Professional Documents

Culture Documents

112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDF

Uploaded by

Fernando VittoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDF

Uploaded by

Fernando VittoCopyright:

Available Formats

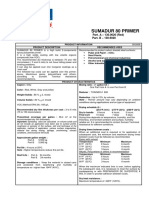

SUMAZINC S-659 PRIMER RICO

EM ZINCO

Code 112.025

PRODUCT INFORMATION Revised 04/2014

PRODUCT DESCRIPTION RECOMMENDED USES

SUMAZINC S-659 PRIMER RICO EM ZINCO is an organic For use over blasted steel:

coating zinc rich and single component.

• Steel structures

Provides cathodic protection, avoiding breakdown for • Exposed surfaces in high humidity environment

mainterance works. Avoid sub-film corrosion progression if • Exposed surfaces in marine environment

suffer mechanical damages.

Not recommended for immersion services.

Have to be applied over blasted steel.

PRODUCT CHARACTERISTICS

Aspect : Flat Reducer : Thinner # 935.

Color : Gray Reduction : up to 10% by volume, if necessary.

Note : Thinner amount may vary depending on ambient

Weight Solids : 81 % + 2, mixed conditions during applications and on type of equipment.

Volume Solids : 47 % + 2, mixed Drying schedule @ :

Note : Estimated value. It’s not possible to get the exact value @61ºF (16ºC) @77ºF (25ºC) @90ºF (32ºC)

by the traditional methods. Dry to touch 50 minutes 30 minutes 20 minutes

Final cure 5 days 3 days 2 days

Recommended dry film thickness : 2 to 3 mils (50 to 80

micrometers) Drying times between coats :

When an additional coat is required or for application of

subsequent coat, the minimum and maximum drying times

between coats must be followed as recommended.

Theoretical coverage per gallon: 21.15 m² at 80 Temperature Minimum Maximum

micrometers dry film thickness. 61ºF 20 hours 28 hours

Important: Spreading rates are calculated on volume solids and do

77°F 18 hours 24 hours

not include an application loss factor due to surface profile, roughness

or porosity of the surface, skill and technique of the applicator, method 90°F 16 hours 20 hours

of application, various surface irregularities, material lost during If exposed to weathering for long time periods, wash the surface

mixing, spillage, overthinning, climatic conditions, and excessive film with water and soap to remove dirt, oil or grease, white corrosion

build. Consider all the loss to calculate the coating quantity to be or other contamination from surface, before coating. Do not use

used. sandpaper.

VOC (EPA 24): 453 g/l Dry heat resistance :

Maximum temperature of 788ºF (420ºC).

Approximate gallon weight : 8,669 kg

Shelf Life: 6 months

Storage conditions : Keep the material in closed cans and

protected from weathering at temperature not higher than

104ºF (40ºC).

SUMAZINC S-659 PRIMER RICO

EM ZINCO

Code 112.025

PRODUCT INFORMATION Revised 04/2014

SURFACE PREPARATION APPLICATION CONDITIONS

Surface must be clean, dry, and in sound condition. Remove Surface temperature:

all oil, dust, grease, dirt, loose rust, and other foreign material minimum................ 41ºF ( 5°C)

to ensure adequate adhesion, with Thinner # 905 or wash with maximum................. 122ºF (50°C)

a SUMACLEAN WB solution. The surface temperature must be at least 3ºC above dew point.

Abrasive Blast to a Near-White Metal in accordance with ISO Material temperature :

8501 – 1 Standard. Visual Standard Sa 2 ½ – ISO 8501-1 minimum................... 41ºF (5°C)

Blast profile : 25 – 75 micrometers (1 – 3 mils). maximum.................. 95ºF (35°C)

Relative humidity : 10% to 85%.

APPLICATION EQUIPMENT APPLICATION INSTRUCTIONS

The following is a guide. Changes in pressures and tip sizes Mixing instructions :

may be needed for proper spray characteristics. Always purge Mix paint vigorously, if possible with mechanical shaker.

spray equipment before using it with listed reducer. Any

reduction must be compatible with existing environmental and Make sure that no pigment is retained at the bottom of the can.

application conditions. Add the thinner in the recomended proportion.

Airless spray : Application:

Pressure ........................... 2700 – 3000 psi Stripe coat all crevices, welds and sharp edges to prevent early

Hose ................................. 3/8“ ID failure in these areas.

Tip ................................... 0,017” - 0,019“ When using spray application, use a 50% overlap with each

Filter .................................. None pass of the gun to avoid holidays, bare areas, and pinholes. If

Reduction............................ Nor recommended necessary, cross spray at a right angle.

Excessive reduction of material can affect film build,

Conventional spray : (continuous agitation required) appearance, and adhesion.

Gun .................................. JGA 5023 Devilbiss

Fluid nozzle ...................... FF

Air nozzle. ......................... 704

Atomization pressure ........ 50 psi

Fluid pressure ................... 20 to 30 psi

Reduction .......................... up to 10%, by volume.

Brush :

To use brush with 75 a 100 mm of width for to larger surfaces

and with 25 a 38 mm for screw, screw-nut, string weld and

retouching.

Roller :

Not recommended.

If specific application equipment is not listed above, equivalent

equipment may be used.

Equipment clean up :

Use THINNER # 935.

You might also like

- 21 Great Answers To: Order ID: 0028913Document13 pages21 Great Answers To: Order ID: 0028913Yvette HOUNGUE100% (1)

- 113.007 - Zinc Clad Xi WB BR PDFDocument2 pages113.007 - Zinc Clad Xi WB BR PDFFernando VittoNo ratings yet

- Interzinc 75V: Zinc-Rich EpoxyDocument4 pagesInterzinc 75V: Zinc-Rich EpoxyTrịnh Minh KhoaNo ratings yet

- High Solids Coal Tar Epoxy Product SpecificationsDocument2 pagesHigh Solids Coal Tar Epoxy Product SpecificationsAbuhurairah MunshiNo ratings yet

- Protective & Marine Coatings: Magnalux 40VDocument2 pagesProtective & Marine Coatings: Magnalux 40VMd Usama100% (1)

- Protective & Marine Coatings: Zinc Clad Iv EuDocument2 pagesProtective & Marine Coatings: Zinc Clad Iv Eusrinath vNo ratings yet

- Transpoxy Tankguard 118 ESDocument5 pagesTranspoxy Tankguard 118 ESFadi MagdyNo ratings yet

- PDS Hempaprime Multi 500 Winter en-GBDocument2 pagesPDS Hempaprime Multi 500 Winter en-GBFreddyNo ratings yet

- Galvit EZ P40.01: Previous Suitable CoatDocument2 pagesGalvit EZ P40.01: Previous Suitable CoatDamian RoweNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- Intergard 276: Epoxy Undercoat/ Tie-CoatDocument4 pagesIntergard 276: Epoxy Undercoat/ Tie-CoatAhmed IbrahimNo ratings yet

- SigmaZinc 100 zinc primer guideDocument4 pagesSigmaZinc 100 zinc primer guideJohnson Chng Hou KiatNo ratings yet

- b3) Zincanode685 4586Document2 pagesb3) Zincanode685 4586Syed FaridNo ratings yet

- Plasite 9133 Product Data SheetDocument3 pagesPlasite 9133 Product Data SheetChris StroudNo ratings yet

- Thermaline 400 Finish PDSDocument3 pagesThermaline 400 Finish PDSQuy RomNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Interbond 600 PDFDocument4 pagesInterbond 600 PDFTrịnh Minh KhoaNo ratings yet

- Coaltar Epoxy - Epilux5 - 0474Document2 pagesCoaltar Epoxy - Epilux5 - 0474GautamNo ratings yet

- KCC - DATASHEET - Cerany IZ1990 (Two-Component) - EngDocument3 pagesKCC - DATASHEET - Cerany IZ1990 (Two-Component) - EngNguyen1987 TrungNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- b6) Zincanode690 2886Document2 pagesb6) Zincanode690 2886Anonymous XVEucVMsENo ratings yet

- ZINCANODE 330 PRODUCT SPECIFICATIONSDocument2 pagesZINCANODE 330 PRODUCT SPECIFICATIONSDinesh ChouguleNo ratings yet

- HEMPADUR 47182 47182 en-GB PDFDocument3 pagesHEMPADUR 47182 47182 en-GB PDFwilfran villegasNo ratings yet

- Carbomastic 615E: Selection & Specification DataDocument6 pagesCarbomastic 615E: Selection & Specification DataAnhera enterpriseNo ratings yet

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Bang OchimNo ratings yet

- Carbozinc 858 PDSDocument4 pagesCarbozinc 858 PDShuycongvuNo ratings yet

- Hempadur Fast Dry 17410 En-GbDocument2 pagesHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaNo ratings yet

- Intertherm 875 High Temperature Silicone Acrylic (Findotek)Document4 pagesIntertherm 875 High Temperature Silicone Acrylic (Findotek)Karsim BoimNo ratings yet

- PDS HEMPADUR 47183 en-USDocument2 pagesPDS HEMPADUR 47183 en-USFreddy Carl Fredricksen0% (1)

- Carbomastic 15 LT: Selection & Specification DataDocument3 pagesCarbomastic 15 LT: Selection & Specification Datasrinath vNo ratings yet

- High Build Epoxy Anti-Corrosive Primer SpecsDocument2 pagesHigh Build Epoxy Anti-Corrosive Primer SpecsMuthuKumar100% (1)

- Dimecote 9 Inorganic Zinc Silicate CoatingDocument4 pagesDimecote 9 Inorganic Zinc Silicate Coatingabdulgafoor54No ratings yet

- PDS Hempaprime Multi 500 Summer en-GBDocument2 pagesPDS Hempaprime Multi 500 Summer en-GBFreddyNo ratings yet

- b1) Zincanode330 6548Document2 pagesb1) Zincanode330 6548chepurthiNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- High Build Epoxy Coating for Steel and ConcreteDocument2 pagesHigh Build Epoxy Coating for Steel and ConcreteTejinder KumarNo ratings yet

- Thermaline 400 Primer PDSDocument3 pagesThermaline 400 Primer PDSQuy RomNo ratings yet

- b1) Zincanode330 6548Document2 pagesb1) Zincanode330 6548Syed FaridNo ratings yet

- k1) Luxatherm1600 3171Document2 pagesk1) Luxatherm1600 3171Syed FaridNo ratings yet

- HEMPEL'S VINYL ESTER GF 35910 Product Data SheetDocument2 pagesHEMPEL'S VINYL ESTER GF 35910 Product Data SheetEngTamerNo ratings yet

- PDS HEMPATHANE FAST DRY 55750 en-GBDocument2 pagesPDS HEMPATHANE FAST DRY 55750 en-GBEli KhawNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- 130.0020 - Sumadur 80 PrimerDocument2 pages130.0020 - Sumadur 80 Primerhelioxavier2No ratings yet

- Technical Data Sheet Jazeera Selfmastic JI-66009: DescriptionDocument3 pagesTechnical Data Sheet Jazeera Selfmastic JI-66009: Descriptionsalam nazarNo ratings yet

- Masteremaco P 130: Two Component Epoxy Based Zinc Rich Primer For SteelDocument2 pagesMasteremaco P 130: Two Component Epoxy Based Zinc Rich Primer For SteelMuhammad AzrinNo ratings yet

- Technical Data Sheet Jazeera Epo-Rich Primer 90 JI-61031: DescriptionDocument3 pagesTechnical Data Sheet Jazeera Epo-Rich Primer 90 JI-61031: DescriptionSyedFarhanNo ratings yet

- E Program Files An ConnectManager SSIS TDS PDF Interfine 629 Eng A4 20151012Document4 pagesE Program Files An ConnectManager SSIS TDS PDF Interfine 629 Eng A4 20151012Theophilus ThistlerNo ratings yet

- Interline 975: Solvent Free Epoxy Tank CoatingDocument4 pagesInterline 975: Solvent Free Epoxy Tank Coatingnoto.sugiartoNo ratings yet

- Al-Jazeera Firedamp 263Document2 pagesAl-Jazeera Firedamp 263EngTamer100% (1)

- Pentatherm CUI - F16Document4 pagesPentatherm CUI - F16Vineet KhanduriNo ratings yet

- Intertuf 5003Document4 pagesIntertuf 5003Trịnh Minh KhoaNo ratings yet

- Jazeera Damp MasticDocument3 pagesJazeera Damp MasticAhmad BougeisNo ratings yet

- Intercryl 530 PDFDocument4 pagesIntercryl 530 PDFTrịnh Minh KhoaNo ratings yet

- PC 1787 - Apcotherm HR 600 PDFDocument3 pagesPC 1787 - Apcotherm HR 600 PDF41464147No ratings yet

- Interclene 336: TBT Free AntifoulingDocument4 pagesInterclene 336: TBT Free AntifoulingTrịnh Minh KhoaNo ratings yet

- HEMPADUR MULTI-STRENGTH GF 35870 Product Data SheetDocument3 pagesHEMPADUR MULTI-STRENGTH GF 35870 Product Data SheetAnuar SalehNo ratings yet

- 3 - PC 7049 - Apcodur MioDocument3 pages3 - PC 7049 - Apcodur Miosujay AvatiNo ratings yet

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDocument2 pagesHempel'S Vinyl Ester GF 35910: Description: Recommended UseSurendra KumarNo ratings yet

- l2) Steelshield1200 3041Document2 pagesl2) Steelshield1200 3041Syed FaridNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- 199-Article Text-434-1-10-20200626Document11 pages199-Article Text-434-1-10-20200626ryan renaldiNo ratings yet

- Travel Agency ManagementDocument47 pagesTravel Agency ManagementKatherine BarretoNo ratings yet

- SEW Motor Brake BMGDocument52 pagesSEW Motor Brake BMGPruthvi ModiNo ratings yet

- Limits, Fits and Tolerances: Prof. S. S. PandeDocument31 pagesLimits, Fits and Tolerances: Prof. S. S. PandeM PankajNo ratings yet

- 3.1-Pile Design Calculation For Boundary (p1 To p50)Document24 pages3.1-Pile Design Calculation For Boundary (p1 To p50)layaljamal2No ratings yet

- Wiley Wesleyan UniversityDocument36 pagesWiley Wesleyan UniversityBirunda SilvaNo ratings yet

- ADII11 Metode Deteksi OutlierDocument50 pagesADII11 Metode Deteksi Outlier21-A-2-19 Nazli Amaliya RamadhaniNo ratings yet

- 21st Century Literature Exam SpecsDocument2 pages21st Century Literature Exam SpecsRachel Anne Valois LptNo ratings yet

- Ancon Channel & Bolt FixingsDocument20 pagesAncon Channel & Bolt FixingsatiattiNo ratings yet

- Mindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicDocument13 pagesMindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicGABRIELNo ratings yet

- The Eukaryotic Replication Machine: D. Zhang, M. O'DonnellDocument39 pagesThe Eukaryotic Replication Machine: D. Zhang, M. O'DonnellÁgnes TóthNo ratings yet

- IPA Assignment Analyzes New Public AdministrationDocument8 pagesIPA Assignment Analyzes New Public AdministrationKumaran ViswanathanNo ratings yet

- Teodorico M. Collano, JR.: ENRM 223 StudentDocument5 pagesTeodorico M. Collano, JR.: ENRM 223 StudentJepoyCollanoNo ratings yet

- Objective QuestionsDocument19 pagesObjective QuestionsDeepak SharmaNo ratings yet

- HR MasterlistDocument6 pagesHR MasterlistLeychelle AnnNo ratings yet

- Technology and Livelihood Education: Agri - Fishery Arts (Agricultural Crops Production) Marketing Agricultural ProductsDocument14 pagesTechnology and Livelihood Education: Agri - Fishery Arts (Agricultural Crops Production) Marketing Agricultural Productslana del rey100% (1)

- Proposed - TIA - 1392 - NFPA - 221Document2 pagesProposed - TIA - 1392 - NFPA - 221Junior TorrejónNo ratings yet

- Critical Thinking Essay-Animal Testing: Rough DraftDocument10 pagesCritical Thinking Essay-Animal Testing: Rough Draftjeremygcap2017No ratings yet

- Action Plan On GadDocument1 pageAction Plan On GadCherish Devora ArtatesNo ratings yet

- Scedule Maintenance KBN Mill 2020Document9 pagesScedule Maintenance KBN Mill 2020slamet supriyadiNo ratings yet

- Popular Mechanics 2010-06Document171 pagesPopular Mechanics 2010-06BookshebooksNo ratings yet

- Final Term Quiz 2 On Cost of Production Report - Average CostingDocument4 pagesFinal Term Quiz 2 On Cost of Production Report - Average CostingYhenuel Josh LucasNo ratings yet

- Brake System PDFDocument9 pagesBrake System PDFdiego diaz100% (1)

- Inventory ManagementDocument60 pagesInventory Managementdrashti0% (1)

- BA 302 Lesson 3Document26 pagesBA 302 Lesson 3ピザンメルビンNo ratings yet

- India An Archaeological History Palaeolithic Beginnings To Early Historic Foundations (Dilip K. Chakrabarti) (Z-Library)Document437 pagesIndia An Archaeological History Palaeolithic Beginnings To Early Historic Foundations (Dilip K. Chakrabarti) (Z-Library)soumadri.2023.1301No ratings yet

- Airframe Exam Review QuestionsDocument23 pagesAirframe Exam Review QuestionsbirukNo ratings yet

- MAPEH 6- WEEK 1 ActivitiesDocument4 pagesMAPEH 6- WEEK 1 ActivitiesCatherine Renante100% (2)

- Astm A105, A105mDocument5 pagesAstm A105, A105mMike Dukas0% (1)