Professional Documents

Culture Documents

40NiCrMo7 PDF

Uploaded by

Amy GriffinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

40NiCrMo7 PDF

Uploaded by

Amy GriffinCopyright:

Available Formats

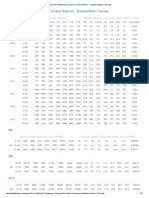

Quality 40NiCrMo7

According to standards UNI 7845: 1978 Lucefin Group

Number --

Chemical composition

C% Si% Mn% P% S% Cr% Mo% Ni%

max max

0,37-0,44 0,15-0,40 0,50-0,80 0,035 0,035 0,60-0,90 0,20-0,30 1,60-1,90 Permissible deviations

± 0.02 ± 0.03 ± 0.04 + 0.005 + 0.005 ± 0.05 ± 0.03 ± 0.05 on the product

Temperature in °C

Hot forming Normalizing Quenching Quenching Tempering Stress relieving

1100-900 860 850 830 550-650 50 under the

air oil or polymer water air temperature of tempering

Soft Isothermal Full End quench Preheating Stress relieving

annealing annealing annealing hardenability test welding after welding

680 800 furnace cooling 800-830 850 300 550 furnace cooling

air to 640 after, air furnace cooling water AC1 AC3 MS Mf

(HB max 250) (HB 230-250) (HB max 250) 725 770 300 80

Mechanical and physical properties

Hot rolled Mechanical properties on test blank after quenching and tempering (valid for products with no heat treatment)

For execution 5 (quenched and tempered material), values must be granted on the product UNI 7845:1978 Only reference.

diameter Testing at room temperature (longitudinal)

mm R Rp 0.2 A% C% Kcu HB

over to N/mm2 N/mm2 min. min. min. J min. for information

16 1030-1230 835 11 -- 30 311-363

16 40 980-1180 785 11 -- 30 295-354

40 100 930-1130 735 12 -- 30 278-339

100 160 850-1030 665 13 -- 30 253-311

160 250 780-980 635 12 -- 30 232-295

Table of tempering values at room temperature for round Ø 10 mm after quenching at 830 °C in oil

HB 504 482 455 432 415 400 381 348 319 294

HRC 51.5 50 48 46 44.5 43 41 37.5 34 31

R N/mm2 1850 1750 1640 1520 1450 1380 1300 1160 1050 980

Rp 0.2 N/mm2 1450 1400 1300 1230 1210 1210 1180 1050 940 880

A % 11.6 11.8 12.0 12.2 12.5 14.0 15.8 18.0 20.0 20.0

C % 45 51 52 50 51 53 57 59 63 63

Kv J 32 27 26 27 34 43 90 124 135 155

Tempering at °C 250 300 350 400 450 500 550 600 650 700

EUROPE EN ITALY UNI CHINA GERMANY DIN FRANCE AFNOR U.K. B.S. RUSSIA USA AISI/SAE

40NiCrMo7 40NiCrMo7 -- 40NiCrMo8 -- 817M40 40HN2M 4340

40NiCrMo7 Lucefin Group

Hot rolled quenched and tempered after Cold drawn +QT +C 817M40 BS 970 pt.3: 1991 Only reference.

size Testing at room temperature (longitudinal) e)

mm R Rp 0.2 A% HB

over to N/mm2 N/mm2 min min for inform.

13 63 1000-1150 850 9 298-347

63 150 850-1000 680 9 253-298

e) values valid also for +QT+C+SL

Cold drawn + quenching and tempering size Cold drawn Cold drawn annealing

size Testing at room temperature (longitudinal) mm obtained from otherwise annealing +

mm R Rp 0.2 A% HB hot rolled Peeled Reeled

over to N/mm2 N/mm2 min min annealing HB max

No indications are shown in the reference standards

Forged quenched and tempered UNI 7874: 1979 Only reference.

size Testing at room temperature

mm R Rp 0.2 A% L A% T A% Q Kv L Kv T Kv Q HB

over to N/mm2 min N/mm2 min min min min J min J min J min for inform.

100 930-1080 735 12 -- -- 30 -- -- 278-327

100 250 880-1010 735 13 12 10 40 30 25 263-300

250 500 835-955 685 14 13 11 40 30 25 250-288

500 800 735-885 590 14 12 10 30 25 25 224-265

800 1200 685-835 540 13 11 10 25 -- -- 209-250

1200 1550 635-785 490 12 10 9 -- -- -- 195-234

L = longitudinal T = tangential Q = radial

UNI 7845: 1978 Jominy test HRC grain size 5 min.

distance in mm from quenched end

1.5 3 5 7 9 11 13 15 20 25 30 35 40 45 50 --

min 52 52 52 52 52 52 52 52 51 50 49 48 47 45 44 --

max 60 60 60 60 60 60 60 60 59 58 58 58 57 56 56 --

Testing at °C 20 100 200 300 400 500 600

Mod. of elasticity E long. N/mm2 210000 -- -- -- -- -- --

Mod. of elasticity G tang. N/mm2 80000 -- -- -- -- -- --

Thermal expansion [(m/m●K) ●10-6 °C-1 ] -- 11.1 12.1 12.9 13.5 13.9 14.1

Specific heat capacity Density Thermal conductivity Specific electric resist. Conductivity

J/(Kg●K) Kg/dm3 W/(m●K) Ohm●mm2/m Siemens●m/mm2

460 7.85 42 0.19 5.26

You might also like

- Pheonwj M Spe 0025 1Document48 pagesPheonwj M Spe 0025 1Iksan Adityo Mulyo100% (1)

- Mazak Programing Class BookDocument510 pagesMazak Programing Class BookBriciu Teofil Mihail100% (7)

- JIS B0401-1986 System of Limits and FitsDocument42 pagesJIS B0401-1986 System of Limits and Fitsxuanphuong2710No ratings yet

- 32 Steel PDFDocument1 page32 Steel PDFIrfan DzakyNo ratings yet

- Iso 53 Indian StandardsDocument12 pagesIso 53 Indian StandardsErhan GencNo ratings yet

- Perkins 1104cDocument140 pagesPerkins 1104cGilvan Junior82% (11)

- Perkins 1104cDocument140 pagesPerkins 1104cGilvan Junior82% (11)

- ISO 17025 NDT Lab Accreditation CertificateDocument3 pagesISO 17025 NDT Lab Accreditation Certificatekiki270977No ratings yet

- 8630Document24 pages8630sunsirNo ratings yet

- Cross Index MaterialDocument4 pagesCross Index MaterialioancNo ratings yet

- Stainless Steel Grade 304 (UNS S30400) BackgroundDocument4 pagesStainless Steel Grade 304 (UNS S30400) BackgroundHenry PoudelNo ratings yet

- Pre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsDocument3 pagesPre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsmukeshkumarjNo ratings yet

- 39NiCrMo3 PDFDocument2 pages39NiCrMo3 PDFAmy GriffinNo ratings yet

- AutoCAD 2013Document264 pagesAutoCAD 2013panosscribd100% (1)

- 1 - Din 1683-1e - 0Document4 pages1 - Din 1683-1e - 0Joaquin AlvarezNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- Molarity and DilutionsDocument21 pagesMolarity and DilutionsRebecca Putri LimbardoNo ratings yet

- ISO 128-50 2001 (E) - Character PDF Document PDFDocument2 pagesISO 128-50 2001 (E) - Character PDF Document PDFNashraat BukhoryNo ratings yet

- Bac Cau Din Iso 12240.1Document67 pagesBac Cau Din Iso 12240.1Nguyen hanhNo ratings yet

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDocument2 pagesAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987No ratings yet

- ISO 965-1 CalibradorDocument7 pagesISO 965-1 CalibradorMICHELNo ratings yet

- Din 7977Document1 pageDin 7977zorghi1No ratings yet

- Alloy CuCr1ZrDocument53 pagesAlloy CuCr1ZrPrashant PuriNo ratings yet

- Din1688 1 PDFDocument4 pagesDin1688 1 PDFFelipe FernandesNo ratings yet

- Prog Eia-Iso MP 6200y PDFDocument356 pagesProg Eia-Iso MP 6200y PDFAmy GriffinNo ratings yet

- ISO 7452-2013-01 Hot-Rolled Steel Plates - TolerancesDocument20 pagesISO 7452-2013-01 Hot-Rolled Steel Plates - TolerancesIrwan PriyambodoNo ratings yet

- 6885 1Document1 page6885 1ajeshNo ratings yet

- DIN 6930-2 Stamped Steel Parts Part 2 General TolerancesDocument17 pagesDIN 6930-2 Stamped Steel Parts Part 2 General TolerancespopoNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- 13-08-26 List of GPS Relevant ISO-Standards - August 2013 - Edition 25 - Publication Date OrderDocument21 pages13-08-26 List of GPS Relevant ISO-Standards - August 2013 - Edition 25 - Publication Date OrderGabriel RoqueNo ratings yet

- Steel-HardnessDocument1 pageSteel-HardnessNoir HamannNo ratings yet

- Steel-HardnessDocument1 pageSteel-HardnessNoir HamannNo ratings yet

- Hollow Bars (ISO2938)Document8 pagesHollow Bars (ISO2938)suku maranNo ratings yet

- Cadfem FKM 2017 eDocument4 pagesCadfem FKM 2017 eSrashmiNo ratings yet

- PBL Series K CatalougeDocument117 pagesPBL Series K CatalougeankitkanujiyaNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument38 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForochableNo ratings yet

- ISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFDocument2 pagesISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFYohanes Wahyu TdNo ratings yet

- BZ 8002953Document15 pagesBZ 8002953uuur35No ratings yet

- Parallel Key Calculation According To DIN 6892Document21 pagesParallel Key Calculation According To DIN 6892zahirshah1436923No ratings yet

- Synchronous Belt Drives - Automotive PulleysDocument14 pagesSynchronous Belt Drives - Automotive Pulleystv-locNo ratings yet

- Astm A307Document1 pageAstm A307SAlman Khan100% (1)

- BS ISO 3547-6-2007 Plain Bearings. Wrapped Bushes. Measurement of Wall Thickness of Thin-Walled BushesDocument14 pagesBS ISO 3547-6-2007 Plain Bearings. Wrapped Bushes. Measurement of Wall Thickness of Thin-Walled Bushesxuanphuong2710No ratings yet

- En 10139Document2 pagesEn 10139releone11No ratings yet

- Iso 683 1 2012Document13 pagesIso 683 1 2012Haluk TOKGÖZNo ratings yet

- 2370 Ed1 ENDocument5 pages2370 Ed1 ENanhthoNo ratings yet

- Ti Spec ANSI B1.8 1988 Contents PDFDocument2 pagesTi Spec ANSI B1.8 1988 Contents PDFDanang PrasetioNo ratings yet

- C45 STD PDFDocument2 pagesC45 STD PDFJeetu GosaiNo ratings yet

- 18 Ni CR Mo 5Document2 pages18 Ni CR Mo 5lavius_mNo ratings yet

- DIN 128 A - Split Spring Washers, Curved, Form ADocument6 pagesDIN 128 A - Split Spring Washers, Curved, Form ASantosh100% (1)

- En 10305 en 10296Document4 pagesEn 10305 en 10296Siti Zaleha HmlonNo ratings yet

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDocument4 pagesMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNo ratings yet

- Plain Flat Washers Type BDocument2 pagesPlain Flat Washers Type Bvpizarro_23No ratings yet

- Din 470 PDFDocument6 pagesDin 470 PDFLuciano FontesNo ratings yet

- Ge Radin 1984Document15 pagesGe Radin 1984Phuor TyNo ratings yet

- ISO Tolerance ChartDocument1 pageISO Tolerance ChartAhmad Shuja100% (1)

- Din 2393-2Document0 pagesDin 2393-2Yalavarthi ChandrasekharNo ratings yet

- Sist en 13104 2009 A2 2014Document12 pagesSist en 13104 2009 A2 2014Юрий КостенкоNo ratings yet

- 54SiCr6 Material Spec SheetDocument1 page54SiCr6 Material Spec SheetRajaSekarsajjaNo ratings yet

- Din 743 E-AssisstDocument24 pagesDin 743 E-AssisstSezgin BayrakNo ratings yet

- DIN 935 - Hexagon Slotted Castle NutsDocument8 pagesDIN 935 - Hexagon Slotted Castle NutsJmmy Son LiNo ratings yet

- Steel grade 1.2312 propertiesDocument4 pagesSteel grade 1.2312 propertiesFrancisco CarrascoNo ratings yet

- Trainguard 100 200 Onboard en PDFDocument4 pagesTrainguard 100 200 Onboard en PDFRizki Fajar NovantoNo ratings yet

- GS52Document3 pagesGS52S.Hasan MirasadiNo ratings yet

- Din 1630 PDFDocument3 pagesDin 1630 PDFv53100% (1)

- Din 5401 PDFDocument12 pagesDin 5401 PDFLuciano FontesNo ratings yet

- Tinius Olsen - Ref 30 - 60000lb Cal Super L - B117GDocument8 pagesTinius Olsen - Ref 30 - 60000lb Cal Super L - B117Gjr_satish6965No ratings yet

- Screw, ISO 7380, Six Lobe, Metic, TorxDocument1 pageScrew, ISO 7380, Six Lobe, Metic, TorxDerekNo ratings yet

- Kisssoft Tut 003 E KeyDocument11 pagesKisssoft Tut 003 E KeyJorge Ronald Cabrera ÑaupaNo ratings yet

- Jis G 3466 - 2006 (JP)Document11 pagesJis G 3466 - 2006 (JP)HongHaiDuongNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- 34CrMo4 steel properties and heat treatment guideDocument2 pages34CrMo4 steel properties and heat treatment guideStefan GhNo ratings yet

- 1 8550-34CrAlNi710Document2 pages1 8550-34CrAlNi710Michel PortalNo ratings yet

- 36NiCrMo16 PDFDocument2 pages36NiCrMo16 PDFAmy GriffinNo ratings yet

- QuickFlex DMG Mori Seiki - enDocument24 pagesQuickFlex DMG Mori Seiki - enAmy GriffinNo ratings yet

- A6-A6M 02b Rolled Steel PDFDocument64 pagesA6-A6M 02b Rolled Steel PDFJoflNo ratings yet

- Catalogo MITUTOYO INGLÊSDocument1 pageCatalogo MITUTOYO INGLÊSAmy GriffinNo ratings yet

- Cincom Evolution Line: Sliding Headstock Type Automatic CNC LatheDocument8 pagesCincom Evolution Line: Sliding Headstock Type Automatic CNC LatheAmy GriffinNo ratings yet

- AÇOS VILLARES VF800-AT - InglesDocument2 pagesAÇOS VILLARES VF800-AT - InglesAmy Griffin100% (1)

- Milk - Run Volkswagen PDFDocument34 pagesMilk - Run Volkswagen PDFAmy GriffinNo ratings yet

- 36NiCrMo16 PDFDocument2 pages36NiCrMo16 PDFAmy GriffinNo ratings yet

- 30 CR Ni Mo 8Document2 pages30 CR Ni Mo 8Amy GriffinNo ratings yet

- Astma105 PDFDocument1 pageAstma105 PDFAmy GriffinNo ratings yet

- 34 CR Ni Mo 6Document2 pages34 CR Ni Mo 6hp_vijaykNo ratings yet

- 40NiCrMo3 PDFDocument1 page40NiCrMo3 PDFAmy GriffinNo ratings yet

- Parker Fluid Power Seal Design Guide 5370Document300 pagesParker Fluid Power Seal Design Guide 5370edwardsheridan0% (1)

- Manual Fresa Dora Ha AsDocument143 pagesManual Fresa Dora Ha AsAmy GriffinNo ratings yet

- Wireline Logging Using ExcelDocument2 pagesWireline Logging Using ExcelYoussef ElbouazaouiNo ratings yet

- Skin Creams: Revision)Document13 pagesSkin Creams: Revision)SaraNo ratings yet

- Chemistry Btech Experiment A Laboratory Experiment in Crystals and Crystal Model BuildingDocument7 pagesChemistry Btech Experiment A Laboratory Experiment in Crystals and Crystal Model BuildingrajaaNo ratings yet

- Project Topics For CL 10Document8 pagesProject Topics For CL 10Nihaas Reddy KoppulaNo ratings yet

- 3.2.2 Reaction Rates QPDocument17 pages3.2.2 Reaction Rates QPjasmeet kahlonNo ratings yet

- Research 2 Mind Map Draft Q1Document1 pageResearch 2 Mind Map Draft Q1Danielle CastilloNo ratings yet

- Techno-Economic Assessment About PropanediolDocument3 pagesTechno-Economic Assessment About PropanediolIntratec SolutionsNo ratings yet

- ChemistryDocument22 pagesChemistrymacaronloverNo ratings yet

- Rock Eval 6Document24 pagesRock Eval 6Mukul GoyalNo ratings yet

- TDS 01ofg V08 enDocument2 pagesTDS 01ofg V08 enDenisTarasNo ratings yet

- PhysicalDocument70 pagesPhysicalGadde Gopala KrishnaNo ratings yet

- Polypropylene RecycleDocument1 pagePolypropylene RecyclealaneeeedNo ratings yet

- DSM-0279.0 Fe SpecialityDocument3 pagesDSM-0279.0 Fe SpecialityStefanoNo ratings yet

- Coventya Pop Sempa 2015Document28 pagesCoventya Pop Sempa 2015LukeNo ratings yet

- Coa - Argan Oil Organic PDFDocument1 pageCoa - Argan Oil Organic PDFDhaval SoniNo ratings yet

- Amin 2010Document8 pagesAmin 2010Reffy AdhaNo ratings yet

- 2016 Progress in Non-Isocyanate Polyurethanes Synthesized PDFDocument38 pages2016 Progress in Non-Isocyanate Polyurethanes Synthesized PDFPilar MayaNo ratings yet

- Experiment No.2 Froth FlotationDocument2 pagesExperiment No.2 Froth FlotationShubham KumarNo ratings yet

- NganalDocument19 pagesNganalWaleed El-azabNo ratings yet

- Pasar PDFDocument70 pagesPasar PDFRalph Carlo EvidenteNo ratings yet

- Process of Production CS2 PDFDocument9 pagesProcess of Production CS2 PDFDinii Lathiifah PertiwiNo ratings yet

- Nordson XALOY - Extrusion - Catalogue - PC - Rev0Document20 pagesNordson XALOY - Extrusion - Catalogue - PC - Rev0berryeletricaNo ratings yet

- DyeingDocument264 pagesDyeingEhsaas RifatNo ratings yet

- Structures and Properties of CeramicsDocument38 pagesStructures and Properties of CeramicsArjayNo ratings yet

- Symbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Document79 pagesSymbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Kameswar MandhataNo ratings yet