings yet

- Fluid Mechanics PDFDocument59 pagesFluid Mechanics PDFsunny chaurasiaNo ratings yet

- Mission 3D Inverter Series Service Manual 2016Document90 pagesMission 3D Inverter Series Service Manual 2016pastilhasNo ratings yet

- S70me-C8 2Document387 pagesS70me-C8 2agusbramasthaNo ratings yet

- P100S Pressurised Water Temperature Control UnitDocument2 pagesP100S Pressurised Water Temperature Control Unitweb312_twNo ratings yet