Professional Documents

Culture Documents

Mta 2042 - Suspension System

Uploaded by

Muhd Syafiq Soffian WongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mta 2042 - Suspension System

Uploaded by

Muhd Syafiq Soffian WongCopyright:

Available Formats

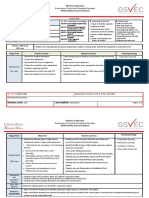

MINISTRY OF EDUCATION, MALAYSIA

VOCATIONAL COLLEGE STANDARD CURRICULUM

COURSE INFORMATION

COURSE NAME : SUSPENSION SYSTEM

CODE NAME : MTA 2042

LEVEL : 1 SEMESTER 2

CREDIT UNIT : 2.0

CONTACT HOUR : FACE TO FACE : 4.0 HOURS/WEEK

NON FACE TO FACE :

COURSE TYPE : VOCATIONAL

PREREQUISITE : -

CORE REQUISITE : -

Document Page 1/22

COURSE OUTCOMES

At the end of the COURSE, students should be able to:-

1. Distinguish front wheel bearings 21. Distinguish vehicle leaf spring assembly

2. Remove front wheel bearings 22. Remove vehicle leaf spring assembly

3. Examine front wheel bearings 23. Examine leaf spring assembly

4. Install front wheel bearings 24. Install vehicle leaf spring assembly

5. Distinguish rear wheel bearings 25. Identify Macpherson strut assembly location

6. Remove rear wheel bearings 26. Remove Macpherson strut assembly

7. Examine rear wheel bearings 27. Dismantle Macpherson strut assembly

8. Install rear wheel bearings 28. Assemble Macpherson strut assembly

9. Distinguish suspension bushes 29.Install Macpherson strut assembly to vehicle

10. Remove suspension bushes 30. Identify suspension ball joint location

11. Examine suspension bushes 31. Remove suspension ball joint assembly

12. Install suspension bushes 32. Check suspension ball joint

13. Distinguish front shock absorber 33. Install suspension ball joint

14. Remove front shock absorber assembly 34. Identify suspension bushes location

15. Examine front shock absorber 35. Remove suspension bushes

16. Install front shock absorber 36. Check suspension bushes

17. Distinguish rear shock absorber 37. Install suspension bushes

18. Remove rear shock absorber assembly 38. Identify suspension control arm location

19. Examine front rear absorber 39. Remove suspension control arm

20. Install rear shock absorber 40. Check suspension control arm

41. Install suspension control arm

COURSE DESCRIPTION

This COURSE covers the vehicle suspension system repair using service manual, hands tools set, special tools, lubricant, grease, workshop

equipment, replacement parts, wheel stopper, safety stands, personal protection equipment and fender cover so that suspension components

location identified, front shock absorber assembly removed, front shock absorber examined, rear shock absorber removed, rear shock absorber

examined, vehicle leaf spring assembly removed, leaf spring assembly examined; front shock absorber, vehicle leaf spring assembly and rear

shock absorber installed; Macpherson strut assembly replacement, suspension ball joint replacement and suspension bushes replacement in

accordance with manufacturer’s service manual and specification.

Document Page 2/22

CONTENT AND LEARNING STANDARDS

PROGRAM : AUTOMOTIVE TECHNOLOGY

COURSE NAME : SUSPENSION SYSTEM

CODE NAME : MTA 2042

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

1. REPLACE FRONT WHEEL 1.1 Distinguish front wheel bearings 1.1.1 Classify the purpose of wheel bearings according to the

BEARINGS manufacturer’s specifications

1.1.2 Define the types and function of front wheel bearings

according to the manufacturer’s specifications

1.1.3 Identify the purpose of wheel bearing oil seal according

to the manufacturer’s specifications

1.1.4 Locate the front wheel bearings of the vehicle according

to manufacturer’s specifications

1.2 Remove front wheel bearings 1.2.1 Describe the procedures of detaching the front wheel

bearings according to the manufacturer’s specifications.

1.2.2 Demonstrate the techniques of detaching the wheel

bearings according to the manufacturer’s specifications.

1.2.3 Detach the front wheel bearings according to the

manufacturer’s specifications

1.3 Examine front wheel bearings 1.3.1 Describe techniques of inspecting front wheel bearings

according to manufactures specification.

1.3.2 Check front wheel bearings condition according to

manufactures specification.

Document Page 3/22

1.4 Install front wheel bearings 1.4.1 Describe the procedures of fixing the front wheel

bearings according to the manufacturer’s specifications

1.4.2 Explain the types of wheel bearing grease according to

the manufacturer’s specifications.

1.4.3 Demonstrate the techniques of packing the wheel

bearing grease according to the manufacturer’s

specifications.

1.4.4 Utilize the techniques of adjusting wheel bearing

according to the manufacturer’s specifications

1.4.5 Pack the wheel bearing grease according to the

manufacturer’s specifications.

1.4.6 Fix the front wheel bearings according to the

manufacturer’s specifications

1.4.7 Fix the wheel bearing oil seal according to the

manufacturer’s specifications

1.4.8 Adjust the front wheel bearing free play according to the

manufacturer’s specifications

Document Page 4/22

CONTENT AND LEARNING STANDARDS

PROGRAM : AUTOMOTIVE TECHNOLOGY

COURSE NAME : SUSPENSION SYSTEM

CODE NAME : MTA 2042

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

2. REPLACE REAR WHEEL 2.1 Distinguish rear wheel bearings 2.1.1 Describe the types of rear wheel bearings according to

BEARINGS the manufacturer’s specifications

2.1.2 Explain the function of rear wheel bearings according

to the manufacturer’s specifications

2.1.3 Explain the constructions of the rear wheel bearings

according to manufacturer’s specifications

2.1.4 Explain the operation of the rear wheel bearings

according to manufacturer’s specifications

2.1.5 Describe the purpose of wheel bearings according to

the manufacturer’s specifications

2.1.6 Describe the purpose of wheel bearing oil seal

according to the manufacturer’s specifications

2.1.7 Locate the rear wheel bearings according to the

manufacturer’s specifications

2.2 Remove rear wheel bearings 2.2.1 Explain the procedures of detaching the rear wheel

bearings according to the manufacturer’s specifications

2.2.2 Describe the techniques of detaching the rear wheel

bearing according to the manufacturer’s specifications

2.2.3 Detach the rear wheel bearings according to the

Document Page 5/22

2.3 Examine rear wheel bearings manufacturer’s specifications

2.3.1 Describe the procedures of inspecting the rear wheel

bearings according to manufacturer’s specifications

2.3.2 Check the rear wheel bearings condition according to

the manufacturer’s specifications

2.4 Install rear wheel bearings

2.4.1 Determine the characteristics of wheel bearing greases

according to the manufacturer’s specifications

2.4.2 Describe the procedures of packing grease into

bearings according to the manufacturer’s specifications

2.4.3 Describe the procedures of fixing rear wheel bearings

according to the manufacturer’s specifications

2.4.4 Describe adjustment of rear wheel bearings free play

according to manufacturer’s specifications

2.4.5 Apply the techniques of packing grease into bearings

according to the manufacturer’s specifications

2.4.6 Fix the rear wheel bearings according to the

manufacturer’s specifications

2.4.7 Fix the rear wheel bearing oil seal according to the

manufacturer’s specifications

2.4.8 Adjust the rear wheel bearing according to the

manufacturer’s specifications

Document Page 6/22

CONTENT AND LEARNING STANDARDS

PROGRAM : AUTOMOTIVE TECHNOLOGY

COURSE : SUSPENSION SYSTEM

NAME

CODE NAME : MTA 2042

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

3. REPLACE VEHICLE 3.1 Distinguish suspension bushes 3.1.1 Determine the purpose of suspension bushes according

SUSPENSION BUSHES to the manufacturer’s specifications

3.1.2 Explain the types of suspension bushes according to

the manufacturer’s specifications

3.1.3 Explain the functions of suspension bushes according

to the manufacturer’s specifications

3.1.4 Interpret the constructions and operations of

suspension bushes according to the manufacturer’s

specifications

3.1.5 Locate the suspension bushes according to

manufacturer’s specifications

3.2 Remove suspension bushes 3.2.1 Explain the procedures of detaching suspension bushes

according to the manufactures specifications

3.2.2 Detach the suspension bushes according to

manufacturer’s specifications

Document Page 7/22

3.3 Examine suspension bushes 3.3.1 Interpret the procedures of inspecting suspension

bushes according to manufacturer’s specifications

3.3.2 Check the condition of suspension bushes according to

manufacturer’s specifications

3.4.1 Interpret the procedures of fixing suspension bushes

3.4 Install suspension bushes

according to the manufacturer’s specifications

3.4.2 Fix the suspension bushes according to the

manufacturer’s specifications

Document Page 8/22

CONTENT AND LEARNING STANDARDS

PROGRAM : AUTOMOTIVE TECHNOLOGY

COURSE : SUSPENSION SYSTEM

NAME

CODE NAME : MTA 2042

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

4. REPLACE FRONT SHOCK 4.1 Distinguish front shock absorber 4.1.1 Describe the purpose of front shock absorber and bump

ABSORBERS stopper according to the suspension manufacturer’s

specifications

4.1.2 Describe the types of front shock absorber and bump

stopper according to the manufacturer’s specifications

4.1.3 Explain the functions of front shock absorber and bump

stopper according to the manufacturer’s specifications

4.1.4 Explain the constructions of front shock absorber and

bump stopper according to the manufacturer’s

specifications

4.1.5 Explain the operations of front shock absorber and

bump stopper according to the manufacturer’s

specifications

4.1.6 Describe the types of suspension coil spring according

to the manufacturer’s specifications

4.1.7 Explain the function of suspension coil spring according

Document Page 9/22

to the manufacturer’s specifications

4.2 Remove front shock absorber 4.1.8 Locate components of front shock absorber and bump

assembly stopper according to the vehicle manual specifications

4.2.1 Describe the procedures of detaching front shock

absorber, coil spring, and bump stopper according to

the manufactures specifications

4.2.2 Describe the procedures of inspecting front shock

absorbers, coil springs, and bump stoppers according

manufacturer’s specifications

4.2.3 Detach the front shock absorbers according to the

vehicle specifications

4.2.4 Detach the shock absorber coil springs according to the

vehicle specifications

4.2.5 Detach the shock absorber bump stoppers according to

the vehicle specifications

4.3 Examine front shock absorber 4.3.1 Describe the procedures of inspecting front shock

absorbers according to the manufacturer’s

specifications

4.3.2 Describe the procedures of inspecting front shock

absorber bump stopper according to the manufacturer’s

specifications

4.3.3 Check the front shock absorber condition according to

the manufacturer’s specifications

4.3.4 Check the front shock absorber bump stopper condition

according to the manufacturer’s specifications

4.4 Install front shock absorber 4.4.1 Determine the procedures of assembling front shock

absorber, coil spring, and bump stopper according to

manufacturer’s specifications

4.4.2 Determine the procedures of fixing front shock absorber

according to the manufacturer’s specifications

4.4.3 Fix the front shock absorber according to the

manufacturer’s specifications

Document Page 10/22

CONTENT AND LEARNING STANDARDS

PROGRAM : AUTOMOTIVE TECHNOLOGY

COURSE : SUSPENSION SYSTEM

NAME

CODE NAME : MTA 2042

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

5. REPLACE REAR SHOCK 5.1 Distinguish rear shock absorber 5.1.1 Describe the rear shock absorber and bump stopper in

ASBORBERS accordance with the manufacturer’s specifications

5.1.2 Explain the types of rear shock absorber and bump

stopper in accordance with the manufacturer’s

specifications

5.1.3 Explain the functions of rear shock absorber and bump

stopper in accordance with the manufacturer’s

specifications

5.1.4 Explain the construction of rear shock absorber and

bump stopper in accordance with the manufacturer’s

specifications.

5.1.5 Explain the operation of rear shock absorber and bump

stopper in accordance with the manufacturer’s

specifications.

5.1.6 Locate the components of rear shock absorber and

bump stopper in accordance with the manufacturer’s

Document Page 11/22

specifications

5.2 Remove rear shock absorber 5.2.1 Explain the procedures of detaching rear shock

assembly absorber in accordance with the manufacturer’s

specification.

5.2.2 Detach the front shock absorbers in accordance with

the manufacturer’s specifications

5.3 Examine front rear absorber 5.3.1 Describe the procedures of inspecting rear shock

absorbers in accordance with the manufacturer’s

specifications

5.3.2 Check the front shock absorber condition in accordance

with the manufacturer’s specifications

5.4 Install rear shock absorber 5.4.1 Describe the procedures of fixing shock absorber in

accordance with the manufacturer’s specifications.

5.4.2 Fix the front shock absorber in accordance with the

manufacturer’s specifications.

Document Page 12/22

CONTENT AND LEARNING STANDARDS

PROGRAM : AUTOMOTIVE TECHNOLOGY

COURSE : SUSPENSION SYSTEM

NAME

CODE NAME : MTA 2042

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

6. REPLACE VEHICLE LEAF 6.1 Distinguish vehicle leaf spring 6.1.1 Describe the purpose of leaf spring in accordance with

SPRING ASSEMBLY assembly the manufacturer’s specifications

6.1.2 Describe the types of leaf spring in accordance with the

manufacturer’s specifications

6.1.3 Explain the functions of leaf spring in accordance with

the manufacturer’s specifications

6.1.4 Explain the constructions of leaf spring in accordance

with the manufacturer’s specifications

6.1.5 Explain the operations of leaf spring in accordance with

the manufacturer’s specifications

6.1.6 Locate the vehicle leaf spring in accordance with the

manufacturer’s specifications

6.2 Remove vehicle leaf spring 6.2.1 Explain the function of leaf spring bush spring in

assembly accordance with the manufacturer’s specification

6.2.2 Describe the procedures of detaching leaf spring

assembly spring in accordance with the manufacturer’s

Document Page 13/22

specifications

6.2.3 Describe the procedures of detaching leaf spring

bushes spring in accordance with the manufacturer’s

specifications

6.2.4 Detach the leaf spring assembly spring in accordance

with the manufacturer’s specifications

6.2.5 Detach the leaf spring bushes spring in accordance with

the manufacturer’s specifications

6.3 Examine leaf spring assembly 6.3.1 Describe the procedures of checking leaf spring in

accordance with the manufacturer’s specifications

6.3.2 Describe the procedures of checking leaf spring bushes

spring in accordance with the manufacturer’s

specifications

6.3.3 Check the condition of leaf spring in accordance with

the manufacturer’s specifications.

6.3.4 Check the condition of leaf spring bushes spring in

accordance with the manufacturer’s specifications

6.4 Install vehicle leaf spring assembly 6.4.1 Describe the procedures of assembling leaf spring in

accordance with the manufacturer’s specifications

6.4.2 Describe the procedures of fixing leaf spring bushes in

accordance with the manufacturer’s specifications

6.4.3 Describe the procedures of fixing leaf spring assembly

in accordance with the manufacturer’s specifications

6.4.4 Assemble the leaf spring in accordance with the

manufacturer’s specifications

6.4.5 Fix the leaf spring bushes in accordance with the

manufacturer’s specifications

6.4.6 Fix the leaf spring assembly in accordance with the

manufacturer’s specifications

Document Page 14/22

CONTENT AND LEARNING STANDARD

PROGRAM : AUTOMOTIVE TECHNOLOGY

COURSE NAME : SUSPENSION SYSTEM

CODE NAME : MTA 2042

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

7.1 Identify Macpherson strut assembly

7. CARRY OUT 7.1.1. Describe type of Macpherson strut assembly in accordance with

location

manufacturer’s service manual

MACPHERSON

7.1.2. Explain the purpose of Macpherson strut assembly in accordance

STRUT ASSEMBLY with manufacturer’s service manual

7.1.3. Describe construction of Macpherson strut assembly in accordance

REPLACEMENT

with manufacturer’s service manual

7.1.4. Locate Macpherson strut assembly in accordance with

manufacturer’s service manual

7.2 Remove Macpherson strut assembly

7.2.1. Detach insulator flange nuts in accordance with manufacturer’s

service manual

7.2.2. Detach steering knuckle from strut assembly in accordance

with manufacturer’s service manual

7.2.3. Detach Macpherson strut assembly in accordance with

manufacturer’s service manual

7.2.4. Detach steering knuckle detaching procedure accordance with

manufacturer’s service manual

7.2.5. Detach Macpherson strut assembly in accordance with

Document Page 15/22

manufacturer’s service manual

7.3 Dismantle Macpherson strut 7.3.1. Describe Macpherson strut assembly components parts in

assembly accordance with workshop service manual

7.3.2. Compress coil spring in accordance with workshop service manual

7.3.3. Detach insulator assembly, upper spring seat, front spring pad,

rubber bump, dust cover and spring, from strut in accordance with

workshop service manual

7.4 Assemble Macpherson strut 7.4.1 Fix Macpherson strut component parts in accordance with

assembly manufacturer’s service manual

7.4.2 Fit the insulator assembly, spring accordance with

workshop service manual

7.4.3 Tighten Flange nut with tightening torque in accordance with

workshop manual service tightening specifications.

7.4.4 Fit insulator assembly and spring. in accordance with manufacturer’s

service manual

7.4.5 Secure Flange nut in accordance with manufacturer’s service

manual

7.5 Install Macpherson strut assembly to 7.5.1 Fix Macpherson strut assembly in accordance with workshop service

vehicle manual

7.5.2 Tighten stabiliser link in accordance with workshop manual service

tightening specifications.

7.5.3 Fix steering knuckle in accordance with manufacturer’s service

manual

Document Page 16/22

CONTENT AND LEARNING STANDARD

PROGRAM : AUTOMOTIVE TECHNOLOGY

COURSE NAME : SUSPENSION SYSTEM

CODE NAME : MTA 2042

CONTENT LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD

8.1 Identify suspension ball joint location 8.1.1. Describe types of suspension ball joint in accordance with

8 CARRY OUT

manufacturer’s service manual

SUSPENSION 8.1.2. Explain the purpose of suspension system in accordance with

manufacturer’s service manual

BALL JOINT

8.1.3. Detach lower arm in accordance with workshop service manual

REPLACEMENT 8.1.4. Locate suspension ball joint in accordance with workshop service

manual

8.1.5. Describe the construction of suspension system in accordance with

manufacturer’s service manual

8.1.6. Locate the suspension ball joint in accordance with workshop

service manual

8.2 Remove suspension ball joint 8.2.1. Detach suspension ball joint in accordance with manufacturer’s

assembly service manual

8.2.2. Describe types of suspension ball joint in accordance with

manufacturer’s service manual

8.2.3. Detach lower arm in accordance with workshop service manual

8.2.4. Lower arm detaching procedure in accordance with workshop

service manual

Document Page 17/22

8.2.5. Detach suspension ball joint in accordance with workshop service

Manual

8.3 Check suspension ball joint 8.3.1. Explain the function of suspension ball joint in accordance with

manufacturer’s service manual

8.3.2. Test the condition of suspension ball joint in accordance with

manufacturer’s service manual

8.3.3. Determine the suspension’s ball joint condition in accordance with

manufacturer’s service manual

8.4 Install suspension ball joint 8.4.1. Attach suspension ball joint in accordance with manufacturer’s

service manual

8.4.2. Secure suspension ball joint in accordance with manufacturer’s

service manual

Document Page 18/22

CONTENT AND LEARNING STANDARD

PROGRAM : AUTOMOTIVE TECHNOLOGY

COURSE : SUSPENSION SYSTEM

NAME

CODE NAME : MTA 2042

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD

9.1 Identify suspension bushes location

9 CARRY OUT 9.1.1 Describe type of suspension bushes in accordance with

manufacturer’s service manual

SUSPENSION

9.1.2 Explain the purpose of suspension bushes in accordance with

BUSHES manufacturer’s service manual

9.1.3 Locate suspension bushes in accordance with workshop

REPLACEMENT

service manual

9.2 Remove suspension bushes

9.2.1 Detach suspension components in accordance with workshop

service manual

9.2.2 Detach suspension bushes in accordance with workshop

service manual

9.3 Check suspension bushes

9.3.1 Describe suspension bushes testing procedure in accordance with

manufacturer’s service manual

9.3.2 Determine condition of suspension bushes in accordance with

workshop service manual

Document Page 19/22

9.4 Install suspension bushes

9.4.1 Fix suspension bushes in accordance with manufacturer’s service

manual

9.4.2 Secure suspension bushes in accordance with manufacturer’s

service manual

9.4.3 Fix suspension components in accordance with manufacturer’s

service manual

9.4.4 Attach suspension bushes in accordance with manufacturer’s

service manual

Document Page 20/22

CONTENT AND LEARNING STANDARD

PROGRAM : AUTOMOTIVE TECHNOLOGY

COURSE NAME : SUSPENSION SYSTEM

CODE NAME : MTA 2042

CONTENT

LEARNING STANDARD PERFORMANCE CRITERIA

STANDARD

10.1 Identify suspension control arm 10.1.1 Explain the purpose of control arm in accordance with

10 CARRY OUT

location manufacturer’s service manual

CONTROL ARM

10.1.2 Describe the construction of the control arm in accordance with

REPLACEMENT

workshop service manual

10.1.3 Locate front / rear control arm in accordance with workshop

service manual

10.2 Remove suspension control arm 10.2.1 Describe control arm attachment parts in accordance with

manufacturer’s service manual

10.2.2 Detach control arm attachment parts in accordance with

manufacturer’s service manual

10.2.3 Detach control arm from vehicle in accordance with manufacturer’s

service manual

10.3 Check suspension control arm 10.3.1 Describe function of suspension control arm in accordance with

manufacturer’s service manual

10.3.2 Describe suspension control arm testing procedure in accordance

Document Page 21/22

with manufacturer’s service manual

10.3.3 Determine condition of suspension control arm in accordance with

manufacturer’s service manual

10.4 Install suspension control arm 10.4.1 Attach suspension control arm in accordance with manufacturer’s

service manual

10.4.2 Secure suspension control arm bolts and nuts in accordance with

manufacturer’s service manual

Document Page 22/22

You might also like

- Mta 202 - Brake System ShamDocument11 pagesMta 202 - Brake System ShamakmalNo ratings yet

- Latesh Emd BannerDocument1 pageLatesh Emd BannerPrashant KuwarNo ratings yet

- 206-02 Rear Disc Brake PICKUP JMC.Document10 pages206-02 Rear Disc Brake PICKUP JMC.RusonegroNo ratings yet

- Practicle Checklist Amt523s1 Braking SystemDocument4 pagesPracticle Checklist Amt523s1 Braking Systemcollins arogoNo ratings yet

- Montageanleitung ZST enDocument16 pagesMontageanleitung ZST enJonathan RojasNo ratings yet

- Heavy Vehicle Inspection ManualDocument74 pagesHeavy Vehicle Inspection ManualAngela MooreNo ratings yet

- Nichiyu FB 10 20 30 Forklift Trucks Workshop Manual PDFDocument230 pagesNichiyu FB 10 20 30 Forklift Trucks Workshop Manual PDFVüsal 1No ratings yet

- Service Manual For Ford Tractor Series 2000, 3000, 4000, 5000, 7000, 3400, 3500, 3550, 4400, 4500, 5500, 5550 Vol. 3Document332 pagesService Manual For Ford Tractor Series 2000, 3000, 4000, 5000, 7000, 3400, 3500, 3550, 4400, 4500, 5500, 5550 Vol. 3Taj Deluria100% (2)

- RC60 Ponts Service PDFDocument80 pagesRC60 Ponts Service PDFmohamedNo ratings yet

- De12t PDFDocument175 pagesDe12t PDFlarasNo ratings yet

- 501-02 Front-End Body Plate PICKUP JMCDocument6 pages501-02 Front-End Body Plate PICKUP JMCRusonegroNo ratings yet

- Motor Vehicle Technician - MVTNDocument6 pagesMotor Vehicle Technician - MVTNSk Akram HossainNo ratings yet

- Meritor Rt40-145p 40kDocument55 pagesMeritor Rt40-145p 40kJuan Rivera100% (1)

- Downloaded From Manuals Search EngineDocument162 pagesDownloaded From Manuals Search EngineAM MotorcyclesNo ratings yet

- Nyk 75 Can-Bus PDFDocument230 pagesNyk 75 Can-Bus PDFDinh Thuong Cao80% (5)

- Arb RD193Document40 pagesArb RD193carzone.santarosaNo ratings yet

- Installation, Operation and Maintenance Manual for AS-series GearboxesDocument35 pagesInstallation, Operation and Maintenance Manual for AS-series GearboxesRamesh BhosleNo ratings yet

- Trouble-Shooting-Guide Engine 15698 2015 en Digital TCM 12-294192Document76 pagesTrouble-Shooting-Guide Engine 15698 2015 en Digital TCM 12-294192lizar69No ratings yet

- RTS TG M78Document9 pagesRTS TG M78woosah1234No ratings yet

- Nichiyu T NG QuátDocument230 pagesNichiyu T NG Quátvanviet280120No ratings yet

- Manual For Multipump - TSM Viking PumpsDocument116 pagesManual For Multipump - TSM Viking PumpsMarcosNo ratings yet

- Maintenance Manual: Dohc EngineDocument22 pagesMaintenance Manual: Dohc EngineelybongoNo ratings yet

- FAG Tec Brochure Wheel Bearings Failure Diagnosis en 04 2012Document20 pagesFAG Tec Brochure Wheel Bearings Failure Diagnosis en 04 2012Victor BalasNo ratings yet

- Maintenance Manual: English VersionDocument80 pagesMaintenance Manual: English VersionArshia AhujaNo ratings yet

- Operating Manual Gearboxes ENDocument31 pagesOperating Manual Gearboxes ENAbel ferreira de britoNo ratings yet

- 206-04-Rear Disc Brake 206-04Document7 pages206-04-Rear Disc Brake 206-04Tiến Phát Công ty TNHH Đầu Tư Xây DựngNo ratings yet

- SECTION 204-01 Front SuspensionDocument23 pagesSECTION 204-01 Front SuspensionTienphat co.,ltdNo ratings yet

- Windshield Washer Pump and Reservoir Removal and Installation PDFDocument1 pageWindshield Washer Pump and Reservoir Removal and Installation PDFMichael HernandezNo ratings yet

- Hidrostatico SandvikDocument256 pagesHidrostatico Sandvikjuan yanayaco ramosNo ratings yet

- Replace rear brake pads or rotorsDocument12 pagesReplace rear brake pads or rotorsahmedNo ratings yet

- Ideal Jawa and Yezdi 250cc motorcycle manualsDocument65 pagesIdeal Jawa and Yezdi 250cc motorcycle manualsZia Al RahmanNo ratings yet

- Screamin Eagle Milwaukee-Eight™ 128/131 Stage Iv Kit: General InformationDocument8 pagesScreamin Eagle Milwaukee-Eight™ 128/131 Stage Iv Kit: General InformationAdrian Surya K.No ratings yet

- Korando B4 D0 NJDocument10 pagesKorando B4 D0 NJlink2ndNo ratings yet

- 6-Automotive UnderchassisDocument3 pages6-Automotive UnderchassisGODNo ratings yet

- 6-Automotive UnderchassisDocument3 pages6-Automotive UnderchassisGOD100% (1)

- Augusta f4 ManualDocument142 pagesAugusta f4 ManualMarcelo Pchevuzinske100% (2)

- CH 6Document140 pagesCH 6Nibha PandeyNo ratings yet

- Improve Productivity with Under-Chassis TrainingDocument106 pagesImprove Productivity with Under-Chassis TrainingnahomNo ratings yet

- Owner's Manual Guide for Multiple LanguagesDocument142 pagesOwner's Manual Guide for Multiple Languagesbiel gamesNo ratings yet

- Owner'S Manual: M 9.9D M 18E M 15DDocument78 pagesOwner'S Manual: M 9.9D M 18E M 15DRoss MelvilleNo ratings yet

- Instruction Manual: Hako-Trac 1950 DA (8084)Document62 pagesInstruction Manual: Hako-Trac 1950 DA (8084)Aleksandra HreščakNo ratings yet

- Air Operated Locking Differential: Installation GuideDocument42 pagesAir Operated Locking Differential: Installation GuideMahomed Samir IdrisseNo ratings yet

- Instalacion Motor Serie S270S PDFDocument80 pagesInstalacion Motor Serie S270S PDFMarlene Sanmartin MazaNo ratings yet

- Design and Analysis of An Integrated Coconut Grating and Milk Extracting Machine (Thesis Format)Document58 pagesDesign and Analysis of An Integrated Coconut Grating and Milk Extracting Machine (Thesis Format)Christian Jay Uayan100% (1)

- 205-01 Drive Shaft PICKUP JMCDocument14 pages205-01 Drive Shaft PICKUP JMCRusonegroNo ratings yet

- Title Demonstrate Knowledge of Wheel Tractor Steering Systems, and Diagnose and Rectify Faults in Them Level 4 Credits 4Document4 pagesTitle Demonstrate Knowledge of Wheel Tractor Steering Systems, and Diagnose and Rectify Faults in Them Level 4 Credits 4Hassan HamdyNo ratings yet

- Installation of Externally Seated Radial Ball Bearings - Asyraaf SyahmiDocument6 pagesInstallation of Externally Seated Radial Ball Bearings - Asyraaf SyahmiMuhammad Asyraaf Syahmi bin YazidNo ratings yet

- Corona RT 46 164 SimpleDocument94 pagesCorona RT 46 164 SimpleRimbert100% (1)

- URAL 2017 - Owners - Manual - EnglishDocument86 pagesURAL 2017 - Owners - Manual - EnglishPerformNo ratings yet

- Giant MPH-3 Disc Brake System Model Year 2002: Owners ManualDocument24 pagesGiant MPH-3 Disc Brake System Model Year 2002: Owners Manuallock.offNo ratings yet

- Giant MPH-3 Disc Brake System Model Year 2002: Owners ManualDocument24 pagesGiant MPH-3 Disc Brake System Model Year 2002: Owners Manuallock.offNo ratings yet

- Vacuum Brake ReportDocument65 pagesVacuum Brake ReportsasikumarNo ratings yet

- Workshop (03W 2205)Document152 pagesWorkshop (03W 2205)Евгений Губарев0% (2)

- Proxima Z 6421-8441 GBDocument222 pagesProxima Z 6421-8441 GBLicínio DâmasoNo ratings yet

- Solo 450 User ManualDocument18 pagesSolo 450 User ManualZoran BeslicNo ratings yet

- Doosan Engine De12 Engine Operation ManualDocument10 pagesDoosan Engine De12 Engine Operation ManualThomas100% (49)

- ARB RD176 ManualDocument40 pagesARB RD176 ManualalanschNo ratings yet

- T-Rex ST50-11&ST125-11Document40 pagesT-Rex ST50-11&ST125-11autopart39No ratings yet

- 2014 Buick Encore Propeller Shaft Replacement GuideDocument16 pages2014 Buick Encore Propeller Shaft Replacement Guidealberto navasNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- History of Suspension SystesmDocument6 pagesHistory of Suspension Systesmmangutkar_amit67% (3)

- VEICULAR - Estabilização No PesadoDocument1 pageVEICULAR - Estabilização No PesadoPablo OliveiraNo ratings yet

- Acdelco Replacement Parts Warranty Quick Reference ChartDocument1 pageAcdelco Replacement Parts Warranty Quick Reference Chartcoach joeNo ratings yet

- 204-02 Rear Suspension - Removal and Installation - Rear Shock AbsorberDocument3 pages204-02 Rear Suspension - Removal and Installation - Rear Shock AbsorberCARLOS LIMADANo ratings yet

- Loaded Strut Training Guide: MotorcraftDocument11 pagesLoaded Strut Training Guide: MotorcraftnightweisoNo ratings yet

- Landing Gear Slide Chapter 2Document42 pagesLanding Gear Slide Chapter 2mellon3duwenNo ratings yet

- Auto Rubber ProductsDocument198 pagesAuto Rubber Productschinmoyd1No ratings yet

- G58 Maintenance ManualDocument20 pagesG58 Maintenance ManualNathaniel LuraNo ratings yet

- 205-02 Rear Drive Axle and Differential - Removal and Installation - Axle AssemblyDocument12 pages205-02 Rear Drive Axle and Differential - Removal and Installation - Axle AssemblyCARLOS LIMADANo ratings yet

- Price List Desember Mmksi 2019Document996 pagesPrice List Desember Mmksi 2019Putri MasyitahNo ratings yet

- Front & Rear Sespention (Part Nos)Document8 pagesFront & Rear Sespention (Part Nos)Basim FakhryNo ratings yet

- Understand Shoring in ConstructionDocument29 pagesUnderstand Shoring in ConstructionMohamad HaniffNo ratings yet

- Steel-Angle Bracing Design-1Document12 pagesSteel-Angle Bracing Design-1rohitbhagat005No ratings yet

- 2010 A5CabrioletDocument90 pages2010 A5CabrioletDavid Mcgregor100% (2)

- 15ae302 - Rear Axle and Suspension System PDFDocument71 pages15ae302 - Rear Axle and Suspension System PDFAahana KhannaNo ratings yet

- TP-300-2: Automotive After Sales Services TrainingDocument6 pagesTP-300-2: Automotive After Sales Services TrainingPokcik ZaidNo ratings yet

- Assignment 1 Landing GearDocument7 pagesAssignment 1 Landing GearArief Sambest100% (1)

- MacPherson StrutDocument5 pagesMacPherson StrutChandra HarshaNo ratings yet

- Aircraft Landing Gear SystemsDocument120 pagesAircraft Landing Gear SystemsJoshua Christopher RamirezNo ratings yet

- Vehicle - Steering and Suspension - SuspensionDocument20 pagesVehicle - Steering and Suspension - Suspensionzakarya yahyaNo ratings yet

- B737 NG Cockpit Companion Full 1 PDFDocument608 pagesB737 NG Cockpit Companion Full 1 PDFPaul Watkins98% (43)

- Cable SystemsDocument30 pagesCable SystemsShiwani TailorNo ratings yet

- Seismic Restraint Manual 2008 LatestDocument202 pagesSeismic Restraint Manual 2008 LatestHassaan HameedNo ratings yet

- Klann Catalog Scule Speciale AutoDocument410 pagesKlann Catalog Scule Speciale AutoRed Xcess100% (1)

- RT 4 ErDocument3 pagesRT 4 ErpisalNo ratings yet

- Rigid Struts for Piping SupportDocument1 pageRigid Struts for Piping SupportfurqanNo ratings yet

- Inspect Suspension SystemsDocument6 pagesInspect Suspension SystemsAmor BayawaNo ratings yet

- D693 13Document413 pagesD693 13newsmurinoNo ratings yet

- Front SuspensionDocument8 pagesFront Suspensionred eagle winsNo ratings yet

- TBM700 - MLG - P:N D23767000:D23768000 - MMDocument161 pagesTBM700 - MLG - P:N D23767000:D23768000 - MMthilo eckardtNo ratings yet