Professional Documents

Culture Documents

Aisi 4130 Si Aisi 4140

Uploaded by

vaseaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aisi 4130 Si Aisi 4140

Uploaded by

vaseaCopyright:

Available Formats

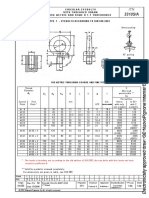

GRAD C Si Mn Cr Mo P S Ni

AISI 4130 0.28 – 0.33 0.15 – 0.35 0.4 – 0.6 0.8 – 1.10 0.15 – 0.25 ≤ 0.040 ≤ 0.035 ≤ 0.5

AISI 4140 0.38 – 0.43 0.15 – 0.35 0.75 – 1.0 0.8 – 1.10 0.15 – 0.25 ≤ 0.040 ≤ 0.035 ≤ 0.5

AISI 4340 0.38 – 0.43 0.15 – 0.35 0.6 – 0.8 0.7 – 0.9 0.2 – 0.3 ≤ 0.025 ≤ 0.025 1.65 – 2.0

F22 0.05 – 0.15 ≤ 0.50 0.3 – 0.6 2.0 – 2.5 0.87 – 1.13 ≤ 0.040 ≤ 0.040 ≤ 0.5

The mechanical properties of AISI 4140 steel VS 4130 Steel are outlined in the following table.

AISI SAE 4140 Steel AISI SAE 4130 Steel

Properties

Properties (behavior) Metric Metric

(behavior)

Tensile strength,

Tensile strength, Ultimate 655 MPa 560 MPa

Ultimate

Tensile strength,

Tensile strength, Yield 415 MPa 460 MPa

Yield

Modulus of

Modulus of elasticity 190-210 MPa 190-210 MPa

elasticity

Bulk modulus 140 GPa Bulk modulus 140 GPa

Shear modulus 80 GPa Shear modulus 80 GPa

Poisson ratio 0.27-0.30 Poisson ratio 0.27-0.30

Elongation at break (in 50 Elongation at break

25.7 % 21.5%

mm) (in 50 mm)

Reduction of area 45 Reduction of area 59.6

Hardness, Brinell Hardness, Brinell

217 Max 217 Max

(Annealing) (Annealing)

Hardness, Rockwell C Hardness,

22 22

(Q+T) Rockwell C (Q+T)

sae 4140 steel VS 4130 Steel welding properties

4130 have lower Carbon composition, so 4130 is easier welding than AISI 4140 steel. And 4130 have

lower Manganese than 4140. So 4130’s Wear-resisting performance is lower than 4140.

sae 4140 VS 4130 Steel Rust resistance properties

4140 steel have higher carbon, but sae 4140 have higher Mn composition. so their rust is very same.

You might also like

- Iso 484 1 2015 en PDFDocument8 pagesIso 484 1 2015 en PDFSebastián Paipa0% (1)

- Chain RollerANSIDocument35 pagesChain RollerANSICallao JimmyNo ratings yet

- Astm A 324 - 73 R00Document3 pagesAstm A 324 - 73 R00Er Widodo50% (2)

- Explosive Depth HardenedDocument1 pageExplosive Depth HardenedShipra MishraNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Stainless Steel Rope Wire: Standard Specification ForDocument2 pagesStainless Steel Rope Wire: Standard Specification Forist93993No ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document3 pagesAisi 4140 Alloy Steel (Uns g41400)diogolabegNo ratings yet

- Astm 434Document3 pagesAstm 434Fabián MartínezNo ratings yet

- IS 5517 - 1993-Hardening & Tempering GradesDocument15 pagesIS 5517 - 1993-Hardening & Tempering GradesMohanrajMJ100% (1)

- Astm A325Document8 pagesAstm A325Nacer KisyNo ratings yet

- Din 1681-GS 60Document9 pagesDin 1681-GS 60Vishnu AgawaneNo ratings yet

- Bronze SAE 64 PDFDocument1 pageBronze SAE 64 PDFIbsonhNo ratings yet

- Iso 683-18-2014Document64 pagesIso 683-18-2014Amit TiwariNo ratings yet

- Asme B18.18.2M R1999Document16 pagesAsme B18.18.2M R1999Gerardo Rivera100% (1)

- Jis G4053 SCM440Document1 pageJis G4053 SCM440Đình Sỹ TTPNo ratings yet

- En10083 2Document2 pagesEn10083 2Sezgin BayrakNo ratings yet

- Bakelite PropertiesDocument6 pagesBakelite PropertiesAlexander PrasetyaNo ratings yet

- Is Iso 7452 2002Document20 pagesIs Iso 7452 2002Ketan ValaNo ratings yet

- Portland-Bolt-Bolt-Torque-Chart - A325 - A307 - A449 - A490 - A193 - A354Document5 pagesPortland-Bolt-Bolt-Torque-Chart - A325 - A307 - A449 - A490 - A193 - A354João Mendonça SantosNo ratings yet

- DIN580 Eye BoltDocument7 pagesDIN580 Eye BoltReda El-AwadyNo ratings yet

- Astm A31 (1995)Document4 pagesAstm A31 (1995)gsb2100% (1)

- 08chapter6 ShaftfixingsDocument12 pages08chapter6 Shaftfixingsreinaldosidejunior100% (1)

- Mill Test Certificate: 7.00 MM 3-Phase Chevron Indented P.C Single Wire, Low RelaxationDocument1 pageMill Test Certificate: 7.00 MM 3-Phase Chevron Indented P.C Single Wire, Low RelaxationJun Xian WaiNo ratings yet

- Ford Wa 960-2004Document1 pageFord Wa 960-2004DanielMa0% (1)

- A 965/A 965M - 06a Standard Specification For Steel Forgings, Austenitic, For Pressure and High Temperature Parts1Document7 pagesA 965/A 965M - 06a Standard Specification For Steel Forgings, Austenitic, For Pressure and High Temperature Parts1Ivan Iglesias MartinezNo ratings yet

- 16mo3 MıgMagDocument4 pages16mo3 MıgMagKerem İnanNo ratings yet

- 283057842 JIS G4053 2003 Low Alloyed Steels for Machine Structural Use 英文版 PDFDocument21 pages283057842 JIS G4053 2003 Low Alloyed Steels for Machine Structural Use 英文版 PDFDewi Lanjarsari Purnama Sastri100% (1)

- Astm A759Document4 pagesAstm A759Laziz AtmaniNo ratings yet

- Astm A192Document11 pagesAstm A192Marcelo VicentiniNo ratings yet

- ISO 4990 - Casting Steel - General Technical Delivery Requirement PDFDocument20 pagesISO 4990 - Casting Steel - General Technical Delivery Requirement PDFLe Van Tam100% (1)

- Asm Metals - Stainless Steel and Nickel Alloys PDFDocument33 pagesAsm Metals - Stainless Steel and Nickel Alloys PDFFernandoiNo ratings yet

- Astm B 505 PDFDocument8 pagesAstm B 505 PDFprodn123No ratings yet

- Supraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilDocument2 pagesSupraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilHugo RodriguezNo ratings yet

- DIN 935 - Hexagon Slotted Castle NutsDocument8 pagesDIN 935 - Hexagon Slotted Castle NutsJmmy Son LiNo ratings yet

- Asme B18.2.3.1M 1999Document18 pagesAsme B18.2.3.1M 1999Jesse ChenNo ratings yet

- Astm A671 2004 PDFDocument9 pagesAstm A671 2004 PDFDevarajanRamasamyNo ratings yet

- Aisi 4140Document2 pagesAisi 4140Tirta BudiawanNo ratings yet

- Hollow Bars (ISO2938)Document8 pagesHollow Bars (ISO2938)suku maranNo ratings yet

- ASTM Material Changes: CCFSS Technical BulletinDocument6 pagesASTM Material Changes: CCFSS Technical BulletinkfctcoNo ratings yet

- Is 3601 PDFDocument24 pagesIs 3601 PDFNagendra Kumar100% (1)

- Sae J200-Epdm-Ts5 - Google SearchDocument2 pagesSae J200-Epdm-Ts5 - Google SearchJessica ApalinNo ratings yet

- Sae J496 1972 (En)Document5 pagesSae J496 1972 (En)Oh No PotatoNo ratings yet

- TM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)Document5 pagesTM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)方綵樺No ratings yet

- SAE 660 Bronze - Technical InformationDocument2 pagesSAE 660 Bronze - Technical Informationtanha56313955No ratings yet

- A572 50 TY1 KrakatauposcoplateASTMproductDocument1 pageA572 50 TY1 KrakatauposcoplateASTMproductSteel BridgeNo ratings yet

- Astm A449 1978Document7 pagesAstm A449 1978rensieoviNo ratings yet

- A132 PDFDocument2 pagesA132 PDFluisNo ratings yet

- ARNOLD - Thread Forming ScrewDocument4 pagesARNOLD - Thread Forming ScrewgirishawantiNo ratings yet

- Astm A 217 - 04Document4 pagesAstm A 217 - 04Raul Humberto Mora VillamizarNo ratings yet

- Asme B18 2 1 1996Document61 pagesAsme B18 2 1 1996Daniyal EzaziNo ratings yet

- ISO 898 Grade 10.9Document2 pagesISO 898 Grade 10.9Mihaela NastaseNo ratings yet

- Astm D1418Document3 pagesAstm D1418Mohamed Reda Hussein Sengar100% (2)

- ASTM A355 Standard Spec For Nitriding PDFDocument3 pagesASTM A355 Standard Spec For Nitriding PDFAntonio J100% (1)

- Asme B18.15-2015Document22 pagesAsme B18.15-2015Kamal El Shawadfy50% (2)

- ASME-B31-3-2014 Table 331.1.3 PDFDocument2 pagesASME-B31-3-2014 Table 331.1.3 PDFImane KhammouriNo ratings yet

- DIN 128 A - Split Spring Washers, Curved, Form ADocument6 pagesDIN 128 A - Split Spring Washers, Curved, Form ASantosh100% (1)

- Pec Ifica Tion .PW: Surface Vehicle InformationDocument11 pagesPec Ifica Tion .PW: Surface Vehicle InformationCelso100% (1)

- As4324 11Document109 pagesAs4324 11Harish KumarNo ratings yet

- ASTM A842 - Corpo de Prova OmegaDocument4 pagesASTM A842 - Corpo de Prova OmegaFabiano MonteiroNo ratings yet

- AISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionDocument3 pagesAISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionGrimmo1979No ratings yet

- Material and Processes Engineer (Aerospace) : Ati Aplicat Deja La Acest Job Scurta Descriere A CompanieiDocument1 pageMaterial and Processes Engineer (Aerospace) : Ati Aplicat Deja La Acest Job Scurta Descriere A CompanieivaseaNo ratings yet

- Din 1302 SupplementDocument2 pagesDin 1302 SupplementRodrigo García Cruz100% (1)

- Surface Roughness ConversionsDocument2 pagesSurface Roughness ConversionsvaseaNo ratings yet

- 1984 Surf Roughness PGDocument8 pages1984 Surf Roughness PGHussn YazdanNo ratings yet

- Metallurgical and Weldability Aspects of The New-Generation Martensitic Stainless Steels: A Case StudyDocument19 pagesMetallurgical and Weldability Aspects of The New-Generation Martensitic Stainless Steels: A Case Studyvasea100% (1)

- Aisi 4340Document3 pagesAisi 4340vaseaNo ratings yet

- CA6NMDocument2 pagesCA6NMjoene3No ratings yet

- Surface Roughness ConversionsDocument2 pagesSurface Roughness ConversionsvaseaNo ratings yet

- Helicoil Plus en 0100Document56 pagesHelicoil Plus en 0100vaseaNo ratings yet

- Basic SuperalloysDocument20 pagesBasic SuperalloysvaseaNo ratings yet

- CATALOG KeensertmetricDocument4 pagesCATALOG KeensertmetricvaseaNo ratings yet

- Article 2Document6 pagesArticle 2vaseaNo ratings yet

- Surface Roughness Conversion ChartDocument1 pageSurface Roughness Conversion ChartAnonymous LtbsU1zNo ratings yet

- 5 SchaefflerDocument14 pages5 Schaefflervasea100% (1)

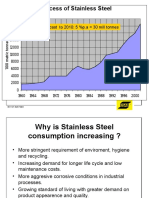

- Success of Stainless Steel: 18000 20000 Forecast To 2010: 5 %p.a 30 Mill TonnesDocument14 pagesSuccess of Stainless Steel: 18000 20000 Forecast To 2010: 5 %p.a 30 Mill TonnesvaseaNo ratings yet

- WLODAWERpart2 PDFDocument80 pagesWLODAWERpart2 PDFvivek1312No ratings yet

- Diseno de Mazarotas PDFDocument45 pagesDiseno de Mazarotas PDFAriel GarciaNo ratings yet

- Propeller Turbine Vs Kaplan TurbineDocument26 pagesPropeller Turbine Vs Kaplan TurbineUmarKhan0% (1)

- Iron SpecsDocument1 pageIron SpecsvaseaNo ratings yet

- 12.role of FerriteDocument2 pages12.role of FerritevaseaNo ratings yet

- Design of Gating and Riser System For Grate Bar CastingDocument6 pagesDesign of Gating and Riser System For Grate Bar CastingvaseaNo ratings yet

- Flow 3d Cast PDFDocument15 pagesFlow 3d Cast PDFvasea100% (1)

- Gating-Risering Sec2Document35 pagesGating-Risering Sec2jagan_4u100% (1)

- Flow 3d Cast PDFDocument15 pagesFlow 3d Cast PDFvasea100% (1)

- Tech Data 8APPENDIXAPolymerQuenchingDocument13 pagesTech Data 8APPENDIXAPolymerQuenchingBalram JiNo ratings yet

- Cast MaterialsDocument6 pagesCast MaterialsJhonny AlvarezNo ratings yet

- Astm A 247 - 67 R98Document2 pagesAstm A 247 - 67 R98Er WidodoNo ratings yet

- JIS G5501-1995 Gray Iron CastingsDocument12 pagesJIS G5501-1995 Gray Iron CastingsNicole Keith100% (2)

- Cast Iron Vs Ductile IronDocument2 pagesCast Iron Vs Ductile IronJayakrishnan RadhakrishnanNo ratings yet

- Seminar Report Design ProjectDocument8 pagesSeminar Report Design Projectfaimy josephNo ratings yet

- Seminar Topics of Civil EngineeringDocument30 pagesSeminar Topics of Civil EngineeringAmit SoniNo ratings yet

- The NSCP 2015 Provisions On The Use of QT TMT Reinforcing BarsDocument33 pagesThe NSCP 2015 Provisions On The Use of QT TMT Reinforcing BarsFritze Hansteen OngNo ratings yet

- Asd Tables For Reinforced Concrete Masonry Walls Based On THE 2012 IBC & 2011 MSJCDocument8 pagesAsd Tables For Reinforced Concrete Masonry Walls Based On THE 2012 IBC & 2011 MSJCJason PowellNo ratings yet

- Combined FootingDocument12 pagesCombined FootingmyNo ratings yet

- Rock Mechanics and Tunneling Course Outline: Part One Rock MechanicsDocument39 pagesRock Mechanics and Tunneling Course Outline: Part One Rock MechanicsMulugeta DefaruNo ratings yet

- Performance Analysis of Pressure Vessel With Various Stiffener Using FEA PDFDocument14 pagesPerformance Analysis of Pressure Vessel With Various Stiffener Using FEA PDFsandeeppandey0789No ratings yet

- The Canadian LRFD Standard For Cold Formed Steel DesignDocument27 pagesThe Canadian LRFD Standard For Cold Formed Steel DesignHadeer MohamedNo ratings yet

- EN1912 Part A - Material SelectionDocument16 pagesEN1912 Part A - Material SelectionHuw ChildNo ratings yet

- Brochure GreenWall - Uk - 2016-ADocument46 pagesBrochure GreenWall - Uk - 2016-ASelena SabrinaNo ratings yet

- Sokution Macihne DesDocument39 pagesSokution Macihne DesSunde PascuaNo ratings yet

- Embedded PlateDocument38 pagesEmbedded PlateAnonymous pD2ymRUguNo ratings yet

- Formulas For InterferenceDocument11 pagesFormulas For InterferenceParag Naik100% (1)

- Handbook The Q-Method Mai 2015 NettutgDocument56 pagesHandbook The Q-Method Mai 2015 Nettutgkeith_tian100% (1)

- Fire Resistance Design of Composite Slabs in Building Structures: From Research To PracticeDocument8 pagesFire Resistance Design of Composite Slabs in Building Structures: From Research To PracticeJamaell BlackNo ratings yet

- High-Temperature Tensile and Creep Data For Inconel 600Document13 pagesHigh-Temperature Tensile and Creep Data For Inconel 600Gustavo Alonso Luévanos Arizmendi100% (1)

- BTME-18301 BTME-18302 BTME-18303 BTME-18304 BTME-18305 BTME-18306 BTME-18307 BTME-18308 Memc-IDocument31 pagesBTME-18301 BTME-18302 BTME-18303 BTME-18304 BTME-18305 BTME-18306 BTME-18307 BTME-18308 Memc-IRohit NathNo ratings yet

- S Chambro N 2008Document7 pagesS Chambro N 2008Jose Luis Ubilla ⎝⏠⏝⏠⎠No ratings yet

- BS-5950-90 Example 001Document7 pagesBS-5950-90 Example 001Maribel Isaura Cunurana YapuchuraNo ratings yet

- Preparation and Investigation of Some Properties of Acrylic Resin Reinforced With Siwak Fiber Used For Denture Base ApplicationsDocument6 pagesPreparation and Investigation of Some Properties of Acrylic Resin Reinforced With Siwak Fiber Used For Denture Base ApplicationsJawad K. OleiwiNo ratings yet

- Mos Series 1 QP Set3Document2 pagesMos Series 1 QP Set3SijuKalladaNo ratings yet

- (Latest) Calculation For Can Crusher DesignDocument8 pages(Latest) Calculation For Can Crusher DesignChoi Agpasa100% (3)

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- The Effect of Impervious Clay Core Shape On The Stability of Embankment DamsDocument9 pagesThe Effect of Impervious Clay Core Shape On The Stability of Embankment Damsyaseen90azizNo ratings yet

- International Journal of Plasticity: Angela Y. Ku, Akhtar S. Khan, Thomas GN Aupel-HeroldDocument32 pagesInternational Journal of Plasticity: Angela Y. Ku, Akhtar S. Khan, Thomas GN Aupel-HeroldpurnashisNo ratings yet

- Engineering Structures: Stefano Sorace, Gloria TerenziDocument13 pagesEngineering Structures: Stefano Sorace, Gloria TerenzipaulkohanNo ratings yet

- DSS QB Unit-3 PDFDocument14 pagesDSS QB Unit-3 PDFDhaladhuli ChekravartyNo ratings yet

- A Guide To The Use of Steel Slag in RoadsDocument35 pagesA Guide To The Use of Steel Slag in RoadsTati LimaNo ratings yet

- Cigre TB 498Document79 pagesCigre TB 498jchinchayNo ratings yet