Professional Documents

Culture Documents

Capacitors Discharge Stud Specifications

Uploaded by

Najib KiwanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Capacitors Discharge Stud Specifications

Uploaded by

Najib KiwanCopyright:

Available Formats

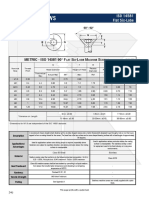

Capacitors Discharge

CFT Flanged

Threaded studs

Stud Material : • Mild Steel 4.8

• Stainless Steel 304,

316, 310

• Brass CuZn37

• Aluminum AlMg3

Dimensions of threaded studs (CFT)

d1 l1 d2 (± 0.2) d4 (± 0.08) l3 (± 0.05) Max h2 h1 α ±1°

6

8

10

12

M3 16 4.5 0.60 0.55 0.6 0.7 to 1.4 3°

20

25

30

35

6

8

10

12

M4 16 5.5 0.65 0.55 0.6 0.7 to 1.4 3°

20

25

30

35

6

8

10

12

16

20

M5 6.5 0.75 0.80 1.0 0.7 to 1.4 3°

25

30

35

40

45

60

8

10

12

16

20

25

M6 30 7.5 0.75 0.80 1.0 0.7 to 1.4 3°

35

40

45

50

..

100

10

12

16

20

25

30

M8 9.0 0.75 0.85 1.5 0.8 to 1.4 3°

35

40

45

50

..

100

Dimensions in mm. We can supply other lengths or dimensions upon request

ZI , 3eme RUE B. 6040 JUMET

TEL : + 32 71.91.97.60 FAX : + 32 71.91.96.71

Web : www.thomas-welding.com

E-mail : info@thomas-welding.com

Basic engineering specifications, which cover all of the studs listed in this publication regardless of size or shape, are

detailed below.

1. Stud material

• Non-alloyed steel

All THOMAS low carbon steel studs are 4.8 steel (weldable) made to our specifications.

This type of steel offers excellent welding quality.

The mechanical propoterites conforms to ISO 898-1 (4.8 property class).

The raw material specifications mentioned conform with EN ISO 13918 and EN ISO 14555.

• Stainless steel 1.4301/1.4303, 1.4571, 1.4401

THOMAS studs are manufactured from material conforming to EN ISO 3506-1.

The raw material specifications mentioned conform with EN ISO 13918 and EN ISO 14555.

• Upon request, for all stud material, certificates of chemical analysis and mechanical properties can be

supplied. This conforms to EN 10204.

The mechanical properties for threaded studs depend on the type of treatment applied to the material, with

the following values guaranteed as minimums:

CFT / AFT Maximum Fastening Torque (in Ncm)

Stud Material Mild steel 4.8 Stainless steel A2-50 Brass Ms 63 Aluminum Almg3

M3 80 50 60 40

M4 180 110 130 90

M5 360 230 270 190

M6 610 380 450 310

M8 1500 950 1100 750

Tensile force limit according to ISO 18800-1 (without deformation)

Code Material Standard Mechanical properties

EN 20898-1 Rm > 420 NR,d = ASP x fu,b,k/(1.25 xym)

EN 20898-1 ReH > 340 N/mm2 fu,b,k = Rm

4.8 *1

EN 20898-1 A5 > 14%

These specifications are only guide

values, as the torque and minimum

CFT EN ISO 3506-3 Rm > 500 failing load depend on the thickness

A2-50 *2 EN ISO 3506-3 Rp 0,2 > 340 N/mm2 and strength of the base material.

EN ISO 3506-3 Al > 0.6 d

ISO 426-1

CuZn37 Rm > 370 N/mm2

ISO 1638

EN AW-AlMg3 EN 573-3 Rm > 180 N/mm2

*1 Plain steel studs are suitable for welding, if the hardness increase is low (C < 0.18%).

Free-cutting steel studs are not suitable for welding.

*2 As a rule, stainless steel studs are suitable for welding, but free-cutting steel studs are not.

2. Stud dimensions

Stud dimensions as given in the dimensional sheet meet the EN ISO 13918 specifications. The length

dimension l2 is the overall length of the stud AFTER WELD. i.e. THOMAS studs are always longer than the

nominal length ordered. Our studs comply with product grade A as specified in ISO 4759-1.

3. Threads

All threads are cold rolled. (Therefore the flow-line of material is not interrupted.) The surface quality is

considerably improved, and its strength is doubled. The thread is less subject to wear and offers more

resistance to corrosion. All THOMAS studs are fitted with threads in accordance with DIN 13, Sheet 20, 6g

4. Plating Available

Unless otherwise specified in the order, all THOMAS low carbon steel studs will be supplied in tensile

class 4.8 electrolytically copper coated (C2E, ISO 4042).

Upon request, other types of surface protection can be supplied: but a minimum order quantity applies.

5. Ordering information

The following specifications are required when ordering :

a) Type of stud

b) Stud diameter “d”

c) Stud length “l”

d) Material

e) Surface protection

Ordering example: CFT M6 x 16 mm in coppered steel.

FT–CFT–0663/2. Issued : 21 January 2007

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Complete Fastener Solutions Hexagon BoltsDocument2 pagesComplete Fastener Solutions Hexagon Boltscoolkaisy100% (2)

- Technical Data Sheet Product CatalogueDocument16 pagesTechnical Data Sheet Product CatalogueKamalNo ratings yet

- High Tensile Bolts TechnicalDocument6 pagesHigh Tensile Bolts Technicalventhan_kalaiNo ratings yet

- RITZ Screw Specification PDFDocument12 pagesRITZ Screw Specification PDFThawatchai DanwangkhawNo ratings yet

- Metric Hex Bolt DimensionsDocument7 pagesMetric Hex Bolt DimensionsVishal MistryNo ratings yet

- WSA 109 - 2011 Flange Gaskets Working SheetDocument1 pageWSA 109 - 2011 Flange Gaskets Working SheetAbit BronjaNo ratings yet

- Fiber Laser Cutting ParametersDocument25 pagesFiber Laser Cutting ParametersKerry Saintz100% (1)

- SAMPAG ANCHOR CHANELS CatalogueNo.8 PDFDocument40 pagesSAMPAG ANCHOR CHANELS CatalogueNo.8 PDFKemo TufoNo ratings yet

- Iso 14581 CSK ScrewDocument1 pageIso 14581 CSK ScrewMitesh MakvanaNo ratings yet

- Din 933Document2 pagesDin 933Sugumar0% (1)

- High Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)Document2 pagesHigh Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)jaison jacobNo ratings yet

- Metric DIN 985 Nylon Insert Lock Nut Dimensions & SpecsDocument4 pagesMetric DIN 985 Nylon Insert Lock Nut Dimensions & Specsvikram jainNo ratings yet

- Data Sheet 30 - Fig Tb705 Basket (Top Hat) StrainerDocument1 pageData Sheet 30 - Fig Tb705 Basket (Top Hat) StrainerSteve NewmanNo ratings yet

- Data Sheet 30 - Fig TB705 Basket (Top Hat) StrainerDocument1 pageData Sheet 30 - Fig TB705 Basket (Top Hat) StrainerSteve NewmanNo ratings yet

- 4.5.Material DescriptionDocument1 page4.5.Material DescriptionAhmed Hamdy WorkNo ratings yet

- Cromax 4140 PDFDocument2 pagesCromax 4140 PDFDidik PrihantoroNo ratings yet

- Instrumentation Tubing ENDocument5 pagesInstrumentation Tubing ENLuis CasasNo ratings yet

- SCRM BrochureDocument6 pagesSCRM BrochureRizwan TonoyNo ratings yet

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745No ratings yet

- Engineer's Handbook General Part: Torque Specification For Bolted ConnectionsDocument2 pagesEngineer's Handbook General Part: Torque Specification For Bolted ConnectionsenzobvNo ratings yet

- Recommended Assembly Torques 2016Document9 pagesRecommended Assembly Torques 2016Mohamed ElkadyNo ratings yet

- Table 5 - Wire Type IQI Selection Table 5 - Wire Type IQI SelectionDocument3 pagesTable 5 - Wire Type IQI Selection Table 5 - Wire Type IQI SelectionBhanu Pratap ChoudhuryNo ratings yet

- Kaysafe Engineering - Data Sheet 30 - Fig Tb705 Basket (Top Hat) StrainerDocument1 pageKaysafe Engineering - Data Sheet 30 - Fig Tb705 Basket (Top Hat) StrainerSteve NewmanNo ratings yet

- PT. SWADAYA GRAHA Engineering TablesDocument9 pagesPT. SWADAYA GRAHA Engineering TablesAndri EkoNo ratings yet

- Soft Magnetic Iron-Nickel AlloysDocument9 pagesSoft Magnetic Iron-Nickel AlloysmiguelNo ratings yet

- Bolt Din 933Document2 pagesBolt Din 933anNo ratings yet

- 316 Stainless Steel Filler Rod and Wire for Urea PlantDocument1 page316 Stainless Steel Filler Rod and Wire for Urea Plantamit singhNo ratings yet

- M48D965Document1 pageM48D965Gulfstream Data, IncNo ratings yet

- #Kobelco Welding Hand BookDocument1 page#Kobelco Welding Hand BookIradahNo ratings yet

- Tool Steel Classification Guide for Properties & CompositionDocument6 pagesTool Steel Classification Guide for Properties & CompositionDiogo HofmamNo ratings yet

- Tool Steel ClassificationsDocument6 pagesTool Steel ClassificationsTalha MahmoodNo ratings yet

- Aluminium IndustrialDocument150 pagesAluminium IndustrialAhtesham AnsariNo ratings yet

- Tabel UkuranDocument11 pagesTabel Ukurans.iskandarNo ratings yet

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDocument4 pagesMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNo ratings yet

- Metric Thread Size Spanner Size A/F DIN (MM) Spanner Size A/F ISO (MM)Document3 pagesMetric Thread Size Spanner Size A/F DIN (MM) Spanner Size A/F ISO (MM)kianoush Volvo construction equipmentNo ratings yet

- Metric Fastener Dimensions and SpecificationsDocument1 pageMetric Fastener Dimensions and SpecificationsDerekNo ratings yet

- Chemical Composition % of Steel C40 (1.0511) : EN 10277-2-2008Document1 pageChemical Composition % of Steel C40 (1.0511) : EN 10277-2-2008CorneNo ratings yet

- Catalogo de Ejes CromsteelDocument20 pagesCatalogo de Ejes CromsteelJhonFerneyBohorquezSaldarriagaNo ratings yet

- IQI All CodeDocument3 pagesIQI All CodeSlamet RiyadiNo ratings yet

- Table 5 Wire Type IQI Selection Table 1Document3 pagesTable 5 Wire Type IQI Selection Table 1Kali AbdennourNo ratings yet

- Hexagon weld nut technical data and article overviewDocument4 pagesHexagon weld nut technical data and article overviewRidhwan MohamedNo ratings yet

- 7 Tool Steels1Document12 pages7 Tool Steels1ontc0109No ratings yet

- NNDDocument9 pagesNNDdardakNo ratings yet

- TurnbucklesDocument4 pagesTurnbucklesFunda TuranNo ratings yet

- Low Alloy Steels Part2 PDFDocument1 pageLow Alloy Steels Part2 PDFnedunchiNo ratings yet

- Socket Head Cap Screws Dimensions and Torque SpecsDocument4 pagesSocket Head Cap Screws Dimensions and Torque SpecssarbiniNo ratings yet

- Drive Technology: Couplings Torque Limiters Clamping Elements Torque Measuring SystemsDocument3 pagesDrive Technology: Couplings Torque Limiters Clamping Elements Torque Measuring SystemsELİF ORTANo ratings yet

- FlangeDocument10 pagesFlangeNurul LailyahNo ratings yet

- ASTM A789 Duplex Stainless TubingDocument10 pagesASTM A789 Duplex Stainless Tubingmathew holeyNo ratings yet

- Welding Rod SpecDocument1 pageWelding Rod SpecMuhammad Hasbi AsidiqiNo ratings yet

- Stainless Steel GradesDocument8 pagesStainless Steel Gradesnathan1979No ratings yet

- Din 17175 PDFDocument22 pagesDin 17175 PDFMilica Antic0% (1)

- Sheetpile Steel Grade PDFDocument4 pagesSheetpile Steel Grade PDFDicaNo ratings yet

- HSFG Part II Bolt & NutDocument1 pageHSFG Part II Bolt & NutvpjagannaathNo ratings yet

- Pipa Lindi TPA Kabupaten KendalDocument1 pagePipa Lindi TPA Kabupaten KendalShafa MauliarizkyNo ratings yet

- A 489 - 00 - Qtq4os1sruqDocument6 pagesA 489 - 00 - Qtq4os1sruqAnderson VelandiaNo ratings yet

- Copper THHN-THWN-2Document1 pageCopper THHN-THWN-2carlosNo ratings yet

- Brochure Bohler Benelux PDFDocument8 pagesBrochure Bohler Benelux PDFBarcelonaNo ratings yet

- Validation Des Poteaux Pour Les Clotures Avec OcculationDocument2 pagesValidation Des Poteaux Pour Les Clotures Avec OcculationNajib KiwanNo ratings yet

- Mechanical Load and French RegulationsDocument2 pagesMechanical Load and French RegulationsNajib KiwanNo ratings yet

- Serie 8560: Cerniere / HingesDocument2 pagesSerie 8560: Cerniere / HingesNajib KiwanNo ratings yet

- CW-FS Cavity Barriers & Fire Stops For Curtain Walling 2120Document9 pagesCW-FS Cavity Barriers & Fire Stops For Curtain Walling 2120Najib KiwanNo ratings yet

- Achieving Safer and More Economical Buildings Through Database-Assisted, Reliability-Based Design For WindDocument25 pagesAchieving Safer and More Economical Buildings Through Database-Assisted, Reliability-Based Design For WindNajib KiwanNo ratings yet

- CW-FS Cavity Barriers & Fire Stops For Curtain Walling 2120Document9 pagesCW-FS Cavity Barriers & Fire Stops For Curtain Walling 2120Najib KiwanNo ratings yet

- Emerge UK - GeneralDocument9 pagesEmerge UK - GeneralNajib KiwanNo ratings yet

- Shoe Brakes N.hyd - NV - HydDocument1 pageShoe Brakes N.hyd - NV - HydNajib KiwanNo ratings yet

- BB93 February 2015Document43 pagesBB93 February 2015pero_peric4No ratings yet

- Boral Plasterboards CatalogueDocument15 pagesBoral Plasterboards Catalogueteng fsNo ratings yet

- SIDERISE CW curtain wall fire barriersDocument22 pagesSIDERISE CW curtain wall fire barriersNajib KiwanNo ratings yet

- N42SMEDocument1 pageN42SMENajib KiwanNo ratings yet

- Dynamics in Building Design: Dynamic Properties of Building StructuresDocument9 pagesDynamics in Building Design: Dynamic Properties of Building StructuresNajib KiwanNo ratings yet

- SWIVEL FITTINGS PROVIDE STRENGTH AND FLEXIBILITY FOR INSULATED GLASS UNITSDocument1 pageSWIVEL FITTINGS PROVIDE STRENGTH AND FLEXIBILITY FOR INSULATED GLASS UNITSNajib KiwanNo ratings yet

- Curtain Wall DesignDocument10 pagesCurtain Wall DesignNajib KiwanNo ratings yet

- Canopy LoadDocument6 pagesCanopy LoadNajib KiwanNo ratings yet

- Choosing the Correct Space Frame StructureDocument27 pagesChoosing the Correct Space Frame StructureNajib KiwanNo ratings yet

- Curtain Wall DesignDocument10 pagesCurtain Wall DesignNajib KiwanNo ratings yet

- Canopy LoadDocument6 pagesCanopy LoadNajib KiwanNo ratings yet

- E308 16Document1 pageE308 16Najib KiwanNo ratings yet

- Bolt TableDocument1 pageBolt TableErebert C. CaracasNo ratings yet

- Welding Stainless Steels-LincolnelectricDocument40 pagesWelding Stainless Steels-LincolnelectricsachinumaryeNo ratings yet

- Catalog GlassfireDocument76 pagesCatalog GlassfireNajib KiwanNo ratings yet

- Dynamics in Building Design: Dynamic Properties of Building StructuresDocument9 pagesDynamics in Building Design: Dynamic Properties of Building StructuresNajib KiwanNo ratings yet

- Direct Analysis Method in RSADocument17 pagesDirect Analysis Method in RSANajib KiwanNo ratings yet

- Wing Bracket DesignDocument7 pagesWing Bracket DesignNajib KiwanNo ratings yet

- Canopy LoadDocument6 pagesCanopy LoadNajib KiwanNo ratings yet

- SJ MEPLA Calculation Protocol:: Basic Form: QuadrangleDocument3 pagesSJ MEPLA Calculation Protocol:: Basic Form: QuadrangleNajib KiwanNo ratings yet

- Film Shield UK Bomb Blast TestDocument1 pageFilm Shield UK Bomb Blast TestNajib KiwanNo ratings yet

- A Review of Natural Fiber Composites PropertiesDocument65 pagesA Review of Natural Fiber Composites Propertieschatgpt51023No ratings yet

- Chemical Engineering Laboratory-1 (CHE F312) Lab Report Engineering Chemistry Lab E-1 Thin Layer ChromatographyDocument13 pagesChemical Engineering Laboratory-1 (CHE F312) Lab Report Engineering Chemistry Lab E-1 Thin Layer ChromatographyHritik LalNo ratings yet

- Technical Data Sheet Permatex General Purpose Epoxy ProductsDocument2 pagesTechnical Data Sheet Permatex General Purpose Epoxy ProductsΧρήστος πορηςNo ratings yet

- Ratio - 3: Mixtures and Alligation QA QuestionsDocument8 pagesRatio - 3: Mixtures and Alligation QA QuestionsAjeet Singh IMS JaipurNo ratings yet

- EM Complete NotesDocument191 pagesEM Complete NoteswsbwaqhpwpvcwuhajkNo ratings yet

- 10151A1Document3 pages10151A1Archana ShuklaNo ratings yet

- Lcy 6733Document1 pageLcy 6733quangga10091986No ratings yet

- Crankbait Build ProcessDocument19 pagesCrankbait Build ProcessSkittlessmannNo ratings yet

- Catálogo Non Automotive 2018Document588 pagesCatálogo Non Automotive 2018Bryan Garcia100% (1)

- 3 Soudotec p20 Et h13 FT Web AnglaisDocument1 page3 Soudotec p20 Et h13 FT Web AnglaisHari KiranNo ratings yet

- Gating System and Feeder Design of Aluminium Alloy (AA6063) Casting For Rectangular ComponentDocument6 pagesGating System and Feeder Design of Aluminium Alloy (AA6063) Casting For Rectangular ComponentPankajNo ratings yet

- EIL A6 Piping Vendor ListDocument16 pagesEIL A6 Piping Vendor Listdhan210100% (2)

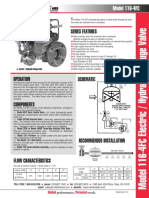

- Hoja de Datos - 116-4FCDocument2 pagesHoja de Datos - 116-4FCHenry Garavito RamirezNo ratings yet

- Soyol Polyol FormulationsDocument3 pagesSoyol Polyol FormulationsurethanNo ratings yet

- Nexus - Polyester Surfacing VeilDocument1 pageNexus - Polyester Surfacing VeilFernando Cesar PérezNo ratings yet

- Plasma Arc Cutting: Prepared By: Raghav SinglaDocument16 pagesPlasma Arc Cutting: Prepared By: Raghav SinglarrameshsmitNo ratings yet

- Mytest Coba ChemistryDocument3 pagesMytest Coba ChemistryDigilib Cambridge TazkiaNo ratings yet

- Building Specifications (Civil Works)Document26 pagesBuilding Specifications (Civil Works)ROOSHEEN AHMADNo ratings yet

- Stock CompletoDocument1 pageStock CompletoFaraz HaiderNo ratings yet

- Unit 6 - Chemical Reactions - Complete NotesDocument57 pagesUnit 6 - Chemical Reactions - Complete Notesapi-508178584No ratings yet

- Chs - Chem - ch3 - Mass - Ratios - and - Law - of - Multiple - Proportions Mod4Document22 pagesChs - Chem - ch3 - Mass - Ratios - and - Law - of - Multiple - Proportions Mod4Marvel Felicity Rosell ArmestoNo ratings yet

- API 570 - 01 API 570 and B31.3 PracticeDocument5 pagesAPI 570 - 01 API 570 and B31.3 PracticeMegan KirbyNo ratings yet

- Calcite Powder Application and Uses by RCM MineralsDocument2 pagesCalcite Powder Application and Uses by RCM Mineralsvivek vaishnavNo ratings yet

- Mobil Dynagear Series Performance ProfileDocument2 pagesMobil Dynagear Series Performance Profileanibal_rios_rivasNo ratings yet

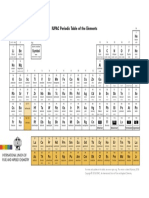

- IUPAC Periodic Table of The Elements: Ti CRDocument1 pageIUPAC Periodic Table of The Elements: Ti CRMargaux HidalgoNo ratings yet

- Industrial Deionization Systems: Standard FeaturesDocument2 pagesIndustrial Deionization Systems: Standard Featuresashraf-84No ratings yet

- Feinguss in India - Sumangal CastingDocument2 pagesFeinguss in India - Sumangal Castingsumangal castingNo ratings yet

- Hardness Conversion Table - Brinell, Rockwell, Vickers, Tensile StrengthDocument2 pagesHardness Conversion Table - Brinell, Rockwell, Vickers, Tensile StrengthSendi LuciverNo ratings yet

- Defects of TimberDocument10 pagesDefects of TimberSandro Soriano100% (1)

- Astm F1554Document9 pagesAstm F1554CPA BTKNo ratings yet