Professional Documents

Culture Documents

AE

Uploaded by

Vangara Harshu0 ratings0% found this document useful (0 votes)

9 views8 pagesAE

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views8 pagesAE

Uploaded by

Vangara HarshuAE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

«2, United States Patent

Wolf et al.

US006650993B2,

US 6,650,993 B2

Nov. 18, 2003

a0) Patent No.:

(45) Date of Patent:

METHOD FOR LOCOMOTIVE ENGIN!

t Wolf, Erie, PA (US); Gerald

Hess, Jr, Erie, PA (US); Jeffrey

ichel, Girard, PA (US)

(73) Assigace: General Electric Company,

Schenectady, NY (US)

(*) Notice: Subject to any disclaimer, the term of this

patent is extended or adjusted under 35

U.S.C. 154(b) by 320 days.

(21) Appl. No.

(22) Filed!

3)

09/873,841

Jun. 4, 2001

Prior Publication Data

US 20020185017 AL Dee. $, 2002

(51) Int. cL?

(52) US. Ch

1066 7/70; FON 17/00

‘OLA; 123/179.4; 701/115;

ToU/Li4

(58) Field of Search ToL/112, 114,

TOU/115, 102, 107, 113, 110; 123/179.4

(56) References Cited

U.S, PATENT DOCUMENTS

5941792 A 81999 Amendt ota

{64126247 A * 102000 Paul et 30377

670852 BL 1/2001 Wisinski

16)322,025 BL * 11/2001 Colbert et a. 246/167 R

SAMSH4 B2 102002. Biess

POREIGN PATENT DOCUMENTS

2002-30503

2002-30504

* 11/2002

> 11/2002

B6OI,/15/40

BOO 15/40

* cited by examiner

Primary Examiner—Hiew T. Vo

(14) Attorney, Agent, or Firm—Seoniger, Powers, Leavitt

& Roedel; Carl Rowold

67) ABSTRACT

‘An_aulomatic start/stop system for locomotive engines

which takes into account operator needs and concerns by

enabling operators to locally prevent automatic shutdowns

of their locomotives without disabling their AE

Thus, operators ean maintain theie lead (andlor other) units

running (ie., for peace of mind, climate control, ete.)

‘without prohibiting other locomotives in consist from auto-

‘matically shutting down. The system preferably includes an

inhibit switch located in each locomotive control cabin

which, when actuated by an operator, prevents that locomo-

tive (and only that locomotive) from automaticaly shutting

down within a predefined duration of time. Techniques for

reminding and prompting an operator to enable an AESS

system include sounding an alarm, displaying and recording

40msi0 A + 81977 Mosher O19 feu data, aod inhibiting motoring ofthe locomotive when

01 A 6/1906 Willis the AESS system is disabled and the operator calls for

Soar copa raat braking or motoring capability.

rat A “9998. Rano

So0R110 4 71909 ernie 29 Claims, 2 Drawing Sheets

[7s

116. enaple |-108

suave

102

a7] neverser | 110 | i a 6

|__MoTor 130 _J

{wane 1?

= | coneures, [Sarmoown a2 ENING,

w_ pnome [uz svasTue134_] werowaee |

7S |

wa] mvaoir [axa

‘SWITCH ALARM COMMAND |__-pisptay pata 127

seme Bm

AuoIBLe '

ADIL biseuay

Cae 326~

US 6,650,993 B2

Sheet 1 of 2

Nov. 18, 2003,

U.S. Patent

get saa

wavy

x

WidSIG agiany

szr

221 VLWG AWIdSIG NYWWOD Wavy HOLIMS |.

___ PIT ALIGTHNI zr

ssav

auvMGuvH ZIT FLLLOWHL Ot

OULNOD wOSSEOOUd ]

3NIONS wALNdWOD =

90t

) OIT waSuaAaY | -—8IT

zor ——

HOLIMS

30T mavna = | 9TT

ssav

SDIA3a

sor] xdoWaW

on T ‘SIs

U.S. Patent Nov. 18, 2003 Sheet 2 of 2 US 6,650,993 B2

REC'D

INHIBIT

COMMAND?

RESET AND RESTA

210_| “INHIBIT TIMER

MOTORING

OR BRAKING

INITIATED?

MOTORING

INITIATED?

INHIBIT

PERIOD

DISPLAY &

RECORD

FAULT DATA | EXPIRED?

228

PREVENT C218

MOTORING REED)

INHIBIT

SIGNAL?.

‘AESS STILL

DISABLED?,

US 6,650,993 B2

1

AUTOMATIC START/STOP SYSTEM AND

METHOD FOR LOCOMOTIVE ENGINES

FIELD OF THE INVENTION

‘The present invention relates to locomotive fuel

‘conservation, and more particularly to automatically stating

and stopping locomotive engines for the purpose of con-

serving ful.

BACKGROUND OF THE INVENTION

In recent years, locomotives have been equipped with

systems for automatically starting and stopping their engines

‘wien one or more conditions exist. The primary purpose of

such systems isto conserve fuel, thereby lowering fuel costs

while also preserving precious energy resources. For

instance, a locomotive may be configured to automatically

shutdown after operating for a certain amount of time in a

parked idle state to prevent the locomotive from needlessly

‘wasting fuel. The locomotive may then automatically restart

‘when, for example, an operator signals an intention to motor

the locomotive, sich as by moving a direction controller

(known as a reverser) from a center position (that is, from a

“neutral” position). A locomotive may also be configured to

automaticaly restart a certain amount of time following an

automatic shutdown, such as two or four hours, or when

‘other conditions exist,

‘The automatic engine start and stop (AESS) system

‘described above has been implemented not only in locomo-

tives which operate independently, but also in. multiple

locomotives that operate together (ce, in eonsist) for pro-

‘viding cumulative (or reserve) towing capacity. The front

locomotive in the consists usually designated the lead ui

while the other locomotives are designated trail units. Each

trail unit typically receives a trainine signal representing the

position of the lead unit's reverser, and treats that signal as

representing the. position of its own reverser (which is

ly placed in the center position when configuring the

‘operation). In the case where a

locomotive’s reverser must be in the center position to

tenable the AESS system, placing the lead unit’ reverser in

the center position will allow the AESS system to be enabled

in each locomotive in the consist. Similarly, in the case

‘where moving an automatically shuldown locomotive’s

reverser from the center position induces an automatic

‘engine restart, moving the reverser in an automatically

shutdown lead unit from the center position induces an

automatic restart for each automatically shutdown locomo-

tive in the consist

Although deployed AESS systems have proven reliable,

the inventors hereof have discovered human factors that

result in unrealized fuel savings. For example, they discov-

fered that operators frequently take sleps fo prevent auto-

‘matic engine shutdowns. This is apparently done so that lead

units (including single units operating independently and not

ina eonsist) remain available upon demand (ie, for operator

peace of mind), al to provide climate control (ie. heating

and air conditioning) to the operator cabin. Common

approaches to preventing automatic engine shutdowns

include maintaining a lead unit’ reverser out of the center

position, and manually moving an automatic start/stop dis-

able switch (ASDS), typically located in a CAL locker, to an

“off” position. Service personnel may also forget to move

the ASDS to its “on” position after switching it “off” for

safety during maintenance procedures. Regardless of how or

why it occurs, preventing an AESS system in a single

0

ss

4s

ss

6s

2

locomotive from performing ils intended function obviously

results in lost fuel savings. Moreover, preventing an auto

shutdown in the lead unit of a consist may prevent an auto

shutdown for each trail unit in the consist. Thus, although an

‘operator may, for example, maintain the lead unit's reverser

‘out of the center position forthe sole purpose of keeping the

lead unit running, the net result may be that 1wo, three, or

feven more trail units eemain running snd consuming fuel, in

addition to the lead unit,

‘A related problem discovered by the inventors is unnec-

essary operator induced restarts, which occur, for example,

when an operator moves the reverser of an automatically

shutdown locomotive away from the center position. The

“apparent reasons for such restarts are essentially the same as

those for preventing automatic engine shutdowns, namely, to

resume on-demand availability of lead units and to provide

climate control to the operator cabin, Again, while an

‘operator's intention may be to simply restaet a lead unit, the

effect may be to restart every locomotive in a consist

‘The inventors have determined that unrealized fuel sav-

ings are often an order of magnitude greater than actual fuel

savings primarily due to operator interaction issues, and

have therefore recognized a need for AESS systems that can

interact more favorably with locomotive operators, taking

into account operator needs and concerns, so as to realize

increased fuel savings and conservation,

SUMMARY OF THE INVENTION

In onder to solve these and other needs in the art, the

inventors hercof have designed an automatic engine start

stop (AESS) system for locomotives which takes into

‘account operator needs and concerns by enabling operators

to locally prevent automatic shutdowns of their locomotives

without disabling their AESS systems. Thus, operators ean

maintain their lead (and/or other) units running (ie., for

peace of mind, climate control, ee.) without disabling their

AESS systems and without prokibiting other locomotives in

‘consist from automatically shutting down. The system pref-

erably includes aa inbibit switch located in each locomotive

control cabin which, when actuated by an operator, prevents

that locomotive (andl only that locomotive) from automati-

cally shutting down within a predefined duration of time,

such as two hours. Ia the event the operator subsequently

motors the locomotive before the predefined duration of

time expires, the AESS system is preferably reset.

Otherwise, when the predefined duration of time has passed,

the locomotive will automatically shutdown (assuming a set

of automatic engine shutdown parameters are satislied at

that time). The present invention also provides several

techniques for reminding and prompting an operator to

enable an AESS system, including sounding an alarm,

displaying and recording fault data, and inhibiting motoring

of the locomotive when the AESS system is disabled and the

operator ealls for braking or motoring capability.

According to one aspect of the present invention, an

engine control system for a locomotive includes a memory

device for storing computer instructions, a computer pro-

‘cessor for executing the computer instructions stored in the

memory device, the computer instructions configuring the

computer processor to output one or more commands when

‘one oF more predefined conditions exist, and engine control

hardware for controlling the locomotive engine in response

to commands output by the computer processor. The com-

puter processor includes an input for receiving « signal

indicative of whether an automatic engine stop system

enabled, The computer instructions coniigure the computer

US 6,650,993 B2

3

processor to normally output an engine shutdown command

‘when the automatic engine stop system is enabled and a set

Of automatic engine shutdown parameters are Satisfied. The

‘computer processor also includes an input for receiving an

inhibit command from an operator of the locomotive. The

‘computer instructions further configure the computer pro=

‘cessor 10 al least delay outputting the engine shutdown

‘command in response t0 the inhibit command,

According to another aspect of the present invention, a

‘method of implementing an automatic engine stop system in

1 locomotive includes deactivating the automatic engine

stop system in response to operator input to prevent the

automatic engine stop system from automatically shutting

‘down the locomotive without disabling the automatic engine

stop system.

According to yet another aspect of the invention, a

‘method for prompting an operator of a locomotive to enable

‘an automatic engine stop system includes sounding an

audible alarm when the automatic engine stop system is

disabled and the operator initiates braking or motoring.

‘According to a further aspect of the invention, a method

for prompting an operator of a locomotive to enable an

automatic engine stop system includes inhibiting motoring

Cf the locomotive until the automatic engine stop system is

‘enabled

‘According to still another aspect of the invention, a

computer-readable medium has computer-executable

instructions recorded thereon for implementing any one or

‘more of the systems and methods described berein,

‘Other aspects and features ofthe present invention will be

in part apparent and in part pointed out hereinafter.

BRIEF DESCRIPTION OF THE DRAWINGS

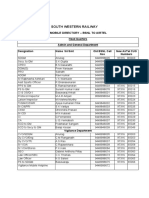

FIG. 1 is a functional block diagram of a locomotive

‘engine control system according to the present invention.

FIG. 2 isa flow chart illustrating a preferred operation of |

the control system of FIG. 1

‘Corresponding reference characters indicate correspond-

ing features throughout the several views of the drawings.

DETAILED DESCRIPTION OF THE

PREFERRED EMBODIMENT.

‘A locomotive engine control system according 0 one

preferred embodiment of the present invention is ilustrated

in FIG. Land indicated generally by reference character 100,

As shown in FIG. 1, the control system 100 includes a

‘computer processor 102, a memory device 104 and engine

‘control hardware 106. The memory device 104 may itself

‘comprise multiple static andor dynamic memory devices, as

is common. The computer processor 102 is provided with

several inputs 108, 110, 112, 114 for receiving signals from

fn automatic engine startstop (AES) enable switeh 116, a

reverser 118, a throttle 120, and an AESS inhibit switeh 122,

respectively, The signal from the AESS enable switch 116

preferably indicates a position of the switeh 116 which, in

turn, indicates whether an AESS system is enabled. The

‘signals from the reverser 118 and the throttle 120 preferably

indicate the respective positions of the locomotive's reverset

and throttle. Although a variety of switch types can be used,

the AESS inhibit switch 122 is preferably a push-button

switch which, when actuated by an operator, seads an inhibit

‘command to the computer processor 102 so as to prevent or

posipone an automatic engine shutdown, as further

described below. As a result, the operator is enabled to

prevent an automatic shutdown of the lead unit in a consist,

0

as

os

ss

4s

50

ss

6s

4

or any other unit similadly equipped withthe control system

100, without disabling an AESS system and without neces-

sarily preventing an automatic shutdown of other locomo-

tives inthe consist

‘The control system 100 further includes an audible alarm

124 and a display device 126. The audible alarm 124

preferably sounds in response 16 receiving an alacm com-

mand 125 from the computer processor 102. In one

embodiment, the alarm 124 is traioline alarm which, when

activated, sounds within each locomotive in a consist. The

display device 126 preferably displays data 127 received

from the computer processor ineluding, when applicable,

data indieating that an AESS sysiem is disabled. In one

embodiment, the display data 127 is frst received by the

computer processor 102 over a trainlne, and indicates that

the AESS system of another locomotive is disabled

‘Those skilled in the art will recognize that the control

system 100 may include components in addition to those

shown in FIG. 1, and that the computer processor may

include inputs and outputs in addition 6 those showa in FIG,

1

The memory device 104 preferably stores computer

insteuctions to be executed by the computer processor 102.

‘These computer instructions configure the computer proces-

Sor to oulput one or more commands when one oF more

predefined conditions exist. For example, the computer

processor 102 may output a motor command 130 in response

to signals from the reverser 118 and the throttle 120 indi-

eating an operator's attempt 10 motor (ie., move) the 1oeo-

motive. The engine control hardware conizols the locomo-

tive engine (not shovin) in response to commands output by

the computer processor, including the motor command 130,

4 shutdown command 132, and a startup command 134. As

apparent 10 those skilled in the art, the engine control

hardware 106 may include a variety of components includ-

ing invertors, relays, an alternator, a Fuel pump, et.

‘A preferted operation of the control system 100 will now

be described with reference tothe flow chart of FIG. 2. After

beginning at block 200, processing proceeds to block 202

where the contol system determines whetber the AESS

system is enabled (6.2, using the signal from the AESS

enable switch 116). If the AESS system is enabled, process-

ing branches to block 204 where the control system deter-

‘mines whether an inhibit command has been received from

the locomotive operator (e., using the signal from the

‘AESS inhibit switeh 122). If not, processing. continues at

block 206 wher itis determined Whether a set of automatic

engine shutdown parameters are satisted. As known in the

ar, this set of parameters may require the engine to have

been running for some minimum amount of time, zero

ground speed, & minimum engine oil temperature, 3 mini-

‘mum brake air pressure, the reverser 118 in the center

position, the theottle 120 inthe idle pesition, etc. I the set

Of auto éngine shutdown parameters are not satisfied, pro-

cessing loops back 10 block 202, as shown in FIG. 2

Otherwise, processing proceeds 10 block 208 where the

locomotive engine is automatically shutdown $0 as to eon-

serve fuel (ex, by sending the shutdown command 132 10

the engine control hardware 106). This is considered the

normal operation of the control system, when no inhibit

command is received from the operator.

Referring again to block 204, if an inbibit command has

been received from the locomotive operator, processing

preferably branches to block 210. In this embodiment, when

the AESS inhibit switch 122 is actuated by the operator, the

control system 100 preferably refrains from automatically

US 6,650,993 B2

5

‘stopping the locomotive engine for a predefined duration of

time, such as two hours. In this manner, the operator ean

temporarily deactivate the AESS system so as to postpone an

automatic engine shutdown without disabling the AESS

system, During this time, the deactivated AESS system

preferably continues to process inputs and outputs, but will

‘ot output the shutdown command 132. The AESS system

is preferably reactivated automatically when the predefined

inhibit period times-out, and will then proceed to automati

cally shutdown the locomotive ifthe set of automatic engine

shutdown parameters ace satisfied and the operator has not

provided another inhibit command. Accordingly, an inhibit

timer (preferably implemented within the computer proces-

‘sor 102) is preferably started in block 210 to measure the

amount of time elapsed following actuation of the AESS

inhibit switch 122. Processing then proceeds to block 212,

‘where the control system determines whether the operator

has initiated motoring of the locomotive (e.g. a8 determined

by signals from the reverser 118 and the throttle 120 ot, in

the ease where the locomotive is operating asa trail unit in

a consist, by trainline signals from the reverser and throttle

Of the lead unit). If motoring has been initiated, processing

automatically reactivates the AESS system by branching

back to block 202, as shown in FIG. 2.

I the control system 100 determines in block 212 that

motoring has not been initiated, processing proceeds to

block 216 where the system determines whether the pre~

defined inhibit period has expired. If not, processing loops

back to block 212. If the inbibit period has expired, pro-

‘cessing continues at block 218 to determine whether another

inhibit signal has been received from the operator. Thus, an

‘operator can preferably repeatedly postpone an automatic

shutdown of a locomotive engine by periodically actuating

the AESS inhibit switch 122. If another inhibit signal has not

been received, processing branches to block 206 to deter-

‘mine whether the set of automatic engine shutdown param-

celers are satisfied, as described above. If the system deter-

‘mines at block 218 that another inhibit signal has been

received from the operator, processing branches back to

block 210 where the inhibit timer is reset and restarted, and

then proceeds as described above.

Il should be clear from the description above that, ia one

preferred embodiment, the AESS system is automatically

reactivated, and the prior inhibit command from the operator

is disregarded, when the predefined inhibit period expices, or

\when the operator initiates motoring (if sooner). This fune-

tionality is preferably implemented locally within each

locomotive in a consist so that the AESS system of a

particular locomotive in the consist ean be locally deacti-

‘vated by aa operator without necessarily affecting the AESS

systems of other locomotives in the consist.

Referring again to block 202 of FIG. 2, if the system 100

‘determines that the AESS system is disabled (¢.g., because

the AESS enable switch 116 is in an “olf” position), pro-

‘cessing proceeds to block 222 where the control system

determines whether the operator bas initiated braking or

motoring. If not, processing loops back to block 202. If

braking or motoring has been initiated, processing continues

at block 224 where an audible alarm is preferably sounded

‘so as to remind and prompt the operator to enable the AESS

system. In one embodiment of the invention, the audible

alarm is a trainline alarm which souads within every loco-

‘motive in a consist, In this manner, an operator in a lead unit

may discover upon initiating braking or motoring that the

AESS system in the lead uoit, or an AESS system in teal

unit, is disabled, Processing then preferably continues at

block 226 where fault information is displayed on the

0

as

os

ss

4s

ss

6s

6

display device 126. The displayed fault information prefer-

ably indicates that the AESS system isdisabled, and prompts

the operator to enable the AESS system (e.g, by explaining

the necessary step(s)). In one embodimeni, the fault infor-

‘mation is placed on the trainline, and is presented on the

display of each locomotive in a consist

‘Also in block 226, fault data is recorded in the memory

device 104 so as to record each instance when the operator

initiates braking or motoring while the AESS system is

disabled (which should generally only occur during a main-

tenance procedure). Continuing at block 228, the control

system 100 may also prevent the locomotive from motoring

(a, by withbolding the motor command 130) while the

AAESS system is disabled, again in an effort to prompt the

‘operator to enable the AESS system. In one embodiment,

this functionality is implemented only locally (.e., not via

the trainline). Therefore, if the AESS system in a trail unit

‘ofa consist is disabled, the lead unit will still have motoring

capability. At block 230, the control system determines

whether the AESS system is still disabled. If is, processing

Toops back to block 224 such that the audible alarm contin=

vues to sound, fault data continues to be displayed and

recorded, and motoring of the locomotive remains inhibited,

“Alternatively, if it is determined in block 230 that the AESS

hhas been enabled, processing loops back to block 204, as

shown ia FIG. 2,

‘The above-described functionality is preferably imple-

‘mented ia computer instructions stored in the memory

device 104 and executed by the computer processor 102.

It should be clear from the description above that the

present invention enables an operator to prevent or at least

postpone an automatic shutdown of a locomotive engine

without disabling an AESS system. Accordingly, during

normal operations (in contrast to maintenance operations),

an operator may have no need for the AESS enable switch

116, which preferably remains in the “on” position. For this,

reason, in one embodiment of the invention, the AESS

enable switch 116 is moved from the CAL locker to a

location less accessible to operators, such as a high voltage

‘maintenance cabinet (eg. the auxiliary cabinet), to further

reduce the likelihood of an operator disabling the AESS

system during normal operations by moving the AESS

enable switch 116 to the “ofl” position,

In the embodiment described above with reference to

FIG. 2, multiple prompts are employed (ic., the alarm

sounel, fault data is displayed! and recorded, and motoring of

the locomotive is inhibited) when the AESS system is

disabled and the operator calls for braking or motoring

capability, all in an elfort to prompt the operator to enable

the AESS system, It should be understood, however, that

fewer than all of such prompts may be used in certain

applications without departing from the scope of the inven

tion, It should also be understood that the teachings of the

present invention ean be applied in conjunetion with or

without automatic engine restart capability

‘When introducing elements or features of the present

invention or the preferred embodiment(s) thereat, the

articles “a”, “an”, “the” and “said” are intended to mean that

there are one or more such elements or features, The terms

comprising”, “including” and “having” are intended to be

inclusive and mean that there may be additional elements or

features other than those listed.

‘As various changes could be made in the above embodi-

‘ments without departing from the scope of the invention, it

is intended that all matter contained in the above description

fr shown in the accompanying drawings shall be interpreted

as illustrative and not in a limiting sense.

US 6,650,993 B2

7

‘What is claimed:

1, An engine conteol system for a locomotive, the control

system comprising:

a memory device for storing computer instructions;

‘8 computer processor for executing the computer instruc~

tions stored in the memory device, the computer

instructions configuring the computer processor 10 out

put one or more commands whea one or more pre-

defined conditions exist; and

engine control hardware for controlling the locomotive—

engine in response to commands output by the com-

Dutler processor;

the computer processor including an input for receiving a

signal indicative of whether an automatic engine stop

system is enabled;

‘the computer instructions configuring the computer pro-

ceessor to normally output an engine shutdown com-

mand when the aufomatic engine stop system is

enabled and a set of automatic engine shutdown param-

ters are satisieds

‘the computer processor including an input for receiving

‘an inhibit command from an operator of the locomo=

tives

the computer instructions further configuring the com-

Duler processor 10 atleast delay outputting the engine

shutclown command in response to the inhibit com-

mand.

2. The control system of claim 1 further comprising an

inhibit switch for generating the inhibit command when the

inhibit switch is actuated by the operator,

3, The control system of claim 1 wherein the computer

instructions configure the computer processor to delay out-

putting the engine shutdown command for a predefined

‘duration of time alier the computer processor receives the

inhibit command.

4. The control system of claim 3 wherein the computer

lions configure the computer processor to disregard

command received from the operator if the

lates motoring during the predefined duration of

'S. The control system of claim 1 wherein the computer

instructions configure the computer processor to normally

‘oulput a motor command 10 the engine control hardware

When the operator initiates motoring, and further configure

the computer processor to withhold the motor command if

the automatic engine stop system is disabled.

‘6. The control system of claim 1 further comprising an

audible alarm for providing an audible alarm signal in

response to an alarm command from the computer

processor, the computer instructions configuring the com-

puter processor to output the alarm command when the

automatic engine stop system is disabled and the operator

initiates braking or motoring.

77. The conteol system of claim 1 wherein the computer

instructions configure the computer processor to record fault

data in the memory device when the automatic engine stop

system is disabled and the operator initiates braking ot

motoring.

8. The control system of claim 1 further comprising a

display device for displaying data received from the com-

puter processor, the computer instructions further configur-

ing the computer processor to send data indicating the

automatic engine stop system is disabled to the display

‘device when the automatic engine stop system is disabled

and the operator initiates braking or motoring.

‘9. A method of implementing an automatic engine stop

system in a locomotive, the method comprising deactivating

0

as

os

ss

4s

ss

6s

8

the automatic engine stop system in response to operator

input fo thereby prevent the automatic engine stop system

from automatically shutting down the locomotive without

disabling the automatic engine stop system.

10. The method of claim 9 wherein deactivating includes

providing a switch which, when actuated by the operator

with the automatic engine stop system enabled, at least

‘temporarily prevents an automatic shutdown of the locomo-

tive.

IL. The method of claim 10 wherein actuating the switeh

renders the automatic engine stop system at least tempo-

rarily inactive, the method further comprising automatically

reaclivating the automatic engine stop system a predeter-

‘mined amount of time after the switch is actuated.

12. The method of claim 10 wherein actuating the switch,

renders the automatic engine stop system at Ieast tempo

rarily inactive, the method further comprising automatically

reaclivating the automatic engine stop system when the

operator initiates motoring.

13. The method of claim 9 wherein the locomotive is one

of a plurality of locomotives operating in consist, cach of

said locomotives having an automatic engine stop system,

and wherein deactivating includes providing a switch in

cach of said locomotives which, when actuated with the

automatic engine stop system for the associated locomotive

enabled, at least temporarily prevents an automatic shut-

down of the associated locomotive.

14. The method of claim 9 wherein the locomotive is one.

of a plurality of locomotives operating in consist, each of

said locomotives having an automatic engine stop system,

and wherein deactivating includes deactivating the auto-

‘matic engine stop system of said one locomotive while

another of said locomotives is automatically shutdown.

15. The method of claim 9 further comprising positioning

an automatic stop enable switch for the automatic engine

stop system in a high voltage maintenance cabinet of the

locomotive.

16. A method for prompting an operator of a locomotive

to enable an automatic engine stop system, the method

comprising sounding an audible alarm when the automatic

engine stop system is disabled and the operator initiates

braking or motoring.

17. The method of claim 16 wherein sounding includes

sounding the audible alarm until the automatic engine stop

system is enabled.

18. The method of claim 16 wherein the locomotive is one

of a plurality of locomotives operating in consist and

‘wherein sounding includes sounding a trainline alarm within

each of said locomotives.

19. The method of claim 16 further comprising displaying

information on a display when the automatic engine stop

system is disabled and the operator initiates braking or

motoring, the displayed information prompting the operator

to enable the automatic engine stop system,

20. The method of claim 16 further comprising, automati-

cally recording fault data when the automatic engine stop

system is disabled and the operator initiates braking or

motoring.

21. The method of claim 16 wherein sounding includes

sounding the audible alarm while the locomotive is motor-

ing.

22. A computer-readable medium having computer-

executable instructions for implementing the method of

claim 16.

23. A method for prompting an operator of a locomotive

to enable an automatic engine stop system, the method

comprising inhibiting motoring of the locomotive until the

automatic engine stop system is enabled.

US 6,650,993 B2

9

24. The method of claim 23 further comprising displaying

information on a display when the automatic engine stop

system is disabled and the operator initiates braking or

motoring, the displayed information prompting the operator

to enable the automatic engine stop system,

25, The method of claim 23 further comprising sounding,

an audible alarm when the automatic engine stop system is

disabled and the operator initiates braking or motoring.

26, The method of claim 28 wherein the locomotive is one

of a plurality of locomotives operating in consist, and the

audible alarm is a trainline alarm which sounds within each

‘of said locomotives,

10

27. The method of claim 23 further comprising automati-

cally recording fault data when the automatic engine stop

system is disabled and the operator initiates braking or

motoring.

28, The method of claim 23 further comprising enabling

the operator to prevent an automatic shutdown of the loco=

motive without disabling the automatic engine stop system,

29. The method of claim 23 wherein the operator can

tenable the automatic engine Slop system via an automatic

10 stop enable switch,

You might also like

- 1099acdc PDFDocument1 page1099acdc PDFVangara HarshuNo ratings yet

- CcbiiDocument5 pagesCcbiiVangara HarshuNo ratings yet

- Joining TimeDocument7 pagesJoining TimeVangara HarshuNo ratings yet

- MC41.Leave Reserve PostsDocument9 pagesMC41.Leave Reserve PostsSubramanyam VangaraNo ratings yet

- Mechanical LOCO No.-13383 WDG3A 5RV: Schedule Particular PIC POH M-24 TS Date Sch. RepairDocument1 pageMechanical LOCO No.-13383 WDG3A 5RV: Schedule Particular PIC POH M-24 TS Date Sch. RepairVangara HarshuNo ratings yet

- Double Line MACLSDocument4 pagesDouble Line MACLSVangara HarshuNo ratings yet

- 0961 AcdcDocument3 pages0961 AcdcVangara HarshuNo ratings yet

- s4INTRO PDFDocument2 pagess4INTRO PDFVangara HarshuNo ratings yet

- Monday, February 21, 2000, 1030 Am Generic EMDEC FaultDocument1 pageMonday, February 21, 2000, 1030 Am Generic EMDEC FaultVangara HarshuNo ratings yet

- Double Line MACLS PDFDocument1 pageDouble Line MACLS PDFVangara HarshuNo ratings yet

- Leave RuleDocument2 pagesLeave RuleVangara HarshuNo ratings yet

- On Line Troubleshooting: COC Handle Was Taken Out and Spindle Adjusted ToDocument1 pageOn Line Troubleshooting: COC Handle Was Taken Out and Spindle Adjusted ToVangara HarshuNo ratings yet

- Use The PC Reader Program and Troubleshoot As Per The Procedures in Either The EMDEC Operation ManualDocument1 pageUse The PC Reader Program and Troubleshoot As Per The Procedures in Either The EMDEC Operation ManualVangara HarshuNo ratings yet

- Leave Rules: Leave On Average PayDocument10 pagesLeave Rules: Leave On Average Payabhimanyutiwari1234No ratings yet

- The Railway Service (Conduct) Rules 1966 (21.03.1966) : Rule 3: GeneralDocument6 pagesThe Railway Service (Conduct) Rules 1966 (21.03.1966) : Rule 3: GeneralVangara Harshu100% (1)

- Central Administrative TribunalsDocument5 pagesCentral Administrative TribunalsVangara HarshuNo ratings yet

- Contents PDFDocument8 pagesContents PDFVangara HarshuNo ratings yet

- Water SystemDocument8 pagesWater SystemVangara HarshuNo ratings yet

- Calculating Specific Fuel Consumption for LocomotivesDocument2 pagesCalculating Specific Fuel Consumption for LocomotivesVangara HarshuNo ratings yet

- Monday, February 21, 2000, 1030 Am Generic EMDEC FaultDocument1 pageMonday, February 21, 2000, 1030 Am Generic EMDEC FaultVangara HarshuNo ratings yet

- Analogue Communication TechniquesDocument25 pagesAnalogue Communication TechniquesBobyNo ratings yet

- Electrical Systems & Traction Alternator DesignDocument11 pagesElectrical Systems & Traction Alternator DesignVangara HarshuNo ratings yet

- SWR Mobile Directory UpdateDocument82 pagesSWR Mobile Directory UpdateVangara Harshu0% (1)

- Holiday Homes On Indian Railways PDFDocument3 pagesHoliday Homes On Indian Railways PDFVangara HarshuNo ratings yet

- 2009 Aug - Practical Loco Handling Training Before Promotion As LP (Goods)Document2 pages2009 Aug - Practical Loco Handling Training Before Promotion As LP (Goods)Vangara HarshuNo ratings yet

- Standard Answer-Key Entrance Test (Class-Vii) : Career PointDocument1 pageStandard Answer-Key Entrance Test (Class-Vii) : Career PointVangara HarshuNo ratings yet

- 3D Geometry Concepts ExplainedDocument0 pages3D Geometry Concepts ExplainedVamsi VangaraNo ratings yet

- Standard Answer-Key Entrance Test (Class-Vii) : Career PointDocument1 pageStandard Answer-Key Entrance Test (Class-Vii) : Career PointVangara HarshuNo ratings yet

- Penalty Trouble and RecoveryDocument2 pagesPenalty Trouble and RecoveryVangara HarshuNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)