Professional Documents

Culture Documents

Hussey Copper Electrolytic Tough Pitch CDA Copper C 110 00

Uploaded by

Michael DoyleOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hussey Copper Electrolytic Tough Pitch CDA Copper C 110 00

Uploaded by

Michael DoyleCopyright:

Available Formats

CDA COPPER NO.

C 110 00 / Electrolytic Tough Pitch

Typical Uses Composition-Percent

ARCHITECTURAL: Building fronts, downspouts, flashing, gutters, roofing, screening, spouting

AUTOMOTIVE: Gaskets, radiators ELECTRICAL: Bus bars, conductivity wire, contacts, switches, terminals, Nominal Min Max

cable wrap, field coils, transformers HARDWARE: Ball floats, burrs, cotter pins, nails, rivets, soldering copper,

tacks MISCELLANEOUS: Anodes, chemical process equipment, kettles, pans, vats, medical, clad metals

Copper - 99.90 -

Common Fabrication Processes Oxygen .04 - -

Blanking; coining; coppersmithing; drawing; etching; forming and bending; heading and upsetting; hot forging and

pressing; piercing and punching; roll threading and knurling; shearing; spinning; squeezing and swaging; stamping.

Physical Properties English Units C G.S. Units

Melting Point (Liquidus) 1,981°F 1,083°C

Melting Point (Solidus) 1,949°F 1,065°C

Density .321-.323 lb./cu. in. @ 68°F 8.89-8.94 gm./cu. cm. @ 20°C

Specific Gravity 8.89-8.94 8.89-8.94

Coefficient of Thermal Expansion .0000094 per °F from 68°F to 212°F .0000170 per °C from 20°C to 100°C

Coefficient of Thermal Expansion .0000096 per °F from 68°F to 392°F .0000173 per °C from 20°C to 200°C

Coefficient of Thermal Expansion .0000098 per °F from 68°F to 572°F .0000177 per °C from 20°C to 300°C

Thermal Conductivity 226 Btu./sq. ft./ft/hr./°F @ 68°F .934 cal./sq. cm./cm./sec./°C @ 20°C

Electrical Resistivity (Annealed) 10.3 Ohms (circ. mil./ft.) @ 68°F 1.71 Microhm-cm. @ 20°C

Electrical Conductivity* (Annealed) 100% IACS @ 68°F .586 Megohm-cm. @ 20°C

Thermal Capacity (Specific Heat) .092 Btu./lb./°F @ 68°F .092 cal./gm./°C @ 20°C

Modulus of Elasticity (Tension) 17,000,000 psi 12,000 Kg/sq. mm

Modulus of Rigidity 6,400,000 psi 4,500 Kg/sq. mm

*Volume and weight basis

Fabrication Properties

Capacity for being Cold Worked Excellent Suitability for being joined by:

Capacity for being Hot Formed Excellent Soldering Excellent

Hot Forgeability Rating (Forging Brass =100) 65 Brazing Good

Hot Working Temperature 1,400-1,600°F or 750-875°C Oxyacetylene Welding Not Recommended

Annealing Temperature 600-1,200°F or 315-650°C Carbon Arc Welding Fair

Machinability Rating (Free Cutting Brass =100) 20 Gas Shielded Arc Welding Fair

Coated Metal Arc Welding Not Recommended

Mechanical Properties

Resistance Welding {

Spot

Seam

Butt

Not Recommended

Not Recommended

Good

(½% Extension

Nominal

of Area - %

Elongation

Under Load)

Reduction

Rockwell Fatigue Strength

Strength

Strength

Strength

Nominal

Nominal

in 2” - %

Hardness

Section

Temper

Tensile

Shear

Form

Yield

Size

psi

Million

psi

psi

F B 30T psi Cycles

FLAT 0.040 in. 0.050 mm 32,000 10,000 - I 45 40 - - 22,000 - -

PRODUCTS 0.025 mm 34,000 11,000 - 45 45 - - 23,000 11,000 100

S Eighth Hard 36,000 28,000 - 30 60 10 25 25,000 - -

Quarter Hard 38,000 30,000 - 25 70 25 36 25,000 - -

Half Hard 42,000 36,000 - 14 84 40 50 26,000 13,000 100

Hard 50,000 45,000 - 6 90 50 57 28,000 13,000 100

Spring 55,000 50,000 - 4 94 60 63 29,000 14,000 100

Extra Spring 57,000 53,000 - 4 95 62 64 29,000 - -

As Hot Rolled 34,000 10,000 - 45 45 - - 23,000 - -

0.250 in. 0.050 mm 32,000 10,000 - 50 40 - - 22,000 - -

Eighth Hard 36,000 28,000 - 40 60 10 - 25,000 - -

Quarter Hard 38,000 30,000 - 35 70 25 - 25,000 - -

Hard 50,000 45,000 - 12 90 50 - 28,000 - -

As Hot Rolled 32,000 10,000 - 50 40 - - 22,000 - -

1.0 in. Hard 45,000 40,000 - 20 85 45 - 26,000 - -

The values listed above represent reasonable approximations suitable for general engineering use. Due to commercial variations in composition and to manufacturing limitations, they

should not be used for specification purposes. See applicable A.S.T.M. specification references.

owned by:

100 Washington Street 724-251-4200 Main

WWW.HUSSEYCOPPER.COM Leetsdale, PA 15056-1099 800-733-8866 Toll-Free

724-251-4243 Fax

You might also like

- AISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDocument2 pagesAISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDiegoAlvarezHuguezNo ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- Ingun Ada Catalogue enDocument80 pagesIngun Ada Catalogue enMichael DoyleNo ratings yet

- Weld Process Cheat SheetDocument1 pageWeld Process Cheat SheetZaheed ManooNo ratings yet

- Usiten 375-1Document6 pagesUsiten 375-1Gerardo Rodríguez100% (1)

- AAR Manual of Standards and Recommended Practices Specifications For Tank CarsDocument38 pagesAAR Manual of Standards and Recommended Practices Specifications For Tank CarsCentre For Total Quality ManagementNo ratings yet

- kme_STOL76_C19010_enDocument1 pagekme_STOL76_C19010_enMattia Terri TerrandoNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- 903 Datasheet 17Document1 page903 Datasheet 17Fred Duarte CaldeiraNo ratings yet

- Cucrzr c18160 Pna 372 - enDocument2 pagesCucrzr c18160 Pna 372 - enSulistyo widiatmokoNo ratings yet

- Cu-ETP Material DatasheetDocument2 pagesCu-ETP Material Datasheetwhoam iNo ratings yet

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENYulwido AdiNo ratings yet

- ATA Heet: LSS Chipper KnifeDocument2 pagesATA Heet: LSS Chipper KnifeX800XL100% (1)

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFtiele_barcelosNo ratings yet

- Alloy 410s Spec SheetDocument2 pagesAlloy 410s Spec SheetALONSO GOMEZNo ratings yet

- Cuzn37-Pna 243 enDocument2 pagesCuzn37-Pna 243 enAbrahan Tinco PariNo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Aisi 304Document2 pagesAisi 304Rohit100% (1)

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- 304 Stainless Steel Tecnical DataDocument2 pages304 Stainless Steel Tecnical DataArmando MátalNo ratings yet

- Alloy 410S Spec SheetDocument2 pagesAlloy 410S Spec SheetPrakash SundharamNo ratings yet

- Motor Design Basic TutorialDocument38 pagesMotor Design Basic TutorialDHRUV UPADHAYANo ratings yet

- 875 Datasheet 16Document1 page875 Datasheet 16Fred Duarte CaldeiraNo ratings yet

- Lss-A286 Astm A453 PDFDocument2 pagesLss-A286 Astm A453 PDFmazolasboNo ratings yet

- C95500 ASTM - Nickel Aluminum BronzeDocument2 pagesC95500 ASTM - Nickel Aluminum BronzethuykvNo ratings yet

- Cusn10-Pna 292 enDocument2 pagesCusn10-Pna 292 enRissi CHNo ratings yet

- Cu Ofe c10100 Pna 203 - enDocument2 pagesCu Ofe c10100 Pna 203 - enNitin KumarNo ratings yet

- 304 Stainless SteelDocument3 pages304 Stainless Steelnum fistismNo ratings yet

- Material Datasheet Cu-OFDocument2 pagesMaterial Datasheet Cu-OFmohsen_267No ratings yet

- Alloy: C97300: Typical UsesDocument2 pagesAlloy: C97300: Typical UsesalextentwentyNo ratings yet

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDocument2 pages304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless Steeldaniel enrique romero robayoNo ratings yet

- Cu Etp c11000 Pna - 211 sm0008 - enDocument2 pagesCu Etp c11000 Pna - 211 sm0008 - enNitin KumarNo ratings yet

- Aisi 5140Document2 pagesAisi 5140rumabiswas853No ratings yet

- AISI 1035 SteelDocument2 pagesAISI 1035 SteelCarlos Andres Garcia MuñozNo ratings yet

- Properties s45cDocument3 pagesProperties s45ctomas duranNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- Material Datasheet Cuzn30Document2 pagesMaterial Datasheet Cuzn30alex94kgNo ratings yet

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENjurreijndersNo ratings yet

- Aço Uddeholm CalmaxDocument12 pagesAço Uddeholm CalmaxDanilo SilvaNo ratings yet

- Alloy 625 Spec Sheet PDFDocument3 pagesAlloy 625 Spec Sheet PDFRaghNo ratings yet

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- WB88SHR M.M.A. welding electrode propertiesDocument1 pageWB88SHR M.M.A. welding electrode propertieslathasri78No ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- Silicon Bronze 655: Herculoy®, High-Silicon Bronze A, UNS C65500, H06 (50%) Temper RodDocument2 pagesSilicon Bronze 655: Herculoy®, High-Silicon Bronze A, UNS C65500, H06 (50%) Temper RodJay PNo ratings yet

- Cu Ni 18 ZN 19 PB 1Document1 pageCu Ni 18 ZN 19 PB 1Isa CatNo ratings yet

- Ra-253-Ma DB Us en PDFDocument12 pagesRa-253-Ma DB Us en PDFbadesharamkNo ratings yet

- Inconel 718 Composition, Properties & UsesDocument2 pagesInconel 718 Composition, Properties & UsesPrathyusha RamadurgamNo ratings yet

- Cu-ETP: C11000 Industrial RolledDocument4 pagesCu-ETP: C11000 Industrial Rolledsrsivaraman81No ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Alloy 718 high strength nickel-base superalloy properties applicationsDocument2 pagesAlloy 718 high strength nickel-base superalloy properties applicationsOnder TemelNo ratings yet

- Applications: Hpalloys Cobalt 6B Product DescriptionDocument4 pagesApplications: Hpalloys Cobalt 6B Product DescriptionJSH100No ratings yet

- Cusn8 Industrial RolledDocument4 pagesCusn8 Industrial RolledPrakash MakadiaNo ratings yet

- Bronze c54400 SpecificationsDocument3 pagesBronze c54400 SpecificationsRam Parimalam100% (1)

- AISI 4340 Steel properties and usesDocument2 pagesAISI 4340 Steel properties and usesJoko TriwardonoNo ratings yet

- Aluminum Bronze Properties and ApplicationsDocument3 pagesAluminum Bronze Properties and ApplicationsAbbasNo ratings yet

- CuSn6-PNA 282 - ENDocument2 pagesCuSn6-PNA 282 - ENasatcholidNo ratings yet

- Nitronic® 40 Stainless Steel: Chemical CompositionDocument2 pagesNitronic® 40 Stainless Steel: Chemical CompositionBagus WicaksanaNo ratings yet

- Copper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument7 pagesCopper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webboydoc inspectionNo ratings yet

- 304Document2 pages304julianmorantesNo ratings yet

- Cunisi-Pna 290 enDocument2 pagesCunisi-Pna 290 enJdjoNo ratings yet

- Alloy 330 Spec SheetDocument2 pagesAlloy 330 Spec SheetArman MominNo ratings yet

- Electric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesFrom EverandElectric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesNo ratings yet

- Data Sheet: AEDR-850xDocument10 pagesData Sheet: AEDR-850xMichael DoyleNo ratings yet

- MN Statutes 182.653Document5 pagesMN Statutes 182.653Michael DoyleNo ratings yet

- Echnical ATA Heet: CastinDocument2 pagesEchnical ATA Heet: CastinMichael DoyleNo ratings yet

- Admin Image Option Editor GoEngineerDocument23 pagesAdmin Image Option Editor GoEngineerMichael DoyleNo ratings yet

- Calculation of Tolerance Stacks Using Direct Position Approach in Geometric Dimensioning and TolerancingDocument10 pagesCalculation of Tolerance Stacks Using Direct Position Approach in Geometric Dimensioning and TolerancingMichael DoyleNo ratings yet

- MN Rules Chapter 5208 DLIDocument24 pagesMN Rules Chapter 5208 DLIMichael DoyleNo ratings yet

- Clean SolidWorks UninstallDocument8 pagesClean SolidWorks UninstallBlueNo ratings yet

- An Employer's Guide To Developing A Workplace Accident and Injury Redictopm (AWAIR) ProgramDocument25 pagesAn Employer's Guide To Developing A Workplace Accident and Injury Redictopm (AWAIR) ProgramMichael DoyleNo ratings yet

- RIGOL DM3058 Technical Characteristics GuideDocument9 pagesRIGOL DM3058 Technical Characteristics GuideMichael DoyleNo ratings yet

- Specification Chart GuideDocument2 pagesSpecification Chart GuideMichael DoyleNo ratings yet

- ASCO Engineering Guide 061108Document34 pagesASCO Engineering Guide 061108Karuna gantiNo ratings yet

- MFG Tooling - 14 Welding FixtureDocument98 pagesMFG Tooling - 14 Welding FixtureRamji RaoNo ratings yet

- Welding DefectsDocument77 pagesWelding DefectsBalakumar100% (1)

- F4281-GEDI-M-SS-ITP-1039-3 ITP For Equipment and Pipe Installation in - Compressed Air System PDFDocument19 pagesF4281-GEDI-M-SS-ITP-1039-3 ITP For Equipment and Pipe Installation in - Compressed Air System PDFDang Hieu NguyenNo ratings yet

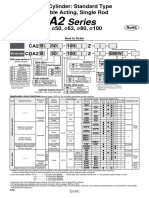

- Series: CA2 Z Z B B 50 50 100 100 M9Bw Cda2Document13 pagesSeries: CA2 Z Z B B 50 50 100 100 M9Bw Cda2arisprakesaNo ratings yet

- Power Piping: ASME Code For Pressure Piping, 831Document6 pagesPower Piping: ASME Code For Pressure Piping, 831ammarashraf91No ratings yet

- THS 2001 - Brochur of All Articles PresentedDocument239 pagesTHS 2001 - Brochur of All Articles Presentedramkumar31No ratings yet

- List of Price of BSDocument15 pagesList of Price of BSPrda WpNo ratings yet

- Spec - 2017-02 - A00-FIELD ERECTED ABOVEGROUND VERTICAL STORAGE TANKS API650Document34 pagesSpec - 2017-02 - A00-FIELD ERECTED ABOVEGROUND VERTICAL STORAGE TANKS API650AL Rajhi ZakariaNo ratings yet

- Poste A Souder Saf Prestotig 160 PFCDocument44 pagesPoste A Souder Saf Prestotig 160 PFCneobelhadjNo ratings yet

- Fabrication Erection and Installation Procedure For PipingDocument36 pagesFabrication Erection and Installation Procedure For PipingThiên Khánh67% (3)

- Aluminium WeldingDocument0 pagesAluminium Weldingrohitbhat2345No ratings yet

- Container ProcessDocument87 pagesContainer ProcessNarayan RoyalmechNo ratings yet

- Manual 005Document64 pagesManual 005Mohammed Mostafa El HaddadNo ratings yet

- Proto - Welds - Application - iXRDDocument4 pagesProto - Welds - Application - iXRDcelestino biasottoNo ratings yet

- Astm A770 PDFDocument5 pagesAstm A770 PDFCristian OtivoNo ratings yet

- A1033-10 (2015) Standard Practice For Quantitative Measurement and Reporting of Hypoeutectoid Carbon and Low-Alloy Steel Phase TransformationsDocument14 pagesA1033-10 (2015) Standard Practice For Quantitative Measurement and Reporting of Hypoeutectoid Carbon and Low-Alloy Steel Phase Transformationstjt4779No ratings yet

- Abbreviations Used in This Manual: 5. Ecu (Electronic Control Unit)Document130 pagesAbbreviations Used in This Manual: 5. Ecu (Electronic Control Unit)jhoan maestreNo ratings yet

- Welded Joint Design 3rd EditionDocument155 pagesWelded Joint Design 3rd EditionThuận Hoàng94% (16)

- GeKa Katalog PDFDocument514 pagesGeKa Katalog PDFElshan FeyzullayevNo ratings yet

- Aqua Therm PPR PipesDocument63 pagesAqua Therm PPR Pipeskalmech2003No ratings yet

- Scout Welder Thermal Arc Ta-4 170h Eng-ImDocument40 pagesScout Welder Thermal Arc Ta-4 170h Eng-ImgomooneyNo ratings yet

- Is 805Document38 pagesIs 805Sse SteelNo ratings yet

- Kada 862 DengDocument7 pagesKada 862 Dengy2k_yah7758No ratings yet

- ASME2019 KeyChangesSectionIDocument8 pagesASME2019 KeyChangesSectionIمحمد نعمان بٹNo ratings yet

- Busbar TightnessDocument11 pagesBusbar Tightnesssanjeev267No ratings yet

- Welding and Cutting Issue 2 2014 LowresDocument64 pagesWelding and Cutting Issue 2 2014 LowresScott TrainorNo ratings yet