Professional Documents

Culture Documents

ACI 304R Guide For Meas., Mix., Transp., & Placing Conc

Uploaded by

Vasanth KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACI 304R Guide For Meas., Mix., Transp., & Placing Conc

Uploaded by

Vasanth KumarCopyright:

Available Formats

AC1 304R-00

Guide for Measuring, Mixing,Transporting,

and Placing Concrete

Reported by AC1 Committee 304

Neil R. Guptill

Chahman

David J. Akers John C. King Kenneth L. Saucier

Casimir Bognacki Gary R. Mass James M. Shilstone, Jr.

James L. Cope Patrick L. McDowell Ronald J. Stickel

Michael R. Gardner Dipak T. Parekh William X. Sypher

Daniel J. Green Roger J. Phares J.A. Tony Tinker

Brian Hanlin James S. Pierce Robert E. Tobin

Terence C. Holland Paul E. Reinhart Joel B. Tucker

Thomas A. Johnson Royce J. Rhoads Kevin Wolf

This guide presents information on the handling, measuring, and batching 2.6-Water and ice

of all the materials used in making normalweight, lightweight structural, 2.7-Fiber reinforcement

and heavyweight concrete. It covers both weight and volumetric

measuring; mixing in central mixtureplants and truckmixers; and concrete

placement using buckets, buggies, pumps, and conveyors. Underwater

Chapter 3-Measurement and batching, p. 304R-6

concrete placement and preplaced aggregate concrete are also covered in 3. 1"General requirements

this guide, as well as procedures for achieving good quality concrete in 3.2-Bins and weigh batchers

completed structures. 3.3-Plant type

3.4"Cementitious materials

Keywords: batching; conveying;

heavyweight

concletes;

lightweight 3.5-Water and ice measurement

concietes; mateiials handling; mixing; placing; pieplaced aggregate concrete; 3.6-Measurement of admixtures

pumped conciete; hemie conciete; volumehic measuring; continuous mixing. 3.7-Measurement of materials for small jobs

3 . 8 4 t h e r considerations

CONTENTS

Chapter 1-Introduction, p. 304R-2 Chapter 4-Mixing and transporting,p. 304R-9

1.l S c o p e 4. 1"General requirements

1.24bjective 4.2-Mixing equipment

1 . 3 4 t h e r considerations 4.3"Central-mixed concrete

4.4-Truck-mixed concrete

Chapter 2-Contro1, handling, and storageof 4.5"Charging and mixing

materials, p. 304R-3

2.1"General considerations 4.6-Mixture temperature

4.7-Discharging

2.2-Aggregates

2.3-Cement 4.8-Mixer performance

2.4"Ground slag and pozzolans 4.9-Maintenance

2.5-Admixtures 4.10-General considerations for transporting concrete

4.11-Returned concrete

AC1 Committee Reports, Guides, Standard Practices, and Commentaries Chapter 5-Placing concrete, p. 304R-13

ae intended for guidance in planning, designing, executing, and inspecting

construction.This document is intended for theuse of individuals who 5. 1"General considerations

arecompetenttoevaluate the significance and limitations of its 5.2-Planning

content and recommendations and who will accept responsibility for

theapplicationofthe material it contains. The AmericanConclete

Institute disclaims any and all responsibility for the stated principles.The

Institute shall notbe liable for any loss or damage arising theiefiom. AC1 304-00 supersedes AC1 304-89 and became effective January 10,2000.

Reference to this document shall be notmade in contract documents. If Copyright O 2000, American Concrete Institute.

items found in this document are desired by the Architecfingineer to be All rights reserved including lights of reproduction and use in any folm or by any

means, including the making of copies by any photo process, or by electronic or

a part of the contract documents, they shall be restated in mandatorylan- mechanical device, printed, written, or oral, or recording for sound or visual

guage for incorporation by the ArchitecVEngineer. reproduction or for use in any knowledge or retrieval system or device, unless

permission in writing is obtained from the copyright proprietors.

304R-1

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

304R-2 AC1 COMMITTEE REPORT

5.3-Reinforcement and embedded items Chapter 13-Volumetric-measuring and

5.&Placing continuous-mixing concrete equipment,

5.5-Consolidation p. 304R-38

5.6-Mass concreting 13.1-General considerations

13.2-Operations

Chapter 6--Forms, joint preparation, and 13.3-Fresh concrete properties

finishing, p. 304R-19

6.1-Forms

6.2-Joint preparation Chapter 14"References, p. 304R-39

6.3-Finishing unformed surfaces 14.1-Referenced standards and reports

14.2-Cited references

Chapter 7-Preplaced-aggregate concrete,

p. 304R-21 CHAPTER 1-INTRODUCTION

7.1-General considerations 1.1-Scope

7.2-Materials This guide outlines procedures for achieving goodresults

7.3-Grout proportioning in measuring and mixing ingredients for concrete, transport-

7.6Temperature control ing itto the site, and placing it. The first six chapters are gen-

7.5-Forms eral and apply to all types of projects and concrete. The

7.6-Grout pipe systems

7.7-Coarse aggregate placement following four chaptersdeal with preplaced-aggregate con-

7 . 8 4 r o u t mixing and pumping crete, underwater placing, pumping, and conveyingon belts.

7.9-Joint construction The concludingthree chapters deal with heavyweight, radia-

7.10-Finishing tion-shielding concrete, lightweight concrete, and volumet-

7.11-Quality control ric-measuring and continuous-mixing concrete equipment.

Chapter 8-Concrete placed under water,

1.2-Objective

p. 304R-24

When preparingthis guide, AC1 Committee 304 followed

8. l a e n e r a l considerations

8.2-Materials this philosophy:

8.3-Mixture proportioning Progress in improvement of concreteconstruction is

8.4"Concrete production and testing better served by the presentation of high standards

8.5-Tremie equipment and placement procedure rather than common practices;

8.6-Direct pumping In many,if notmost, cases, practices resulting in the

8.7"Concrete characteristics production and placement of high-quality concrete can

8.8-Precautions be performed as economically as those resulting in poor

8 . 9 S p e c i a l applications concrete. Many of the practices recommended in this

8.10-Antiwashout admixtures document improve concrete uniformityas well as qual-

Chapter 9-Pumping concrete, p. 304R-28 ity, yielding a smoother operation and higher produc-

9. l a e n e r a l considerations tion rates, both of which offset potential additional cost;

9.2-Pumping equipment and

9.3-Pipeline and accessories Anyone planning to use this guide should have a basic

9.4-Proportioning pumpable concrete knowledge of the general practices involved in concrete

9.5-Field practice work. If more specific information on measuring, mix-

9.6-Field control ing, transporting, and placing concrete is desired, the

reader should refer to the list of references given at the

Chapter 10-Conveying concrete, p. 304R-30

end of this document, and particularly to the work of

10.1-General considerations

the U.S. Bureau of Reclamation (1981), the U.S.

10.2-Conveyor operation

10.3-Conveyor design Department of Commerce (1966), the Corps of Engi-

10.&Types of concrete conveyors neers (1994a), ASTM C 94, AC1 311.1R, andAC1 318.

10.5-Field practice To portray more clearly certain principles involved in

achieving maximum uniformity,

homogeneity, and

Chapter 11-Heavyweight and radiation-shielding quality of concrete in place, figures that illustrate good

concrete, p. 304R-33 and poor practices are also included in this guide.

11.1-General considerations

11.2-Materials 1.3-Other considerations

11.3-Concrete characteristics All who are involved with concrete work should know the

11.&Mixing equipment importance of maintaining the unit water content as low as

11.5-Formwork possible

and

still

consistent

with

placing

requirements

11.6-Placement (Mielenz1994;Lovern1966). If thewater-cementitious

11.7-Quality control materials ratio (wlcm) is kept constant, an increase in unit

Chapter 12-Lightweight structural concrete, watercontentincreases the potential for drying-shrinkage

p. 304R-36 cracking,andwiththiscracking, the concrete can lose a

12.1-General considerations portion of its durability and other favorable characteristics,

12.2-Measuring and batching such

monolithic

as properties

and

lowpermeability.

12.3-Mixing Indiscriminate addition of water that increases the wlcm

12.&Job controls adversely affects both strength and durability.

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

MEASURING, MIXING, TRANSPORTING, AND PLACING CONCRETE 304R-3

The more a form is filled with the right combination of sol- effective control of gradation, handling operations thatdo not

ids and the less it is filled with water, the better the resulting increase the undersized materials in aggregates significantly

concrete will be. Use only as much cement as is required to before their use in concrete are essential (Fig. 2.1 and 2.2).The

achieve adequatestrength, durability, placeability, workabil- gradation of aggregate as it enters the concrete mixer should

ity, and other specified properties. Minimizing the cement be uniform and within specification limits. Sieve analyses of

content is particularly important in massive sections subject coarse aggregate shouldbe made with sufficient frequency to

to restraint, as the temperature rise associated with the hydra- ensure that grading requirements aremet. When two or more

tion of cement can result in cracking because of the change aggregate sizes are used, changes may be necessary in the

in volume (AC1 207.1R and 207.2R). Useonly as much wa- proportions of the sizes to maintain the overall gradingof the

ter and fine aggregate as is required to achieve suitable work- combined aggregate. When specification limits for grading

ability for proper placement and consolidation by means of cannot be met consistently, specialhandling methods should

vibration. be instituted. Materials tend to segregate

during

transportation, so reblending may be necessary. Rescreening

CHAPTER 2-CONTROL, HANDLING, AND the coarse aggregate as it is charged to the bins at the batch

STORAGE OF MATERIALS plant to remove undersized materials will effectively

2.1-General considerations eliminate undesirablefines when usual storage and handling

Coarse and fine aggregates, cement, pozzolans, and chem- methods are not satisfactory. Undersized materials in the

ical admixtures should be properly stored, batched, and han- smallercoarseaggregate fractions canbe consistently

dled to maintain the quality of the resulting concrete. reduced to as low as 2% by rescreening (Fig. 2.2). Although

rescreening is effective in removing undersized particles, it

2.2-Aggregates will not regrade segregatedaggregates.

Fine and coarse aggregates should be of good quality, un- 2.2.2 Fine aggregate (sand)-Fine aggregate should be

contaminated, and uniform in grading and moisture content. controlled to minimize variations in gradation, giving special

Unlessthis is accomplishedthroughappropriatespecifica- attention to keeping finer fractions uniform and exercising

tions (ASTM C 33) and effective selection, preparation, and care to avoid excessive removalof fines during processing.

handling of aggregates (Fig. 2.1), the production of uniform If the ratio of fine-to-coarse aggregate is adjusted in accor-

concrete will bedifficult (Mielenz 1994; AC1 221R). dance with AC1 21 1.1 recommendations for mixture propor-

2.2.1 Coarse aggregate-The coarse aggregate should be tioning, a wide range of fine aggregate gradings can be used

controlled to minimize segregationand undersized material. (Tynes 1962). Variations in grading during production of con-

The following sections deal with prevention of segregation crete should be minimized, however, andthe ASTM C 33 re-

and control of undersized material. quirement that the fineness modulusof the fine aggregate be

2.2.1.1 Sizes-A practical method of minimizing coarse maintained within 0.20of the design value should be met.

aggregate segregationis to separate the material into several Give special attention to the amount and nature of material

size fractions and batch these fractions separately. As the finer than the No. 200 screen (75 pm sieve). As stated in

range of sizes in each fraction is decreased and the number ASTM C 33, if this material is dust of fracture, essentially

of size separations is increased, segregation is further free of clay or shale, greater percentages of materials finer

reduced.Effective control of segregation and undersized than the No. 200 screen(75 pm sieve) are permissible. If the

materials is most easily accomplished when the ratio of reverse is true, however, permissible quantities should be

maximum-to-minimum size in each fraction is held to not significantly reduced. The California sand equivalent test is

more than four for aggregates smallerthan 1 in. (25 mm) and sometimes used to determine quantitatively the type,

totwo for larger sizes. Examples of someappropriate amount, and activity of this fine material (Mielenz 1994;

aggregate fraction groupings follow: ASTM D 2419). Excessive quantities of material finer than

the No. 200 screen (75pm sieve) increase the mixing-water

Example 1 requirement, rate of slump loss, and drying shrinkage, and

Sieve designations therefore decrease strength.

No. 8 to 3/8 in. (2.36 to 9.5 mm) Avoid blendingtwo sizes of fine aggregate by placing al-

No. 4 to 1 in. (4.75 to 25.0 mm) ternate amounts in bins or stockpiles or when loading cars or

3/4 to 1-1/2 in. (19.0 to 37.5 mm) trucks. Satisfactory results are achieved when different size

fractions are blended as theyflow into a stream from regulat-

Example 2 ing gates or feeders. A morereliable method of control for a

Sieve designations wide range of plant and job conditions, however, is to sepa-

No. 4 to 3/4 in. (4.75 to 19.0 mm) rate storage, handling, and batching of the coarse and fine

3/4 to 1-1/2 in. (19.0 to 37.5 mm) fractions.

1-1/2 to 3 in. (37.5 to 75 mm) 2.2.3 Storage-Stockpiling of coarse aggregate should

3 to 6 in. (75 to 150 mm) be keptto a minimum becausefines tend to settle and accu-

mulate.Whenstockpiling is necessary,however,use of

2.2.1.2 Control of undersized material-Undersized correct methods minimizes problems with fines, segrega-

material for a given aggregatefraction is defined as material tion, aggregate breakage, excessive variation in gradation,

that will pass a sieve having an opening 5/6 of the nominal and contamination. Stockpiles should be built up in hori-

minimum size of each aggregate fraction (U.S. Bureau of zontal or gentlysloping layers, not by end-dumping.

Reclamation 1981).In Example 2in Section 2.2.1.1,it would Trucks, loaders, and dozers, or other equipment should not be

be material passing the following sieves:No. 5 (4.0 mm), 5/8 operated on the stockpiles because, in addition to breaking the

in. (16.0 mm),1-1/4 in. (31.5 mm), and 2-1/2in. (63 mm). For aggregate, they frequently track dirt onto the piles (Fig. 2.1).

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

304R-4 AC1 COMMITTEE REPORT

INCORRECT METHODS OF STOCKPILING AGGREGATES

CAUSE SEGREGATIONAND BREAKAGE

PREFERABLE

OBJECTIONABLE

CRANE OR OTHER MEANS OFPLACING MATERIALIN

PILEINUNITSNOTLARGERTHANATRUCKLOAD METHODS WHICHPERMITME AGGREGATE TOROLL

WHICH REMAIN WHEREW E D AND DO NOT RUN DDWNTHESLOPEASITISADDEDTOTHEPILE

DOWN SLOPE. OR PERMITHAULING EQUIPMENTTOOPERATEOVER

THE SAME LEVEL REPEATEDLY,

LlMlTEOACCEPTABILIT-GENERALLY OBJECTIONABLE

PILE

BUILT

RADIALLY IN HORIZONTAL

LAYERS

BULLDOZER

BY OR FRONT

LOADER

STACKING

PROGRESSIVE LAYERS ON

BULLDOZER OR FRONT UNDERWORKING FROM MATERIALS AS SLOPE NOT FLATTER THAN3:i.UNLESS MATERIALS

DROPPED FROMC O N V N R BELT A ROCK LADDER MAY STRONGLY RESISTBREAKAGE,THESEMETHODSARE

NEEDED

OBJECTIONABLE.ALSO

BE IN SETUP

b. C.

CORRECT

CHIMNEY SURROUNDING MATERIAL FALLING

FROM ENDOF CONVEYOR BELTTO PREVENT

WINDFROMSEPARATINGFINEANDCOARSE

MATERIALS. OPENINGS PROVIDED AS REQUIRED

TD DISCHARGE MATERIALSATVARIOUS

ELEVATIONS ON THE PILE.

INCORRECT

FREE FALLOF MATERIAL FROM HIGH END WHENSTDCKPILINGMRGESIZEDAGGREGATES

OFSTACKER PERMlTlNG WINDTOSEPARATE FROM ELEVATED CONVEYORS. BREAKAGEIS

FINE FROM COARSE MATERIAL MINIMIZEDBYUSEOFAROCKLADDER

UNFINISHEDOR FINE AGGREGATE STORAGE FINISHEDAGGREGATESTORAGE

(DRY MATERIALS)

NOTE: IF EXCESSIVE FINES CANNOT BE AVOIDED

IN COARSE AGGREGATEW T I O N S BY STOCKPILING METHODS USED, FINISH

SCREENING PRIORTO TRANSFER To BATCH PLANT BINS WILL BE REQUIRED.

Fig. 2.1-Correct and incorrect methodsof handling and storing aggregates.

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

MEASURING, MIXING, TRANSPORTING, AND PLACING CONCRETE 304R-5

DOUBLE DECK 2.2.5 Samples for testSamples representing the various

V I B R A T I N G SCREEN aggregate sizes batched shouldbe obtained as closely as pos-

sible to the point of their introduction into the concrete. The

difficulty in obtaining representative samples increases with

TO WASTE F I N E AGG.

the size of the aggregate. Therefore, sampling devicesrequire

careful design to ensure meaningful test results. Methods of

K!/

FEEDBELT

sampling aggregates are outlined indetail in ASTM D 75.

CEMENT

C.AGG.

\\ #I i

I FINE

AGG.

/

/'

C.AGG. Maintaining a running average of the results of the five to

10 previous gradationtests, dropping the results of the oldest

and adding the most recent to the total on which the average

is calculated, is good practice. This average gradation can

then be used for both quality control and for proportioning

purposes.

Fig. 2.2-Batching plant rescreen arrangement.

2.3-Cement

Provide a hard base with good drainageto prevent contami- Allcementshouldbestoredinweathertight,properly

nation from underlyingmaterial. Prevent overlap of the dif- ventilatedstructurestopreventabsorption of moisture.

ferent sizes by suitable walls orample spacing between piles. Storage facilitiesforbulk cement shouldinclude separate

Protect dry, fine aggregate from being separated by the wind compartments for each type of cement used. The interior of a

by using tarps or windbreaks. Do not contaminate stockpiles cement silo should be smooth, witha minimum bottom slope

by swinging aggregate-filled buckets or clam-shovels over of 50 degrees from the horizontalfor a circular silo and55 to

the other piles of aggregate sizes. In addition, fine aggregate 60 degrees for a rectangular silo. Silos should be equipped

that is transported over wet, unimproved haul roads canbe- with nonclogging air-diffuser flow pads through which small

come contaminatedwith clay lumps. The sourceof this con- quantities of dry, oil-free, low-pressure air canbe introduced

tamination is usually accumulationof mud between the tires intermittently at approximately 3 to 5 psi (20 to 35 kPa) to

and on mud flaps that is dislodged during dumping of the

loosen cement that has settled tightly in the silos. Storage silos

transporting unit. Bottom-dump trailers are particularly sus-

should be drawn down frequently, preferably once per month,

ceptible to causing contamination when they drive through

to prevent cement caking.

discharged piles. Clay lumps or clay balls can usually bere-

moved from the fine aggregate by placing a scalping screen Each bin compartmentfrom which cement is batched

over the batch plant bin. should include aseparate gate, screw conveyor,air slide, ro-

Keep storage bins as full as practical to minimize breakage tary feeder, or other conveyance that effectively allows both

and changes in grading as materials are withdrawn. Deposit constant flowand precise cutoff to obtain accurate batching

materials into the bins vertically and directly over the bin out- of cement.

let (Fig. 3.lb). Pay particular attention to the storage of spe- Make sure cement is transferred to the correct silo by

cial concrete aggregates, including lightweight, high-density, closely monitoring proceduresand equipment. Fugitive dust

and architectural-finish aggregates. Contamination of these should becontrolled during loading and transferring.

materials has compounding effects on other propertiesof the Bags of cement should be stackedon pallets or similar plat-

concrete in which they are to be used (Chapters 11 and 12). forms to permit proper circulationof air. For a storage period

2.2.4 Moisture control-Ensure, as practically as possible, of less than 60 days, stackthe bags no higher than 14 layers,

a uniform and stable moisture content in the aggregate as and for longer periods, no higher than seven layers. As an ad-

batched. The useof aggregates with varying amountsof free ditional precaution the oldest cement should be used fxst.

water is one of the most frequent causesfor loss of control of

concrete consistency (slump). In some cases, wetting the 2.4-Ground slag and pozzolans

coarse aggregate in the stockpiles or on the delivery belts Fly ash, ground slag, or other pozzolans should be han-

may be necessary to compensate for high absorption or to dled, conveyed, and stored in the same manner as cement.

provide cooling. When this is done, the coarse aggregates The bins, however, should be completelyseparate from ce-

should be dewatered to prevent transfer of excessive free wa- ment bins without common walls that could allowthe mate-

ter to the bins. rial to leak into the cement bin. Ensure that none of these

Provide adequate time for drainage of free water from fine materials is loaded into a cementbin on delivery.

aggregate before transferring it to the batch plant bins. The

storage time required depends primarilyon the grading and

2.5-Admixtures

particle shape of the aggregate. Experience has shown that a

free-moisture content of as high as 6%, and occasionally as Most chemical admixtures are delivered in liquid form and

high as 8%, can bestable in fine aggregate. Tighter controls, should be protected against freezing. If liquid admixtures are

however, may berequired for certain jobs.Theuse of frozen, they should be properly reblended before they are

moisture metersto indicate variations in the moisture of the used in concrete. Manufacturers' recommendations should

fine

aggregate as batched, and the use of moisture be followed.

compensators for rapidbatchweightadjustments,can Long-term storage of liquid admixtures in vented tanks

minimize the influence of moisture variations in the fine should be avoided. Evaporation of the liquid could adversely

aggregate (Van Alstine 1955, Lovern 1966). affect the performance of the admixture (AC1 212.3R).

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

304R-6 AC1 COMMITTEE REPORT

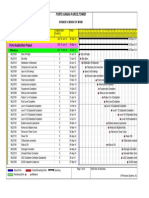

Table 3.1.2-Typical batching tolerances

I Batch weights greater than 30% of scale capacity I Batch weights less than 30% of scale capacity

Inmedient I Individual batchinr I Cumulative batchinr I I Cumulative batchinr

Individual batchinr

Cement and other cementitious +1%of required mass or +0.3% of scale capacity, Not less than required weightor 4% more than

materials whichever is greater required weight

% +1 INot recommended Water (by volume I

+1or weight), recommended

Not

I

+0.3% of scale capacity or

+3% of required cumula-

Aggregates, %

tive weight, whichever is

I I I I

less

Admixtum

volume

(by or weight), % I +3 INot recommended I +3 I

recommended

Not

2.6-Water and ice 3.1.2 Tolerances-Mostengineeringorganizations,both

Water for concrete productioncan besupplied fromcity or public and private,issue specifications containing detailed re-

municipal systems, wells, truck wash-out systems, or from quirements for manual,semiautomatic,partiallyautomatic,

any other source determined to be suitable. If questionable, and automatic batching equipmentfor concrete (U.S. Bureau

the quality of the water should be tested for conformance of Reclamation 1981, CorpsofEngineers 1994b, ASTM C 94,

with the requirements givenin ASTM C 94. Concrete made AASHTO 1993). Batching equipmentcurrentlymarketed

with recycled wash water can show variations in strength, will operate within theusual specified batch-weight toleranc-

setting time, and response to air-entraining and chemicalad- es whenthe equipment is maintainedin good mechanical con-

mixtures. Recycled wash water may be required to meet dition. The “Concrete Plant Standards of the Concrete Plant

chemical requirements of ASTM C 94. Compensation may Manufacturers Bureau” (Concrete Plant Manufacturers Bu-

be necessary for the solids in recycled water to maintain reau 1996a) andthe “Recommended Guide Specifications for

yield and total water contentin the concrete. Batching Equipmentand Control Systems in Concrete Batch

The water batcher and the water pipes should beleak-free. Plants” (ConcretePlant Manufacturers Bureau 1996b)are fre-

If ice is used, the ice facilities, including the equipment for quentlyused for specifying batchingand scale accuracy.

batching and transporting to the mixer, should be properly Batching tolerances commonly used aregiven in Table 3.1.2.

insulated to prevent the ice from melting before it is in the Othercommonlyusedrequirements include: beam or

mixer. scale divisions of O. 1% of total capacity and batchinginter-

lock of 0.3% of total capacity at zero balance (Concrete Plant

ManufacturersBureau1996a);

quantity of admixture

2.7-Fiber reinforcement weighed neverto be so small that 0.4% of full scale capacity

Synthetic fiber reinforcement is available inone cubic exceeds 3%of the required weight; isolation of batching

yard (one cubic meter)or multicubic yard (cubic meter) in- equipment fromplant vibration; protection of automatic con-

crements frommost manufacturers. These prepackaged units trols fromdust and weather; and frequentchecking and

should bereadily accessible so they can be added directly to cleaning of scale and beam pivot points. With good inspec-

the mixer duringthe batching process. tion and plant operation, batching equipment can be expect-

Steel fibers are packaged in various sizes; the most com- ed to perform consistently within the required tolerances.

mon are 50 or 100 lb (23 or 45 kg) increments. Appropriate

equipment should be used to disperse the fibers into the mix- 3.2-Bins and weigh batchers

er to minimize the potential for the development of fiber Batch plant bins and components should be of adequate

balls. Steel fibers should be stored so that they are not ex- size to accommodate the productive capacity of the plant.

posed to moisture or other foreign matter. For more informa- Compartments in bins should separate the various concrete

tion on working with steel fibers, see AC1 544.3R. materials, and the shape and arrangement of aggregate bins

should be conduciveto the prevention of aggregate segrega-

CHAPTER 3-MEASUREMENT AND BATCHING tion andbreakage. The aggregatebins should be designedso

3.1-General requirements that material cannot hang up in the bins or spill from one

3.1.1 Objectives-An importantobjectiveinproducing compartment to another.

concrete is to achieve uniformity and homogeneity, as indi- Weigh batchers should be charged with easily operated

cated by physical properties such as unit weight, slump, air clamshell or undercut radial-type bin gates. Gates used to

content, strength, and air-free unit weight of mortar in individ- charge semiautomatic and fully automatic batchers should

ual batches and successive batches of the same mixture pro- be power-operated and equipped with a suitable dribble con-

portions (U.S. Department of Reclamation 1981, U.S. trol to allow the desired weighing accuracy. Weigh batchers

Department of Commerce 1966, Bozarth 1967,ASTM C 94, should be accessible for obtaining representative samples,

Corps of Engineers 1994b). Duringmeasurement operations, and they should be arrangedto obtain the proper sequencing

aggregates should be handled so that the desired grading is and blending of aggregates during chargingof the mixer.

maintained, and all materials should be measured within the Illustrations showing proper and improper design and ar-

tolerances acceptablefor desired reproducibility of the select- rangement of batch plant bins and weigh batchers are given

ed concretemixture. Another important objective of success- in Fig. 3.1.

ful batching is the proper sequencing and blending of the

ingredients (U.S. Department of Commerce 1966, Bozarth 3.3-Plant type

1967). Visual observation of each material being batched is Factors affecting the choice of the batching systems are:

helpful in achieving this objective. 1) size of job; 2) required production rate; and 3) required

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

MEASURING, MIXING, TRANSPORTING, AND PLACING CONCRETE 304R-7

U N I F O R M I T OYCF O N C R E T I EAS F F E C T E B0TY H AE R R A N G E M E N T

OF B A T C H E R - S U P P L BY I N AS N O W E I G H B A T C H E R S

b.

I N C O R R EC CO TR R E C T I N C O R R E C TC O R R E C T

F U L L BOTTOM S L O P I N G 50' F L PBTO T T O EMI N S DR THOSE WITH

UNY M A T E R I A L DROPS V E R T I C A L L Y C H U T I N GM A T E R I A LI N T OB I N

FROMHORIZONTUL IN ALL ARRPNGEMENT OF SLOPES HPVlNG CORNERS I N T O B I N OIRECTLYOVERTHE ON UPNN G L M E .A T E R I P L

D I R E C T I O N S TO

OUTLET

WITH DR A R E ASSU CTHH UPTLML P T E R I PILN D I S C H U R G EO P E N I N GP E R M I T T I N G F A L L I N G OTHERTHPNOIRECTLY

CORNERS OF B I N PROPERLY BINS

WILL NOT

FLOW

REUOILY THROUGH DISCHURGEOF MORE GENERALLY OVEROPENINGNOTALWAYSIINI-

ROUNDED SO T H AMLTOLaU- T L W

E Tl T H O lSJ H

T OVELING. UN lFORl4 MUTER I U L . FORM ns o ISCHARGED.

T E R I A L MOVES TOWPRD

THE

OUTLET.

C.

GRUVI

SLOPE OF AGGREGATE B I N BOTTOMS

L -

d.""::lNGS&$ I y/

AGGREGATE B I NF I L L I N G

CUMULUTIVE

-HEXAGONAL BATCHER

OR SQUARE (CEMENT

SHAPE WEIGHED

SEPARATELY)

-SUSPENDED

BATCHER

R E F E R R E D A R R A N G E M E N AT C C E P T A B L EA R R A N G E M E N 1 P O O R A R R A N G E M E N T S

UUTOMATICWEIGHINGOFEPCHINGREOIEPT UGGREGATEUUTOMPTICPLLYWEIGHEDSEPPRPTELI EITHER OF n B o v E CLOSE G R O U P I N G S OF B I N

I NI N D I V I D U A LW E I G HB P T C H E R S , O I S C H P R G - OR CUMULUTIVELY. CEMENT WEIGHED SEPARUTEL) DISCHARGESWHICHCAUSELONGSLOPES OF

INGTHROUGHCOLLECTINGCONEDIRECTLY B A T C H E R SI N S U L U T E OF R O MP L U N TV I B R A T I O N . M U T E R I U ILNE I N SR E S U L TI NS E P A R U T I O N

INTO MIXER. DISCHARGE OF CEMENT BATCH- WEIGHT R E C O R D I N G EUUIPMENT P L n l m Y VISIBLE PNO I M P A I R E DU N I F O R M I T Y .

ER CONTROLLED SO THRT CEMENT I S FLOWING T O OPERPTOR. PROPER SEQUENCE OF DUMPING

W H I L E UGGREGUTE I S B E I N GD E L I V E R E D . MUTERIPLS NECESSARY. AVOID AGGREGATE CON-

B A T C H E R SI N S U L A T E DF R O MP L A N VT I E R U T I O N . STPNTLYFLOWING OVER TOP OF M P T E R I P LI N

WILLPERMITOVERLOUDCORRECTION. BINSW . ILL NOTPERMIT ( )RRECTING OVERLOUOS.

. LENO

VIEW

- S I D EV I E W

ENDVIEW-

-

P R E F E R R AE R

D R A N G E M E N T A C C E P T A B L AE R R A N G E M E N T

QGGREGUTEAUTOMPTICPLLYWEIGHEDCUMULATIVELY,ANUCURRIED UGGREGATE AUTOMATICALLYWEIGHEO CUMULATIVELY. CEMENT

WEIGHED

TO M I X E R ON CONVEYOR B E L T . CEMENT

WEIGHED

SEPARATELY UNO SEPPRUTELY AND

DISCHPRGE

CONTROLLED SO THAT

CEMENT I S FLOW-

DISCHPAGE I S CONTROLLED so THUT CEMENT I S FLOWING WHILE INGWHILEUGGREGATE I S B E I N GD E L I V E R E D .

AGGREGRTE I S B E I N GD E L I V E R E D .

Fig. 3.1-Correct and incorrect methodsof batching.

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

304R-8 AC1 COMMITTEE REPORT

standards of batching performance. The production capacity the reading of the scale within 0.1% of the scale capacity or

of a batch plant is determined by a combination of the ma- one increment of any volumetric batching device. A digital

terials handling system, bin size, batcher size, and mixer batch-documentation recorder should record information on

size and number. each material in the mixture along withthe concrete mixture

Available weigh batch equipment falls into four generalcat- identification, size of batch, and production facility identifi-

egories: manual; partially automatic; semiautomatic; andfully cation. Required information can be preprinted, written, or

automatic (Concrete Plant Manufacturers Bureau 1996a). stamped on the document. The recorder should identify the

3.3.1 Manual weigh batching-As the name implies, all load by a batch-count number or aticket serial number. The

operations of weighing and

batching of the concrete recorder, ifinterlocked to anautomaticbatchingsystem,

ingredients are controlled manually.Manual plants are shouldshowa single indication of all batchingsystems

acceptable for small jobs having low

batching-rate meetingzeroorempty balance interlocks. All recorders

requirements.As the job size increases, automation of should produce two or more tickets containing the informa-

batching operations is rapidly justified. Attempts to increase tion stated previously and also leave space forthe identifica-

the capacity of manual plants by rapid batching can result in tion of the job or project, location of placement,sand

excessive weighing inaccuracies. moisture content, delivery vehicle, driver’s signature, pur-

3.3.2 Partially automaticweigh batching-A partially au- chaser’s representative’s signature, and the amount of water

tomatic system consists of a combination of batching con- added at the project site.

trols where at least one of the controls for weighing either 3.3.4.2 Individualautomatic weighbatching-This

cement or aggregates iseither semiautomatic or automatic as systemprovidesseparate scales andbatchers for each

described as follows.Weighing of the remaining materials is aggregate size and for everyothermaterialbatched. The

manually controlled and interlockingof the batching system weighing cycle is started bya single start switch, and

to any degree is optional. This system canalso lack accuracy individual batchers are charged simultaneously. Interlocks

when rapid batching is required. for interrupting weighing and discharge cycles when

3.3.3 Semiautomatic weigh batching-In this system, aggre- tolerances are exceeded, mixture selectors, aggregate

gate-bin gates for charging are opened by manually operated moisture meters and compensators, and recorders differ only

buttons or switches. Gatesare closed automatically whenthe slightly from those described forcumulative automatic

designated weight of material has been delivered. With sat- batching systems.

isfactory plant maintenance, the batching accuracy should 3.3.5 Volumetric batching-When aggregates or cementi-

meet the tolerancesgivenin Section 3.1.2. The system tious materials are batched by volume, it is normally a con-

should contain interlocks that prevent batcher charging and tinuous

operation

coupled

with

continuous

mixing.

discharging from occurring simultaneously. In other words, Volumetric batching and continuous mixing are covered in

when the batcher is being charged, it cannot bedischarged, Chapter 13.

and whenit is being discharged, it cannot becharged. Visual

confirmation of the scale reading for each material being 3.4-Cementitious materials

weighed is essential. 3.4.1 Batching-Forhigh-volumeproductionrequiring

3.3.4 Automatic weigh batching-Automatic weigh batch- rapid andaccuratebatching,bulkcementitiousmaterials

ing of all materials is activated by asingle starter switch. In- should be weighed with automatic,rather than semiautomat-

terlocks, however, interrupt the batching cycle when the ic or manual, equipment. All equipment should provide ac-

scale does not return to 0.3% of zero balance or when preset cess for inspection and permit samplingat any time. The bins

weighing tolerances detailed in Section 3.1.2 are exceeded. and weigh batchers shouldbe equippedwith aeration devic-

3.3.4.1 Cumulative automatic

weigh

batching- es, vibrators, or both to aid in the smooth and complete dis-

Interlocked sequential controls are required for this type of charge of the batch. Return to zero and weighing tolerance

batching. Weighing will not begin, and it will be automatically interlocks described inSection 3.1.2 should be used.Cement

interrupted when preset tolerances in any of the successive should be batched separately and kept separate from all in-

weighings exceed values such as those given in Section 3.1.2. gredients before discharging. When both cement and poz-

The charging cycle will not begin when the batcher discharge zolan orslag are to be batched, separate silos should be used.

gate is open, and the batcher discharge cycle will not begin They canbe batched cumulatively, however,if the cement is

when batcher charging gates are open or when any of the weighed first.

indicated material weights is not within applicable tolerances. 3.4.2 Discharging-Effective precautions should be taken

Presetting of desiredbatchweightsiscompletedbysuch to prevent loss of cementitious materials during mixer charg-

devices as punched cards, digital switches, or rotating dials ing. At multiple-stop plants where materials are charged sep-

and computers. Setting of weights, starting the batch cycle, arately, losses can be minimized by

discharging the

and dischargingthe batch are all manually controlled. Mixture cementitiousmaterialsthrougharubber drop chute. At

and batch-sizeselectors, aggregate moisture meters, manually one-stop plants, cement and pozzolan can be successfully

controlled fine aggregate moisture compensators, and graphic charged along with the aggregate through rubber telescopic

or digital devices for recording the batchweight of each dropchutes. For plant mixers, a pipe should be used to dis-

material are required for good plant control (VanAlstine charge the cementitious materials to a point near the center

1955; Lovern 1966). This type of batching system provides of the mixer after the water and aggregates have started to

greater accuracy for high-speed production than either the enter the mixer. Proper and consistent sequencingand blend-

manual or semiautomatic systems. ing of the variousingredients into the mixerduring the

A digital recorder can have a single measuring device for charging operation will contribute significantly toward the

each scale or a series of measuring devices canrecord on the maintenance of batch-to-batch uniformity and, perhaps, re-

same tape or ticket. This type of recorder should reproduce duced mixing time when confirmed by mixer performance

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

MEASURING, MIXING, TRANSPORTING, AND PLACING CONCRETE 304R-9

tests (U.S. Department of Commerce1966,Gaynor and The operating mechanismin the water measuring devices

Mullarky 1975,ASTM C 94). should besuch that leakage (dribbling or watertrail) will not

occur when the valve is closed. Water tankson truck mixers

3.5-Water and ice measurement or other portable mixers should be constructed so that the in-

3.5.1 Batching equipment- large jobs and in central dicating device will register, within the specified accuracy,

batching and mixing plants where high-volume production is the quantity of water discharged, regardless of the inclina-

required, accurate water and ice measurement can onlybe ob- tion of the mixer.

tainedby the use of automaticweighbatchersormeters.

Equipment and methods used should, under all operating con- 3.6-Measurement of admixtures

ditions, be capableof routine measurement within the1%tol- Batching tolerances (Section 3.1.2) and charging and dis-

erance specified in Section 3.1.2. Tanks or vertical cylinders charge interlocks described previouslyfor other mixture in-

with a center-siphon discharge can be permitted as an auxil- gredients should also be provided for admixtures. Batching

iary part of the weighing, but should not be used as the direct and dispensing equipment should be readily capable of cali-

means of measuring water. For accurate measurement,dig- a bration. When timer-activated dispensers are used for large-

ital gallon (liter) meter should be used. All equipment for volumeadmixtures suchas calcium chloride, acontainer

water measurement should be designed for easy calibration with a sight tube calibrated to show admixture quantity (usu-

so that accuracy can be quickly verified. Ice-batching equip- ally referred to as a “calibration tube”) should be usedto al-

ment should beinsulated to avoid meltingthe ice. low visual confirmation of the volume being batched. In

3.5.2 Aggregate moisture determination and compensa- practice, calibration tubes are usually installed for all liquid

tion-Measurement of the correct total mixing water de- admixtures.

pends on knowing the quantity and variation of moisture in Refer to AC1212.3R for additional information on recom-

the aggregate (particularly in the fine aggregate) as it is mended practices in the use and dispensing of admixtures in

batched. Aggregatethat is not saturated surface dry will ab- concrete.

sorb mixture water from the concrete. Fine aggregate mois-

ture meters are frequently usedin plants and when properly 3.7-Measurement of materials for small jobs

maintained do satisfactorily indicate changes in fine aggre- If the concrete volume on a job is small, establishing and

gate moisture content. Use of moisture metersin fine sizes of maintaining a batch plant and mixer at the construction site

coarse aggregateis also recommended if these materials vary may not be practical. In such cases, using ready-mixed con-

in moisture content. Moisture meters should be calibrated to crete or mobile volumetric batching and continuous mixing

oven-dried samples for optimum consistency of readings. equipment may be preferable. If neither is available, precau-

Moisture meters should be recalibrated monthly or whenever tions should be taken to properly measure and batch concrete

the slump of the concrete producedis inconsistent. materials mixedon the job site. Bags of cementitious materials

Moisture-compensating equipment can also be used that should be protectedfrommoisture and fractional bags

can reproportion waterand fine aggregateweights for a should not be used unless they are weighed. The water-mea-

change in aggregate moisture content, with a single setting suring device should be accurate and dependable, and the

adjustment. Compensators are usually used on the fine ag- mixer capacity should not be exceeded.

gregate, but occasionally are also used on the small coarse

aggregate size fractions. The moisture setting on the com- 3.8-Other considerations

pensators is made manually with calibration dials, buttons, In addition to accurate measurement of materials, correct

or levers. The use of moisture compensatorsis recommend- operating procedures shouldalso be usedif concrete unifor-

ed when used in conjunction with calibrated moisture meters mity is to be maintained. Ensure that the batched materials

or regularly performed conventional moisture-controltests. are properly sequencedand blended so that they are charged

Under these conditions, compensators can be useful tools for uniformly into the mixture (U.S. Department of Commerce

maintaining satisfactory control of the fine aggregate and the 1966;Bozarth 1967). Arrange the batching plant control

mixing water content. room, if possible, with the plant operator’s station located in

Mostcomputer-controlledbatchingsystemsnowhave a position where the operator canclosely and clearly see the

software that interlocks moisture meters or compensating scales and measuring devices during batching of the con-

equipment with the measuring of fine aggregate and water. crete, as well as the charging, mixing,and discharging of the

Readings are taken automatically and incorporated into the mixtures without leavingthe operating console. Some com-

batching of these ingredients. Some systems work with an mon batching deficiencies to be avoided are: overlapping of

individual reading, whereas others can continuously record batches; loss of materials; loss or hanging up of a portion of

moisture as the fine aggregate is batched. Regardless of the one batch, or its inclusion with another.

system used, the software should impose user-defined upper

and lower moisturelimits and alert the operator when mois- CHAPTER 4-MIXING AND TRANSPORTING

ture values are outside those limits. Proper maintenanceand 4.1-General requirements

calibration of equipment is essential to satisfactory perfor- Thorough mixing is essential for the productionof uniform,

mance and consistent production of concrete. quality concrete. Therefore, equipment and methods should be

3.5.3 Total mixingwater-In addition to the accurate capable of effectively mixing concrete materials containing

weighing of added water, uniformity in the measurement of the largest specified aggregate to produce uniform mixtures of

total mixing water involves control of such additional water the lowest slump practical for the work. Recommendations on

sources as mixer wash water, ice, and free moisture in aggre- maximum aggregate size and slump to be used for various

gates. One specified tolerance (ASTM C 94)for accuracy in types of construction are given in AC1 21 1.1 for concretes

*

measurement of total mixing water from all sources is 3%. made with ASTM C 150 and C 595M cements, and in AC1

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

304R-10 AC1 COMMITTEE REPORT

223R for concretes made with ASTM C 845 expansive hy- mixergenerally usedfor roller-compacted concrete and

draulic cements. Sufficient mixing, transporting, and placing cement-treated base. Aggregates,cement, and fly ash are

capacity should be provided so that unfinished concrete lifts measured by weight or volume and fedinto the charging end

can be maintained plastic and free of cold joints. of the pugmillbyvariable-speed belts. Water is metered

either from an attached tank or an outside source. Mixing is

4.2-Mixing equipment accomplishedbypaddlesattached to one ortwo rotating

Mixers can be stationary parts of central mixture plants or horizontal shafts. The mixture is lifted and folded as it is

of portable plants. Mixerscan also be truckmounted. moved from the charging end to the discharging end of the

Satisfactorily designed mixers have a bladefinorarrangement pugmill, where the completed mixture is discharged onto an

anddrumshape that ensureanend-to-endexchange of elevated conveyor belt for easy loading into trucks. These

materials parallel to the axis of rotation or a rolling, folding, types of continuous-feedmixerscan be used for normal

and spreading movementof the batch over itself asit is being concretes as well. These would be considered semimobile

mixed. For additional descriptions of some of the various plants as they are mounted on wheels and can be broken down

mixer types, refer to the publications of the Concrete Plant for transport. Refer to Chapter 13 for additional information

ManufacturersBureau (1996~)and of the TruckMixer on continuous mixing equipment.

Manufacturers Bureau (1996). 4.2.7 Separatepaste mixing-Experimentalworkhas

The more common types of mixing equipment are: shown that the mixing of cement and waterinto a paste before

4.2.1 Tilting drum mixer-This is a revolving drum mixer combining these materials with aggregates can increase the

that discharges by tilting the axis of the drum. Inthe mixing compressive strength of the resulting concrete (Mass 1989).

mode, the drum axis can be either horizontal or at an angle. The paste is generallymixedinahigh-speed,shear-type

4.2.2 Nontilting drum mixer-Thisis a revolving drum mixer at a wlcm of 0.30 to 0.45 by mass.The premixed paste

mixer that charges, mixes, and discharges with the axis of the is then blended with aggregates and any remaining batch wa-

drum horizontal. ter, and final mixing is completed in conventional concrete

4.2.3 Vertical shaft mixer-This is often called a turbine mixing equipment.

orpan-typemixer.Mixingisaccomplishedwith rotating

blades or paddles mounted on avertical shaft in either a sta- 4.3-Central-mixed concrete

tionary pan or one rotating in the opposite direction to the Central-mixed concrete is mixed completely in a station-

blades. The batch can be easily observed and rapidly adjust- ary mixer and thentransferred to another piece of equipment

ed, if necessary. Rapid mixing and low overall profile are for delivery. This transporting

equipmentcan be a

other significant advantages. This type of mixer does an ex- ready-mixed truck operating as an agitator, or an open-top

cellent job of mixing relatively dry concretes and is often truck body with or without an agitator. The tendency of con-

used for laboratory mixing and by manufacturers of concrete crete to segregate limits the distance it can be hauled in trans-

products. porters not equipped with an agitator. If a truck mixer or a

4.2.4 Pugmill mixers-These mixers are defined in AC1 truck body with an agitator is used for central-mixed con-

116R as“a mixer having astationary cylindrical mixing com- crete, ASTM C94 limits the volume of concrete chargedinto

partment, with the axis of the cylinder horizontal, and one or the truck to 80% of the drum or truck volume.

more rotating horizontal shafts to which mixing blades or pad- Sometimes the central mixer will partially mix the con-

dles are attached.” Although this isanaccurate definition, crete with the final mixing and transporting being done ina

there are many types, styles, and configurations. Pugmills can revolving-drumtruckmixer.Thisprocess is often called

have single or double shafts. They can have a curved blade “shrink mixing” as it reduces the volume of the as-charged

configuration or a paddle configuration that is vertical to the mixture. When using shrinkmixing, ASTM C 94 limits the

shaft. In either case, they are designed to fold and move the volume of concrete charged into the truck to 63% of the

concrete from oneend of the pugmill to the other. drum volume.

These mixers are suitable for harsh, stiff concrete mix-

tures. They have primarily been used in the production of 4.4-Truck-mixed concrete

concrete block units, cement-treated bases, and roller com- Truck mixing is a process by which previously propor-

pacted concrete. Newer versions of these mixers are used in tioned concrete materialsfrom a batch plantare charged into

the production of normal- and high-strength concrete, with a ready-mixed truckfor mixing and delivery tothe construc-

slumps of up to 8 in. (200 mm). tion project. To achieve thorough mixing, total absolute vol-

4.2.5 Truckmixers-There are twotypes of revolving ume of all ingredients batched in a revolving drum truck

drum truck mixerscurrently in use-rear discharge and front mixer should not exceed 63% of the drum volume (Truck

discharge. The rear-discharge, inclined-axis mixer predomi- Mixer Manufacturers Bureau 1996; ASTM C 94).

nates. In both, fins attached to the drum mix concrete in the

mixing mode and also discharge theconcrete when drum ro- 4.5-Charging and mixing

tation is reversed. The method and sequence of charging mixers is of great

4.2.6 Continuous mixingequipment-Two types

of importanceindeterminingwhether the concrete will be

continuous mixing equipment are available. In the first type, properly

mixed.For central plant mixers, obtaining

a

all materials come together at the base of the mixing trough. preblendingorribboning effect bychargingcementand

Mixing is accomplishedbya spiral blade rotated at a aggregates simultaneously asthe stream of materials flow into

relatively high speed inside the enclosed trough, which is the mixer is essential (U.S. Department of Commerce 1966;

inclined at 15 to 25 degrees fromthe horizontal. These canbe Bozarth 1967; Gaynor and Mullarky1975).

mobile,mounted either onatruck chassis ora trailer, or In truck mixers, all loading procedures should be designed

stationary. The secondtype is acontinuous-feedpugmill to avoid packing ofthe material, particularly sand and cement,

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

MEASURING, MIXING, TRANSPORTING, AND PLACING CONCRETE 304R-11

in the head of the drum during charging. The probability of mixing speed for approximately 30 revolutions to enhance

packing is decreased by placing approximately 10% of the uniformity.

coarse aggregate and water in the mixer drum before the Mixer charging, mixing, and agitating speeds vary with

sand and cement. each truck and mixer-drum manufacturer. ASTM C 94 re-

Generally, approximately 1/4 to 1/3 of the water should be quires that these speeds and the mixing and agitating capac-

addedto the dischargeend of the drum afterallother ity of each drum be shownon a plate attached to the unit.

ingredients have been charged. Water-chargingpipes should Maximum transportation time can be extendedby several

be of proper design and of sufficient size so that water enters different procedures. These procedures are often called dry

at a point well inside the mixer and charging is complete batching and evolved to accommodate long hauls and un-

within the first 25% of the mixing time (Gaynor andMullarky avoidable delays in placing by attempting to postpone the

1975). Refer to Section 4.5.3.1 for additional discussion of mixing of cement with water. When cement and damp aggre-

mixing water. gate comein contact with each other, however, free moisture

The effectiveness of chemical admixtures will vary de- on the aggregate results in some cement hydration. There-

pending upon when they are added during the mixing se- fore, materials cannot be heldin this manner indefinitely.

quence.Follow the recommendations of the admixture Inonemethod, the dry materials are batched into the

supplier regarding when to add a particular product. Once ready-mixed truck andtransported to the job site where all of

the appropriate timein the sequence is determined, chemical the mixing water is added. Water should be added under

admixtures should be charged to the mixer at the same point pressure, preferably at both the front and rear of the drum

in the mixing sequence for every batch. Liquid admixtures with it revolving at mixing speed, and then mixing is com-

should be charged with the water or on dampsand, and pow- pleted with the usual 70to 100 revolutions. The total volume

dered admixtures should be ribboned into the mixer with of concrete that can be transported in truck mixers by this

other dry ingredients. When more than one admixture is method is the same as for regular truck mixing, approximate-

used, each should be batchedseparately unless premixingis ly 63% of the drum volume (Truck Mixer Manufacturers Bu-

allowed by the manufacturer. reau 1996, ASTM C94).

Synthetic fiber reinforcement can beadded any time dur- Another approachto accommodate longhauls is touse ex-

ing the mixing processas long as at least 5 min of mixing oc- tended-set admixtures. The concrete is mixed and treated

curs after the addition of the synthetic fibers. with the admixture before leavingthe plant. The admixture

4.5.1 Central mixing-Procedures for charging central dosage is typically selected to wear off shortly after the con-

mixers are less restrictive than those necessaryfor truck mix- crete arrives at the placement site, allowing the concrete to

ers because a revolving-drum central mixer is not chargedas set normally. In some instances, an accelerator is added to

full as a truck mixer and the blades and mixing action are activate the concrete once it arrives at the placement site.

quite different. In a truck mixer,there is little folding action Concrete has been transported over 200 miles (320 km) us-

compared withthat in a stationary mixer. Batchsize, howev- ing this technique.

er, should not exceed the manufacturer’s rated capacity as 4.5.3 Water

marked on the mixer nameplate. 4.5.3.1 Mixing water-The water required for proper

The mixing time required should be based on the ability of concrete consistency (slump) is affected by variables such as

the mixer to produce uniform concrete throughout the batch amount and rate of mixing, lengthof haul, time of unloading,

and from batch to batch. Manufacturers’ recommendations and ambient temperatureconditions. In cool weather,or for

and other typical recommendations, such as 1 min for 1 yd3 short hauls and prompt delivery, problems such as loss or

(3/4 m3) plus 1/4 min for each additional cubic yard (cubic variation in slump, excessive mixing water requirements,

meter) of capacity can be usedas satisfactory guides for es- and discharging, handling, and placingproblems rarely

tablishing initial mixing time. Final mixing times, however, occur. The reverseis true, however, when rate of delivery is

should be based on the results of mixer performance tests slow or irregular, haul distances are long, and weather is

made at frequent intervals throughout the duration of the job warm.Loss of workabilityduring warm weathercanbe

(U.S. Bureau of Reclamation1981; U.S. Department of minimized by expediting delivery and placement andby

Commerce 1966;ASTM C 94; CRD-C 55). The mixing time controlling the concrete temperature. Good communication

should be measured fromthe time all ingredients are in the between the batching plant and the placement site is essential

mixer. Batchtimers with audible indicators used in combina- for coordination of delivery. It may be necessary to use a

tion withinterlocks that prevent under-or over-mixing of the retarder to prolong the time the concrete will respond to

batch and discharge before completion of a preset mixing vibration after it is placed. When feasible, all mixing water

time are provided on automatic plants and are recommended should beadded at the central or batch plant. In hot weather,

on manual plants. The mixer should be designed for starting however, it is better to withhold some of the mixing water

and stopping underfull-load conditions. until the mixer arrives at the job. With the remaining water

4.5.2 Truck mixingaenerally, 70 to 100 revolutions at added, an additional 30 revolutions at mixingspeed is

mixing speed are specified for truck mixing. ASTM C 94 required to adequately incorporatethe additional water into

limits the total number of revolutions to a maximumof 300. the mixture. When loss of slump or workability cannot be

This limits the grinding of soft aggregates, loss of slump, offset by these measures, the proceduresdescribed in

wear on the mixer, and other undesirable effects that can Section 4.5.2. should be considered.

occurinhot weather.Finalmixingcanbedone at the 4.5.3.2 Addition of water on the job-The maximum

producer’s yard, or, more commonly,at the project site. specified or approvedwlcm should never be exceeded.

If additional time elapses after mixing and before discharge, If all the water allowed by the specification or approved

the drum speed is reduced to the agitation speed or stopped. mixture proportions has not been addedthe at start of mixing,

Then, before discharging, the mixer should be operated at it may be permissible, depending upon project specifica-

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

304R-12 AC1 COMMITTEE REPORT

tions, to addthe remaining allowable water at the point of de- by using heated water, aggregates, or both. Recommenda-

livery. Once part of a batch has been unloaded, however, it tions for control of concrete temperatures are discussed in

becomes impractical to determine what wlcm is produced by detail in AC1 305R and 306R.

additional water.

The production of concrete of excessive slump or adding 4.7-Discharging

water in excess of the proportioned wlcm to compensate for Mixers should be capable of discharging concrete of the

slump loss resulting from delays in delivery or placement lowest slump suitable for the structure being constructed,

should be prohibited. Persistent requests for the addition of without segregation(separation of coarse aggregate from the

water should beinvestigated. mortar). Before discharge of concrete transported in truck

Where permitted, a high-range water-reducing admixture mixers, the drum should again be rotated at mixing speedfor

(superplasticizer) can be added to the concrete to increase about 30 revolutions to reblend possible stagnantspots near

slump while maintaining low a wlcm (Cement and Concrete the discharge endinto the batch.

Association 1976; Prestressed Concrete Institute 1981). Ad-

dition of the admixture can be made by the concrete supplier 4.8-Mixer performance

or the contractor by a variety of techniques. When this ad- The performance of mixers is usually determined by a

mixture is used, vibration for consolidation is reduced. In series of uniformity tests made on samples taken from two or

walls and sloping formedconcrete, however, somevibration three locations within the concrete batch after it has been

is necessary to remove air trapped in the form. Useof this ad- mixed for a given time period(U.S. Bureau of Reclamation

mixture canalso increase formpressure. 1981,ASTMC 94and CRD-C 55). Mixerperformance

4.5.3.3 Wash water-Most producers find it necessary requirements are based on allowable differences in test

to rinse off the rear fins of the mixer between loads and wash results of samples fromany two locations or a comparisonof

and discharge the entire mixer only atthe end of the day. Hot individual locations with the average of all locations. The

weather and unusualmixtureproportionscan require procedures publishedby Gaynor and Mullarky (1975)are an

washing and discharge of wash water after every load. Rinse excellent reference.

water shouldnotremain in the mixer unless it canbe Among the many tests used to check mixer performance,

accurately compensated for in the succeeding batch. Rinse the following are the most common: air content; slump; unit

water can be removed from the mixer by reversing the drum weight of air-free mortar;coarseaggregate content; and

for 5 to 10 revolutions at medium speed. Pollution-control compressive strength.

regulations make it increasingly difficult to wash out after Another importantaspect of mixer performance is

every loadand have createdan interest in systems to reclaim batch-to-batchuniformity of the concrete, whichisalso

and reuse both wash water andreturned concreteaggregates. affected by the uniformity of materials and their

ASTM C 94 describes the reuse of wash water based on measurement as well asby the efficiency of the mixer.

prescribed tests. Particular attention is necessary when ad- Visualobservation of the concreteduringmixing and

mixtures are being used because the required dosages can discharge fromthe mixer is an important aid in maintaining

change dramatically. When wash water is used, admixtures a uniform mixture,particularly with a uniformconsistency.

should be batched into a limited quantity of clean water or Some consistency-recordingmeters, such as those operating

onto damp sand. from the amperage draw on the electric motor drives for

Wash water canalso be treated using extended-set admix- revolving-drum mixers, have also proven to be useful. The

tures. In this case, a limited amount of wash water is added most positive control method for maintaining batch-to-batch

to a drum after all solid materials are discharged. Typically uniformity, however, is a regularly scheduled program of

50 gal. (200 L) instead of the normal 500 gal. (2000 L) are tests of the fresh concrete, including unit weight, air content,

used. The admixture is added tothe drum and the drum is ro- slump, and temperature. All plants should havefacilities and

tated to ensure that all surfaces are coated. This treated wash equipment for conveniently obtaining representative

water can be left in the truck overnight or overa weekend. The samples of concrete for routine control tests in accordance

next morning or after the weekend, concrete can be batched with ASTMC 172. Although strength tests provide an

using the treated wash water part as of the mixing water. Giv- excellent measure of the efficiency of the quality control

en the small amount of the admixture usedfor this application, procedures that are employed, the strength-test results are

use of an activating admixture isnot usually required. available too late to be of practical use in controlling day-to-

day production.

4.6-Mixture temperature

Batch-to-batch uniformity of concrete from a mixer,par- 4.9-Maintenance

ticularly with regard to slump, water requirement, and air Mixers should be properly maintained to prevent mortar

content, also depends on the uniformity of the concrete tem- and dry material leakage. Inner mixer surfaces should be

perature. Controlling the maximum and minimum concrete kept clean and worn blades should be replaced. Mixers not

temperatures throughoutall seasons of the year is important. meeting the performance tests referenced in Section 4.8

Concrete can be cooled using ice, chilled mixing water, should be taken out of service until necessary maintenance

chilled aggregates, or liquid nitrogen. In-place concrete tem- and repair corrects their deficient performance.

peratures as low as 40 F (4 C) are not unusual.

Liquid nitrogen at a temperature of -320 F (-196 C) can 4.10-General considerations for transporting

beused to chill mixture water, aggregates, or concrete concrete

(Anon. 1977). Liquid nitrogenhas been injected directly into 4.10.1 General-Concrete can be transported by a variety

central mixers, truck mixers, or both toachieve required con- of methods and equipment, suchas pipeline, hose, conveyor

crete temperatures (Anon. 1988). Concrete can be warmed belts, truck mixers, open-top truck bodieswith and without

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

MEASURING, MIXING, TRANSPORTING, AND PLACING CONCRETE 304R-13

agitators, or buckets hauled by truck or railroad car. The 4.1 1-Returned concrete

method of transportation should efficiently deliver the con- Disposal of returned concreteis becoming more and more

crete to the point of placement withoutlosing mortar or sig- difficult for some producers. Two approaches for alleviating

nificantly altering the concrete’s desired properties this problem are currently being used:

associated with wlcm, slump, air content, and homogeneity. 4.11.1 Admixtures-Extended-set admixtures weredevel-

Various conditions should be considered when selecting a oped to address the need to holdreturned concreteovernight.

method of transportation, such as: mixture ingredients and These admixtures are also used to hold concrete during the

proportions; type and accessibility of placement; required day for reuse on the same day.

delivery capacity; location of batch plant; and weather con- The appropriate dosageof admixture is determined by the

ditions. These conditions candictate the type of transporta- mixture characteristics, the quantity of concrete to be stabi-

tion best suited for economically obtaining quality in-place lized or held, and the length of time that the concrete is to be

concrete. held. Depending on the length of time that the concrete is

4.10.2 Revolving drum-In this method, the truck mixer held, an accelerating admixture may be required. The stabi-

(Section 4.2.5) serves as an agitating transportation unit. The lized concrete is usually blended with freshly batched con-

drum is rotated at charging speed during loading andis re- crete before beingsold.

duced to agitating speed or stopped after loading is complete. Various methods have been developed by concrete pro-

The elapsed time before discharging the concrete can bethe ducers to handle and determine the volume of returned con-

same as for truck mixing and the volume carried can be in- crete. In some cases, all returned concrete is transferred at

creased to 80% of the drum capacity(ASTM C 94). the end of a day to a single mixer for treatment andholding.

4.10.3 Truck body with and without an agitator-Units Other producers have elected to handle the concrete on a

used in this form of transportation usually consist ofan truck-by-truck basis.

open-top body mounted on a truck, although bottom-dump 4.11.2 Mechanical methods-Equipment has been devel-

trucks have been used successfully. The metal body should oped to process plastic, unused concrete returnedto a plant.

have smooth, streamlined contact surfaces and is usually de- This equipment typically involves washing the concrete to

signed for discharge of the concrete at the rear when the body separate it into two or more components. Someor all of the

is tilted. A dischargegate and vibrators mounted on the body components are then reused in concreteproduction.The

should be provided at the point of discharge for control of components can include coarse and fine aggregate, com-

flow. An agitator, if the truck body isequipped with one, aids bined aggregate, and a slurry of cement and water, some-

in the discharge and ribbon-blends the concrete as it is un- times called gray water.

loaded. Water should neverbe added to concrete in the truck Although the processed components can often be reusedin

body because no mixingis performed by the agitator. new concrete, a concrete producer should take care to ensure

Use of protective covers for truck bodies during periods of that these materials will not adversely affect the new con-

inclement weather, proper cleaning of all contact surfaces, crete. Variations in aggregate grading canoccur due to deg-

and smooth haul roadscontribute significantly to the quality radation of the previously used aggregate during mixingor

and operational efficiency of this form of transportation. The reclaiming. Use of the slurry can affect strength and setting

maximum delivery time specified is usually 30 to 45 min, al- time. Conduct appropriatetesting to verify that the concrete

thoughweather conditionscan require shorter or permit meets project requirements.

longer times.

Trucks that have to operate on muddy haul roads should CHAPTER 5-PLACING CONCRETE

not be allowed to discharge directly on the grade or drive 5.1-General considerations

through the discharged pile of concrete. This chapter presents guidelines for transferring concrete

4.10.4 Concrete buckets on trucks or railroadcars-This from the transporting equipment to its final position in the

is a common method of transporting concrete fromthe batch structure.

plant to a location close to the placement areaof a mass con- Placement of concrete is accomplished with buckets, hop-

crete placement. A crane then lifts the bucket to the final pers,manualormotor-propelledbuggies,chutesanddrop

point of placement. Occasionally,transfer cars operating on pipes, conveyor belts, pumps, tremies, and paving equipment.

railroad tracks are used to transport the concrete from the Figure 5.1 and 5.2 show a number of handling and placing

batch plant to buckets operating from cableways. Discharge methods discussed in this chapter and give examples of both

of the concrete fromthe transfer cars into the bucket, which satisfactory and unsatisfactory construction procedures.

can be from the bottom or bysome formof tilting, should be Placement of concrete by the preplaced aggregate method

closely controlled to prevent segregation. Delivery time for and by pumps and conveyors is discussed in Chapters 7, 9,

bucket transportation is the same as for other nonagitating and 10, respectively. In addition, placing methodsspecific to

units-usually 30 to 45 min. underwater,heavyweight, and lightweightconcreting are

4.10.5 Other methods-Transporting of concreteby noted in Chapters 8, 11, and 12, respectively. Another effec-

pumpingmethodsandbybeltconveyorsare discussed in tive placement techniquefor both mortar and concrete is the

Chapters 9 and 10, respectively. Helicopter deliveries have shotcrete process. Thin layers are applied pneumatically to

been used in difficult-to-reach areas where other transporting areas where forming is inconvenient or impractical, access

equipment could not be used. This system usually employs or location provides difficulties, or normal casting tech-

one of the methods described previously to transport the niques cannot be employed (AC1 506R).

concrete to the helicopter, which then lifts the concrete in a Placing of concrete by the roller-compacted methodis not

lightweight bucketto the placement area. covered in this guide. Refer to AC1 207.5R.

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

304R-14 AC1 COMMITTEE REPORT

~~

UNLEO

S SI S C H A R G

COEF N C R E FT RE OMMI X E R S I S C O N T R O L L E TOHU. EN I F O R M I TR YE S U L T I N G

F R OEMF F E C T I VMEI X I N G

"- WILL BE U E S l R O Y ESB O

EY P A R A T I O N

b.

17

I N C O RCROE RC RT E C T

DfiOPPING OF CONCRETE DROPPING OF CONCRET!

A O E O U A T E D I R E C T L Y O V E R GATE ON S L O P I N GS I D E S Cf

OPEN 1NG HOPPER

CONCRETF

OISCHARGE

SHObLD

F I L L I C

N O

G N C R E T E

H O P P E R S O R B U C K E ~ S

I I I I

C O R R E C l

E l l H E R O f THE

ARRPNGEMENTS

ATTHL

LEFTPRE'JENTSSEPARATIONREGARDLESS

OF L E N G T H OF CHUTE OR CCNVEYOR, I N C O R R E C T

WETHER UISCHORGING CONCP!IC INTO

BUCKETS. CARS,

TRUCKS,

C O N RT

CR HOPPERS.

O L O F SE P A R A T I O N A S

I DISCHARGE FROM C E N l L R O P E N I N G T O

G EVTE R T I C A L

BUGGY ALTERNATE

DROP I N T O CENTER OF

APPROACH

~~~

FROP4

SLOPINGHOPPERGATE)LIHICH

ARE I NE F F E C TC H U T E S

OUT [NDCONTROLCPUSING

WITH

c0K c R E T E Is r~J s c H A R G E 0 O P P O S I T E S I D E S P E R M I T S AS R A P I D D E J L C I I O N O B L ES E P A R A T I O NI N

F R O M M I X E R S LOODING O S MAY BE O B T A I N E OL I I T H F I L L I N G THE BUGGIES

I H EO B J F l T I C N A h L ED I V I D E DH O P P E R S

H A \ I I f I ú T..C DISCHARGEGATES

d.

D I S C H A R G E O F H O P F E FR OS R

BAÇfLE \CRAPERRUBBER HEAD INCH

ROOF: FOR

UOWNP I P t

PVOVIDE A{o'$/ . " ..

t O U N T E R WEIGH1 L O A D I CN OG P ! C R E T E

NO B A F F L E

e.

B U G G I E S I o/

HEADROOM

F O R UOdNPIPE

I N C O R R E C T C O R R E C T

THE A B O ' l i ARRANGEMENT PREVENTS I Y P R @ P l R O R CONPLETE

LACK O F COIIIROL PT

S E P A R P T I O N OF CONCRETE

WHETHER ENO O F B E LUTS U A L L Y A B A F F L E OR SHOLLOIJ

IT I S B E I N G DISCHARGED INTO

HOP- tIOPPER YERELY C H A N G t ST H ED I R E C T I O N DF C O R R E C T

PERS, BUCKLTS. CORS.

TRUCKS, OR SEPARATION THC ABO'JE ARRANGEMEIIT PREVENTSSEPA-