Professional Documents

Culture Documents

API 650 Poınts

Uploaded by

Samet Belli0 ratings0% found this document useful (0 votes)

716 views4 pagesAPI 650 Poınts

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAPI 650 Poınts

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

716 views4 pagesAPI 650 Poınts

Uploaded by

Samet BelliAPI 650 Poınts

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Southern Inspection Services

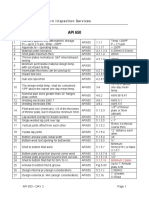

API 650

Standard applied only atmospheric storage Temp <200ºF

1 API650 1.1.1

Pr – up to 2 ½ psi, temp - 200ºF P – 2 ½ psi

2 Appendix M – operating temp. API650 1.1.17 > 200ºF

3 Material under tolerance API650 4.2.1.2.3 0.25mm/ 0.01inch

4 Shell plate maximum thick API650 4.2.1.4 45mm

Thicker plates normalized, Q&T killed &impact

5 API650 4.2.1.4 40mm

testing

Minimum permissible material design temp.

6 API650 Fig. 41

with out impact testing

7 Insert plate thickness can be used up to API650 4.2.1.4 100mm

8 Impact test size API650 4.2.8.5 10x10mm

>80% of material

9 Sub size specimen API650 4.2.8.5

thick

15ºF/8ºC above

The design metal temp. shall be considered

10 API650 3.4 one day mean

15ºF above the lowest one day mean temp.

temp.

Nominal pipe sizes greater than 24” flanges

11 API650 4.6.2 ASNI B16.47

shall confirm

12 Welding electrodes E60/ 7 API650 4.8.1 AWS 5.1

13 Welding electrodes E80 API650 4.8.2 AWS 5.5

1/3rd of thinner

Fillet weld size (minimum) ,1/3 of the thickness

14 API650 5.1.3.3 plate or 5mm

of thinner plate, but it should be minimum 5mm

(atleast)

15 Lap welded overlap for double welded API650 5.1.3.5 < 2”

16 Single welded lap joint over lap API650 5.1.3.5 < 1”

5t min, t is thicker

17 Vertical joints offset from each other API650 5.1.5.2

course thick

12” distance each

18 3 plate lap joints API650 5.1.5.4

other

19 Bottom annular plate radial width API650 5.1.5.4 24”

20 Bottom weld root opening for butt welds API650 5.1.5.5 ¼“

Minimum

21 Shell to bottom fillet weld API650 5.1.5.7 5mm(3/16”) or table

3.1.5.7

22 Bottom plate projection beyond corner weld API650 5.1.5.7.d 1/2”

23 Annular plate projection beyond shell out side API650 5.1.5.7.d 1/2”

24 Shell to bottom fillet filet for GrIV to VI API650 3.1.5.7e Minimum 2 pass

Up to 1” Annular

25 Annular to bottom filet & groove API650 Fig.5-3C

plate A=B

26 Design internal pr.(design consideration) API650 5.2.1.c 2.5lbf/in2

1” of water,

27 Design external pr. Min.(design consideration) API650 5.2.1b

0.25kpa

API 653 – DAY 2 Page 1

Southern Inspection Services

28 Design external pr. Max.(design consideration) API650 5.2.1b 1.01lbf/in2, 6.9kpa

29 Tank capacity API650 5.2.6.1 API RP 2350

30 Shell thickness Vs dia. Of tank API650 5.6.1.1 Min 5mm

31 Shell plate width API650 5.6.1.2 72 inch

32 Annular plate thickness API650 Table 5.1 Min. 6 mm

33 Appendix A tank with spot RT ‘E’ is API650 5.6.2.3 0.85

34 Appendix A tank with out spot RT ‘E’ is API650 5.6.2.3 0.7

35 Periphery of the insert plate taper API650 5.7.1.7 1:4

36 Reinforcement for nozzle API650 5.7.2.1 >2”

37 Max. size of weld for shell to reinforcing plate API650 5.7.2.7 38mm, 1 ½ “

Min thick of shell or

38 Min. size of weld for shell to reinforcing plate API650 5.7.2.7

reinforcing plate

600ºC to650ºC

39 Thermal stress relief temp. API650 5.7.4.2

(1100ºF to 1200ºF)

6mm, ¼ “ hole. 1/8”

40 Tell-tale hole size API650 5.7.2.10

thread

48” for I to IIIA

41 Height of flush type cleanout fittings API650 5.7.7.2

36” for IV to VI

Permanent attachment fillet welds max leg

42 API650 5.8.1.2 13mm

dimension

Space between the attachment weld to

43 API650 5.8.1.2 3”

horizontal joint

44 Space between attachment to vertical joint API650 5.8.1.2 6”

45 Nozzle flanges shall meet requirement API650 5.8.5.1 ASME B16.5

Cover plate thick of roof opening shall not be

46 API650 5.8.6.2 3/16”

less than

Intermediate wind girders to horizontal weld of

47 API650 5.9.7.5 > 6”

the shell distance

3/16” /7 gauge

48 Roof plate min thick API650 5.10.2.2

sheet

All internal & external structural matl. shall

49 API650 5.10.2.4 0.17”/ 4.3mm

have min nominal thick

Only top side,

Roof plate shall be attached to top angle with

50 API650 5.10.2.5 Filet size <5mm

continues filet weld

only

51 Dimension of draw off sumps for 3” NPS API650 Table 5.16

19mm in 300mm

52 Support cone roof slope API650 5.10.4.1

¾ “ in 12”

53 Normal venting shall meet the requirements of API650 xxxxxx API std 2000

54 Tank anchorage spacing shall not exceed API650 5.12.3 10ft

55 Shearing of plates shall be limited to API650 6.1.2 ≤ 10mm

56 Shaping of shell plate API650 6.1.3 Fig 6 – 1

57 Tank welding procedure/ qualification welders API650 7.2.1.1 ASME Sec IX

58 No welding shall be less than 0ºC API650 7.2.1.2 Less than 0ºC

59 Preheating temp of the metals during welding API650 7.2.1.2 Table 7 – 1

API 653 – DAY 2 Page 2

Southern Inspection Services

60 Undercutting for vertical welds API650 8.5.1.b 1/64”

61 For horizontal welds, under cutting not exceed API650 8.5.1.b 1/32”

62 Reinforcement of vertical welds API650 8.5.1.d 2.5mm to 5mm

3mm for ½ “

63 Horizontal weld reinforcement API650 8.5.1.d 6mm for 1” and

above

64 Low hydrogen electrodes for plate thicker than API650 7.2.1.10.a ½ “ for group I – III

All thick of group IV

65 Low hydrogen electrodes for plate thick API650 7.2.1.10.b

- VI

10% plate thick or

66 Misalignment for vertical welds >5/8” API650 7.2.3.1

3mm

67 Misalignment for vertical welds <5/8” API650 7.2.3.1 1/16”

20% plate thick or

68 Misalignment for horizontal welds >5/8” API650 7.2.3.2

3mm

69 Misalignment for horizontal welds <5/8” API650 7.2.3.2 1/16”

MPI/ Vacuum/ air

70 Shell to bottom welds – examination API650 7.2.4.1

leak

Vacuum box, tracer

71 Examination of bottom welds API650 7.3.3

gas

Inspection of reinforcement plate welds by tell- 15psi pneumatic

72 API650 7.3.4

tale hole test

73 Plumpness of the tank API650 7.5.2 1/200 of the height

<40’ – 13mm

74 Roundness at 1 ft above bottom plate API650 7.5.3 < 150’ – 250’ –

25mm

75 Peaking & banding API650 7.5.4 ½“

3mm in 30ft, 6mm

Concrete ring level tolerance in horizontal

76 API650 7.5.5.2 in total

plane

circumference

3mm in 10ft, 13mm

77 When concrete ring wall not provided – level API650 7.5.5.2 in total

circumference

78 RT required for flush type connection API650 8.1.1 Butt weld

79 Vertical joint ≤10mm (type and thick) API650 8.1.2.2 Spot in 10ft (first)

80 Additional RT API650 8.1.2.2 1spot in 100ft

25% of selected

81 Junctions of vertical and horizontal API650 8.1.2.2

spots

Additional of one

82 Butt weld 10mm to < 25mm API650 8.1.2.2

spot

2 spot RT each

83 Lowest course of shell API650 8.1.2.2

vertical

84 Vertical > 1” thick API650 8.1.2.2 100% RT

3” vertical, 2” each

85 Each film shall show min of weld length API650 8.1.2.2

side (T)

API 653 – DAY 2 Page 3

Southern Inspection Services

The butt weld around the periphery of insert

86 API650 8.1.2.2 100%

man hole nozzle

One spot – first 10ft

87 Horizontal joint RT API650 8.1.2.3 One additional spot

in 200ft

88 RT shall clearly show minimum of weld length API650 8.1.2.8 6”

Annular bottom welds double welded butt One spot in 10%

89 API650 8.1.2.9

joints joints

One spot in 50%

90 Annular bottom welds single welded butt joints API650 8.1.2.9

joints

91 RT shall be carried out as per API650 8.1.3.1 Sec. V Article 2

Max 1.3mm for ≤ ½

Finish surface the weld reinforcement of the

92 API650 8.1.3.4 “

RT jt.

3mm for > 25mm

93 RT acceptance criteria of welds API650 8.1.5 ASME UW 51b

94 MPI – method API650 8.2.1 Article 7 of ASME V

95 UT – method of examination shall API650 8.3.2.2 Article 5 of ASME V

Vacuum testing shall be carried by using

96 API650 8.6.3 3 to 5 psi

pressure

Operator (vacuum box test) jogger type 2 by

97 API650 8.6.4 12” distance

distance

98 Vacuum box over lap shall API650 8.6.5 50mm / 2”

99 Angle joint (corner joint) API650 9.1.1 0º to 90º

Design metal temperature below 10ºC, vertical

100 API 650 9.2.2.3 Impact test

joint procedure requires

Vertical joints made by automatic or semi Heat affect zone

101 API650 9.2.2.3

automatic also impact test

When design metal temperature less than -7ºC

102 API650 9.2.2.4 Impact test

all welding procedures requires

Nominal thick

103 Small tanks design, Appendix A API650 A.1.1

<12.5mm

104 Small tank spot RT API650 A.3.4 Joint efficiency 0.85

105 Small tanks no spot RT API650 A.3.4 Joint efficiency 0.70

Table A-

106 Capacity of the tank API650 C=0.14D²H

1b

API 653 – DAY 2 Page 4

You might also like

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- 38) Api 653 Day 1 Book (1-112)Document115 pages38) Api 653 Day 1 Book (1-112)SHAHIDALI100% (1)

- Api 653 QuestionsDocument28 pagesApi 653 Questionskorichi100% (1)

- Section 1 - Scope: API-653 Exam Prep Course BAY Technical Associates, Inc. (610) 594-9036Document49 pagesSection 1 - Scope: API-653 Exam Prep Course BAY Technical Associates, Inc. (610) 594-9036Shaalan AliNo ratings yet

- Tank-API-650-docx V-V-I-P PDFDocument20 pagesTank-API-650-docx V-V-I-P PDFtomj9104100% (1)

- Api 650Document4 pagesApi 650arif99pak100% (1)

- P Peaking BandingDocument4 pagesP Peaking BandingSUBHOMOYNo ratings yet

- API 650 PageDocument2 pagesAPI 650 PageGerry Dan ChanliongcoNo ratings yet

- API 650 Storage TankDocument9 pagesAPI 650 Storage Tankdada shaikNo ratings yet

- Storage Tank Weld JointsDocument16 pagesStorage Tank Weld JointsDilip Varadharajan100% (1)

- Essential Weld Fit-Up ChecksDocument10 pagesEssential Weld Fit-Up ChecksManoj KumarNo ratings yet

- IOCL Refinery Project Tank Settlement Survey ReportDocument1 pageIOCL Refinery Project Tank Settlement Survey Reportarkaprava ghosh100% (1)

- Storage Tank (API 650)Document20 pagesStorage Tank (API 650)sbmmla83% (6)

- Open Book For API 653Document10 pagesOpen Book For API 653Shaalan AliNo ratings yet

- Dimensional Tolerances Based On API 650Document2 pagesDimensional Tolerances Based On API 650Farhan PutraNo ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- API 650 and 653 Daily Exam QuestionsDocument5 pagesAPI 650 and 653 Daily Exam QuestionsAriq FauzanNo ratings yet

- API 653 Tank Inspection Code - 04 PDFDocument70 pagesAPI 653 Tank Inspection Code - 04 PDFvignesh100% (1)

- Api 653Document3 pagesApi 653Mohammed IlliasuddinNo ratings yet

- Open Book Testing - API 653Document9 pagesOpen Book Testing - API 653EdisonCorderoNo ratings yet

- API 653 Important Open Book Questions TableDocument11 pagesAPI 653 Important Open Book Questions TableShaalan Ali100% (1)

- Technical Inquiries To API 1104Document20 pagesTechnical Inquiries To API 1104Rey Fiedacan92% (12)

- API 510 CalculaorDocument36 pagesAPI 510 CalculaorSana Alzaki33% (3)

- SOP Hydrotest Storage TankDocument3 pagesSOP Hydrotest Storage TankRidwan Nursalam100% (1)

- Checklist Tank NewDocument11 pagesChecklist Tank NewamevaluacionesNo ratings yet

- 510 E10 Addendum1Document1 page510 E10 Addendum1Gonzalo TelleríaNo ratings yet

- This Is Very Common in Tank ConstructionDocument11 pagesThis Is Very Common in Tank ConstructionsbmmlaNo ratings yet

- Api 635 Exam PDFDocument40 pagesApi 635 Exam PDFAhmad Rizki100% (2)

- Approximate RT Calculation For API 650 TankDocument2 pagesApproximate RT Calculation For API 650 Tankjayaarnav100% (6)

- Pip Vefv1102Document1 pagePip Vefv1102ParkerNo ratings yet

- RoundnessDocument35 pagesRoundnesssrinivasansscNo ratings yet

- Asme Ix QuizDocument5 pagesAsme Ix Quizamalhaj2013No ratings yet

- Open Book For API 653Document10 pagesOpen Book For API 653jayaarnavNo ratings yet

- 2021-API 570 Piping Inspector Preparation Course BROCHUREDocument8 pages2021-API 570 Piping Inspector Preparation Course BROCHUREMarzuqi A. Halim100% (1)

- Api 653Document11 pagesApi 653raghava1975No ratings yet

- PWHT For Shell Nozzle of Steel Storage Tanks-21Document27 pagesPWHT For Shell Nozzle of Steel Storage Tanks-21الGINIRAL FREE FIRE100% (1)

- Tank Settlement Report As Per API 653Document2 pagesTank Settlement Report As Per API 653Toñita Ramos0% (1)

- Welded Tube Joint SpecDocument8 pagesWelded Tube Joint SpecAvinash ShuklaNo ratings yet

- Pipe Fitting Weight ChartDocument1 pagePipe Fitting Weight Chartab5918590No ratings yet

- API 650 Technical Inquiries SummaryDocument28 pagesAPI 650 Technical Inquiries SummaryIgnatios Staboulis0% (1)

- API 653 Exam 1 Prep Course QuestionsDocument4 pagesAPI 653 Exam 1 Prep Course Questionsgurdeepsarora873871% (7)

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationDocument8 pagesAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinNo ratings yet

- ASME Section VIII Div 2 Welded Joint CategoriesDocument17 pagesASME Section VIII Div 2 Welded Joint CategoriesnanivenkatgauravNo ratings yet

- API 653 PC Final OpenDocument7 pagesAPI 653 PC Final OpenMuhammad Nozar100% (1)

- Vaccum Test MethodDocument4 pagesVaccum Test MethodMahmud AlamNo ratings yet

- API 510 QUIZ No.1Document3 pagesAPI 510 QUIZ No.1Hatem RagabNo ratings yet

- Oil Penetration Leak Test Procedure Rev ADocument4 pagesOil Penetration Leak Test Procedure Rev AAzuwan MohamadNo ratings yet

- API653 Closed Book QDocument23 pagesAPI653 Closed Book Qabsarya100% (8)

- Welded Tank Oil Storage Inspection StandardDocument106 pagesWelded Tank Oil Storage Inspection StandardiraprobotNo ratings yet

- 39) API 653 DAY 2 BOOK (1 To 46)Document46 pages39) API 653 DAY 2 BOOK (1 To 46)SHAHIDALI100% (1)

- Daily Revise - Practice Southern InspectionDocument113 pagesDaily Revise - Practice Southern Inspectionajayachuth97No ratings yet

- Inspection and Repair of Storage Tanks 1710346228Document113 pagesInspection and Repair of Storage Tanks 1710346228Jayapal BhukyaNo ratings yet

- Annular Plate CalculationDocument1 pageAnnular Plate CalculationTanish Ramasamy SekarNo ratings yet

- GLV-Catalogue - Botil IndiaDocument18 pagesGLV-Catalogue - Botil IndiaHamza LamamraNo ratings yet

- VT IPH 21 BDI 90115 enDocument16 pagesVT IPH 21 BDI 90115 enwag008No ratings yet

- STC (Buffer Tank 25KL) - Calc PDFDocument4 pagesSTC (Buffer Tank 25KL) - Calc PDFAvril Rindra T PNo ratings yet

- K65 Tubes PDFDocument4 pagesK65 Tubes PDFAnonymous rZVnzuKTNo ratings yet

- EIL motive power cells Flooded tubular technologyDocument20 pagesEIL motive power cells Flooded tubular technologyHareeshNo ratings yet

- Lead Free Brass Ball ValveDocument1 pageLead Free Brass Ball ValveS V RAJA LEHRYNo ratings yet

- RS-13 5-8-5m Annular BOP Operaion ManualDocument6 pagesRS-13 5-8-5m Annular BOP Operaion ManualAlexsandro Cordeiro100% (2)

- Welding Defects and PropertiesDocument85 pagesWelding Defects and PropertiesSamet BelliNo ratings yet

- English - Can Do - Interactive Picture Dictionary & Word GamesDocument77 pagesEnglish - Can Do - Interactive Picture Dictionary & Word GamesPrimagamaEnglishCourseGarutNo ratings yet

- Ovality MisaligntDocument1 pageOvality MisaligntSamet BelliNo ratings yet

- Nwtcs Oct 09Document6 pagesNwtcs Oct 09Samet BelliNo ratings yet

- Welding and Cutting SampleDocument64 pagesWelding and Cutting SampleCalberttNo ratings yet

- Welding EngineerDocument10 pagesWelding EngineerNnamdi Celestine NnamdiNo ratings yet

- Welding of P91Document37 pagesWelding of P91Shyam Sundar GayenNo ratings yet

- Welding and Cutting SampleDocument64 pagesWelding and Cutting SampleCalberttNo ratings yet

- WeldingofStainlesssSteelandotherJoiningMethods 9002Document0 pagesWeldingofStainlesssSteelandotherJoiningMethods 9002jvs11021102No ratings yet

- API 650 PoıntsDocument4 pagesAPI 650 PoıntsSamet BelliNo ratings yet

- Standard Test Method Visual Inspection: WARNING: UNCONTROLLED COPY Printed On 15/12/09. Check For Latest Issue Before UseDocument2 pagesStandard Test Method Visual Inspection: WARNING: UNCONTROLLED COPY Printed On 15/12/09. Check For Latest Issue Before UseSamet BelliNo ratings yet

- FlangeDocument11 pagesFlangeSamet BelliNo ratings yet

- HeatTreatingDataEBook 2011Document115 pagesHeatTreatingDataEBook 2011mario fisgaNo ratings yet

- MT CodeDocument11 pagesMT CodeSamet BelliNo ratings yet

- Metal Welding - Types and ProcessesDocument4 pagesMetal Welding - Types and ProcessesuismechprojectNo ratings yet

- AWS ELECTRODE CLASSIFICATION GUIDEDocument8 pagesAWS ELECTRODE CLASSIFICATION GUIDEFuaz Sukarya Abu Fatih100% (1)

- 054 - Welding Engineering BookletDocument8 pages054 - Welding Engineering BookletAnonymous 8s5BkZAjNo ratings yet

- AWS ELECTRODE CLASSIFICATION GUIDEDocument8 pagesAWS ELECTRODE CLASSIFICATION GUIDEFuaz Sukarya Abu Fatih100% (1)

- Interpretationanddocumentationiso9001 151210114259Document134 pagesInterpretationanddocumentationiso9001 151210114259Samet BelliNo ratings yet

- HdpeeDocument38 pagesHdpeeSamet BelliNo ratings yet

- Boehler EMK 6 de en 5Document1 pageBoehler EMK 6 de en 5Samet BelliNo ratings yet

- Available Standards Presentation by TWI 21.10.2010Document52 pagesAvailable Standards Presentation by TWI 21.10.2010Zeljko RisticNo ratings yet

- ASNT NDT Level III Certification GuideDocument8 pagesASNT NDT Level III Certification GuideIndigo Wave0% (2)

- HDPE Lining Case StudyDocument9 pagesHDPE Lining Case StudymujeebscribdNo ratings yet

- Electrofusion CouplingsDocument27 pagesElectrofusion CouplingsSamet BelliNo ratings yet

- GSE Geomembrane IQAM GuideDocument47 pagesGSE Geomembrane IQAM GuideSamet Belli0% (1)

- HDPE Typical Pipe SizesDocument2 pagesHDPE Typical Pipe SizesSamet Belli100% (2)

- Welding Defect Causes and CuresDocument19 pagesWelding Defect Causes and CuresMohammed Mushraf UddinNo ratings yet

- 15 Destructive Testing Production WeldsDocument6 pages15 Destructive Testing Production WeldsAkhilesh KumarNo ratings yet

- English Solar Farm Proposal by TSF Oct 123Document38 pagesEnglish Solar Farm Proposal by TSF Oct 123Atiqah HamzahNo ratings yet

- Sigma Marine Coatings Manual - Part106Document2 pagesSigma Marine Coatings Manual - Part106Tommy2020No ratings yet

- Inst TMRT Brochure PDFDocument2 pagesInst TMRT Brochure PDFgrupa2904No ratings yet

- MGD2004D FL Ybs PDFDocument10 pagesMGD2004D FL Ybs PDFEverton DoradoNo ratings yet

- Amplifier Owner'S Manual: Power AmplifiersDocument19 pagesAmplifier Owner'S Manual: Power AmplifiersJose Antonio Montiel QuirosNo ratings yet

- 5kv CableDocument2 pages5kv Cableencarn1092No ratings yet

- Tie 2016Document8 pagesTie 2016Cristian MăndicăNo ratings yet

- Tamilnadu Engineering Admissions 2011 - Information About The CollegesDocument288 pagesTamilnadu Engineering Admissions 2011 - Information About The CollegeskayalonthewebNo ratings yet

- Pad Eye ACS 10Document10 pagesPad Eye ACS 10irnaldi yoza wijayaNo ratings yet

- House in Mediterranean ClimateDocument25 pagesHouse in Mediterranean ClimateRgv RebeiraNo ratings yet

- Smartlight Installation and Programing ManualDocument72 pagesSmartlight Installation and Programing ManualQuick sickNo ratings yet

- Tia13 13 2Document47 pagesTia13 13 2Vidur ShibnauthNo ratings yet

- Belt Weigh Scale PDFDocument33 pagesBelt Weigh Scale PDFMohammad AsifNo ratings yet

- Soil Testing 1 - Shear Strength - Part IDocument20 pagesSoil Testing 1 - Shear Strength - Part IamoddatherNo ratings yet

- ChillerDocument79 pagesChillerSameera LakmalNo ratings yet

- G314 PDFDocument4 pagesG314 PDFAnonymous Q6OloSJcvmNo ratings yet

- BSI Group - Smart-cities-report-Mapping-Smart-City-Standards-UK-EN PDFDocument47 pagesBSI Group - Smart-cities-report-Mapping-Smart-City-Standards-UK-EN PDFPepe JeansNo ratings yet

- Mach 3 Brochure enDocument3 pagesMach 3 Brochure enIsaías AguilarNo ratings yet

- Data Sheet ASTM A514 Grade B 2017-04-19 221 371857150 enDocument2 pagesData Sheet ASTM A514 Grade B 2017-04-19 221 371857150 enkanteron6443No ratings yet

- Buyers Guide For MDUDocument18 pagesBuyers Guide For MDUjatinrastogi28No ratings yet

- Journalnx ToolDocument3 pagesJournalnx ToolJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- DLNSS BL2PDF 9 24 13 PDFDocument65 pagesDLNSS BL2PDF 9 24 13 PDFaswardiNo ratings yet

- Census of India 2011 Houses, Household Amenities and Assets Figures at A GlanceDocument12 pagesCensus of India 2011 Houses, Household Amenities and Assets Figures at A GlanceHashirKhanNo ratings yet

- Owner Manual 4stroke 2007 Eng st1Document80 pagesOwner Manual 4stroke 2007 Eng st1Brian ConacherNo ratings yet

- CDJ 100SDocument28 pagesCDJ 100SMarcos ZanelliNo ratings yet

- Group - 6 MobileyeDocument14 pagesGroup - 6 MobileyevNo ratings yet

- Profile Company JagDocument4 pagesProfile Company JagYudhistira PratamaNo ratings yet

- W.A.T.T.: Design Project Check ListDocument2 pagesW.A.T.T.: Design Project Check ListDhanya Geethanjali SasidharanNo ratings yet

- Optical Network Monitoring System Onmsi Ensures Municipality Fiber Network Availability Case StudiesDocument2 pagesOptical Network Monitoring System Onmsi Ensures Municipality Fiber Network Availability Case StudiesgagaNo ratings yet

- SunstoneDocument8 pagesSunstonePisos PorcelánicosNo ratings yet