Professional Documents

Culture Documents

APN Broucher

Uploaded by

pixieCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APN Broucher

Uploaded by

pixieCopyright:

Available Formats

Our Company APN

Ace Petro Networks is a Singapore based Private Limited Company, incorporated in 2003. It is up coming in the market and we serve quality products to customers,

in accordance with their customized specification or in compliance with API or ASME Standards. We have already established ourselves as a reputed supplier within

our work scope. We also have a strong & potential team working on Engineering, Quality, Sales and Marketing and with our experience & commitment, we are

determined to deliver the highest quality products to achieve customers’ trust.

We believe in forming long-term relationships with all our customers and delivering products within scheduled time and budget of our customers. Our company has

formed a strategic alliance with approved vendors with ISO & API Certifications

Singapore India

1, Bukit Batok Crescent 31/39, TMP Nagar

#06-35, Wcega Plaza, P/ Code 658064 Padi, Chennai, Pin 600 050

Tel 65-63163893 Tel 91-44-26259294

Fax 65-63163891 Fax 91-44-26259037

apn999@singnet.com.sg enquiry@acepetro.com

www.acepetro.com www.acepetro.com

Components for Valve and Sealing

Quality products for Oil & Gas, Marine and Petrochemical Industries

Our Products APN

• Valve components • Gaskets (RTJ)

Seat ring Adaptors R Series Bonnet gasket (flat type)

Bonnet Hand wheels RX Series Customized gaskets

Gate Gland BX Series

Stem Ball ½” to 16”

Bearing cap

RX Series Bonnet gasket (flat type)

Seat rings Stem Hand Wheel

R Series BX Series Customized gasket

Bonnet Bearing Cap Gland

• Spiral wound gasket

Type I Filler with winding strip

Type II Filler with Winding strip & Outer ring

Type III Filler with Winding strip & Inner ring

Gate Adapter Ball Type IV Filler with Winding strip, Outer & Inner ring

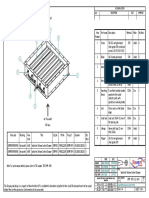

• Flanges (API 6A) Gate Valve Part List

1 Item Description Qty Item Description Qty

Threaded flange

Weld neck flange 8 1 Handwheel aseembly 1 15 Grease Fitting 1

Blind flange 17 7 2 Bearing Cap 1 16 Gasket 1

Instrument flange 3

4

9

5 3 Grease Fitting 2 17 Stem 1

2 6

13 10 4 O-Ring 1 18 Gate 1

12 11 5 Bearing Race 4 19 Retainer Plate 2

15 14 6 Thrust Bearing 2 20 Seat Ring2

16 16

7 O-Ring 1 21 Seal Ring (Seat Ring) 2

8 Stem Adapter 1 22 Pin (Not Shown) 2

9 Stem Pin 1 23 Body 1

10 Packing Gland 1 24 Guide 2

Threaded flange Blind flange

11 “J” Packing 1 25 Seal Ring (Body Bushing) 2

24,19 23 20 21 26 25

12 Nut 8 26 Body Bushing 2

13 Stud 8 27 Name Plate (Not Shown) 1

14 Bonnet 1

Weld neck flange Instrument flange * Material :AISI grads Dimensi

Dimension:ASME/API

s on:ASME/API Standards Or Customers Specifications

Components for Valve and Sealing

Quality products for Oil & Gas, Marine and Petrochemical Industries

Agency Products

APN

Fasteners Dimension Range For Open Die Forgings

Material ASTM A194 Grade B7 & B7M

ASTM A193 Grade 2H & 2HM ID

Instrument valve fitting

Material SS316, SS316L CS, Alloy 400

Fastener

& Alloy 600 h h

D

Hammer Union

D max = 1.800mm

Material ASTM and AISI standards &

h max = 400 mm OD

confirm to API 16C Specifications max. weight = 9.000 kg

Instrument valve & accessories, OD max = 950mm

Tube fittings, manifolds h max = 2.500 mm

Open & close Die forgings

max. weight = 4.500 kg

Material ASTM and AISI standards (or)

Customer specifications & drawings

ID

Investment casting

Customer specification & drawings Hammer Unions h D

Iron & steel casting OD L

Customer specification & drawings D max = 2.200mm D max = 850mm

h max = 800 mm h max = 10.000 mm

max. weight = 6.000 kg max. weight = 12.000 kg

Quarter turn Gear Box

Open & close Die forging

Customer specified brands and applications

Forged Steel flanges Other services

Material ASTM and AISI standards (or) • Heat treatment

Customer specifications & drawings • Vacuum Heat treatment

Investment casting • Plating (Copper Zinc, Silver.Xylon)

• Nitriding

• Plasma nitriding

• Laser welding

• Lapping

• Zinc

Z phosphate

Forged steel flanges gear box Iron & steel casting • M

Molybdenum disulphide coating

Components for Valve and Sealing

Quality products for Oil & Gas, Marine and Petrochemical Industries

Our Process APN

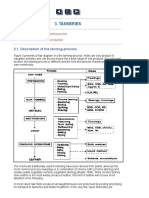

ACE PETRO NETWORKS - Process Management

Investors Interact and obtain customer feedback

Performance Interact and obtain Clarifications

Improvements

Auditors ( Internal & External) No

Process Owners / Managers Yes Receive

Customer Design documents / Feasible

Customer / Client provided

Coordination & Requirements design Information / Drawings

Potential Improvements

No Yes

Design & Development by

Shopfloor Team ACE Petro Networks ( India)

Pvt. Limited Marketing

Process Management View (Review the

Enquiry Enquiry Review

Influences Drawings & accept the

Management Systems Material Specifications order)

Machining Dimensions

ults

Knowledge & Skills

Res

Packing Requirements

Structure & Roles Plating procedures Submission of Quote by Marketing

Processes Behaviours Performance

Attitude Cost Sheet

Production Plan

Perceptions Process Flow Chart

Control Plan Receipt of PO / Job Order with or without Trial Order Inform / Send copy to

IT Systems Operating Standard ( With or without Mateial) Purchasing / Production

Quality Objectives Work Instructions & Quality

Input to MRM Daily Production Log Purchasing

• Results of Audits First Off Inspection report Issue of Internal Work Order

• Customer Feedback Inprocess Inspection report

• Process Performance & Product Conformity Indent

• Status of Preventive and corrective actions Preparation of Process Flow Chart, Control Plan List of Approved Suppliers

• Followup actions of Previous MRM & Operating Standard by Production & QA Drawings

• Changes that could affect the quality Control of NC Product Material Specifications

• Management System Packing Requirements

• Recommendations for improvemen Plating procedures

• Trends of Product Conformity Identification & Test Status Matrix

• Changes to applicable petroleum and natural Customer Feedback Production Store Suplier Registration

gas industry standards Supplier Assessment & Rating

• Recommendations for improvement

• Quality Objectives Master List of Measuring Devices Control of Monitoring & Inward Register

Measuring devices Identification Tags

Input to MRM Calibration History Card

Final inspection Report Quality Assurance Tooling Management &

Management Review Maintenance Master list of Gauges

Process Capability Master List of Drawings

Input to MRM Improvement reports Tool Life record

Master List of Equipment

Monogram Punching for Identification & Test Status - Histroy Record

Internal Audit API Products Tooling Management Matrix List of Critical Spares

API Monogram

Continual Improvement marking Procedure

Plating

Packing required

Yes

Opportunities for improvement

• Cost Reduction Quality Assurance Outsourcing

• Cycle Time Reduction

• Quality improvement

• Enhance the Skill set Receipt of Products / from

Supplier Material

To control the Documents, Drawings, Instructions, Manuals, To control the Records for effective

Procedures, Process Maps, Work Formats, External Management System of QMS in line

Proactive Quality HR & Training Origin Standards Instructions for effective Management with API / ISO requirements

Management Representative System of QMS in line with API / ISO requirements

“Create Quality Management System as per

API / ISO that will produce less or no defects” Control of Documents Control of Records Corrective Action Preventive Action

Material List of Documents Material List of Records

Driven by

customer

needs Legends

• Control of Documents • Control of NC Product Procedures

Led by • Control of Records • Corrective action

Senior Enabled by FLCB • Management Review • Preventive action Process

Mgmt Assocites • Internal Audit

Inputs / Information

Activity

Components for Valve and Sealing

Quality products for Oil & Gas, Marine and Petrochemical Industries

Ring Joint Gaskets

APN

APN Ring joint gaskets are being manufactured according to API6A and ASME B16.20 Standards and Marked with API monogram and licence no. It can be

used in high pressure vessels, Petrochemical and gas plants, valves in pipe lines and oil field productions equipments up to PSL 1 to 4 standards.

Materials The material of a gasket should be selected based on the service condition and flange material. The most common materials which are used for

production are shown below. The other type of stainless steel and nickel alloy materials are also available to meet customer requirements

Ring joint gasket material - Hardness Chart

Soft Iron Low Carbon 4-6% Chrome 304 Stainless 304L Stainless 316 Stainless 316L Stainless Nickel Alloy

Material Steel 1/2% Moly Steel Steel Steel Steel

Ring identification D S F5 S304 S304L S316 S316L 825

Hardness

Brinell (Max) 90 120 130 160 160 160 160 D3

Rockwell (Max) 56 68 72 83 83 83 83 200

P

P

23º ±0º 30’

R series Ring joint gaskets

R series ring joint gaskets have both oval and Octagonal cross section and

they are having identical PCD. The flanges have flat bottom groove. Both

H

B

shapes can be used and it suits the flanges with API 6A, ASME B16.5,

ASME 16.47 A series and BS 1560 standards C

R1 A R1

A

Octagonal Oval

Chart 1

Nominal

Pipe ½” ¾” 1 1-¼” 1-½” 2” 2-½” 3” 3-½” 4” 5” 6” 8” 10” 12” 14” 16” 18” 20” 22” 24” 26” 28” 30” 32” 34” 36”

Ring Number at Pressure Class Rating

150 R-15 R-17 R-19 R-22 R-25 R-29 R-33 R-36 R-40 R-43 R-48 R-52 R-56 R-59 R-64 R-68 R-72 R-80 R-76

300/ R-11 R-13 R-16 R-18 R-20 R-23 R-26 R-31 R-34 R-37 R-41 R-45 R-49 R-53 R-57 R-61 R-65 R-69 R-73 R-81 R-77 R-93 R-94 R-95 R-96 R-97 R-98

600

ASME

Pressure Rating in lbs

900 R-12 R-14 R-16 R-18 R-20 R-24 R-27 R-31 – R-37 R-41 R-45 R-49 R-53 R-57 R-62 R-66 R-70 R-74 – R-78 R-100 R-101 R-102 R-103 R-102 R-105

1500 R-12 R-14 R-16 R-18 R-20 R-24 R-27 R-35 – R-39 R-44 R-46 R-50 R-54 R-58 R-63 R-67 R-71 R-75 – R-79 – – – – – –

2500 R-13 R-16 R-18 R-21 R-23 R-26 R-28 R-32 – R-38 R-42 R-47 R-51 R-55 R-60 – – – – – – – R-101 R-102 R-103 R-104 R-105

2000/

API-6B

3000 – – R-16 R-18 R-20 R-23 R-26 R-31 – R-37 R-41 R-45 R-49 R-53 R-57 R-61 R-65 R-69 R-73 – – – – – – – –

5000 – – R-16 R-18 R-20 R-24 R-27 R-35 R-37 R-39 R-44 R-46 R-50 R-54 – – – – – – – – – – – – –

Components for Valve and Sealing

Quality products for Oil & Gas, Marine and Petrochemical Industries

Ring Joint Gaskets APN

P 23º ±0º 30’

RX series Ring joint gaskets

RX series ring joint gaskets have Octagonal cross section and it is suitable for

H

the flanges of API 6 B style. This series gaskets are designed to hold pressure

up to 10,000 Psi

D

R1 C R1

A OD

Chart 2

Nominal

Pipe 1” 1–3/8” 1–1/2” 1–13/16” 2” 2–1/2” 2–9/16” 3” 3–1/2” 4” 4–1/16” 5” 6” 8” 10” 12” 14” 16” 18” 20”

Pressure Class Rating

2000

– – RX-20 – RX-23 RX-26 – RX-31 – RX37 – RX-41 RX-45 RX-49 RX-53 RX-57 – RX-65 RX-69 RX-73

Ring Number at

lbs

API-6B

3000 – – RX-20 – RX-24 RX-27 – RX-31 – RX37 – RX-41 RX-45 RX-49 RX-53 RX-57 – RX-69 RX-73 RX-82

lbs

5000

lbs – RX-201 RX-20 RX-205 RX-24 RX-27 RX-201 RX-35 – RX-39 RX-215 RX-44 RX-46 RX-50 RX-54 – RX-63 – – –

D

23º ±0º 15’ 23º ±0º 15’

P P

BX series ring joint gaskets

BX series ring joint gaskets also have Octagonal cross section designed to hold H

pressure up to 20,000 Psi. It is suitable for the flanges of API BX styles.

P C P

A

007

00

Chart 3

Nominal

Pipe 1–11/16” 1–13/16” 2–1/16” 2–9/16” 3–1/16” 4–1/16” 5–1/8” 6–5/8” 7–1/16” 8–9/16” 9” 11” 11–5/32” 13–5/8” 16–3/4” 18–3/4” 21–1/4” 26–3/4” 30”

2000 – – – – – – – – – – – – – – – – – BX-167 BX-303

Ring Number at Pressure Class Rating

lbs

3000 – – – – – – – – – – – – – – – – – BX-168 BX-303

lbs

5000 – – – – – – – – – – – – – BX-160 BX-161 BX-163 BX-165 – –

API-6BX

lbs BX-162

10000 BX-150 BX-151 BX-152 BX-153 BX-154 BX-155 BX-169 BX-170 BX-156 BX-171 BX-157 BX-158 BX-172 BX-159 BX-162 BX-164 BX-166 – –

lbs

15000 BX-150 BX-151 BX-152 BX-153 BX-154 BX-155 – BX-170 BX-156 BX-171 BX-157 BX-158 BX-172 BX-159 BX-162 BX-164 – – –

lbs

20000 BX-151 BX-152 BX-153 BX-154 BX-155 – – BX-156 – BX-157 BX-158 – BX-159 – – – – –

lbs

How to order

The series of gaskets indicated are available in ex woks/ex stock or will be ready in a short lead time. Please submit the following data when ordering.

E.g.,

• Standard of gasket (API/ASME)

• Type of material (SI,LCS,S316,Inconel 825 etc)

• Shapes of Gasket (Oval or Octagonal)

• Ring Size

• Coating requirements (note: Normally soft Iron and Low carbon steel gaskets are coated with electroplated Zinc)

• Packing, labelling and shipping requirements

Or Customer specifications

Components for Valve and Sealing

Quality products for Oil & Gas, Marine and Petrochemical Industries

Spiral wound Gaskets APN

APN spiral wound gaskets are being manufactured according to ASME B Type II Filler with Winding strip & Outer ring

16.20 standards and it is suitable for the flanges of ASME B16.5, ASME B

16.47 Series B and BS 1560 Standards.. The basic type filler with outer ring which is centralise the sealing, gives more

radial strength and prevents blow outs suitable for flanges with flat faces and

Materials raised faces

Standard metal winding strip is Stainless steel grade 304. The other grades

according to customers requirements are 304L, 316 , 316L , Monel, Inconel

etc.

Filler material: Graphite with minimum purity of 98% and PTFE, Thickness

4.5mm

Standard material for inner and outer rings is Carbon steel. Other grades

according to customers’ requirements are 304. 304L, 316, 316L 410, Monel,

Inconel etc. Standard Thickness 3.0 mm

Note: Material selection should be based on the temperature, pressure and type

Outer Ring

of fluids

Type III Filler with Winding strip & Inner ring

Type I Filler with winding strip The basic type filler with inner ring which gives more pressure in sealing suits

for male and female type flanges

The Basic type suits for flanges with tongue and groove , flat face and recess,

male and female

Filler

Inner Ring

Strips

Components for Valve and Sealing

Quality products for Oil & Gas, Marine and Petrochemical Industries

Spiral wound Gaskets

APN

Type IV Filler, Winding strip, outer & inner ring How to order

The GC type fitter with inner ring which centralises the sealing, and prevents The types of gaskets indicated are available in ex woks/Ex stock or will be

windings and flange damages. Suitable for flanges with flat faces and raised ready in a short lead time. Please submit the following data when ordering.

faces.

E.g.

Gasket type APN Spiral wound gasket type I

Nominal size of pipe 4”

Pressure class Class 600

Standard ASME B16.20

Winding & filler S316, Graphite

Outer Ring S304

Inner Ring S316

Outer Ring Inner Ring Or your specification

Flange Face Types

Type 1 Type 2 Type 3 Type 4 Type 5

Raised Face Flat Face Recess Tongue and Groove Male and Female

Components for Valve and Sealing

Quality products for Oil & Gas, Marine and Petrochemical Industries

You might also like

- Fittings Grease GuideDocument10 pagesFittings Grease GuideveereshNo ratings yet

- Torque & Service SpecificationsDocument60 pagesTorque & Service Specificationsapi-3833108100% (1)

- Statical ChapmanDocument385 pagesStatical ChapmanpixieNo ratings yet

- Steel Wire RopesDocument23 pagesSteel Wire RopeskevinNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Introduction and Bravais LatticesDocument17 pagesIntroduction and Bravais LatticesBilal BarutNo ratings yet

- Denison T6 Vane Pump PDFDocument19 pagesDenison T6 Vane Pump PDFZoran JankovNo ratings yet

- 1KZ-T EngineDocument318 pages1KZ-T EngineFerry Darmawan100% (1)

- WCB bolted bonnet OS&Y gate valve documentDocument2 pagesWCB bolted bonnet OS&Y gate valve documentAlex VarHer100% (1)

- Important Product Catalogue Covers Piston RangeDocument236 pagesImportant Product Catalogue Covers Piston RangeAmit Chopra AmitNo ratings yet

- From Conceptual To Executable BPMN Process Models: A Step-by-Step MethodDocument27 pagesFrom Conceptual To Executable BPMN Process Models: A Step-by-Step MethodpixieNo ratings yet

- Organic II Reactions (Complete) BETADocument21 pagesOrganic II Reactions (Complete) BETATheoNo ratings yet

- Co2 Damper6Document4 pagesCo2 Damper6sabir hussainNo ratings yet

- Wellhead Fittings & Valve Components - PGI-WFDocument28 pagesWellhead Fittings & Valve Components - PGI-WFIan KevinNo ratings yet

- EnardoDocument2 pagesEnardoDwi April YantoNo ratings yet

- Engineering Materials MCQs PDFDocument41 pagesEngineering Materials MCQs PDFRamesh KondriNo ratings yet

- API602 Forged Steel Gate & Globe ValvesDocument4 pagesAPI602 Forged Steel Gate & Globe ValvesThomasFrenchNo ratings yet

- Solution Manual For Principles of Engineering Thermodynamics 1st Edition by ReiselDocument22 pagesSolution Manual For Principles of Engineering Thermodynamics 1st Edition by Reisela213115530100% (2)

- Catalog Cast Steel Swing Check ValveDocument4 pagesCatalog Cast Steel Swing Check ValvezahoorNo ratings yet

- CT WKM Ball Dynaseal 310Document1 pageCT WKM Ball Dynaseal 310JonathanNo ratings yet

- GLT Gate ValveDocument6 pagesGLT Gate Valveputra keluarga cipta bangunNo ratings yet

- STARLINE StandardDocument5 pagesSTARLINE StandardJacobus CalvelageNo ratings yet

- Everdigm Rocktools: DTH Back HammerDocument2 pagesEverdigm Rocktools: DTH Back Hammergustavo caicedoNo ratings yet

- Safety Valve-Fainger LesserDocument8 pagesSafety Valve-Fainger LesserRoopa MahtoNo ratings yet

- Positive and Adjustable Choke CatalogueDocument7 pagesPositive and Adjustable Choke CatalogueAmer RehanNo ratings yet

- Valvulas IntermodalDocument36 pagesValvulas IntermodaljorgettciNo ratings yet

- Spec Sheet Sucker Rod Stripper Rev 03 2016Document2 pagesSpec Sheet Sucker Rod Stripper Rev 03 2016emilianoNo ratings yet

- SPV-3P-M: Features & OptionsDocument2 pagesSPV-3P-M: Features & OptionsGerman BetancurNo ratings yet

- 카달로그 - 4Way Diverter ValveDocument9 pages카달로그 - 4Way Diverter Valvetazghat beghdadiNo ratings yet

- Standard Bolt Torque Specifications B-2Document4 pagesStandard Bolt Torque Specifications B-2lone_anarchistNo ratings yet

- 32P 5/2 Valve Series GuideDocument4 pages32P 5/2 Valve Series GuideRamanathanNo ratings yet

- BL E109208 PDFDocument2 pagesBL E109208 PDFJairo andres Guarnizo SuarezNo ratings yet

- Swing check valve design featuresDocument4 pagesSwing check valve design featuresdmitosNo ratings yet

- Wedge Gate Valves PDFDocument4 pagesWedge Gate Valves PDFkopnangNo ratings yet

- RASCOflex Americas SpecSheetDocument4 pagesRASCOflex Americas SpecSheetJohn loboNo ratings yet

- Pop Nut PDFDocument48 pagesPop Nut PDFJavier A. ValenzuelaNo ratings yet

- Adjustable Chokes For Wellhead, API.6A Stream Flo (Master FLO)Document7 pagesAdjustable Chokes For Wellhead, API.6A Stream Flo (Master FLO)Budiman AgusNo ratings yet

- Specification Sheet: MartensiticDocument7 pagesSpecification Sheet: MartensiticErick Renzo Hidalgo OrtegaNo ratings yet

- Metso Knife Gate Valve Technical DescriptionDocument8 pagesMetso Knife Gate Valve Technical DescriptionAdelmoKarigNo ratings yet

- Catalogue-Water Works ButterflyDocument5 pagesCatalogue-Water Works ButterflyAVINASHRAJNo ratings yet

- Grundfosliterature - CRI Ensambles 1 A 5Document17 pagesGrundfosliterature - CRI Ensambles 1 A 5Rudo RockNo ratings yet

- 5/2, 3/2 Convertible Poppet Type, Namur Solenoid Valve: FeaturesDocument2 pages5/2, 3/2 Convertible Poppet Type, Namur Solenoid Valve: FeaturesShajil VazhakkalilNo ratings yet

- 4way diverter CatalogueDocument10 pages4way diverter CatalogueMohd Khairi Mohd NorzianNo ratings yet

- Imi PBM - Pb-Af3 - 2022Document2 pagesImi PBM - Pb-Af3 - 2022ariesca.instrumentacionNo ratings yet

- Testing: Needle Valve SeriesDocument3 pagesTesting: Needle Valve SeriesToty DzNo ratings yet

- SR Series: J Flow ControlsDocument5 pagesSR Series: J Flow ControlsJimmy RojasNo ratings yet

- 5/3 Internal Pilot Operated, Center Off Poppet Solenoid ValveDocument2 pages5/3 Internal Pilot Operated, Center Off Poppet Solenoid ValveGaurav TripathiNo ratings yet

- H RV100 e 2002 01 PDFDocument2 pagesH RV100 e 2002 01 PDFMELEK MECHRINo ratings yet

- 47XU Gate CraneFS DS p103 0620Document1 page47XU Gate CraneFS DS p103 0620Younis JanNo ratings yet

- Rascoflex - Flexible Hose SprinklerDocument4 pagesRascoflex - Flexible Hose SprinklerPaulina CabreraNo ratings yet

- Filler and Drain Plugs GuideDocument5 pagesFiller and Drain Plugs Guidemetin metinNo ratings yet

- Series 2700 Maintenance ManualDocument12 pagesSeries 2700 Maintenance ManualLuciusNo ratings yet

- TAPARIIA Price List Nov 2018Document24 pagesTAPARIIA Price List Nov 2018abhaysharma184No ratings yet

- Curb Stop Ball Valves: Features and UsesDocument2 pagesCurb Stop Ball Valves: Features and UsesVijay DaeNo ratings yet

- JOT Oil Tools CatalogueDocument55 pagesJOT Oil Tools CatalogueInderjeet HoodaNo ratings yet

- Jot Brochure 2021-22Document60 pagesJot Brochure 2021-22Darshan MakwanaNo ratings yet

- GC Consumables GCMS Consumables Brochure - GC Consumables GuideDocument15 pagesGC Consumables GCMS Consumables Brochure - GC Consumables GuideSupervision ServicioNo ratings yet

- 47XU F Gate CraneFS DS 1021 p103Document1 page47XU F Gate CraneFS DS 1021 p103Alexander HuamanNo ratings yet

- TYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsDocument6 pagesTYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsKapa KamalakarNo ratings yet

- High Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFDocument2 pagesHigh Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFjayakumarNo ratings yet

- TB Hydro MIV CatalogueDocument2 pagesTB Hydro MIV CatalogueavinashuklaNo ratings yet

- Forged High Pressure Ball Valves GuideDocument4 pagesForged High Pressure Ball Valves GuideFabio GiehlNo ratings yet

- FT Valvula Acero 300 LBS Crane 33xu.fDocument1 pageFT Valvula Acero 300 LBS Crane 33xu.fFernando CarreñoNo ratings yet

- Gripper Parts ListDocument4 pagesGripper Parts Listjhon jairo arangoNo ratings yet

- Presentación 28k + Otras ValDocument53 pagesPresentación 28k + Otras ValCamilo MendozaNo ratings yet

- DPCVDocument4 pagesDPCVjamil voraNo ratings yet

- English-French and French-English dictionary of the motor car, cycle, and boatFrom EverandEnglish-French and French-English dictionary of the motor car, cycle, and boatNo ratings yet

- DuPont Tyvek 1417 HazMat Coverall Suit TY125SVPDocument1 pageDuPont Tyvek 1417 HazMat Coverall Suit TY125SVPpixieNo ratings yet

- Case StudyDocument41 pagesCase StudypixieNo ratings yet

- Alloy Wheel H-2000-3805-01 MC PDFDocument6 pagesAlloy Wheel H-2000-3805-01 MC PDFAliya RaheelNo ratings yet

- Whatmakesagoodprocess BPTrendsDocument8 pagesWhatmakesagoodprocess BPTrendsBudiarso BudiarsoNo ratings yet

- Alloy WheelDocument80 pagesAlloy WheelpixieNo ratings yet

- TRWIAINo76 PDFDocument27 pagesTRWIAINo76 PDFekaNo ratings yet

- Rubric For All Written WorkDocument1 pageRubric For All Written WorkpixieNo ratings yet

- Wal MartDocument21 pagesWal MartKelvin LeongNo ratings yet

- Span of ControlDocument68 pagesSpan of ControlpixieNo ratings yet

- Major Airline Satisfaction Survey - WainwrightDocument7 pagesMajor Airline Satisfaction Survey - WainwrightpixieNo ratings yet

- Managing Service Quality: An International Journal: Article InformationDocument27 pagesManaging Service Quality: An International Journal: Article InformationpixieNo ratings yet

- Cabin Safety - Crew Stress Fatigue Article Jan 04Document25 pagesCabin Safety - Crew Stress Fatigue Article Jan 04Haseeb Abu AlwanNo ratings yet

- Hub of The WorldDocument5 pagesHub of The WorldcoolmikengNo ratings yet

- JEC's Human Capital Investment Plan Drives Manufacturing ExcellenceDocument10 pagesJEC's Human Capital Investment Plan Drives Manufacturing ExcellencepixieNo ratings yet

- Urban Architecture in The 20 Century: Florida International UniversityDocument6 pagesUrban Architecture in The 20 Century: Florida International UniversitypixieNo ratings yet

- APN BroucherDocument8 pagesAPN BroucherpixieNo ratings yet

- Micropreparation of RuH2 (P (C6H5) 3) 4: A Transition Metal Hydride CompoundDocument17 pagesMicropreparation of RuH2 (P (C6H5) 3) 4: A Transition Metal Hydride CompoundramlihitamNo ratings yet

- European Legal Limits For Migration From Food PackagingDocument10 pagesEuropean Legal Limits For Migration From Food PackagingmarianagajardoNo ratings yet

- Intellipak Manual ProgrammingDocument157 pagesIntellipak Manual ProgrammingArt kNo ratings yet

- MiniProject Stage 3 - Process Dynamic & ControlDocument8 pagesMiniProject Stage 3 - Process Dynamic & ControlFarihah Eyfa100% (2)

- Fibrolit® - Fett-Ld: Safety Data SheetDocument5 pagesFibrolit® - Fett-Ld: Safety Data Sheetks2000n1No ratings yet

- TANNERIESDocument7 pagesTANNERIESzalabiNo ratings yet

- Ocean Pollution ThesisDocument7 pagesOcean Pollution Thesisjenniferslatteryranchocucamonga100% (2)

- Boiler Section - 400 To 800HP RSDocument79 pagesBoiler Section - 400 To 800HP RSmynor8josh8juarezNo ratings yet

- ARN Report 3-13-15Document9 pagesARN Report 3-13-15reagandrNo ratings yet

- Assessment of Drought Tolerance in Mung Bean Cultivarslines As Depicted by The Activities of Germination Enzymes, Seedling's Antioxidative Potential and Nutrient AcquisitionDocument33 pagesAssessment of Drought Tolerance in Mung Bean Cultivarslines As Depicted by The Activities of Germination Enzymes, Seedling's Antioxidative Potential and Nutrient AcquisitionFaisal ShehzadNo ratings yet

- Halogenoalkanes Alcohols and Modern Analytical TechniquesDocument17 pagesHalogenoalkanes Alcohols and Modern Analytical TechniquesDaniel KirovNo ratings yet

- DilutionDocument12 pagesDilutioncristina tina100% (1)

- Supreme Motor Oil MSDSDocument7 pagesSupreme Motor Oil MSDSsofelsbabaNo ratings yet

- Jairo Alonso Paredes-C., Luís Miguel Romero-R., Julián David de Bedout-O. & Carlos Mauricio Bernal-RDocument7 pagesJairo Alonso Paredes-C., Luís Miguel Romero-R., Julián David de Bedout-O. & Carlos Mauricio Bernal-RJhon barreraNo ratings yet

- Tabla de Colores Winsor & NewtonDocument8 pagesTabla de Colores Winsor & NewtonArq Copy ChorrillosNo ratings yet

- A Review On Hybrid Laser Arc WeldingDocument22 pagesA Review On Hybrid Laser Arc WeldingAkshay AcchuNo ratings yet

- Transdermal Drug Delivery System ReviewDocument8 pagesTransdermal Drug Delivery System ReviewParth SahniNo ratings yet

- Catalog: PrefaceDocument155 pagesCatalog: PrefaceTalita Yasmin TalitaNo ratings yet

- Organic Chemistry: Alkanes and AlkenesDocument73 pagesOrganic Chemistry: Alkanes and AlkenesRosemaryTanNo ratings yet

- Prodution of Ferrous Sulfate From Steelmeking Mill ScaleDocument7 pagesProdution of Ferrous Sulfate From Steelmeking Mill ScaleElmuntaser EltayebNo ratings yet

- Parts List 21dxs288rd BR MR MBDocument5 pagesParts List 21dxs288rd BR MR MBAhmadNo ratings yet

- Comparing Fermentation Rates of Wheat, Gram, Rice and PotatoDocument10 pagesComparing Fermentation Rates of Wheat, Gram, Rice and PotatovipulNo ratings yet

- High Pressure Steam Sterilizer Operation ManualDocument47 pagesHigh Pressure Steam Sterilizer Operation ManualLuis HernanNo ratings yet

- CHROMITEDocument5 pagesCHROMITETayyab FiazNo ratings yet

- Appendix Chemical Engineering 34Document154 pagesAppendix Chemical Engineering 34JAGATHA NAGESWARA RAONo ratings yet