Professional Documents

Culture Documents

APRA Position Paper 2

Uploaded by

Craciun AlexandruCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APRA Position Paper 2

Uploaded by

Craciun AlexandruCopyright:

Available Formats

Remanufacturing as best practice of the Circular Economy

A Position Paper of the Automotive Parts Remanufacturer Association – Europe

Key messages:

1. Remanufacturing is an essential part of the automotive aftermarket with growing relevance in the future.

2. A remanufactured product is a best value proposition for the end customer.

3. Remanufacturing is sustainable and reduces CO2eq at lower costs for the consumer.

4. Remanufacturing is a best practice of circular economy but needs political support.

The importance of circular economy for the automotive aftermarket:

For service and maintenance of motor vehicles, the automotive industry has to provide the relevant spare parts

to the aftermarket. These service parts have

to be available for decades after the original

parts were developed and produced. Market

demands, even for older vehicles, quality

spare parts at a reasonable price. Often,

this is only possible with a remanufactured

product.

The customer has, when purchasing a

remanufactured spare part, the right to

return the defect used part [Core] out of his

vehicle. The reverse logistic process, back

to the supplier is supported by financial

incentives. Cores are the raw material for

the next remanufacturing cycle. Within the

European Community about 10% of the technical spare parts in the automotive aftermarket are remanufactured.

The automotive aftermarket and future challenges:

Motor vehicles are progressively getting more complex using

specific production processes and a higher diversity of materials.

Many of these specific production processes will not be available in

future decades. For example today the life-cycle of semiconductors

is less than the production life of a vehicle. We can expect that in

the future the production costs of new spare parts will dramatically

increase.

Without remanufacturing, spare parts for a reasonable price will not

be available. Relatively new cars will be scraped as maintenance is

getting unaffordable and prohibitive for the customer.

Today the preferred end of life treatment of motor vehicles is

shredding. Actual processes are highly efficient to reach the legally

requested demands. But most of the materials besides iron, aluminum and copper are lost. Future need to

recover strategic elements cannot be achieved with today’s recycling technology.

page 1/2

Automotive Parts Remanufacturers Association USA

7250 Heritage Village Plaza, Suite 201

Gainesville, VA 20155

USA

Phone: +001 703 968-2772

Fax: +001 703 753-2445

info@apra.org

www.apra.org

Tax ID: 53-0260372

The remanufacturing process

A remanufactured part fulfills a function which is at least equivalent

compared to the original part. It is restored from an existing part (Core),

using standardized industrial processes in line with specific technical

specifications. A remanufactured part is given the same warranty as a

new part and it clearly identifies the part as a remanufactured part and

states the remanufacturer.

Social and environmental benefits of remanufacturing

In the remanufacturing process the core (failed part) is used as raw material for the production.

REMANUFACTURING has positive impacts on:

Environment

Reducing potential of CO2 emissions by 400 kt

(only EU 28).

Saving natural resources – up to 85% of

raw material – using only 55% of the energy

compared to that of producing a new unit.

Safety

Remanufactured products fulfill the equivalent

function and are warranted as the “original

product”.

Employment

32,000 jobs are offered (only EU 28).

Economy

Best choice for the end user by offering the

best quality at a reasonable price compared with a new unit.

How to make circular economy fit for success – policy recommendations

• The used part, intended to be remanufactured [Core], is the raw material for remanufacturing. This core

should be handled and declared as valuable raw material within reverse logistics. An official guideline for

transport and customs declaration is missing.

• The reverse logistic process is supported with financial incentives, a surcharge. Various tax authorities

are tempted to consider the core surcharge as an income, turnover. If we are committed to the circular

economy surcharges should be free of tax / VAT.

• Cars have become more and more „computers on wheels“. While technological innovations provide

better emissions control as well as more safety and comfort, they make it challenging to service or repair

a vehicle and to remanufacture the parts.

• The right to repair, including the access to technical information has to be extended for the automotive

remanufacturing.

• To ensure that strategic elements and materials stay in the production cycle, remanufacturing should be

positioned as preferred end of life treatment in related legal guidelines.

About APRA:

APRA is a global association with over 1,000 member companies with a combined revenue of approximately

25 billion euros.

The Association’s objective is to promote the general business interests of the remanufacturing industry as a

whole and to foster the spirit of circular economy in pursuit of a better environment. It also provides members

with forums, exhibitions and workshops to interact and consult with each other on issues affecting the entire

industry.

page 2/2

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Blades in The Dark - Doskvol Maps PDFDocument3 pagesBlades in The Dark - Doskvol Maps PDFRobert Rome20% (5)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Annotated BibliographyDocument9 pagesAnnotated Bibliographyapi-309971310100% (2)

- Agricultural Machinery 2018-2019Document548 pagesAgricultural Machinery 2018-2019Craciun AlexandruNo ratings yet

- Istambul: Cheltuieli de Promovare, Participare La Târguri, Evenimente, Conferințe, Cheltuieli Privind StudiileDocument2 pagesIstambul: Cheltuieli de Promovare, Participare La Târguri, Evenimente, Conferințe, Cheltuieli Privind StudiileCraciun AlexandruNo ratings yet

- Employee salaries over 4 quartersDocument1 pageEmployee salaries over 4 quartersCraciun AlexandruNo ratings yet

- Employee salaries over 4 quartersDocument1 pageEmployee salaries over 4 quartersCraciun AlexandruNo ratings yet

- Employee salaries over 4 quartersDocument1 pageEmployee salaries over 4 quartersCraciun AlexandruNo ratings yet

- Full Explanation of AlternatorDocument32 pagesFull Explanation of AlternatorEddwin Rodri RodriguezNo ratings yet

- CVT-7A Alternator ConnectionsDocument3 pagesCVT-7A Alternator ConnectionsCraciun AlexandruNo ratings yet

- Aviation Industry in India - Challenges For The Low Cost CarriersDocument11 pagesAviation Industry in India - Challenges For The Low Cost Carrierstake3No ratings yet

- 12 Jun 2019 PDFDocument12 pages12 Jun 2019 PDFAnonymous dy7g4jzo7No ratings yet

- Economic History of The PhilippinesDocument4 pagesEconomic History of The PhilippinesClint Agustin M. RoblesNo ratings yet

- Questions With Answers On is-LM ModelDocument12 pagesQuestions With Answers On is-LM ModelAkshay Singh67% (3)

- Inter-regional disparities in industrial growthDocument100 pagesInter-regional disparities in industrial growthrks_rmrctNo ratings yet

- List of Maharashtra Pharrma CompaniesDocument6 pagesList of Maharashtra Pharrma CompaniesrajnayakpawarNo ratings yet

- 10.18.2017 LiabiltiesDocument4 pages10.18.2017 LiabiltiesPatOcampoNo ratings yet

- The Impact of Colonialism On African Economic DevelopmentDocument13 pagesThe Impact of Colonialism On African Economic Developmentsulaiman yusufNo ratings yet

- 4 93-F Y B A - Micro-EconomicsDocument3 pages4 93-F Y B A - Micro-EconomicsSanjdsgNo ratings yet

- IBM - Multiple Choice Questions PDFDocument15 pagesIBM - Multiple Choice Questions PDFsachsanjuNo ratings yet

- Iraqi Dinar - US and Iraq Reached On Agreement To IQD RV - Iraqi Dinar News Today 2024Document2 pagesIraqi Dinar - US and Iraq Reached On Agreement To IQD RV - Iraqi Dinar News Today 2024Muhammad ZikriNo ratings yet

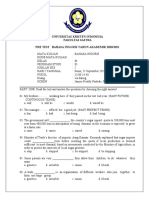

- Pre Test of Bahasa Inggris 21 - 9 - 2020Document5 pagesPre Test of Bahasa Inggris 21 - 9 - 2020magdalena sriNo ratings yet

- IBT-REVIEWERDocument10 pagesIBT-REVIEWERBrenda CastilloNo ratings yet

- 2011 - PSEP 01 Main Report PDFDocument204 pages2011 - PSEP 01 Main Report PDFNaveed ChandioNo ratings yet

- An Introduction To Private Sector Financing of Transportation InfrastructureDocument459 pagesAn Introduction To Private Sector Financing of Transportation InfrastructureBob DiamondNo ratings yet

- Bridge Over Bhagirathi AllotmentDocument6 pagesBridge Over Bhagirathi AllotmentKyle CruzNo ratings yet

- Fremantle Line: Looking For More Information?Document12 pagesFremantle Line: Looking For More Information?lerplataNo ratings yet

- Ratan TataDocument7 pagesRatan TatadrankurshahNo ratings yet

- E@@e ®@@e ®@@e: M.A. ECONOMICS (With Specialization in World Economy)Document27 pagesE@@e ®@@e ®@@e: M.A. ECONOMICS (With Specialization in World Economy)SimeonNo ratings yet

- Ethio-Views Online News PaperDocument1 pageEthio-Views Online News PaperBelayneh zelelewNo ratings yet

- Sales and Purchases 2021-22Document15 pagesSales and Purchases 2021-22Vamsi ShettyNo ratings yet

- Airborne Express CaseDocument3 pagesAirborne Express Casehowlnmadmurphy2No ratings yet

- Schram y Pavlovskaya ED 2017 Rethinking Neoliberalism. Resisiting The Disciplinary Regime LIBRODocument285 pagesSchram y Pavlovskaya ED 2017 Rethinking Neoliberalism. Resisiting The Disciplinary Regime LIBROJessica ArgüelloNo ratings yet

- Week 8Document2 pagesWeek 8Nikunj D Patel100% (1)

- Energia Solar en EspañaDocument1 pageEnergia Solar en EspañaCatalin LeusteanNo ratings yet

- Neoliberalising The Urban New Geographies of Power and Injustice in Indian CitiesDocument13 pagesNeoliberalising The Urban New Geographies of Power and Injustice in Indian CitiesHash SinghNo ratings yet

- 1 Fmom - Basic Supporting DocumentDocument50 pages1 Fmom - Basic Supporting DocumentArnold BaladjayNo ratings yet

- Fisker Karma Specs V2Document1 pageFisker Karma Specs V2LegacyforliveNo ratings yet