Professional Documents

Culture Documents

EE428 Industrial Process Control: Dr. Ammar Hasan

Uploaded by

abdurrehman0 ratings0% found this document useful (0 votes)

20 views36 pagesLecture on Industrial Process Control

Original Title

Lecture 1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLecture on Industrial Process Control

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views36 pagesEE428 Industrial Process Control: Dr. Ammar Hasan

Uploaded by

abdurrehmanLecture on Industrial Process Control

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 36

EE428 Industrial Process Control

Dr. Ammar Hasan

Dr. Ammar Hasan SEECS, NUST

Pre requisite

• EE332 Linear Control Systems

• You are expected to know the basics i.e.

– basic purpose of control

– concept of feedback/open loop

– purpose of sensors/actuator

– Transient response characteristics

• No need to know PID, root locus, Nyquist etc.

Dr. Ammar Hasan SEECS, NUST

Difficulty level

• Unlike LCS/DCS, it doesn’t include difficult

concepts or mathematics

• This course is more oriented towards

imparting information/knowledge/general

practices

• You will need a good memory to pass this

course

Dr. Ammar Hasan SEECS, NUST

Distribution of Marks

• Quizzes 9%

• 4-5 Assignments 3.5%

• OHTs 12.5% + 12.5%

• Lab 25%

• Final Exam 37.5%

Dr. Ammar Hasan SEECS, NUST

Quizzes and Assignments

• Six to seven graded quizzes

• Quizzes may be announced or un-announced

• There may be few practice quizzes, which are

ungraded

• Three to five assignments

• No “best of” policy

• There may be a make-up/extra credit assignment

after OHT2

Dr. Ammar Hasan SEECS, NUST

Cheating and Plagiarism

• Zero tolerance policy

• Any one found guilty will be penalized. Maximum penalties

could be

– zero in all assignments and quizzes

– Case sent to SEECS disciplinary committee for award of ‘F’ grade

• Plagiarism includes

– copying full or part of class mate’s assignment

– copy text from book, webpage, or paper, etc. without rephrasing and

proper referencing

Dr. Ammar Hasan SEECS, NUST

Labs

• 12-15 labs

• If you miss a lab, you can do it in your spare

time. Just talk to the lab engineer.

• In case of any issues with the lab, contact the

lab engineer. You can come to me if the issue

is not resolved.

• No decision yet for lab exam / viva / project

Dr. Ammar Hasan SEECS, NUST

Text Book

• Industrial Electronics by Terry L. Bartelt (2006)

• Industrial Automated Systems: Instrumentation and Motion

Control by Terry Bartelt (2011)

• Industrial Control Electronics by Terry Bartelt (2005)

Dr. Ammar Hasan SEECS, NUST

How to contact me

• Try to ask questions during the class so that

everyone can benefit from the answer

• After lectures

• During lab (if I am there)

• By Email

• Never call me on my mobile phone

Dr. Ammar Hasan SEECS, NUST

Class Rules

Avoid disruptive activities/behavior

-mobile phones

-talking in lectures

-being late

-etc.

Water bottles/drinks allowed in class (especially in summers)

Dr. Ammar Hasan SEECS, NUST

What is

Industrial Process Control (IPC)?

IPC is an area of engineering that deals with the

automation of tasks/processes in the industry.

It is also known by the following names

– Industrial Automation

– Industrial Control

– Instrumentation and control

Dr. Ammar Hasan SEECS, NUST

What is the relation/difference

between IPC and control theory?

Dr. Ammar Hasan SEECS, NUST

Application areas

• Oil and gas sector

• processed food manufacturing

• cement industry

• textile industry

• plastics industry

• medicine industry

• Almost every production/manufacturing industry

Dr. Ammar Hasan SEECS, NUST

What will be the general flavor of

this course?

Dr. Ammar Hasan SEECS, NUST

Labs / Lectures

Dr. Ammar Hasan SEECS, NUST

Course Contents

1. Indroduction to Industrial Process 14. Analytical Instrumentation

Control 15. Industrial Process Instrumentation

2. Interfacing devices 16. Process control methods

3. Thyristors 17. Industrial sensors and interfacing

4. The controller operation 18. Introduction to PLCs

5. DC motors 19. Fundamental PLC programming

6. AC motors 20. Advanced PLC programming

7. Servo Motors 21. Motion Control feedback devices

8. DC Drives 22. ELements of motion control

9. AC Drives 23. fundamentals of Serovmechanism

10. Pressure Systems

11. Temperature Control

12. Flow Control

13. Level Control Systems

Dr. Ammar Hasan SEECS, NUST

History

• The industrial revolution began in England during the mid-

1700s when it was discovered that productivity of spinning

wheels and weaving machines could be dramatically

increased by fitting them with steam-powered engines.

• Further inventions and new ideas in plant layouts during the

1850s enabled the United States to surpass England as the

manufacturing leader of the world. Around the turn of the

twentieth century, the electric motor replaced steam and

water wheels as a power source.

Dr. Ammar Hasan SEECS, NUST

History

• The concept of assembly line became popular in the early

20th century that significantly increased the production

• Between World Wars I and II, the feedback control system was

developed, enabling manually operated machines to be

replaced by automated equipment.

Dr. Ammar Hasan SEECS, NUST

Definition

• The term industrial controls is used to define the type of

system that uses feedback to automatically monitor

manufacturing processes and takes appropriate corrective

action if the operation is not performing properly.

Dr. Ammar Hasan SEECS, NUST

1.1 Classifications of Industrial

Control

• Industrial control systems are often classified

by what they control: either motion or

process.

Dr. Ammar Hasan SEECS, NUST

1.1.1 Motion control

• A motion control system is an automatic

control system that controls the physical

motion or position of an object. One example

is the industrial robot arm which performs

welding operations and assembly procedures.

Dr. Ammar Hasan SEECS, NUST

1.1.1 Motion control

• There are three characteristics that are

common to all motion control systems.

• Measurement of position/speed/acceleration

of a mechanical object

• Control position, speed or acceleration, or

deceleration

• Quick response that is usually in fractions of

seconds

Dr. Ammar Hasan SEECS, NUST

1.1.1 Motion control

• Motion control systems are also referred to as

servos, or servomechanisms.

• Some other examples of motion control

– CNC machine

– printing presses

– office copiers

– packaging equipment

– electronics parts insertion machines that place

components onto a printed circuit board.

Dr. Ammar Hasan SEECS, NUST

1.1.2 Process Control

• In process control, one or more variables of a

chemical/material/product are regulated

during the manufacturing of a product. These

variables may include temperature, pressure,

flow rate, liquid and solid level, pH, or

humidity. Examples include cement and paint

industry

Dr. Ammar Hasan SEECS, NUST

1.1.2 Process Control

• This regulated process must compensate for

any outside disturbance that changes the

variable.

• The response time of a process control

system is typically slow, and can vary from a

few seconds to several minutes

• Process control systems are divided into two

categories, batch and continuous.

Dr. Ammar Hasan SEECS, NUST

1.1.2.1 Batch Process

• Batch processing is a sequence of timed

operations executed on the product being

manufactured.

• An example is an industrial machine that

produces various types of biscuits

Dr. Ammar Hasan SEECS, NUST

1.1.2.1 Batch Process example:

Biscuit manufacturing

Dr. Ammar Hasan SEECS, NUST

1.1.2.1 Batch Process

• Batch process is also known as sequence (or

sequential) process

Dr. Ammar Hasan SEECS, NUST

1.1.2.2 Continuous Process

• In a continuous process, one or more

operations are being performed as the

product is being passed through a process.

Raw materials are continuously entering and

leaving each process step.

• An example is the production of paper

Dr. Ammar Hasan SEECS, NUST

1.1.2.2 Continuous Process

example: paper production

Dr. Ammar Hasan SEECS, NUST

1.1.2.2 Continuous Process

• The continuous process can last for hours, days, or

even weeks without interruption.

• Manufacturing of wire, textiles, plastic bags is a

continuous process.

• Other examples of continuous process control

applications are wastewater treatment, nuclear

power production, oil refining, and natural gas

distribution through pipe lines.

• Another term commonly used instead of process

control is instrumentation.

Dr. Ammar Hasan SEECS, NUST

1.1 Process control vs Motion

control

• The primary difference between process and motion

control is the control method that is required.

• In process control, the emphasis is placed on

sustaining a constant condition of a parameter, such

as level, pressure, or flow rate of a liquid.

• In servo control, the input command is constantly

changing. The emphasis of the system is to follow the

changes in the desired input signal as closely as

possible. Variations of the input signal are typically

very rapid.

Dr. Ammar Hasan SEECS, NUST

1.1 Classifications of Industrial

Control

• One of the classifications is with respect to the

type of system to be controlled.

• Another classification is whether the control is

open loop / closed loop

Dr. Ammar Hasan SEECS, NUST

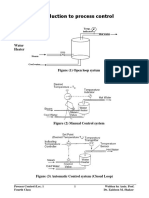

1.1.3 Open loop systems

• It is a system without feedback.

• Example is a tank that supplies water for

irrigation

Dr. Ammar Hasan SEECS, NUST

1.1.4 Closed loop systems

• Closed loop control is required in applications

require continuous monitoring and self-

correcting action of the operation for long

periods of time without interruption.

• This automatic system employs a feedback

loop to keep track of how closely the system is

doing the job it was commanded to do.

Dr. Ammar Hasan SEECS, NUST

1.1.4 Closed loop systems

Dr. Ammar Hasan SEECS, NUST

You might also like

- Course Introduction: - KlmsDocument75 pagesCourse Introduction: - Klms이정우No ratings yet

- Designs For Process SafetyDocument32 pagesDesigns For Process SafetyRobert WilsonNo ratings yet

- Today's EEE 101 Lecture: EEE 101 C 2002 M.C. Ramos UP EEE DepartmentDocument19 pagesToday's EEE 101 Lecture: EEE 101 C 2002 M.C. Ramos UP EEE DepartmentJulie AlicosNo ratings yet

- Chapter 1Document24 pagesChapter 1Anonymous tytJlPojNo ratings yet

- Mini-Split Maintenance: Best PracticesDocument16 pagesMini-Split Maintenance: Best PracticesFrancisco Sanchez RNo ratings yet

- Aseptic Processing The New GuidanceDocument56 pagesAseptic Processing The New Guidanceipatoff100% (1)

- Control Engineering For Chemical EngineersDocument11 pagesControl Engineering For Chemical EngineersYoga WiranotoNo ratings yet

- Dynamic Simulation and Chemical EngineeringDocument7 pagesDynamic Simulation and Chemical EngineeringhassanNo ratings yet

- CHE 61403 Week 1 Safety in Process Plant DesignDocument31 pagesCHE 61403 Week 1 Safety in Process Plant DesignPorkkodi SugumaranNo ratings yet

- Defect EliminationDocument8 pagesDefect EliminationHariKishore SudarsanamNo ratings yet

- AssignmentDocument16 pagesAssignmentMohamed SalemNo ratings yet

- Control System Training: History of Automation and ProcessDocument17 pagesControl System Training: History of Automation and Processchafic WEISSNo ratings yet

- 2 SET UTECH S and R 2024 INTRODUCTION HAZ CTRL RISK MGMTDocument27 pages2 SET UTECH S and R 2024 INTRODUCTION HAZ CTRL RISK MGMTChristieNo ratings yet

- Plant Operating ManualDocument28 pagesPlant Operating Manualshabbir100% (1)

- ARM Microcontroller & Embedded Systems Course Quality AttributesDocument22 pagesARM Microcontroller & Embedded Systems Course Quality Attributesshreyans.suggaNo ratings yet

- Unit-II: Characteristics of Embedded SystemsDocument25 pagesUnit-II: Characteristics of Embedded SystemsbalakrishnaNo ratings yet

- Process InstrumentationDocument71 pagesProcess InstrumentationPrasanna kumar subudhiNo ratings yet

- Predictive Maintenance (PDM) & Proactive Maintenance (Pam) : Dr. Khaleel AbushgairDocument22 pagesPredictive Maintenance (PDM) & Proactive Maintenance (Pam) : Dr. Khaleel AbushgairAbd Elrahman IssaNo ratings yet

- Slides 2017 04 UE SafetyDocument14 pagesSlides 2017 04 UE SafetyOsvald97No ratings yet

- Process DevelopmentDocument8 pagesProcess DevelopmentJesus DanielNo ratings yet

- Instrumentation For Process ControlDocument153 pagesInstrumentation For Process ControlAudrey Patrick KallaNo ratings yet

- Introduction to Instrumentation FundamentalsDocument31 pagesIntroduction to Instrumentation FundamentalsTeodoro Jr de JesusNo ratings yet

- Introduction OnkeshDocument12 pagesIntroduction OnkeshPatricia JosephNo ratings yet

- Hazard and Operability Study Guide (HAZOPDocument75 pagesHazard and Operability Study Guide (HAZOPVikas GaikwadNo ratings yet

- Lessons Learned From Process Safety Management A Practical Guide To Defense in DepthDocument24 pagesLessons Learned From Process Safety Management A Practical Guide To Defense in Depthselvajanar100% (1)

- (LCT-0001) EEE 101 IntroductionDocument4 pages(LCT-0001) EEE 101 IntroductionAnonymous EnggrUsmNo ratings yet

- Ch1 - Lecture 2Document54 pagesCh1 - Lecture 2Umer ImranNo ratings yet

- Process Dynamic and Control Lecture NoteDocument120 pagesProcess Dynamic and Control Lecture NoteUb UsoroNo ratings yet

- Safety and Health at WorkplaceDocument79 pagesSafety and Health at Workplaceمحمدفرحان100% (6)

- Production Line Instant NoodleDocument13 pagesProduction Line Instant NoodleAnisah Aniz100% (1)

- Chapter 2Document14 pagesChapter 2Sachin KNo ratings yet

- Process Control & Tuning of Industrial Control LoopsDocument2 pagesProcess Control & Tuning of Industrial Control LoopsHasen BebbaNo ratings yet

- Advanced Process Control and DynamicsDocument273 pagesAdvanced Process Control and DynamicsYinka OlatunjiNo ratings yet

- MA 4wrkshp Sept ZDocument4 pagesMA 4wrkshp Sept ZAszrol PonimanNo ratings yet

- Syllabus QuestionDocument4 pagesSyllabus QuestionHdhd HdhhdNo ratings yet

- Inherent SafetyDocument50 pagesInherent SafetyChing-Liang ChenNo ratings yet

- Introduction To Process Dynamics And ControlDocument34 pagesIntroduction To Process Dynamics And ControlJazer Mari CantosNo ratings yet

- MEM 355 Performance Enhancement of Dynamical Systems: Introduction To Control System DesignDocument26 pagesMEM 355 Performance Enhancement of Dynamical Systems: Introduction To Control System DesignmarbonfNo ratings yet

- NIOSH Work Permit System NewDocument92 pagesNIOSH Work Permit System Newsanpkaru100% (1)

- Infection Prevention in Design and Construction of The Healthcare EnvironmentDocument69 pagesInfection Prevention in Design and Construction of The Healthcare EnvironmentjariyarasheedNo ratings yet

- Sistem Kendali: Sesi 1Document45 pagesSistem Kendali: Sesi 1Ayu Yunita SariNo ratings yet

- HazopDocument75 pagesHazopSaima Saima89% (9)

- 3014all - 7th Semester - Mineral EngineeringDocument62 pages3014all - 7th Semester - Mineral EngineeringadNo ratings yet

- 1.1. The Very BasicsDocument3 pages1.1. The Very BasicsAndres Echeverri CastroNo ratings yet

- Environmental Stress Screening TutorialDocument30 pagesEnvironmental Stress Screening TutorialMariut Elena LarisaNo ratings yet

- National University Process Dynamics Modelling & Control CourseDocument15 pagesNational University Process Dynamics Modelling & Control CourseKundayi ChagwederaNo ratings yet

- Embedded System Design Concepts Module-4: Characteristics & Quality Attributes of Embedded SystemsDocument14 pagesEmbedded System Design Concepts Module-4: Characteristics & Quality Attributes of Embedded Systemsbalajibs203285No ratings yet

- Human Factors CHPT 7Document34 pagesHuman Factors CHPT 7Johnson MangumaNo ratings yet

- Operating Procedures, Safety Procedures & TrainingDocument51 pagesOperating Procedures, Safety Procedures & TrainingashwaniNo ratings yet

- Importance of Control ValvesDocument31 pagesImportance of Control ValvesIndranil Hatua100% (1)

- Group-1 Introduction ChE-5202Document5 pagesGroup-1 Introduction ChE-5202Zoren A. Del MundoNo ratings yet

- Preventive MaintenanceDocument20 pagesPreventive MaintenanceMuhammad Aqeel Ashraf50% (2)

- Industrial Training PresentationDocument16 pagesIndustrial Training PresentationChia Yi MengNo ratings yet

- Basic Hydraulic SystemDocument142 pagesBasic Hydraulic SystemAlif Aizat Azman100% (1)

- Characteristics and quality attributes of embedded systemsDocument24 pagesCharacteristics and quality attributes of embedded systemsKarneshwar SannamaniNo ratings yet

- My Notes PCTDocument36 pagesMy Notes PCTPortia ShilengeNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- ArticleDocument9 pagesArticleabdurrehmanNo ratings yet

- UAF 2022-23 Postgraduate Prospectus SummaryDocument2 pagesUAF 2022-23 Postgraduate Prospectus SummaryabdurrehmanNo ratings yet

- A Biochemical Network Modeling of A Whole CellDocument14 pagesA Biochemical Network Modeling of A Whole CellabdurrehmanNo ratings yet

- Lec 1Document21 pagesLec 1abdurrehmanNo ratings yet

- EE428 Industrail Process Control - OutlineDocument3 pagesEE428 Industrail Process Control - OutlineabdurrehmanNo ratings yet

- Fba Mastery ConsentDocument2 pagesFba Mastery ConsentabdurrehmanNo ratings yet

- Dated: 15 June, 2016 To Whom It May ConcernDocument1 pageDated: 15 June, 2016 To Whom It May ConcernabdurrehmanNo ratings yet

- Single-Phase VFD Cooling Control ProposalDocument11 pagesSingle-Phase VFD Cooling Control ProposalabdurrehmanNo ratings yet

- Lecture 2Document37 pagesLecture 2abdurrehmanNo ratings yet

- Frequency Controlled Air ConditioningDocument10 pagesFrequency Controlled Air ConditioningabdurrehmanNo ratings yet

- White Paper For Variable Frequency Controlled Air ConditioningDocument2 pagesWhite Paper For Variable Frequency Controlled Air ConditioningabdurrehmanNo ratings yet

- PESTE Analysis On Different Types Energy Processes - Energy From WasteDocument6 pagesPESTE Analysis On Different Types Energy Processes - Energy From Wasteabdurrehman100% (2)

- Employee EngagementDocument8 pagesEmployee EngagementabdurrehmanNo ratings yet

- Lecture 5 Block Diagram Representation of Control Systems PDFDocument60 pagesLecture 5 Block Diagram Representation of Control Systems PDFNicole Anne BorromeoNo ratings yet

- Pe-3032 WK 1 Introduction To Control System March 04Document70 pagesPe-3032 WK 1 Introduction To Control System March 04Charlton S.Inao100% (2)

- Turbine Flow Loop ReportDocument20 pagesTurbine Flow Loop ReportajalbornozNo ratings yet

- DSP Control of Stepper MotorDocument5 pagesDSP Control of Stepper MotorAhmedHyderMohdNo ratings yet

- Instrumentation Diploma Process Control GuideDocument126 pagesInstrumentation Diploma Process Control GuideShakerMahmoodNo ratings yet

- Control Systems Manual StudentDocument75 pagesControl Systems Manual StudentJamesNo ratings yet

- Kta 3504Document29 pagesKta 3504Juan Manuel Gutierrez AguilarNo ratings yet

- R&M ControlMaster PDFDocument6 pagesR&M ControlMaster PDFUongNo ratings yet

- Controlling DC Motor Position, Using PID Controller Made by PIC MicrocontrollerDocument9 pagesControlling DC Motor Position, Using PID Controller Made by PIC Microcontrollerminh nguyenNo ratings yet

- Control Systems Engineering PDFDocument243 pagesControl Systems Engineering PDFranjitha gavniNo ratings yet

- EE2253 Control Systems NotesDocument124 pagesEE2253 Control Systems NotesrameshsmeNo ratings yet

- Temperature Control of Exothermic ReactionDocument8 pagesTemperature Control of Exothermic ReactionAhmad MuzammilNo ratings yet

- Modern Control Design with MATLAB and SIMULINKDocument518 pagesModern Control Design with MATLAB and SIMULINKPrajwal Bikram Thapa94% (17)

- Sankalchand Patel UniversityDocument3 pagesSankalchand Patel UniversityDivyNo ratings yet

- Magtrol: AHB Series Compressed-Air-Cooled Hysteresis BrakesDocument12 pagesMagtrol: AHB Series Compressed-Air-Cooled Hysteresis Brakessezgin bayramNo ratings yet

- 1.1.3.11 Lab - Draw A Process DiagramDocument3 pages1.1.3.11 Lab - Draw A Process DiagramZeidan Mohammad0% (1)

- Internship ReportDocument39 pagesInternship ReportUtkarsh YadavNo ratings yet

- Journal of Manufacturing Processes: Peter Groche, Florian Hoppe, Daniel Hesse, Stefan CalmanoDocument9 pagesJournal of Manufacturing Processes: Peter Groche, Florian Hoppe, Daniel Hesse, Stefan CalmanoheryuanoNo ratings yet

- Process Instrumentation 2Document8 pagesProcess Instrumentation 2Aditya RasalNo ratings yet

- Mechatronics Characteristics and Control SystemsDocument27 pagesMechatronics Characteristics and Control SystemsShivani Ekant Yadav100% (14)

- Yaska L1000a Ac DriveDocument16 pagesYaska L1000a Ac DriveShahid YousafNo ratings yet

- Mod-5 22 Eme13Document22 pagesMod-5 22 Eme13SHARATH RNo ratings yet

- Automation & ControlDocument107 pagesAutomation & ControlAlpesh Shah100% (1)

- Temperature Control SystemDocument5 pagesTemperature Control SystemGoutham HereNo ratings yet

- PDF Drive Command Data Sets en V2 1Document34 pagesPDF Drive Command Data Sets en V2 1Luis RodriguezNo ratings yet

- Zairus Fadzli CV 2010Document8 pagesZairus Fadzli CV 2010ABB_Zairus_FadzliNo ratings yet

- Pid Tuning ClassicalDocument18 pagesPid Tuning ClassicalVo Quang HuyNo ratings yet

- YAKO MS-S3 User Manual-V2.1-190604Document26 pagesYAKO MS-S3 User Manual-V2.1-190604dominant cncNo ratings yet

- Lect 1 Introduction To Process ControlDocument4 pagesLect 1 Introduction To Process ControlZaidoon MohsinNo ratings yet