Professional Documents

Culture Documents

Bridge Bearing

Uploaded by

Yss CastañedaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bridge Bearing

Uploaded by

Yss CastañedaCopyright:

Available Formats

How A Neoprene Bearing Pad Handles Heavy Loads

You may identify neoprene rubber as the elastomeric material that wetsuits and laptop sleeves are made of. That

kind of neoprene material is soft to the touch and exhibits a superior degree of flexibility and elasticity. However,

neoprene rubber can also be used for heavy construction applications. One primary example of such an application is

in bridge construction. A neoprene bearing pad is a thick and durable version of the elastomer that is used in

numerous construction applications. Thick neoprene paddingis employed in such applications to endure the pressure

of heavy weights and resist outdoor variables such as oils and ozone.

Many people do not realize this, but the many bridges across the country that you may drive your car across are

constructed with the assistance of durable neoprene components. Pads of neoprene have been and are still

commonly used in concrete bridges to prevent damage from bridge activities and movements. A good solid neoprene

block can provide the perfect protective barrier that is required in important construction jobs.

Although they are both derived from the base compound polychloroprene, the neoprene in wetsuits is not the same

form present in a neoprene bearing pad. Wetsuits, laptop sleeves and mouse pads are made of cellular neoprene, a

form of neoprene that is the result of the introduction of a foaming agent into its creation process. The type of

neoprene pads for bridges are made of dense sheet rubber and do not use a foaming agent in the production

process. In contrast to the softer and more foamy looking cellular rubber, the material of a neoprene bearing pad is

solid and firm to the touch, offering little flexibility for the sake of enhanced durability.

What exactly is a bridge bearing pad? Conjure the best image of a concrete bridge in your head. You should see

concrete piers holding up the bridge deck. A bridge bearing is located where the piers connect to the subsurface of

the bridge deck. This device is meant to transfer any loads and movements from the deck into the foundation. It is a

safety mechanism that gives bridges the ability to flex with movements instead of being damaged by them. A

neoprene bearing pad is uniquely qualified for this task simply by virtue of its physical features.

There are three types of bearings: elastomeric, plane sliding and multiple roller bearings. A neoprene bearing pad

falls directly into the elastomeric category; that is, they utilize the inherent elasticity of rubber. Despite the limited

flexibility of a thick and solid neoprene block, the fact that it is a rubber material gives the pad a better level of

elasticity for the purposes of shock absorption. Elasticity is a trait common to rubbers, although each specific type has

its own level of it. Elastomeric bearings are also a more economical choice when compared to the other types of

bearings .

Neoprene padding offers two important physical functions that can help to prevent damage to bridges:

Absorbs shock: The shock absorbing property of durable neoprene material dissipates any loads

and impacts that may damage the structural integrity of the bridge deck and supports. Using

neoprene pads for bridges also promotes the absorption of movements caused by thermal

expansion and contraction of the materials in the beams or bridges. This feature of a neoprene

bearing pad helps in the proper and stable functioning of a bridge.

Promotes movement: The inherent elasticity of neoprene allows for lateral and longitudinal

movement of the bridge. The elastic nature of neoprene allows the beam to rotate slightly from

impact, only to rebound unaffected. Even the most durable neoprene material has a small amount

of elasticity, just enough to make a difference. This feature makes neoprene, and rubber in

general, a popular material to use in these types of construction projects.

A neoprene bearing pad is a cost effective and useful plate for use on precast, pre-stressed concrete or metal beams

in bridges. Neoprene pads for bridges allow effortless and consistent transmission of mass from the beam down. This

permits sideways shift of the beam caused by natural thermal energy. Neoprene padding is easier to install than

plane sliding and multiple roller bearings. Neoprene rubber’s resistance to ozone, UV rays, certain chemicals, and

weathering ensures that the elastomer won’t degrade from outdoor use. The operable temperature range of neoprene

is also very wide, which ensures consistent performance. It is truly amazing what a neoprene block can do! Next time

you are on a bridge, just know that the chances are good that you are being supported through the aid of a neoprene

bearing pad.

http://www.rubbercal.com/sheet-rubber/neoprene-bearing-pad/#bottom

You might also like

- N) :retz - 6.S13 - $.S$$: Frfi) If$TrufltlfilvDocument13 pagesN) :retz - 6.S13 - $.S$$: Frfi) If$TrufltlfilvYss CastañedaNo ratings yet

- Caltech para Sa TagumpayDocument22 pagesCaltech para Sa TagumpayNeil Norman Simon ManansalaNo ratings yet

- WaiverDocument4 pagesWaiverYss CastañedaNo ratings yet

- PresentationDocument42 pagesPresentationauyinNo ratings yet

- Occupational Safety and Health Standards: Engr. Alyssa Marie A. CastañedaDocument19 pagesOccupational Safety and Health Standards: Engr. Alyssa Marie A. CastañedaYss CastañedaNo ratings yet

- ResourcesDocument1 pageResourcesYss CastañedaNo ratings yet

- OJTDocument4 pagesOJTYss CastañedaNo ratings yet

- Occupational Safety and Health Standards: Engr. Alyssa Marie A. CastañedaDocument19 pagesOccupational Safety and Health Standards: Engr. Alyssa Marie A. CastañedaYss CastañedaNo ratings yet

- Progress Photos (1-30 April 2017)Document19 pagesProgress Photos (1-30 April 2017)Yss CastañedaNo ratings yet

- Student's OJT Program EvaluationDocument1 pageStudent's OJT Program EvaluationYss CastañedaNo ratings yet

- Philippine Constitution - Civil Service Exam ReviewerDocument41 pagesPhilippine Constitution - Civil Service Exam ReviewerYzza Veah Esquivel50% (2)

- Rev29jan2019oftemplate OSHprogram Asof 290119Document12 pagesRev29jan2019oftemplate OSHprogram Asof 290119GelinaNo ratings yet

- LoveDocument1 pageLoveYss CastañedaNo ratings yet

- AgahayaynndfdfhDocument27 pagesAgahayaynndfdfhYss CastañedaNo ratings yet

- Number 1 - Solution To Long QuizDocument1 pageNumber 1 - Solution To Long QuizYss CastañedaNo ratings yet

- Amazing R AceDocument1 pageAmazing R AceYss CastañedaNo ratings yet

- Major and Minor Tectonic Plates (39 charactersDocument1 pageMajor and Minor Tectonic Plates (39 charactersYss CastañedaNo ratings yet

- Distance Between Two Points: Alyssa Marie A. Castañeda GC11Document1 pageDistance Between Two Points: Alyssa Marie A. Castañeda GC11Yss CastañedaNo ratings yet

- Boq Rogacicabridge EngDocument19 pagesBoq Rogacicabridge EngYss CastañedaNo ratings yet

- FKHJDocument1 pageFKHJYss CastañedaNo ratings yet

- CSiBridge SummaryDocument1 pageCSiBridge SummaryYss CastañedaNo ratings yet

- Ateneo de Naga University College of Science and Engineering Department of Civil EngineeringDocument1 pageAteneo de Naga University College of Science and Engineering Department of Civil EngineeringYss CastañedaNo ratings yet

- Problem Set 001Document2 pagesProblem Set 001Yss CastañedaNo ratings yet

- Calculate investment earnings and loan payments over timeDocument1 pageCalculate investment earnings and loan payments over timeYss CastañedaNo ratings yet

- Soil ProblemsDocument3 pagesSoil ProblemsYss CastañedaNo ratings yet

- RRL EditDocument3 pagesRRL EditYss CastañedaNo ratings yet

- Manang Netty 3 Driver GiloyDocument1 pageManang Netty 3 Driver GiloyYss CastañedaNo ratings yet

- Design Methodology for a Cable-Stayed BridgeDocument3 pagesDesign Methodology for a Cable-Stayed BridgeYss CastañedaNo ratings yet

- SP DefinitionDocument4 pagesSP DefinitionYss CastañedaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Assignment 6 TextDocument8 pagesAssignment 6 TextPaola AlvaradoNo ratings yet

- Homebrew 5e RacesDocument8 pagesHomebrew 5e RacesMarc AndréNo ratings yet

- Volleyball court rules and positions under 40 charactersDocument4 pagesVolleyball court rules and positions under 40 charactersmider886No ratings yet

- Activity 1Document11 pagesActivity 1Jann ericka Jao67% (3)

- Types of DanceDocument3 pagesTypes of DanceCici JavierNo ratings yet

- A4 - in The Dungeons of The Slave LordsDocument36 pagesA4 - in The Dungeons of The Slave LordsSturm75% (4)

- 3-Step Passing Route ConceptsDocument9 pages3-Step Passing Route ConceptsMark MileshikNo ratings yet

- DK-17 PlanoDocument2 pagesDK-17 PlanoodeiviNo ratings yet

- Sport and Energy Drinks Consumption Before, During and After TrainingDocument7 pagesSport and Energy Drinks Consumption Before, During and After TrainingGhana FirstaNo ratings yet

- Death Denied - The Book of The UndeadDocument194 pagesDeath Denied - The Book of The UndeadEdoardo Ossola67% (3)

- Skeletal and muscular system overviewDocument86 pagesSkeletal and muscular system overviewrambabs369No ratings yet

- Sports FestDocument9 pagesSports Festcris gerard trinidadNo ratings yet

- Perpectives: Bsce 5C-Steel Design Architectural Plan Proposed Three - Storey Commercial BuildingDocument15 pagesPerpectives: Bsce 5C-Steel Design Architectural Plan Proposed Three - Storey Commercial BuildingShōya IshidaNo ratings yet

- Dokumen - Pub Modern Poker Theory Building An Unbeatable Strategy Based On Gto Principles 1909457892 9781909457898Document811 pagesDokumen - Pub Modern Poker Theory Building An Unbeatable Strategy Based On Gto Principles 1909457892 9781909457898hacker a100% (8)

- Go Winds: NEW Manyfaces of Go NEW Yutopian Books Handbook of Star Point JosekiDocument12 pagesGo Winds: NEW Manyfaces of Go NEW Yutopian Books Handbook of Star Point JosekiAnonymous tadjbbYIzeNo ratings yet

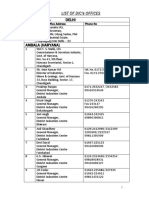

- Northn Zone-Delhi: List of Dic'S OfficesDocument54 pagesNorthn Zone-Delhi: List of Dic'S OfficesvijaiviruNo ratings yet

- TSR 2137 Lankhmar City of Adventure 2nd Ed - CompressDocument200 pagesTSR 2137 Lankhmar City of Adventure 2nd Ed - CompressAstronomer855No ratings yet

- Yamaha XT 350 E EC (Modell 1992) Microfiche, EnglischDocument57 pagesYamaha XT 350 E EC (Modell 1992) Microfiche, EnglischchavchirNo ratings yet

- Gautam Research ReportDocument81 pagesGautam Research ReportDeep ChoudharyNo ratings yet

- Proteus 2023 1Document11 pagesProteus 2023 1Alroy AlmeidaNo ratings yet

- News-Herald Rate Card (National) 2015Document1 pageNews-Herald Rate Card (National) 2015The News-HeraldNo ratings yet

- Rose Colored Boy LyricsDocument4 pagesRose Colored Boy LyricsJenevieve ManlapazNo ratings yet

- Barbarian Tower Level 20-30 PDFDocument16 pagesBarbarian Tower Level 20-30 PDFIqbal BaihaqiNo ratings yet

- Moskovski Vektor - Robert LudlumDocument593 pagesMoskovski Vektor - Robert Ludlumsilvana55No ratings yet

- TGfU ConceptDocument11 pagesTGfU ConceptRohizamNo ratings yet

- Pokemon 5e PHB - Gen I - VDocument117 pagesPokemon 5e PHB - Gen I - VC-dawg100% (11)

- Here To Slay RulesDocument2 pagesHere To Slay RulesKushal KumarNo ratings yet

- Cel Animation HandoutDocument2 pagesCel Animation Handoutapi-475274369No ratings yet

- CBSE Class 9 Science Worksheet - Force and Laws of MotionDocument3 pagesCBSE Class 9 Science Worksheet - Force and Laws of MotionJagannath BhattacharyyaNo ratings yet

- Mythgard Faction QuestsDocument5 pagesMythgard Faction QuestsbogdanalaciNo ratings yet