Professional Documents

Culture Documents

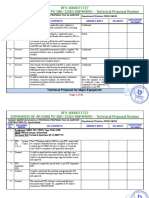

SR No Project Name Dept Problem Date (Tentative) Work Executed by Problem Pointed by

Uploaded by

dhavalesh0 ratings0% found this document useful (0 votes)

38 views5 pagesOriginal Title

Learnings from Projects.xlsx

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views5 pagesSR No Project Name Dept Problem Date (Tentative) Work Executed by Problem Pointed by

Uploaded by

dhavaleshCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 5

Sr No Project Name Dept Problem Date (tentative) Work Executed by Problem Pointed by

The % boroscopy selected for electropolished

Purified water at tubing in Unit-1 is 20% and DLP was 10%.This 2/24/17

1 Design Phase Nishith/Aditya Mr.Dharmesh Panchal

DLP was being debated and the ASME BPE

guidelines specifies minimum 20%.

The PCD of the manual flush ball valve at

reactor bottom was not matching with

2 Decoquinate - SRU Instrumentation Actuated FBV PCD. Also, the FBV stem was 1/1/17 Ilayaraja/Irshad Irshad

designed to move upward which was fouling

with bottom valve

Decoquinate Critical spares not considered in budget. Also, 12/1/16

3 Design Phase Ilayaraja/Abhinav Mr.Dharmesh Panchal

24TPM they were not ordered on time

Modifications done in clean area without

4 PWS API-1, 6 & 7 Mechanical clearance from all departments. HVAC 2/23/17 Nishith/Bharathiraja Mr.Vishakanta - QA

integrity was lost.

MSGLR's for Gabapentin process ordered to

Gabapentin Tech Swiss Glass coat. Based on Engg dept

5 expansion at API-7 Design Phase experience, GMM reactors are recommended 1/1/17 Veeraraghavan TP Prashantha

and Swiss Glass coat has repeated failures

The PCD of the flush ball valve at reactor

Decoquinate

6 Instrumentation bottom R 510 was not matching with Pad 12/20/16 Abhinav/Sachin Abhinav

24TPM flange PCD

The GA drawing was approved with

Venlafaxine, RCVD Bonfiglioli gear box. Final, As build drawing

Project for GA Approval &

7 was found with premium make gear box. (The 16-02-2017 TPI/ Pednekar Naveen

Intermediates Fabrication premium word is typed in brackets on the

drying above row under Motor, Bill of materials)

Some Centrifugal pumps are procured with a

NPSH-R of 2.8 m , where as NPSH-A is 23 m. TPI/Abhinav/ Mohan

8 API-5 Expansion Design Phase Excess NPSH resulted in deviation of pump 3/30/17 Ilayaraja kumar

performance and pressure w.r.t design.

During comissioning of pumps in more

quantity, discrepancy in pump start up

Ilayaraja/Abhinav/Aditya Ilayaraja/Abhinav/TPI

9 API-5 / SRU Execution Phase related to seal cooling and pump number 3/30/17 /Santhosh

mismatch resulted in mechanical seal

failures.

Corrective action taken How to implement for future projects

1. Study the related guidleines prior to

Under discussion with vendor to designing.

implement 20% boroscopy 2. Understand from SME (subject matter

expert)

1. GAD of reactor (pad flange PCD) to be

Spare valve available with Engg verified with PCD of FBV & manual valve prior

was utilized to ordering. 2. Instrumentation, PE & Project

engineer to check the drawings and orientation

prior to ordering

Spares ordered during execution 1. To be included in IP file

of project

Particle count etc scheduled for 1. Execution to be done with documented

the areas clearances from all dept's involved

1. Discuss with site engineering team prior to

Under discussion release of order for major equipments.

1. GAD of reactor (pad flange PCD) to be

Spare valve available with SRU is verified with PCD of FBV. 2. Instrumentation, PE

utilized & Project engineer to check the drawings and

orientation prior to ordering

As the supplied, gear box of 1. Unnecessary words mentioned in the GA

other make premium drawing to be removed, if there is ambiguity

transmission also is technically find meanings only from Vendor, not google.

ok and already used in the site, 2. Increase awarness on various vendors who

there was no further concern supply major parts of your equipment

Under discussion

Dedicated checklists prepared

for pump comissioning , covering It is mandatory to comission the pumps by de-

coupling as per the checks.

all the steps to be followed.

Civil

Design Phase

Electrical

Mechanical

Safety

Instrumentation

You might also like

- Subsea Rigid Pipelines – Methods of InstallationFrom EverandSubsea Rigid Pipelines – Methods of InstallationRating: 5 out of 5 stars5/5 (1)

- Interior & Exterior PaintingDocument11 pagesInterior & Exterior PaintingGabriel Gabe50% (2)

- Ledge Wall ConstructionDocument3 pagesLedge Wall ConstructionGabriel Gabe100% (1)

- Schedule of Rates 2011 Rev1Document144 pagesSchedule of Rates 2011 Rev1Screen BiruNo ratings yet

- BORL Feedback: Workshop On Project Execution StrategiesDocument24 pagesBORL Feedback: Workshop On Project Execution StrategiesVinothrajaNo ratings yet

- 1994 CaRs R2 05july2023 Instrument Installation Detail Drawing For Fly Ash Handling SystemDocument6 pages1994 CaRs R2 05july2023 Instrument Installation Detail Drawing For Fly Ash Handling SystemVao Van Ngam VaoNo ratings yet

- 1993 CaRs R2 04july2023 Instrument Installation Detail Drawing For Bottom Ash Handling SystemDocument6 pages1993 CaRs R2 04july2023 Instrument Installation Detail Drawing For Bottom Ash Handling SystemVao Van Ngam VaoNo ratings yet

- We Design ReportDocument45 pagesWe Design Reportorode franklynNo ratings yet

- Cars XXXX (r1) - Vt4e T Dmpps PMB M 17 0211 Ms TanksDocument10 pagesCars XXXX (r1) - Vt4e T Dmpps PMB M 17 0211 Ms Tankstrần quânNo ratings yet

- Construction Methodology - Maholiya ProjectDocument6 pagesConstruction Methodology - Maholiya ProjectPrateek DasNo ratings yet

- IO DR 59 For The TCPH Flange Interf 89DP92 v2 1Document41 pagesIO DR 59 For The TCPH Flange Interf 89DP92 v2 1zstNo ratings yet

- Department: Piping Document No: 00/L.02A/0011Document4 pagesDepartment: Piping Document No: 00/L.02A/0011Tiger HongNo ratings yet

- Solid Block WorkDocument8 pagesSolid Block WorkGabriel GabeNo ratings yet

- IPS-MBD20031-In-512 - Data Sheet of Rotameter - ADocument3 pagesIPS-MBD20031-In-512 - Data Sheet of Rotameter - ANikhil KarkeraNo ratings yet

- Mgad IpsDocument8 pagesMgad IpsSuvranil BanerjeeNo ratings yet

- Basement Floor Screed ConcreteDocument5 pagesBasement Floor Screed ConcreteQAQC NandanamNo ratings yet

- IO DR 59 For The TCPH Flange Interf 89DP92 v2 2Document41 pagesIO DR 59 For The TCPH Flange Interf 89DP92 v2 2zstNo ratings yet

- Comments Resolution Sheet (CRS)Document31 pagesComments Resolution Sheet (CRS)SrinivasNo ratings yet

- Interͳdiscipline Check (Idc) : Civil Engineer LS Construction Engineer KRH 08Ͳ12Ͳ21 OwnerDocument21 pagesInterͳdiscipline Check (Idc) : Civil Engineer LS Construction Engineer KRH 08Ͳ12Ͳ21 Ownerramadh diyyazNo ratings yet

- YSD-P02-0508-HV-BKG-MS-00024 (01) - Air Handling Units-B PDFDocument1,168 pagesYSD-P02-0508-HV-BKG-MS-00024 (01) - Air Handling Units-B PDFZac Riego100% (2)

- Technical Specification for Level Control ValvesDocument13 pagesTechnical Specification for Level Control ValvesAylaNo ratings yet

- RevisionDocument154 pagesRevisionhalyNo ratings yet

- Standard Support GS RFCC Cilacap 2013Document269 pagesStandard Support GS RFCC Cilacap 2013Arief KarebetNo ratings yet

- VEN 3250 HGE 5-26-0019 1 GRV Pipe and ElbowDocument34 pagesVEN 3250 HGE 5-26-0019 1 GRV Pipe and ElbowOiltech EngineeringNo ratings yet

- 1793 CaRs R1 12sep2022 Outline Dimensional and Internal Drawing For Panels, Junction Box, LCP For Bottom Ash Handling System - HDEC ReplyDocument4 pages1793 CaRs R1 12sep2022 Outline Dimensional and Internal Drawing For Panels, Junction Box, LCP For Bottom Ash Handling System - HDEC ReplyVao Van Ngam VaoNo ratings yet

- Note On Working Estimate - Package-2Document6 pagesNote On Working Estimate - Package-2gkkmailzNo ratings yet

- F Qa 48 Ppap Readiness Sheet For 0.7lDocument4 pagesF Qa 48 Ppap Readiness Sheet For 0.7lVikas RaiNo ratings yet

- Hydrotest Procedure For PipelineDocument12 pagesHydrotest Procedure For PipelineCarlos Luis Esquerdo Marcano100% (3)

- Comments On Chilled Water Pipes MethodDocument3 pagesComments On Chilled Water Pipes MethodAbdelrhman EsawyNo ratings yet

- Design Document Review Report - MEP PDFDocument3 pagesDesign Document Review Report - MEP PDFmohamed abd elatifNo ratings yet

- Strategic Reservoirs at Makkah Phase Ii & Taif Phase I Revision SheetDocument2 pagesStrategic Reservoirs at Makkah Phase Ii & Taif Phase I Revision SheetAnonymous uLAATWpfNo ratings yet

- Tracking Sheet - 01-25-2019 - GF ResponseDocument11 pagesTracking Sheet - 01-25-2019 - GF Responsewalid MegahedNo ratings yet

- Bulk Material/Part Ppap Process Checklist / Approval: Required?Document32 pagesBulk Material/Part Ppap Process Checklist / Approval: Required?krds chidNo ratings yet

- SP 1211Document87 pagesSP 1211Anoop gokhaleNo ratings yet

- 7 CFT MOM 29 10 14 - With Comments - 1Document2 pages7 CFT MOM 29 10 14 - With Comments - 1spdhimanNo ratings yet

- Engineering Contractor's Scope for HRRL Surface Condenser PackageDocument11 pagesEngineering Contractor's Scope for HRRL Surface Condenser PackageSubrata DasNo ratings yet

- Engineering Contractor's Scope for HRRL Surface CondensersDocument12 pagesEngineering Contractor's Scope for HRRL Surface CondensersSubrata DasNo ratings yet

- MHP-21-DEC-CEB-0289 From DEICDocument16 pagesMHP-21-DEC-CEB-0289 From DEICPasan RajasingheNo ratings yet

- Membrane Nitrogen Generator Datasheet ReviewDocument3 pagesMembrane Nitrogen Generator Datasheet ReviewVijay - Spantech EngineersNo ratings yet

- PPAP Documents for Needle Roller BearingsDocument12 pagesPPAP Documents for Needle Roller Bearingssiva dhamotharanNo ratings yet

- Ds-pp-0006 - Data Sheet For Sampling Jars (Rev.0) - 24!10!2023Document3 pagesDs-pp-0006 - Data Sheet For Sampling Jars (Rev.0) - 24!10!2023Panisa BanimaNo ratings yet

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDocument4 pagesNghi Son 2 BOT Thermal Power Plant Project Design Query SheetMr NgocNo ratings yet

- Owner Status Code: PMC Status CodeDocument4 pagesOwner Status Code: PMC Status CodebalajikrishnanNo ratings yet

- Interͳdiscipline Check (Idc) : Civil Engineer LS Construction Engineer KRH 08Ͳ12Ͳ21 OwnerDocument52 pagesInterͳdiscipline Check (Idc) : Civil Engineer LS Construction Engineer KRH 08Ͳ12Ͳ21 Ownerramadh diyyazNo ratings yet

- Painting MSDocument11 pagesPainting MSGabriel GabeNo ratings yet

- RFX 4000071727 - AR RASS PV 380/132kV GIS Technical ProposalDocument40 pagesRFX 4000071727 - AR RASS PV 380/132kV GIS Technical ProposalHaniegrace Lopez SandroNo ratings yet

- 01 Revamp Unit Lessons Learnt PPT - ProcessDocument22 pages01 Revamp Unit Lessons Learnt PPT - ProcessDeepak KatiyarNo ratings yet

- Circulating Water Pipes and Fittings - Rev 1Document14 pagesCirculating Water Pipes and Fittings - Rev 1Yurizal firmansyahNo ratings yet

- PC Scope of Work For Rumaitha / Shanayel Production Restoration & 20% Technical Rate ADNOC Contract No.: 16597.01 Project No: P44019Document41 pagesPC Scope of Work For Rumaitha / Shanayel Production Restoration & 20% Technical Rate ADNOC Contract No.: 16597.01 Project No: P44019talalNo ratings yet

- Nigeria LNG Limited Piping Components ProcedureDocument16 pagesNigeria LNG Limited Piping Components ProcedureMathias OnosemuodeNo ratings yet

- Method For Installation of PEHD ManholesDocument14 pagesMethod For Installation of PEHD ManholesPipeline EngineerNo ratings yet

- Interͳdisciplinecheck (Idc)Document63 pagesInterͳdisciplinecheck (Idc)ramadh diyyazNo ratings yet

- Technical Description of Chemical Injection SystemsDocument5 pagesTechnical Description of Chemical Injection Systemsbmanojkumar16No ratings yet

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDocument4 pagesNghi Son 2 BOT Thermal Power Plant Project Design Query SheetMr NgocNo ratings yet

- Smn-V-Fbi-P-Pd-00-001 - Rev 1 - ItpDocument6 pagesSmn-V-Fbi-P-Pd-00-001 - Rev 1 - Itpono_czeNo ratings yet

- API667 VS API662-1 ChangesDocument11 pagesAPI667 VS API662-1 Changesinspectormag8793No ratings yet

- Ilovepdf MergedDocument47 pagesIlovepdf MergedVijay Allimuthu AvathipalayamNo ratings yet

- Procedure For Preparation of Water/Foam Monitor Data Sheet: Quality Management System DocumentDocument7 pagesProcedure For Preparation of Water/Foam Monitor Data Sheet: Quality Management System DocumentmNo ratings yet

- 26071-100-VSC-CV5-00009 - Method Statment of Sheet Pile 00ADocument13 pages26071-100-VSC-CV5-00009 - Method Statment of Sheet Pile 00ARezky BaskoroNo ratings yet

- Final Inspection Report 12-E-101 ADocument4 pagesFinal Inspection Report 12-E-101 AYudi Ibnu ChannelNo ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- B31.1 Vs B31.3Document18 pagesB31.1 Vs B31.3Muhammed Ali Noureddeen100% (2)

- A Method For Prediction of Gas/Gas Ejector PerformanceDocument6 pagesA Method For Prediction of Gas/Gas Ejector PerformancedhavaleshNo ratings yet

- GDE Intro To Headspace PDFDocument35 pagesGDE Intro To Headspace PDFEdwin Guevara RNo ratings yet

- cs5 2ch1Document60 pagescs5 2ch1sitipertiwiNo ratings yet

- TK Trunnion Mounted Ball Valves Brochure PDFDocument32 pagesTK Trunnion Mounted Ball Valves Brochure PDFAcid HadiNo ratings yet

- Sizing Vacuum PumpsDocument3 pagesSizing Vacuum PumpsIka SetyaningsihNo ratings yet

- Linx2 Dissolved Gas Headspace Equilibration CalcsDocument4 pagesLinx2 Dissolved Gas Headspace Equilibration CalcsdhavaleshNo ratings yet

- Heating & Cooling Load Calculation Program - CLTD/CLF/SCL MethodDocument43 pagesHeating & Cooling Load Calculation Program - CLTD/CLF/SCL MethodSenthilnathanNo ratings yet

- Dielectric ConstantsDocument3 pagesDielectric ConstantsVanessa CarneiroNo ratings yet

- DJB82 (Chemical) : Remember - More Details Better Answers Also: If You Get A Response It's Polite To Respond To ItDocument14 pagesDJB82 (Chemical) : Remember - More Details Better Answers Also: If You Get A Response It's Polite To Respond To ItdhavaleshNo ratings yet

- Compressed Air System Design ManualDocument26 pagesCompressed Air System Design ManualBadrul HishamNo ratings yet

- Chemical Engineering Process Design: Mody and Marchildon: Chapter 16 Mixing and AgitationDocument11 pagesChemical Engineering Process Design: Mody and Marchildon: Chapter 16 Mixing and AgitationdhavaleshNo ratings yet

- Xvii Paper 44Document17 pagesXvii Paper 44dhavaleshNo ratings yet

- Whitepaper Optimal Temperature Solution enDocument8 pagesWhitepaper Optimal Temperature Solution endhavaleshNo ratings yet

- 1 2 3Document17 pages1 2 3dhavaleshNo ratings yet

- Fediol COD 2303Document31 pagesFediol COD 2303dhavaleshNo ratings yet

- How to Size Liquid Ring Vacuum PumpsDocument3 pagesHow to Size Liquid Ring Vacuum PumpsdayrogNo ratings yet

- Relief Batch ProcessesDocument20 pagesRelief Batch ProcessesMasood AkbarzaiNo ratings yet

- Quickly Design CO2 - Amine AbsorberDocument6 pagesQuickly Design CO2 - Amine AbsorbersnapshotspixNo ratings yet

- cs5 2ch1Document60 pagescs5 2ch1sitipertiwiNo ratings yet

- Chap3 2Document8 pagesChap3 2Sampathkumar AttuluriNo ratings yet

- Unesco - Eolss Sample Chapters: Measurement Tools For Pollution Sources and Ambient ConcentrationsDocument10 pagesUnesco - Eolss Sample Chapters: Measurement Tools For Pollution Sources and Ambient ConcentrationsdhavaleshNo ratings yet

- ArachchigeEJSR87 1Document10 pagesArachchigeEJSR87 1Trina HaqueNo ratings yet

- 6 12Document22 pages6 12forughshNo ratings yet

- Verification of The ASTM G-124 Purge Equation: Katherine E. Robbins and Samuel Eddie DavisDocument16 pagesVerification of The ASTM G-124 Purge Equation: Katherine E. Robbins and Samuel Eddie DavisdhavaleshNo ratings yet

- Study of CO2 Absorption & Desorption in A Packed ColumnDocument5 pagesStudy of CO2 Absorption & Desorption in A Packed ColumnCitra Queen'zNo ratings yet

- Principles of Inertization and Blanketing SystemsDocument14 pagesPrinciples of Inertization and Blanketing SystemserstendrainNo ratings yet

- 1455531920emergency Chlorine Scrubber TenderDocument21 pages1455531920emergency Chlorine Scrubber TenderdhavaleshNo ratings yet

- Engine Service Tool ReferenceDocument4 pagesEngine Service Tool ReferenceandrzejNo ratings yet

- Applying The Haar Wavelet Transform To Time Series InformationDocument27 pagesApplying The Haar Wavelet Transform To Time Series InformationJohn LemonNo ratings yet

- Software Hardware Tech x86 VirtDocument9 pagesSoftware Hardware Tech x86 VirtwyfwongNo ratings yet

- E12817 GT AC5300 Manual EnglishDocument152 pagesE12817 GT AC5300 Manual Englishlegato1984No ratings yet

- SPP 40 Series Sponsored BE MTech Projects CollegewiseDocument145 pagesSPP 40 Series Sponsored BE MTech Projects CollegewiseVinay KumarNo ratings yet

- Skybox Security Sales&Tech OverviewDocument46 pagesSkybox Security Sales&Tech Overviewerdem100% (1)

- Slurry Flo BrochureDocument4 pagesSlurry Flo BrochureChristian Andres Campa HernandezNo ratings yet

- BS 5896 2010Document33 pagesBS 5896 2010shashiresh50% (2)

- TNB AR 2022 Corporate StructureDocument2 pagesTNB AR 2022 Corporate StructureZamzuri P AminNo ratings yet

- Dealer FeedbackDocument3 pagesDealer FeedbackTarun BhatiNo ratings yet

- Paint Color Comparison ChartDocument132 pagesPaint Color Comparison ChartCarlos Rubiños AlonsoNo ratings yet

- NETWORK ANALYSIS Chap.8 TWO PORT NETWORK & NETWORK FUNCTIONS PDFDocument34 pagesNETWORK ANALYSIS Chap.8 TWO PORT NETWORK & NETWORK FUNCTIONS PDFsudarshan poojaryNo ratings yet

- Audio (Amplifier) - Electrical DiagnosticsDocument195 pagesAudio (Amplifier) - Electrical DiagnosticsRafael CherechesNo ratings yet

- Model Railroad Plans and DrawingsDocument7 pagesModel Railroad Plans and DrawingsBán ZoltánNo ratings yet

- Masterseal 550Document4 pagesMasterseal 550Arjun MulluNo ratings yet

- 3095MV Calibration Procedure W QuickCal Merian 4010Document8 pages3095MV Calibration Procedure W QuickCal Merian 4010luisalbertopumaNo ratings yet

- How To Choose Food StarchesDocument20 pagesHow To Choose Food StarchesBoat Tanin100% (3)

- Nec 2006Document59 pagesNec 2006loots69No ratings yet

- EOG Project2010Document34 pagesEOG Project2010Amey Kadam100% (2)

- Documentation of Xabe - FFmpegDocument11 pagesDocumentation of Xabe - FFmpegTomasz ŻmudaNo ratings yet

- Artikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsDocument9 pagesArtikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsJohny DoelNo ratings yet

- Damage To Stern Tube Bearing and SealsDocument4 pagesDamage To Stern Tube Bearing and SealsJoão Henrique Volpini MattosNo ratings yet

- Digital Logic and Microprocessor Design With Interfacing 2nd Edition Hwang Solutions ManualDocument27 pagesDigital Logic and Microprocessor Design With Interfacing 2nd Edition Hwang Solutions Manualdacdonaldnxv1zq100% (27)

- V 2172 0020 0031 - Rev - 6 (3458748) PDFDocument262 pagesV 2172 0020 0031 - Rev - 6 (3458748) PDFLG Milton LuisNo ratings yet

- Oracle SCM TrainingDocument9 pagesOracle SCM TrainingVishnu SajaiNo ratings yet

- Kodak 2000 Um SM SCHDocument157 pagesKodak 2000 Um SM SCHВиталий КоптеловNo ratings yet

- Breaking Water Protection Paradigms: RTM Composite DomesDocument52 pagesBreaking Water Protection Paradigms: RTM Composite DomesaerostressNo ratings yet

- Design Rules CMOS Transistor LayoutDocument7 pagesDesign Rules CMOS Transistor LayoututpalwxyzNo ratings yet

- College Report of Optical Burst SwitchingDocument21 pagesCollege Report of Optical Burst Switchingimcoolsha999No ratings yet