Professional Documents

Culture Documents

50TON

Uploaded by

Jorge SandovalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

50TON

Uploaded by

Jorge SandovalCopyright:

Available Formats

Submittal

Trane is pleased to provide the enclosed submittal for your review and approval.

Product Summary

Qty Product

2 27 1/2-50 Ton Packaged Commercial Rooftop - VOYAGER3

2 3-10 Ton R410A PKGD Unitary Gas/Electric Rooftop - Y4C

The attached information describes the equipment we propose to

furnish for this project, and is submitted for your approval.

Phone:

Fax:

Table of Contents

Product Summary ............................................................................................................................................................. 1

27 1 2-50 Ton Packaged Commercial Rooftop (Item A1)

Tag Data ....................................................................................................................................................................... 2

Product Data ................................................................................................................................................................ 2

Performance Data ........................................................................................................................................................ 2

Dimension Drawings .................................................................................................................................................... 3

ITEM: A1 -- Fan Curves-Acoustics .......................................................................................................................... 3

ITEM: A1 -- Unit Dimension Drawings ..................................................................................................................... 4

ITEM: A1 -- Weights & Rigging Drawings ................................................................................................................ 6

ITEM: A1 -- Field Wiring Drawings........................................................................................................................... 7

ITEM: A1 -- Mechanical Specs ................................................................................................................................ 8

3-10 Ton R410A PKGD Unitary Gas Electric Rooftop (Item B1)

Tag Data ..................................................................................................................................................................... 10

Product Data .............................................................................................................................................................. 10

Performance Data ...................................................................................................................................................... 10

Dimension Drawings .................................................................................................................................................. 11

ITEM: B1 -- Unit Dimension Drawings ................................................................................................................... 11

ITEM: B1 -- Weights & Rigging Drawings .............................................................................................................. 14

ITEM: B1 -- Mechanical Specs .............................................................................................................................. 16

PAQ 50TONs Page 1

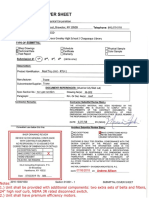

27 1/2-50 Ton Packaged Commercial Rooftop (Qty 2)

Item Tag(s) Model Number Qty

A1 TCH600BF0 -- VOYAGER3-A-2 TC600 2

Product Data

Item A1 Total Unit Quantity 2 Tags(s) TCH600BF0 -- VOYAGER3-A-2

Base Unit

Dx Cooling Only

Horizontal Supply and Horizontal Return

50 ton 60 Hertz

230 Volt 60 Hertz 3 Phase

Cooling Only Unit

Standard Efficiency Throwaway Filter 2"

20 Hp Supply Motor

675/562 (60/50 hz) Supply Fan Drive

0% Fresh Air

CV (ZTC) zone temp control

Standard efficiency unit

None

Performance Data

Item A1

Base Unit

Ambient temp (F) 95.00

Design airflow (cfm) 20000

Cooling EDB (F) 80.00

Cooling EWB (F) 67.00

Gross sensible capacity (MBh) 464.33

Gross total capacity (MBh) 585.43

Minimum circuit ampacity (A) 248.40

Maximum overcurrent protection (A) 300.00

ESP (in H2O) 1.00

Cooling LWB (F) 58.59

Cooling LDB (F) 61.10

Gross latent capacity (MBh) 121.10

Net total capacity (MBh) 540.42

Net sensible capacity (MBh) 419.32

Outdoor motor power (kW) 4.27

Compressor power (kW) 40.79

Actual Supply Motor BHP (bhp) 16.26

Indoor motor power (kW) 13.19

Supply Motor Power (kW) (rpm) 658

System power (kW) 58.24

Operating EER (EER) 9.3

Evaporator face area (sq ft) 36.70

Evaporator rows (Each) 5.00

Evaporator fin spacing (Each) 180.00

Tube outside diameter (in) 0.38

Evaporator face velocity (ft/min) 545

Condenser rows (Each) 2.00

Ent air relative humidity (%) 51.08

Net sensible heat ratio (%) 77.59

Total static pressure (in H2O) 2.16

Compressor 1 RLA (A) 50.50

Compressor 2 RLA (A) 50.50

Compressor 3 RLA (A) 56.00

Supply fan FLA (A) 49.40

PAQ 50TONs Page 2

Condenser fan FLA (A) 7.00

Condenser fan count (Each) 4.00

Exhaust fan FLA (A) 0.00

Exhaust fan count (Each) 0.00

Electric heater FLA (A) 0.00

Minimum disconnect switch size (A) 269.00

Crankcase heater FLA (A) 0.00

EER @ AHRI (EER) 10.3

IGV Static Pressure Drop (in H2O) 0.00

Max. unit operating weight (lb) 4904.0

Fan motor heat (MBh) 45.01

Discharge duct - 63 Hz (dB) 98

Discharge duct - 125 Hz (dB) 96

Discharge duct - 250 Hz (dB) 86

Discharge duct - 500 Hz (dB) 87

Discharge duct - 1 kHz (dB) 80

Discharge duct - 2 kHz (dB) 78

Discharge duct - 4 kHz (dB) 73

Discharge duct - 8 kHz (dB) 69

Return duct - 63 Hz (dB) 89

Return duct - 125 Hz (dB) 88

Return duct - 250 Hz (dB) 85

Return duct - 500 Hz (dB) 82

Return duct - 1kHz (dB) 78

Return duct - 2 kHz (dB) 76

Return duct - 4 kHz (dB) 76

Return duct - 8 kHz (dB) 77

Run acoustics Yes

Outdoor - 63 Hz (dB) 104

Outdoor - 125 Hz (dB) 97

Outdoor - 250 Hz (dB) 96

Outdoor - 500 Hz (dB) 97

Outdoor - 1 kHz (dB) 95

Outdoor - 2 kHz (dB) 93

Outdoor - 4 kHz (dB) 88

Outdoor - 8 kHz (dB) 79

IEER @ AHRI (EER) 10.9

HFCF-410A refrigerant charge - circuit 1 (lb) 20.0

HFCF-410A refrigerant charge - circuit 2 (lb) 38.8

EDB in HGRH (F) 73.00

EWB in HGRH (F) 64.00

Ambient in HGRH (F) 75.00

Reheat setpoint (F) 70.00

Leaving coil DB (F) 58.59

Leaving coil WB (F) 57.63

PAQ 50TONs Page 3

ITEM: A1 PRODUCT: VOYAGER3 TAGS(S): TCH600BF0 -- VOYAGER3-A-2

V60

Unit Model: 600A

5.0 Operating Airflow: 20000.00 cfm

Operating Static Pressure: 2.16 in H2O

Operating RPM: 658.00

Operating Brake Horse Power: 16.26 bhp

4.5 800 RPM 40 %WO

Altitude: 0.00 Date: 4/17/17

Design Temp: 80.00 F

50 %WO

4.0 750 RPM

Total Static Pressure (in H2O)

60 %WO

3.5 700 RPM

3.0 650 RPM

70 %WO

600 RPM

2.5

550 RPM

2.0 80 %WO

500 RPM

1.5 450 RPM

400 RPM

1.0 90 %WO

0.5

10.00 bhp

15.00 bhp

20.00 bhp

7.50 bhp

0.0

0 5000 10000 15000 20000 25000 30000 35000

Airflow (cfm)

63Hz 125Hz 250Hz 500Hz 1 kHz 2 kHz 4 kHz 8 kHz

Discharge duct: 98 96 86 87 80 78 73 69

Return duct: 89 88 85 82 78 76 76 77

Outdoor sound: 104 97 96 97 95 93 88 79

PAQ 50TONs Page 4

ITEM: A1 PRODUCT: VOYAGER3 TAGS(S): TCH600BF0 -- VOYAGER3-A-2

NOTES:

90 5/8" 1. SEE DETAIL HOOD DRAWING FOR HORIZONTAL /

DOWNFLOW UNITS FOR ADDITIONAL DIMENSION

AND LOCATION.

2.ON HORIZONTAL SUPPLY & RETURN UNITS, THE VFD

IS LOCATED BETWEEN THE SUPPLY & RETURN DUCTWORK,

WHICH MAKES ACCESS LIMITED.

232 3/4"

SEE NOTE 1

3 1/4"

49 9/16"

77"

5 5/16"

93 3/8"

1 1/4" FEMALE 7 9/16"

PVC PIPE

GAS INLET 232 3/8"

47"

4 11/16"

CUSTOMER 90 1/16"

CONNECTION POINT

SEE NOTE 1

SUPPLY RETURN 70 1/8"

4 3/8"

55 7/16" 53 1/8" 36 1/16"

2 7/16"

HORIZONTAL SUPPLY AND HORIZONTAL RETURN CONFIGURATION

DIMENSIONAL DRAWING

PAQ 50TONs Page 5

ITEM: A1 PRODUCT: VOYAGER3 TAGS(S): TCH600BF0 -- VOYAGER3-A-2

ELECTRICAL / GENERAL DATA

UNIT

Model (Tonnage) TCH600 (50.0)

Operating voltage range: 207 - 253

Primary voltage: 230

Hertz: 60

Phase: 3

EER / IEER: 10.3 EER/10.9 EER

HEATING - PERFORMANCE COMPRESSOR

Heat: N/A Number 2/1

Heating Input (Btu/h): N/A Tons 13.0/15.0

First Stage (Btu/h): N/A Compressor Rated Load Amps 50.5 / 56.0

Heating Output (Btu/h): N/A Locked Rotor Amps 315.0 / 351.0

First Stage (Btu/h): N/A

No Burners: N/A

No. Stages / Turn Down Rate: N/A ELECTRIC HEATER

Electric Heater kw N/A

Gas Supply Pressure (in w.c.)

N/A Electric Heater Full Load Amps N/A

Natural or LP:

Gas Connection Pipe Size: N/A

INDOOR MOTOR SUPPLY FAN OUTDOOR MOTOR

Horsepower 20.0 Number 4

Motor speed (rpm) 1,760 Horsepower 1.1

Indoor motor full load amps 49.4 Phase 1

Outdoor motor full load amps 7.0

(7)

EXHAUST MOTOR FILTERS

Number N/A Type Throwaway

Horsepower N/A Furnished Yes

Phase N/A Number 17

Exhaust motor full load amps N/A Recommended size 16"x20"x2"

(6)

REFRIGERANT TYPE

Type R-410A

Factory Charge (Circuit #1) 20.0 lb

Factory Charge (Circuit #2) 38.8 lb

Cooling MCA = (1.25 x Load 1) + Load 2 + Load 4

Cooling MOP = (2.25 x Load 1) + Load 2 + Load 4

Notes:

1. LOAD 1= Current of the largest motor (Compressor or Fan Motor); LOAD 2=Sum of the currents of all remaining motors

LOAD 3= FLA(Full Load Amps) of the electric heater; LOAD 4= Any other load rated at 1 amp or more.

2. For Electric Heat MCA, MOP, RDE values, calculate for both cooling and heating modes.

3. If selected Max Over Cur is less than the Min Cir Amp, then select the lowest maximum fuse size which is equal to or larger

than the Min Cir Amp, provided the selected fuse size does not exceed 800 amps.

4. The use of Liquid Propane (LP) requires unit modification. Contact a Trane salesman for information.

5. Compressor KW at AHRI rating conditions of 80/67 -95

6. Refrigerant charge is an approx. value. For a more precise value, see unit nameplate and service instructions.

7. Filter dimension are actual. Norminal filter size 16"x20"

PAQ 50TONs Page 6

ITEM: A1 PRODUCT: VOYAGER3 TAGS(S): TCH600BF0 -- VOYAGER3-A-2

84"

96"

48"

D E F

72" 96"

CLEARANCE NOTES:

1. HORIZONTAL AND DOWNFLOW UNITS,

ALL SIZES.

2. CONDENSER COIL IS LOCATED AT THE

END AND SIDE OF THE UNIT.

3. CLEARANCES ON MULTIPLE UNIT

INSTALLATIONS ARE DISTANCES BETWEEN X

UNITS.

4. ECONO / EXHAUST END MULTIPLE

UNITS 144". C B A

5. CONDENSER COIL END/SIDE 192"

TO 96" 48"

6. SERVICE SIDE ACCESS 96" Y

ESTIMATED OPERATING WEIGHT

OPERATION WEIGHT: 4904.0 lb

CENTER OF GRAVITY OPTIONAL COMPONENTS

X 43" Y 108" POWER EXHAUST N/A BARO. RELIEF N/A SERVICE VALVES N/A

N/A

CORNER LOADING PERCENTS ECONOMIZER THRU-BASE ELECTRICAL N/A DISC. SWITCH N/A

A B C D E F MANUAL DAMPERS N/A GFI WITH DISCON. SWITCH N/A VFD N/A

17% 18% 18% 14% 16% 16% ULTRA LOW LEAK EXH. N/A ULTRA LOW LEAK ECON N/A

COIL HAIL GUARD N/A MOD. HOT GAS REHEAT N/A

WEIGHT NOTES:

1. THE WEIGHT SHOWN REPRESENTS THE TYPICAL UNIT OPERATING WEIGHT FOR THE CONFIGURATION SELECTED. ESTIMATED AT

+/- 10 % OF THE NAMEPLATE WEIGHT.

2. THE ACTUAL WEIGHT IS STAMPED ON THE UNIT NAMEPLATE.

PAQ 50TONs Page 7

ITEM: A1 PRODUCT: VOYAGER3 TAGS(S): TCH600BF0 -- VOYAGER3-A-2

LTB1

149 TEST 1

137 TEST 2

36 20

132 19

133 18

34 17

1 2 3

93 16

119 15

113 14

118 13

49 12

46 11

79 10

78 9

77 8

76 7

75 6

74 5

73 4

72 3

71 2 2

70 1 1

L2

L1 L3

HTB1

ZONE SENSOR WIRE TABLE

WIRE SIZE MAXIMUM WIRE LENGTH in

22 GAUGE 1800"

20 GAUGE 3000"

18 GAUGE 4500"

16 GAUGE 7200"

14 GAUGE 11700"

NOTE:

1. All wiring and devices shown dashed to be supplied and installed by the customer in accordance with national and local electrical codes.

2. Low voltage control wiring must not be run in conduit with power wiring.

3. Cut wire jumper adjacent to the terminal 1 on zone sensor.

PAQ 50TONs Page 8

General R-410A

The units shall be downflow, horizontal, or mixed airflow. T he operating range shall be between 115°F and 0°F in cooling

as standard from the factory for all units. Cooling performance shall be rated in accordance with AHRI testing procedures.

All units shall be factory assembled, internally wired, fully charged with R-410A refrigerant and 100% run tested to check

cooling operation, fan and blower rotation and control sequence before leaving the factory. Wiring internal to the unit shall

be numbered for simplified identification. Units shall be cULus listed.

Compressors R410A

The 3-D Scroll shall provide a completely enclosed compressor chamber with optimized scroll profiles which leads to

increased efficiency. T he 3-D Scroll shall include a direct-drive, 3600 rpm, suction gas cooled hermetic motor. The

compressor shall include a centrifugal oil pump, scroll tips seals, internal heat shield that lowers the heat transfer from

discharge and suction gas, oil level sight glass and oil charge valve. Some compressor models shall also provide a dip

tube that allows for oil draining, in addition to a low leakage internal discharge check valve to help prevent refrigerant

migration. Each compressor shall have a crankcase heater installed, properly sized to minimize the amount of liquid

refrigerant present in the oil sump during off cycles.

Casing

Unit casing shall be constructed of zinc coated, heavy gauge, galvanized steel. Cabinet surface shall be tested 672 hours

in salt spray in compliance with ASTM B117. All components shall be mounted in a weather resistant steel cabinet with a

painted exterior. Where top cover seams exist, they shall be double hemmed and gasket sealed to prevent water leakage.

Cabinet construction shall allow for all maintenance on one side of the unit. Service panels shall have handles and shall

be removable while providing a water and air tight seal. Control box access shall be hinged. T he indoor air section shall

be completely insulated with fire resistant, permanent, odorless, foil faced glass fiber material. The base of the unit shall

have provisions for crane lifting.

Phase and Voltage Monitor

Standard on all Voyager Commercial units. Shall protects 3-phase equipment from phase loss, phase reversal, and low

voltage. Any fault condition shall send the unit into an auto stop condition. cULus approved.

Refrigerant Circuits

Each refrigerant circuit shall have independent thermostatic expansion devices, service pressure ports and refrigerant line

filter driers factory-installed as standard. An area shall be provided for replacement suction line driers.

Outdoor Fans

The outdoor fan shall be direct-drive statically and dynamically balanced, draw through in the vertical discharge position.

The fan motors shall be permanently lubricated and have built-in thermal overload protection.

Ev aporator and Condenser Coils - R410A

Condenser coils shall have all Aluminum Microchannel coils. Evaporator coils shall be internally finned Copper tubes

mechanically bonded to high performance Aluminum plate fins. All coils shall be leak tested at the factory to ensure

pressure integrity. The evaporator coil is pressure tested to 450 psig and the condenser coil at 650 psig. All dual circuit

evaporator coils shall be of intermingled configuration. Sloped condensate drain pans are standard.

Indoor Fan, 60 Hz Supply Motor

Unit will have belt driven, forward curve, centrifugal fans with fixed motor sheaves. T he supply fan motors will be circuit

breaker protected. All 60 Hz supply fan motors meet the Energy Independence and Security Act of 2009 (EISA).

Constant Volume Control Option

The unit shall be provided with all the necessary controls to operate rooftop from a zone sensor, including microprocessor

unit control.

2" Standard Efficiency Filters, MERV4

2" Standard Efficiency, throwaway filters shall be standard

Controls

Unit shall be completely factory wired with necessary controls and terminal block for power wiring. Units shall provide an

external location for mounting fused disconnect device. ReliaTel controls shall be provided for all 24 volt control functions.

The resident control algorithms shall make all heating, cooling and/or ventilating decisions in response to electronic

signals from sensors measuring indoor and outdoor temperatures. The control algorithm maintains accurate temperature

control, minimizes drift from set point and provides better building comfort. ReliaT el controls shall provide anti-short cycle

timing and time delay between compressors to provide a higher level of machine protection.

Unit Interrupt Rating (Standard Short Circuit Current Rating-SCCR)

A 5,000 Amp rating shall be applied to the unit enclosure using a non-fused circuit breaker for disconnect switch purposes.

Fan motors, compressors, and electric heat circuits shall be provided with series rated circuit breakers that will provide the

unit rated level of protection. The unit shall be marked with approved cULus markings and will adhere to cULus

regulations.

PAQ 50TONs Page 9

3-10 Ton R410A PKGD Unitary Gas/Electric Rooftop (Qty 2)

Item Tag(s) Model Number Qty

B1 Y4C-A-2 -- YSC090F3RLA YS 2

Product Data

Item B1 Total Unit Quantity 2 Tags(s) Y4C-A-2 -- YSC090F3RLA

DX Cooling, Gas Heat 3-10 Ton

DX cooling, gas heat

Standard efficiency

Convertible configuration

7.5 Ton Single compressor

208-230/60/3

Microprocessor controls 3ph

Low gas heat 3ph

Major design sequence

Performance Data

Item B1

DX Cooling, Gas Heat 3-10 Ton

Design Airflow (cfm) 3000

Airflow Application Downflow

Cooling Entering DB (F) 80.00

Cooling Entering WB (F) 67.00

Ent Air Relative Humidity (%) 51.08

Ambient Temp (F) 95.00

Evap Coil Leaving Air Temp (DB) (F) 59.44

Evap Coil Leaving Air Temp (WB) (F) 57.46

Cooling Leaving Unit DB (F) 61.42

Cooling Leaving Unit WB (F) 58.21

Gross Total Capacity (MBh) 89.00

Gross Sensible Capacity (MBh) 66.61

Gross Latent Capacity (MBh) 22.39

Net Total Capacity (MBh) 83.50

Net Sensible Capacity (MBh) 61.11

Net Sensible Heat Ratio (Number) 0.73

Heating EAT (F) 70.00

Heating LAT (F) 99.90

Heating Delta T (F) 29.90

Input Heating Capacity (MBh) 120.00

Output Heating Capacity (MBh) 96.00

Output Heating Cap. w/Fan (MBh) 101.50

Design ESP (in H2O) 1.00

Component SP (in H2O) 0.00

Field supplied drive kit required None

Indoor mtr operating power (bhp) 1.80

Indoor RPM (rpm) 1123

Indoor Motor Power (kW) 1.34

Outdoor Motor Power (kW) 0.50

Compressor Power (kW) 6.14

System Power (kW) 7.99

IPLV @ AHRI (IPLV) 12.2

MCA (A) 38.20

MOP (A) 60.00

Compressor 1 RLA (A) 25.00

Compressor 2 RLA (A) 0.00

Evaporator fan FLA (A) 3.60

Condenser fan FLA (A) 3.30

PAQ 50TONs Page 10

Evaporator face area (sq ft) 9.89

Evaporator rows (Each) 4.00

Evaporator fin spacing (Per Foot) 192

Evaporator face velocity (ft/min) 303

Min. unit operating weight (lb) 767.0

Max. unit operating weight (kg) 463

Fan motor heat (MBh) 5.50

Dew Point (F) 56.19

Run Acoustics Yes

Ducted Discharge Heating - 63 Hz (dB) 86

Ducted Discharge Heating - 125 Hz (dB) 83

Ducted Discharge Heating - 250 Hz (dB) 77

Ducted Discharge Heating - 500 Hz (dB) 73

Ducted Discharge Heating - 1 kHz (dB) 72

Ducted Discharge Heating - 2 kHz (dB) 70

Ducted Discharge Heating - 4 kHz (dB) 70

Ducted Discharge Heating - 8 kHz (dB) 65

Ducted Inlet Heating - 63 Hz (dB) 91

Ducted Inlet Heating - 125 Hz (dB) 80

Ducted Inlet Heating - 250 Hz (dB) 66

Ducted Inlet Heating - 500 Hz (dB) 66

Ducted Inlet Heating - 1 kHz (dB) 62

Ducted Inlet Heating - 2 kHz (dB) 62

Ducted Inlet Heating - 4 kHz (dB) 60

Ducted Inlet Heating - 8 kHz (dB) 53

Outdoor Noise Heating - 63 Hz (dB) 91

Outdoor Noise Heating - 125 Hz (dB) 95

Outdoor Noise Heating - 250 Hz (dB) 90

Outdoor Noise Heating - 500 Hz (dB) 87

Outdoor Noise Heating - 1 kHz (dB) 84

Outdoor Noise Heating - 2 kHz (dB) 79

Outdoor Noise Heating - 4 kHz (dB) 75

Outdoor Noise Heating - 8 kHz (dB) 68

Rated capacity (AHRI) (MBh) 83.00

Exhaust fan power (kW) 0.65

Refrig charge (HFC-410A) - ckt 1 (lb) 5.9

Saturated Suction Temp Circuit 1 (F) 49.91

Saturated Discharge Temp Circuit 1 (F) 116.85

ASHRAE 90.1 Yes

IEER 12.20

EER @ AHRI Conditions (EER) 11.2

Total Static Pressure (in H2O) 1.00

PAQ 50TONs Page 11

ITEM: B1 PRODUCT: Y4C TAGS(S): Y4C-A-2 -- YSC090F3RLA

TOP PANEL

EVAPORATOR

SECTION ACCESS PANEL

CONDENSER FAN

CONDENSATE DRAIN (ALT)

3/4"-14 NPT DIA. HOLE

CONDENSER COIL

4 1/4"

27 5/8"

UNIT CONTROL WIRE 7/8" DIA. HOLE

47 7/8"

SERVICE GAUGE PORT ACCESS 1 3/8" DIA. HOLE

UNIT POWER WIRE

1/2" NPT GAS CONNECTION CONTROL AND COMPRESSOR ACCESS PANEL

(80MBH & 120MBH)

3/4" NPT GAS CONNECTION

(150MBH, 200MBH & 250MBH)

THROUGH THE BASE

CONDENSATE 27 5/8"

NOTES:

4 1/8" 1. THRU -THE -BASE ELECTRICAL AND GAS IS NOT STANDARD ON

ALL UNITS.

2. VERIFY WEIGHT, CONNECTION, AND ALL DIMENSION WITH

INSTALLER DOCUMENTS BEFORE INSTALLATION

33" 32 1/8"

SUPPLY RETURN

4"

17 1/2" 9 7/8" 17 1/2" 3 5/8"

PLAN VIEW UNIT

DIMENSION DRAWING

RETURN 32 1/4" 40 7/8"

HORIZONTAL

SUPPLY 23 7/8" AIR FLOW

18 1/2"

9 5/8"

5 5/8"

4 3/4"

19 1/4" 9 3/8" 16 3/4" 3 7/8" 4 1/4"

CONDENSATE 5 5/8"

7 5/8"

88 5/8"

53 1/4"

PACKAGED GAS / ELECTRICAL

DIMENSION DRAWING

PAQ 50TONs Page 12

ITEM: B1 PRODUCT: Y4C TAGS(S): Y4C-A-2 -- YSC090F3RLA

SUPPLY

RETURN

3/4"-14 DIA HOLE

CONDENSATE DRAIN

27 5/8"

4 3/4"

ISOMETRIC-PACKAGED COOLING

PAQ 50TONs Page 13

ITEM: B1 PRODUCT: Y4C TAGS(S): Y4C-A-2 -- YSC090F3RLA

ELECTRICAL / GENERAL DATA

(2)(4)(6)

GENERAL HEATING PERFORMANCE

Model: YSC090F Oversized Motor HEATING - GENERAL DATA

Unit Operating Voltage: 187-253 MCA: N/A

Unit Primary Voltage: 208 Heating Model: Low

MFS: N/A

Unit Secondary Voltage 230 Heating Input (BTU): 120,000

MCB: N/A

Unit Hertz: 60 Heating Output (BTU): 96,000

Unit Phase: 3 No. Burners: 3

No. Stages 1

EER 11.2

Standard Motor Field Installed Oversized Motor Gas Inlet Pressure

MCA: 38.2 MCA: N/A Natural Gas (Min/Mix): 4.5/14

MFS: 60.0 MFS: N/A LP (Min/Max) 11.0/14.0

MCB: 60.0 MCB: N/A Gas Pipe Connection Size: 1/2"

INDOOR MOTOR

Standard Motor Oversized Motor Field Installed Oversized Motor

Number: 1 Number: N/A Number: N/A

Horsepower: 1.0 Horsepower: N/A Horsepower: N/A

Motor Speed (RPM): -- Motor Speed (RPM): N/A Motor Speed (RPM): N/A

Phase 3 Phase N/A Phase N/A

Full Load Amps: 3.6 - 3.5 Full Load Amps: N/A Full Load Amps: N/A

Locked Rotor Amps: 12.5 Locked Rotor Amps: N/A Locked Rotor Amps: N/A

COMPRESSOR Circuit 1/2 OUTDOOR MOTOR

Number: 1 Number: 1

Horsepower: 6.7 Horsepower: 0.7

Phase: 3 Motor Speed (RPM): 1100

Rated Load Amps: 25.0 Phase: 1

Locked Rotor Amps: 164.0 Full Load Amps: 3.3

Locked Rotor Amps: 9.5

(3) (2)

POWER EXHAUST ACCESSORY FILTERS REFRIGERANT

(Field Installed Power Exhaust)

Type

Phase: N/A Type: Throwaway

Horsepower: N/A Yes Factory Charge

Furnished: 5.9 lb

Motor Speed (RPM): N/A 4 Circuit #1

Number

Full Load Amps: N/A 16"x25"x2" Circuit #2 N/A

Recommended

Locked Rotor Amps: N/A

NOTES:

1. Maximum (HACR) Circuit Breaker sizing is for installations in the United States only.

2. Refrigerant charge is an approximate value. For a more precise value, see unit nameplate and service instructions.

3. Value does not include Power Exhaust Accessory.

4. Value includes oversized motor.

5. Value does not include Power Exhaust Accessory.

6. EER is rated at AHRI conditions and in accordance with DOE test procedures.

PAQ 50TONs Page 14

ITEM: B1 PRODUCT: Y4C TAGS(S): Y4C-A-2 -- YSC090F3RLA

INSTALLED ACCESSORIES NET WEIGHT DATA

ACCESSORY WEIGHTS

ECONOMIZER

MOTORIZED OUTSIDE AIR DAMPER

C D MANUAL OUTSIDE AIR DAMPER

BAROMETRIC RELIEF

OVERSIZED MOTOR

BELT DRIVE MOTOR

POWER EXHAUST

THROUGHT THE BASE ELECTRICAL/GAS (FIOPS)

UNIT MOUNTED CIRCUIT BREAKER (FIOPS)

UNIT MOUNTED DISCONNECT (FIOPS)

POWERED CONVENIENCE OUTLET (FIOPS)

HINGED DOORS (FIOPS)

HAIL GUARD

B A

SMOKE DETECTOR, SUPPLY / RETURN

NOVAR CONTROL

PACKAGED GAS / ELECTRICAL

STAINLESS STEEL HEAT EXCHANGER

CORNER WEIGHT

REHEAT

ROOF CURB

BASIC UNIT WEIGHTS CORNER WEIGHTS CENTER OF GRAVITIY

SHIPPING NET A 243.0 lb C 155.0 lb (E) LENGHT (F) WIDTH

862.0 lb 767.0 lb B 221.0 lb D 149.0 lb 45" 21"

NOTE:

1. All weights are approximate.

2. Weights for options that are not list refer to Installation guide.

3. The actual weight are listed on the unit nameplate.

4. Refer to unit nameplate and installation guide for weights before scheduling transportation and installation

of unit.

5. The weight shown represents the typical unit operating weight for the configuration selected. Estimated

at +/- 10 % of the nameplate weight. .

6. Verify weight, connection, and all dimension with installer documents before installation.

7. Corner weights are given for information only.

8. Net/Shipping weight of optional accessories should be added to unit weight when ordering factory or field

installed accessories.

E F

PACKAGED GAS / ELECTRICAL

RIGGING AND CENTER OF GRAVITY

PAQ 50TONs Page 15

ITEM: B1 PRODUCT: Y4C TAGS(S): Y4C-A-2 -- YSC090F3RLA

CLEARANCE FROM TOP OF UNIT 72"

CLEARANCE 36"

CLEARANCE 48"

SUPPLY

RETURN

DOWNFLOW CLEARANCE 36"

HORIZONTAL CLEARANCE 18"

CLEARANCE 36"

PACKAGED GAS / ELECTRIC

CLEARANCE

ROOF OPENING

UNIT OUTLINE

46" 53 1/4"

46"

88 5/8"

PACKAGED GAS / ELECTRIC

DOWNFLOW TYPICAL ROOF OPENING

PAQ 50TONs Page 16

General

The units shall be convertible airflow. T he operating range shall be between 115°F and 0°F in cooling as standard from

the factory for units with microprocessor controls. Operating range for units with electromechanical controls shall be

between 115°F and 40°F. Cooling performance shall be rated in accordance with ARI testing procedures. All units shall be

factory assembled, internally wired, fully charged with R-410A, and 100 percent run tested to check cooling operation, fan

and blower rotation, and control sequence before leaving the factory. Wiring internal to the unit shall be colored and

numbered for simplified identification. Units shall be cULus listed and labeled, classified in accordance for Central Cooling

Air Conditioners.

Casing

Unit casing shall be constructed of zinc coated, heavy gauge, galvanized steel. Exterior surfaces shall be cleaned,

phosphatized, and finished with a weather-resistant baked enamel finish. Unit's surface shall be tested 672 hours in a salt

spray test in compliance with ASTM B117. Cabinet construction shall allow for all maintenance on one side of the unit.

Service panels shall have lifting handles and be removed and reinstalled by removing two fasteners while providing a

water and air tight seal. All exposed vertical panels and top covers in the indoor air section shall be insulated with a

cleanable foil-faced, fire-retardant permanent, odorless glass fiber material. T he base of the unit shall be insulated with

1/8 inch, foil-faced, closed-cell insulation. All insulation edges shall be either captured or sealed. The unit's base pan shall

have no penetrations within the perimeter of the curb other than the raised 1 1/8 inch high downflow supply/return

openings to provide an added water integrity precaution, if the condensate drain backs up. The base of the unit shall have

provisions for forklift and crane lifting, with forklift capabilities on three sides of the unit.

Unit Top

The top cover shall be one piece construction or, where seams exist, it shall be double-hemmed and gasket-sealed. The

ribbed top adds extra strength and enhances water removal from unit top.

Filters

Throwaway filters shall be standard on all units. Optional 2-inch MERV 8 and MERV 13 filters shall also be available.

Compressors

All units shall have direct-drive, hermetic, scroll type compressors with centrifugal type oil pumps. Motor shall be suction

gas-cooled and shall have a voltage utilization range of plus or minus 10 percent of unit nameplate voltage. Internal

overloads shall be provided with the scroll compressors.

Dual compressors are outstanding for humidity control, light load cooling conditions and system back-up applications. Dual

compressors are available on 7½-10 ton models and allow for efficient cooling utilizing 3-stages of compressor operation

for all high efficiency models.

Notes:

Crankcase heaters are optional on YSC (036, 048, 060, 072, 090, 102, 120); standard on YHC (036, 048, 060, 072, 092,

102, 120).

Indoor Fan

The following units shall be equipped with a direct drive plenum fan design (T /YSC120F,T/YHC074F,

T/YHC092F,T /YHC102F, 120F). Plenum fan design shall include a backward-curved fan wheel along with an external rotor

direct drive variable speed indoor motor. All plenum fan designs will have a variable speed adjustment potentiometer

located in the control box.

3 to 5 ton units (high efficiency 3-phase with optional motor) are belt driven, FC centrifugal fans with adjustable motor

sheaves. 3 to 5 ton units (standard and high efficiency 3-phase) have multispeed, direct drive motors. All 6 to 8½ ton units

(standard efficiency) shall have belt drive motors with an adjustable idler-arm assembly for quick-adjustment to fan belts

and motor sheaves. All motors shall be thermally protected. All 10 tons, 6 ton (074), 7½ to 8½ (high efficiency) units have

variable speed direct drive motors. All indoor fan motors meet the U.S. Energy Policy Act of 1992 (EPACT).

Outdoor Fans

The outdoor fan shall be direct-drive, statically and dynamically balanced, draw-through in the vertical discharge position.

The fan motor shall be permanently lubricated and shall have built-in thermal overload protection.

PAQ 50TONs Page 17

Ev aporator and Condenser Coils

Internally finned, 5/16" copper tubes mechanically bonded to a configured aluminum plate fin shall be standard.

Evaporator coils are standard for all 3 to 10 ton standard efficiency models. Microchannel condenser coils are standard for

all 3 to 10 ton standard efficiency models and 4,5,6, 7.5, 8.5 ton high efficiency models.The microchannel type condenser

coil is not offered on the 4 and 5 ton dehumidification model. Due to flat streamlined tubes with small ports, and

metallurgical tube-to-fin bond, microchannel coil has better heat transfer performance. Microchannel condenser coil can

reduce system refrigerant charge by up to 50% because of smaller internal volume, which leads to better compressor

reliability. Compact all-aluminum microchannel coils also help to reduce the unit weight.These all aluminum coils are

recyclable. Galvanic corrosion is also minimized due to all aluminum construction. Strong aluminum brazed structure

provides better fin protection. In addition, flat streamlined tubes also make microchannel coils more dust resistant and

easier to clean. Coils shall be leak tested at the factory to ensure the pressure integrity.The evaporator coil and condenser

coil shall be leak tested to 600 psig.The assembled unit shall be leak tested to 465 psig.The condenser coil shall have a

patent pending 1+1+1 hybrid coil designed with slight gaps for ease of cleaning.A plastic, dual-sloped, removable and

reversible condensate drain pan with through-the-base condensate drain is standard.

Controls

Unit shall be completely factory-wired with necessary controls and contactor pressure lugs or terminal block for power

wiring. Unit shall provide an external location for mounting a fused disconnect device. A choice of microprocessor or

electromechanical controls shall be available. Microprocessor controls provide for all 24V control functions. T he resident

control algorithms shall make all heating, cooling, and/or ventilating decisions in response to electronic signals from

sensors measuring indoor and outdoor temperatures. The control algorithm maintains accurate temperature control,

minimizes drift from set point, and provides better building comfort. A centralized microprocessor shall provide anti-short

cycle timing and time delay between compressors to provide a higher level of machine protection. 24-volt

electromechanical control circuit shall include control transformer and contactor

High Pressure Control

All units include High Pressure Cutout as standard.

Phase monitor

Phase monitor shall provide 100% protection for motors and compressors against problems caused by phase loss, phase

imbalance, and phase reversal. Phase monitor is equipped with an LED that provides an ON or FAULT indicator. There

are no field adjustments. T he module will automatically reset from a fault condition.

Refrigerant Circuits

Each refrigerant circuit offer thermal expansion valve as standard. Service pressure ports, and refrigerant line filter driers

are factory-installed as standard. An area shall be provided for replacement suction line driers.

Gas Heating Section

The heating section shall have a progressive tubular heat exchanger design using stainless steel burners

and corrosion resistant steel throughout. An induced draft combustion blower shall be used to pull the combustion products

through the firing tubes. T he heater shall use a direct spark ignition (DSI) system. On initial call for heat, the combustion

blower shall purge the heat exchanger for 20 seconds before ignition After three unsuccessful ignition attempts, the entire

heating system shall be locked out until manually reset at the thermostat/zone sensor. Units shall be suitable for use with

natural gas or propane (field-installed kit) and also comply with the California requirement for low NOx emissions

(Gas/Electric Only).

PAQ 50TONs Page 18

You might also like

- Commercial Blower Coil Air Handlers: TraneDocument2 pagesCommercial Blower Coil Air Handlers: TraneWan Norhisyam Wan Mohamad100% (2)

- Performance Chiller YVAA0263BGF40BAVDocument2 pagesPerformance Chiller YVAA0263BGF40BAVEnzo VizcardoNo ratings yet

- The Big Bang Never HappenedDocument3 pagesThe Big Bang Never HappenedIvan Vule Fridman100% (1)

- ETABS Building Structure Analysis and Design ReportDocument84 pagesETABS Building Structure Analysis and Design ReportMd Awesshadab0% (1)

- CL Rtu-1 MCNDocument18 pagesCL Rtu-1 MCNArq Javier Larios ArciniegaNo ratings yet

- VOYAGER3 - TCD600B4 - Consolidated Customer PackageDocument11 pagesVOYAGER3 - TCD600B4 - Consolidated Customer PackageVincent Aarón RodríguezNo ratings yet

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraNo ratings yet

- VOYAGER3 Product ReportDocument2 pagesVOYAGER3 Product ReportarmandoNo ratings yet

- VOYAGER3 - TED600B4E - Consolidated Customer PackageDocument14 pagesVOYAGER3 - TED600B4E - Consolidated Customer PackageairemexNo ratings yet

- ACSA - CH-01 - Consolidated Customer PackageDocument17 pagesACSA - CH-01 - Consolidated Customer PackageTomas VazquezNo ratings yet

- Chiller InductorDocument2 pagesChiller InductorAlberto Steven Ospino GómezNo ratings yet

- LPG Amine Cooler-SummaryDocument15 pagesLPG Amine Cooler-SummaryJEEVITHANo ratings yet

- AVX-B Performance (Vertical Compressor)Document4 pagesAVX-B Performance (Vertical Compressor)Inzamam ShithilNo ratings yet

- ERTAF - ERTAF-2 - Product ReportDocument2 pagesERTAF - ERTAF-2 - Product ReportSajidNo ratings yet

- AVX-B & ACHX-B PerformanceDocument12 pagesAVX-B & ACHX-B PerformanceInzamam ShithilNo ratings yet

- 08 KFR-70GW-NA1 Service ManualDocument58 pages08 KFR-70GW-NA1 Service ManualLcj RefrigeraNo ratings yet

- 08 KFR-70GW-NA1 Service Manual PDFDocument58 pages08 KFR-70GW-NA1 Service Manual PDFLcj RefrigeraNo ratings yet

- Identification Data: Description Fan - 1 Fan - 2 Fan - 3 Fan - 4 CommentsDocument13 pagesIdentification Data: Description Fan - 1 Fan - 2 Fan - 3 Fan - 4 CommentsAngel CarvajalNo ratings yet

- VOYAGER3 - 30 Tons - Consolidated Customer PackageDocument8 pagesVOYAGER3 - 30 Tons - Consolidated Customer Packagetc01No ratings yet

- Voyager II (W4V) Product ReportDocument2 pagesVoyager II (W4V) Product ReportFranklinIgorLeytonMoragaNo ratings yet

- Air-Cooled Series R (TM) CRTAG Product ReportDocument2 pagesAir-Cooled Series R (TM) CRTAG Product ReportfaizalNo ratings yet

- Jenbacher Combustion Air CoolingDocument10 pagesJenbacher Combustion Air CoolingAli AbbasiNo ratings yet

- M 40ua1 PDFDocument1 pageM 40ua1 PDFAngan KitaNo ratings yet

- ERTAF - ERTAF-2 maco-2 - Product ReportDocument2 pagesERTAF - ERTAF-2 maco-2 - Product ReportKaran GnaniNo ratings yet

- Datasheet 1 RTG 1223160 E 2,400.0Document2 pagesDatasheet 1 RTG 1223160 E 2,400.0Edson PulaskiNo ratings yet

- Tag Model Location Qty: QN 21090714 Devine Mercy Hospital Bangladesh Daveen 9/30/21 2:18 PMDocument3 pagesTag Model Location Qty: QN 21090714 Devine Mercy Hospital Bangladesh Daveen 9/30/21 2:18 PMfakir mohammadNo ratings yet

- Technical Data 16 KvaDocument6 pagesTechnical Data 16 Kvaamza njatonoNo ratings yet

- ACHX-B Performance (Horizontal Compressor)Document3 pagesACHX-B Performance (Horizontal Compressor)Inzamam ShithilNo ratings yet

- YLAA0155SE46 DataSheetSpecDocument2 pagesYLAA0155SE46 DataSheetSpecgustavo olveraNo ratings yet

- TSC072 PKGD Unitary Cooling Rooftop (T4C) Product ReportDocument2 pagesTSC072 PKGD Unitary Cooling Rooftop (T4C) Product ReportJennyfer Isidro FloresNo ratings yet

- Fujitsu ACDocument16 pagesFujitsu ACNora SmithNo ratings yet

- ZP31K5E PFV CompressorDocument8 pagesZP31K5E PFV CompressorAliNo ratings yet

- Tips para CobranzaDocument9 pagesTips para CobranzaGabriel DelgadoNo ratings yet

- YVAA0233 (MTY) at 95 F - DataSheetSpecDocument2 pagesYVAA0233 (MTY) at 95 F - DataSheetSpecMohammed EmamNo ratings yet

- Dawn of War II Manual - ENDocument45 pagesDawn of War II Manual - ENelmarcusIINo ratings yet

- Air Cooled Screw Chiller Performance DatasheetDocument2 pagesAir Cooled Screw Chiller Performance DatasheetJuan Carlos Soto OrihuelaNo ratings yet

- Am060txmdec TLDocument1 pageAm060txmdec TLaandresleo86No ratings yet

- PUHY-P400YKB-A1 and PUHY-P450YKB-A1 heat pump specificationsDocument1 pagePUHY-P400YKB-A1 and PUHY-P450YKB-A1 heat pump specificationsCristian JianuNo ratings yet

- YVAA0490 - DataSheetSpec. - Rev01pdfDocument2 pagesYVAA0490 - DataSheetSpec. - Rev01pdfMohamed AskarNo ratings yet

- Output Ratings: Prime RatingDocument6 pagesOutput Ratings: Prime Ratingสุกิจ วิโรจน์สิริNo ratings yet

- P22-1 (Skid) Generator SetDocument6 pagesP22-1 (Skid) Generator Setamza njatonoNo ratings yet

- Performance Chiller HG QueretaroDocument2 pagesPerformance Chiller HG QueretaroAntonio Chavez GarciaNo ratings yet

- Acds120 Chiller SpecsDocument8 pagesAcds120 Chiller SpecsitovelaNo ratings yet

- Heat Stable Reactor Heater 1.5 KG - HR (9.24 MM ID Tube)Document38 pagesHeat Stable Reactor Heater 1.5 KG - HR (9.24 MM ID Tube)Ravindra BarangeNo ratings yet

- Output Summary: See Data Check Messages Report For Warning Messages. See Runtime Message Report For Warning MessagesDocument1 pageOutput Summary: See Data Check Messages Report For Warning Messages. See Runtime Message Report For Warning MessagesIdil FitriNo ratings yet

- Brosur P220 FG WilsonDocument6 pagesBrosur P220 FG WilsonHendraNo ratings yet

- KR - Single Package - R410A - 5060Hz - HP - Saudi - MFL67452919 - 20220920Document134 pagesKR - Single Package - R410A - 5060Hz - HP - Saudi - MFL67452919 - 20220920Mohanad ElgayarNo ratings yet

- Catalogue RAC Mitsubishi ElectricDocument10 pagesCatalogue RAC Mitsubishi ElectricYizhar Bechamel MestokoNo ratings yet

- SmartCool SC22D064-2X20-0 + 2xCR50Document4 pagesSmartCool SC22D064-2X20-0 + 2xCR50EngSalah RamadanNo ratings yet

- CRNQ 0500 CopelandDocument6 pagesCRNQ 0500 CopelandRivaldoNo ratings yet

- Split Type Air Conditioner Specifications and Installation ManualDocument34 pagesSplit Type Air Conditioner Specifications and Installation ManualMihaela CaciumarciucNo ratings yet

- Rooftop Package ClimaCreator Tropical R410A 50Hz (Brochure)Document2 pagesRooftop Package ClimaCreator Tropical R410A 50Hz (Brochure)rodrigobenitez754No ratings yet

- Change for Life Service ManualDocument67 pagesChange for Life Service ManualElena TanevaNo ratings yet

- C7.1-De220e0 200kvaDocument8 pagesC7.1-De220e0 200kvaMudhafar SadiqNo ratings yet

- P26-3S - 50Hz: Output RatingsDocument6 pagesP26-3S - 50Hz: Output RatingsnuqNo ratings yet

- Fisa Tehnica VentilatorDocument2 pagesFisa Tehnica VentilatorFlorian Marian MarțanNo ratings yet

- Manejadora PaqueteDocument12 pagesManejadora PaqueteEduardo AntonioNo ratings yet

- BPGDE - 15 Tons - Consolidated Customer PackageDocument7 pagesBPGDE - 15 Tons - Consolidated Customer Packagetc01No ratings yet

- AE2425Z Technical DataDocument4 pagesAE2425Z Technical DataMageon7No ratings yet

- FJ SM Asy9 12 LSBCW PDFDocument16 pagesFJ SM Asy9 12 LSBCW PDFMihaela CaciumarciucNo ratings yet

- Technical Service Manual for 13SEER Comfortstar Plus Air ConditionersDocument34 pagesTechnical Service Manual for 13SEER Comfortstar Plus Air Conditionerstitomotta0% (2)

- QuietR Rotary Duct Liner Product Data SheetDocument2 pagesQuietR Rotary Duct Liner Product Data SheetJorge SandovalNo ratings yet

- Technical Note: Kingspan Koolduct - Ductwork Commissioning and TestingDocument5 pagesTechnical Note: Kingspan Koolduct - Ductwork Commissioning and TestingJorge SandovalNo ratings yet

- Merv Rating Chart PDFDocument1 pageMerv Rating Chart PDFJorge SandovalNo ratings yet

- Reducer GroovedDocument2 pagesReducer GroovedJorge SandovalNo ratings yet

- QuietR Rotary Duct Liner Product Data SheetDocument2 pagesQuietR Rotary Duct Liner Product Data SheetJorge SandovalNo ratings yet

- SS Tubing Pressure Ratings SANITARYDocument1 pageSS Tubing Pressure Ratings SANITARYJorge SandovalNo ratings yet

- VALVULASDocument21 pagesVALVULASJorge SandovalNo ratings yet

- QuietR Rotary Duct Liner Product Data SheetDocument2 pagesQuietR Rotary Duct Liner Product Data SheetJorge SandovalNo ratings yet

- 50 ZPB Carrier-PaqueteDocument5 pages50 ZPB Carrier-PaqueteJorge SandovalNo ratings yet

- 22-Stainless Steel Aisi 316 (A4)Document1 page22-Stainless Steel Aisi 316 (A4)Paul OnionsNo ratings yet

- 22-Stainless Steel Aisi 316 (A4)Document1 page22-Stainless Steel Aisi 316 (A4)Paul OnionsNo ratings yet

- Pages From B1-20-1 - 2013 PDFDocument3 pagesPages From B1-20-1 - 2013 PDFAhmad Jukliv Pandu YoedhawanNo ratings yet

- Lovejoy Power Transmission Product Safety GuideDocument28 pagesLovejoy Power Transmission Product Safety GuideJorge SandovalNo ratings yet

- Introduction Static ForceDocument35 pagesIntroduction Static ForceRichard VillónNo ratings yet

- FreeVibrations Freestudy Co UkDocument0 pagesFreeVibrations Freestudy Co Ukdeepak_dce_meNo ratings yet

- Mechanics Book 1Document399 pagesMechanics Book 1abhijet29No ratings yet

- Product Documentation: Release NotesDocument3 pagesProduct Documentation: Release NotesArmando CisternasNo ratings yet

- Binder Modul WMS 10Document52 pagesBinder Modul WMS 10sandhiakhmadNo ratings yet

- Mechanical Engineering Conference ProgramDocument40 pagesMechanical Engineering Conference Programirinuca12No ratings yet

- Ne7207 Nis Unit 2 Question BankDocument2 pagesNe7207 Nis Unit 2 Question BankalgatesgiriNo ratings yet

- Nextion InstructionDocument53 pagesNextion InstructionMacp63 cpNo ratings yet

- Inductive TransducersDocument12 pagesInductive TransducersMUKESH SUNDARARAJANNo ratings yet

- Z 80 HelptopicsDocument5 pagesZ 80 HelptopicsEverly NNo ratings yet

- Unit 10 - Week 9: Assignment 9Document4 pagesUnit 10 - Week 9: Assignment 9shubhamNo ratings yet

- AminesDocument31 pagesAminesJoseph YayenNo ratings yet

- TCP Operational Overview and The TCP Finite State Machine (FSM)Document4 pagesTCP Operational Overview and The TCP Finite State Machine (FSM)Mayank JaitlyNo ratings yet

- Flow Chart SymbolsDocument7 pagesFlow Chart SymbolsAbhishekNo ratings yet

- Essential Statistics For The Behavioral Sciences 1st Edition Privitera Solutions ManualDocument7 pagesEssential Statistics For The Behavioral Sciences 1st Edition Privitera Solutions Manualspinifexcandock8zf100% (26)

- Woodward MFR 13Document91 pagesWoodward MFR 13OryaNo ratings yet

- The Architecture Tradeoff Analysis MethodDocument11 pagesThe Architecture Tradeoff Analysis MethoducinfpracticasNo ratings yet

- 1900.65A Monitor DatasheetDocument26 pages1900.65A Monitor DatasheetAncuța DanielNo ratings yet

- Seminar ReportDocument45 pagesSeminar Reportmanaskollam0% (1)

- Er DiagramsDocument20 pagesEr DiagramsMatthew BloomfieldNo ratings yet

- Fulltext PDFDocument454 pagesFulltext PDFVirmantas JuoceviciusNo ratings yet

- Unit 6 - Quantitative Analysis NotesDocument53 pagesUnit 6 - Quantitative Analysis Notesapi-182809945No ratings yet

- Digital Image Processing TechniquesDocument34 pagesDigital Image Processing Techniquesaishuvc1822No ratings yet

- Structural Steel Design: Design of Tension Members 2: Universal College of ParañaqueDocument36 pagesStructural Steel Design: Design of Tension Members 2: Universal College of ParañaqueFritz LuzonNo ratings yet

- Geotechnical Engineering Notes 333Document40 pagesGeotechnical Engineering Notes 333TinaNo ratings yet

- Viscosity Vs ConsistencyDocument6 pagesViscosity Vs Consistencysontakke manmathNo ratings yet

- Class 9 Sample Paper 2020-21Document3 pagesClass 9 Sample Paper 2020-21sasta jiNo ratings yet

- KujiDocument17 pagesKujiGorumbha Dhan Nirmal Singh100% (2)

- Analysis of Structure of C Type Hydraulic PressDocument10 pagesAnalysis of Structure of C Type Hydraulic PressShubhamNo ratings yet

- Solidworks Flow SimulationDocument7 pagesSolidworks Flow SimulationpatrickNX94200% (1)

- Barrels & Actions by Harold HoffmanDocument238 pagesBarrels & Actions by Harold HoffmanNorm71% (7)