Professional Documents

Culture Documents

Abst 24 2 p122 jc615 Kim

Uploaded by

donyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abst 24 2 p122 jc615 Kim

Uploaded by

donyaCopyright:

Available Formats

International Journal of Offshore and Polar Engineering (ISSN 1053-5381) http://www.isope.

org/publications

Copyright © by The International Society of Offshore and Polar Engineers

Vol. 24, No. 2, June 2014, pp. 122–128

Dynamic Coupling Between Ship Motion and Three-Layer-Liquid Separator

by Using Moving Particle Simulation

Kyung Sung Kim* and Moo Hyun Kim*

Department of Civil Engineering, Texas A&M University

College Station, Texas, USA

Jong-Chun Park

Department of Naval Architecture and Ocean Engineering, Pusan National University

Busan, Korea

The initial separation of mixed oil/gas and water from risers is done by wash tanks inside the FPSO/FLNG hull. As the

vessel size increases, larger-sized separators/wash tanks and storage tanks are considered. The performance of separators/wash

tanks is in general affected by the vessel motions, and the vessel motions themselves are influenced by multi-layer-liquid

sloshing motions inside the wash tanks. The MPS (Moving Particle Simulation) method has shown that it is adequate in

predicting violent sloshing patterns and the corresponding impact loading on tank walls in single-phase-liquid problems.

However, the application of the MPS method to the multi-layer-liquid system has been very rare in the open literature. In the

multi-liquid system, a proper buoyancy model including surface tension has to be incorporated to more accurately simulate the

behavior among different-density particle members. Another important factor of the multi-liquid problem is the reasonable

treatment for tracing multiple interfaces and imposing proper kinematic and dynamic boundary conditions at the interfaces.

The newly developed MPS method for multiple-liquid layers is validated by comparison against linear potential theory (in the

case when interfacial amplitudes are small) and by comparison against some available experimental results. The multi-liquid

MPS sloshing program is also coupled in time domain with a ship-motion program to assess their interactions in a typical

operational sea environment. The generation of interfacial sloshing waves depending on the excitation wave period is clearly

demonstrated, and the internal waves are in several cases much greater than the free-surface waves. Since various interfacial

sloshing motions of different frequencies can be generated at the respective interfaces, the influence of large separators on

vessel motion can be more complicated than the single-liquid tank.

INTRODUCTION The motions of inner fluids can thus become an important issue.

At the design stage, it is important to confirm that undesirable

Due to the increase in demand for oil and gas, the offshore resonant motions of the multiple interfaces do not occur under the

industry is moving into deeper water depths for exploration and typical operational/survival environmental conditions. Therefore, a

production. In this regard, many new floating offshore platforms, consistent dynamic analysis, including the coupling effect between

such as FPSO, FSRU, and FLNG, are planned to be installed the vessel motion and the sloshing of multiple inner fluids, needs

in the coming years. Another interesting point is that the multi- to be developed. In particular, the internal sloshing at the inner

well system will become more popular in future development. To interfaces needs to be predicted in a reliable manner to guarantee

increase the processing efficiency of those floating platforms, many the high performance of wash tanks.

new ideas have been suggested. For instance, subsea separators The multi-liquid sloshing problem was studied by Molin et al.

were newly introduced for maximizing the production efficiency of (2012) through both experiments and numerical simulations. Three

new types of deepwater oil wells. Usually, separators are placed different fluid layers in a rectangular tank were used in the study.

on deck and separate oil, water, and gas from produced fluids. La Rocca et al. (2005) also investigated both theoretically and

Recently, a new idea for a larger-scale “wash tank” was also experimentally the two-liquid-layer sloshing in a rectangular tank.

suggested as a pre-processor for conventional separators. The wash In Rocca et al.’s study, Molin et al.’s three-immiscible-liquid-layer-

tank is for the initial separation of oil and seawater, with the help sloshing problem is revisited, and the whole fluid dynamics are

simulated by a newly developed MPS method. The simulated

of emulsion fluid, in simply shaped storage tanks inside the hull for

interface elevations are compared against Molin et al.’s experimental

maximizing process efficiency. One or two large-scale wash tanks

results, which show good agreement between them. Molin et al.

with three liquid layers can be positioned inside the FPSO hull. (2012) also presented their CFD results, in which VOF is used for

tracing interfaces. Under mild harmonic motions, their CFD results

also agree well against their experimental results. However, the

*ISOPE Member.

Received October 16, 2013; updated and further revised manuscript received VOF method may not be so reliable in a case of violent interface

by the editors January 7, 2014. The original version (prior to the final motions, including breaking, mixing, splashing, and detached

updated and revised manuscript) was presented at the Twenty-third particles, which may occur when vessel motions are large. In this

International Offshore and Polar Engineering Conference (ISOPE-2013), regard, the Lagrangian approach, such as MPS, is extended in the

Anchorage, Alaska, USA, June 30–July 5, 2013.

present study to solve the multi-liquid sloshing and its coupling

KEY WORDS: Multi-layer-liquid tank, separator/wash tank, MPS, multi-

ple interfacial boundary conditions, buoyancy model, surface tension, effects on vessel motions.

internal (interfacial) waves/sloshing, multi-liquid sloshing/vessel motion The MPS method was proposed by Koshizuka and Oka (1996)

interaction. for incompressible-flow simulations. In the original MPS method,

You might also like

- Handbook of Mechanical In-Service InspectionDocument704 pagesHandbook of Mechanical In-Service InspectionJojolasNo ratings yet

- Understanding Aperture - A Beginner's GuideDocument37 pagesUnderstanding Aperture - A Beginner's GuideSullivan Da'CalenderNo ratings yet

- Wind Load (NSCP)Document1 pageWind Load (NSCP)dantevarias100% (4)

- Differential CalculusDocument4 pagesDifferential CalculusIsiahTanEdquibanNo ratings yet

- Welding Inspection: Weld ProceduresDocument22 pagesWelding Inspection: Weld Proceduresanon_90890103No ratings yet

- Cohesive Sediments in Open Channels: Erosion, Transport and DepositionFrom EverandCohesive Sediments in Open Channels: Erosion, Transport and DepositionNo ratings yet

- Motion of Three Offshore Structures Due To The Effect of Hydrodynamic InteractionDocument11 pagesMotion of Three Offshore Structures Due To The Effect of Hydrodynamic InteractionMuhammad Farid Abdul HalimNo ratings yet

- Stratigraphic Well CorrelationsDocument36 pagesStratigraphic Well CorrelationsFrancois FournierNo ratings yet

- Bamboo ConnectionsDocument1 pageBamboo ConnectionsEngineers Without Borders UK100% (1)

- Yianatos (2007)Document13 pagesYianatos (2007)Nicolas PerezNo ratings yet

- Spe 146580 MS PDocument17 pagesSpe 146580 MS Pdownloader1983No ratings yet

- OTC 24437 A Comprehensive Analysis On Gas-Liquid Slug Flows in Horizontal PipesDocument12 pagesOTC 24437 A Comprehensive Analysis On Gas-Liquid Slug Flows in Horizontal PipesbabyweiNo ratings yet

- NotchesDocument15 pagesNotchesAshwin KhandelwalNo ratings yet

- CFD Analysis of Sloshing Within TankDocument6 pagesCFD Analysis of Sloshing Within TankDipankar NathNo ratings yet

- VLC Based Vehicle To Vehicle CommunicationDocument2 pagesVLC Based Vehicle To Vehicle CommunicationIJRASETPublicationsNo ratings yet

- Flame Arrester Technical FormDocument7 pagesFlame Arrester Technical FormHmd MokhtariNo ratings yet

- Comparing Various Methods For Topology and Shape ODocument15 pagesComparing Various Methods For Topology and Shape ORochimHadisantosaNo ratings yet

- Applied Ocean Research: A-Man Zhang, Xue-Yan Cao, Fu-Ren Ming, Zhi-Fan ZhangDocument8 pagesApplied Ocean Research: A-Man Zhang, Xue-Yan Cao, Fu-Ren Ming, Zhi-Fan ZhangFahmy ArdhiansyahNo ratings yet

- Research Article: Experimental and Numerical Study of Stratified Sloshing in A Tank Under Horizontal ExcitationDocument14 pagesResearch Article: Experimental and Numerical Study of Stratified Sloshing in A Tank Under Horizontal Excitationtravail compteNo ratings yet

- Energy - Sloshing With Floating FoamsDocument23 pagesEnergy - Sloshing With Floating FoamsSuresh HubballiNo ratings yet

- Preprints201609 0007 v1Document14 pagesPreprints201609 0007 v1Medardo TorresNo ratings yet

- Indentification of ReservoirDocument12 pagesIndentification of ReservoirdagingoNo ratings yet

- minerals-11-00031Document19 pagesminerals-11-0003122-081Fahmi SyaifullahNo ratings yet

- M12 - Jurnal Prof Ming 2020Document16 pagesM12 - Jurnal Prof Ming 2020Mark SandyNo ratings yet

- Applied Ocean Research: R.A. Watai, F. Ruggeri, A.N. SimosDocument22 pagesApplied Ocean Research: R.A. Watai, F. Ruggeri, A.N. SimosVictor DaggersNo ratings yet

- 1-s2.0-S0309170809001870-mainDocument13 pages1-s2.0-S0309170809001870-mainAvinash SajwanNo ratings yet

- Flujo5005spe 169426 MsDocument38 pagesFlujo5005spe 169426 MsJeanPierre BazanNo ratings yet

- Understanding The Effects Small Scale Heterogeneity On Buoyancy - 2017 - EnergyDocument7 pagesUnderstanding The Effects Small Scale Heterogeneity On Buoyancy - 2017 - EnergyBruno PinaNo ratings yet

- Jmse 09 01236 With CoverDocument50 pagesJmse 09 01236 With CoverDocholosoNo ratings yet

- Can J Chem Eng - 2022 - Pukkella - An Integrated CFD Methodology For Tracking Fluid Interfaces and Solid Distributions in ADocument20 pagesCan J Chem Eng - 2022 - Pukkella - An Integrated CFD Methodology For Tracking Fluid Interfaces and Solid Distributions in AArjun KumarNo ratings yet

- Numerical and Experimental Investigation On The Ballast Flushing SystemDocument11 pagesNumerical and Experimental Investigation On The Ballast Flushing Systemjoujoukos kritikosNo ratings yet

- Computers and Geotechnics: H. Elsafti, H. OumeraciDocument25 pagesComputers and Geotechnics: H. Elsafti, H. OumeracisugyanibalaNo ratings yet

- SPE-179691-MS A Microfluidic Investigation of The Synergistic Effect of Nanoparticles and Surfactants in Macro-Emulsion Based EORDocument16 pagesSPE-179691-MS A Microfluidic Investigation of The Synergistic Effect of Nanoparticles and Surfactants in Macro-Emulsion Based EOREliasNo ratings yet

- Preprints202007 0387 v1Document15 pagesPreprints202007 0387 v1Karin Setia MuktiNo ratings yet

- SPE-173269-MS A Comprehensive Reservoir Simulator For Unconventional Reservoirs Based On The Fast Marching Method and Diffusive Time of FlightDocument22 pagesSPE-173269-MS A Comprehensive Reservoir Simulator For Unconventional Reservoirs Based On The Fast Marching Method and Diffusive Time of FlightDavid MontoyaNo ratings yet

- Wnk2018 Article CFDAnalysisOfShip-To-ShipHydroDocument18 pagesWnk2018 Article CFDAnalysisOfShip-To-ShipHydroIszysax MediaNo ratings yet

- OMAE2017-62228: Internal Fluid Effect Inside A Floating Structure: From Frequency Domain Solution To Time Domain SolutionDocument10 pagesOMAE2017-62228: Internal Fluid Effect Inside A Floating Structure: From Frequency Domain Solution To Time Domain SolutionSakshi IngaleNo ratings yet

- Ocean Dynamics and Modeling: HypopDocument3 pagesOcean Dynamics and Modeling: HypoppostscriptNo ratings yet

- A LES-based Eulerian-Lagrangian Approach To Predict The DynamicsDocument10 pagesA LES-based Eulerian-Lagrangian Approach To Predict The DynamicsStephany CamacaroNo ratings yet

- A CFD Methodology of Finding Dispersion Coefficient in Stabilization PondsDocument8 pagesA CFD Methodology of Finding Dispersion Coefficient in Stabilization PondsOmar BolañosNo ratings yet

- 1 s2.0 S0889974622000585 MainDocument23 pages1 s2.0 S0889974622000585 MainRIGOBERTO NAVA GONZALEZNo ratings yet

- Spe 191213 MsDocument11 pagesSpe 191213 MsFidel Vladimir Chuchuca AguilarNo ratings yet

- A Perspective On Flotation, A ReviewDocument24 pagesA Perspective On Flotation, A ReviewCarlos LopezNo ratings yet

- sharma2002Document8 pagessharma2002thien.le1811No ratings yet

- Pressure Pulsing at The ReservoirDocument13 pagesPressure Pulsing at The ReservoirddqylxgNo ratings yet

- Hydrodynamics of An FLNG System in Tandem Offloading OperationDocument13 pagesHydrodynamics of An FLNG System in Tandem Offloading Operationmahera wijaksaraNo ratings yet

- Water ConingDocument13 pagesWater ConingAminollah PayvandNo ratings yet

- SPE 176101 Fracture CorridorsDocument15 pagesSPE 176101 Fracture CorridorsAzalea HidayatNo ratings yet

- Yu Et Al. - 2019 - A Versatile Lattice Boltzmann Model For Immiscible Ternary Fluid FlowsDocument15 pagesYu Et Al. - 2019 - A Versatile Lattice Boltzmann Model For Immiscible Ternary Fluid Flowsdongwang12126No ratings yet

- Modeling IPRDocument19 pagesModeling IPRfreelancer2earnNo ratings yet

- Wallevik Mansour ID 362Document10 pagesWallevik Mansour ID 362Khalid EL ABBAOUINo ratings yet

- Cornett Coastlab 14 P QDocument19 pagesCornett Coastlab 14 P QChristos AntoniadisNo ratings yet

- Simulation of Fluid Sloshing in A Tank: June 2010Document7 pagesSimulation of Fluid Sloshing in A Tank: June 2010Dipankar NathNo ratings yet

- Coupled Vessel Dry Granular Cargo Roll Dynamics in Regula - 2016 - Ocean EngineeDocument8 pagesCoupled Vessel Dry Granular Cargo Roll Dynamics in Regula - 2016 - Ocean Engineejsouza16No ratings yet

- Tajali (2011) Hydrodynamic Analysis of Multi-Body Floating Piers Under Wave ActionDocument9 pagesTajali (2011) Hydrodynamic Analysis of Multi-Body Floating Piers Under Wave ActionkometmayorNo ratings yet

- Effects of Sloshing in A380 Passenger AircraftDocument31 pagesEffects of Sloshing in A380 Passenger AircraftPrincessNo ratings yet

- Coastal Engineering: Crina-Stefania Ciocan, Francisco Taveira-Pinto, Luciana Das Neves, Paulo Rosa-SantosDocument12 pagesCoastal Engineering: Crina-Stefania Ciocan, Francisco Taveira-Pinto, Luciana Das Neves, Paulo Rosa-SantosEsperanza OlivaresNo ratings yet

- Comparison Between The Dynamic Behavior of The Non-Stepped and Double-Stepped Planing Hulls in Rough Water: A Numerical StudyDocument16 pagesComparison Between The Dynamic Behavior of The Non-Stepped and Double-Stepped Planing Hulls in Rough Water: A Numerical StudyGerasimos FragopoulosNo ratings yet

- Experimental Measurements of Bubble Convection Models in Two-PhaseDocument9 pagesExperimental Measurements of Bubble Convection Models in Two-PhaseStephany CamacaroNo ratings yet

- Fluid Composition Equilibrium A Proxy FoDocument15 pagesFluid Composition Equilibrium A Proxy FoAhmed GharbiNo ratings yet

- Proppant Optimization For Foam Fracturing in Shale and Tight ReservoirsDocument14 pagesProppant Optimization For Foam Fracturing in Shale and Tight ReservoirsVatsal ShahNo ratings yet

- Msiptc PDFDocument28 pagesMsiptc PDFAiwarikiaarNo ratings yet

- Energies 15 06457 v2Document17 pagesEnergies 15 06457 v2mohamed farokNo ratings yet

- Analytical and Numerical Modeling of Flow in A Fractured Gneiss AquiferDocument6 pagesAnalytical and Numerical Modeling of Flow in A Fractured Gneiss Aquifermoody_ceNo ratings yet

- How To Use COMSOL Multiphysics For Coupled Dual-PeDocument9 pagesHow To Use COMSOL Multiphysics For Coupled Dual-PeJorge León IllanesNo ratings yet

- Large Diameter Propeller Emergence RiskDocument13 pagesLarge Diameter Propeller Emergence RiskMuhammad Rafiq RavinNo ratings yet

- Effects of Water Depth, Mooring Line Diameter and Hydrodynamiccoefficients On The Behaviour of Deepwater FPSOsDocument13 pagesEffects of Water Depth, Mooring Line Diameter and Hydrodynamiccoefficients On The Behaviour of Deepwater FPSOsabuNo ratings yet

- Introduction To The Thematic Set Fault and Top SealsDocument2 pagesIntroduction To The Thematic Set Fault and Top SealsAlfian GilangNo ratings yet

- CFD Simulation of Multiple Moored Floating Structures Using Open FoamDocument54 pagesCFD Simulation of Multiple Moored Floating Structures Using Open FoamPaúl ZambranoNo ratings yet

- Questionnaire For: Liquid Jet Vacuum Ejectors For Continuous OperationDocument2 pagesQuestionnaire For: Liquid Jet Vacuum Ejectors For Continuous OperationdonyaNo ratings yet

- © Association For Scientific Research: Mathematical and Computational Applications, Vol. 15, No. 1, Pp. 137-147, 2010Document11 pages© Association For Scientific Research: Mathematical and Computational Applications, Vol. 15, No. 1, Pp. 137-147, 2010Mocheedy UbahNo ratings yet

- (translate68.ir مترجم متن) 10.1088 - 0959-5309 - 57 - 4 - 301Document13 pages(translate68.ir مترجم متن) 10.1088 - 0959-5309 - 57 - 4 - 301donyaNo ratings yet

- Pressure Drop Measurements in Distillatio ColumnsDocument5 pagesPressure Drop Measurements in Distillatio Columnsdonya100% (1)

- Processes MTP 03 00684 v2Document15 pagesProcesses MTP 03 00684 v2akshaykgNo ratings yet

- Chemical Engineering CommunicationsDocument15 pagesChemical Engineering CommunicationsdonyaNo ratings yet

- Select ejector options and stagesDocument2 pagesSelect ejector options and stagesdonyaNo ratings yet

- Unified correlations for predicting drop size in liquid-liquid extraction columnsDocument14 pagesUnified correlations for predicting drop size in liquid-liquid extraction columnsdonyaNo ratings yet

- (Doi 10.1002/0471238961), - Kirk-Othmer Encyclopedia of Chemical TechnologyDocument13 pages(Doi 10.1002/0471238961), - Kirk-Othmer Encyclopedia of Chemical TechnologyHenry ArenasNo ratings yet

- Distillation Trays That Operate Beyond The Limits of Gravity by Using Centrifugal SeparationDocument6 pagesDistillation Trays That Operate Beyond The Limits of Gravity by Using Centrifugal SeparationdonyaNo ratings yet

- Experimental Investigation of An Ejector: Received 6 September 1985 Revised 16 September 1985Document3 pagesExperimental Investigation of An Ejector: Received 6 September 1985 Revised 16 September 1985donyaNo ratings yet

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocument2 pagesE-03.0) General Static-Mixing Customer Specification QuestionnairedonyaNo ratings yet

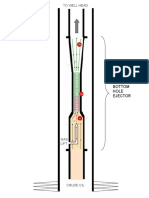

- BOTTOMHOLEEJECTORDocument1 pageBOTTOMHOLEEJECTORdonyaNo ratings yet

- Size Distributions in Strongly Coalescing Agitated Liquid-Liquid SystemsDocument4 pagesSize Distributions in Strongly Coalescing Agitated Liquid-Liquid SystemsdonyaNo ratings yet

- FF - Mar-Apr - 2018 - Zero Waste Urea Production - ONLINEDocument3 pagesFF - Mar-Apr - 2018 - Zero Waste Urea Production - ONLINEdonyaNo ratings yet

- 6200 Area - Urea Plant: Process OverviewDocument8 pages6200 Area - Urea Plant: Process OverviewtreyzzztylerNo ratings yet

- Objectlistview Python Edition StableDocument77 pagesObjectlistview Python Edition StabledonyaNo ratings yet

- Inventions 04 00016Document54 pagesInventions 04 00016donyaNo ratings yet

- Theresa Renee Anthony: All Rights ReservedDocument53 pagesTheresa Renee Anthony: All Rights ReserveddonyaNo ratings yet

- Data Sheet Ejector PDFDocument1 pageData Sheet Ejector PDFdonyaNo ratings yet

- Entropy: Thermodynamic Modelling of An Ejector With Compressible Flow by A One-Dimensional ApproachDocument15 pagesEntropy: Thermodynamic Modelling of An Ejector With Compressible Flow by A One-Dimensional Approachkoustavghosh1986No ratings yet

- Size Distributions in Strongly Coalescing Agitated Liquid-Liquid SystemsDocument4 pagesSize Distributions in Strongly Coalescing Agitated Liquid-Liquid SystemsdonyaNo ratings yet

- Modelling Gas Liquid Flow in Venturi SCR PDFDocument7 pagesModelling Gas Liquid Flow in Venturi SCR PDFdonyaNo ratings yet

- Questionnaire For: Liquid Jet Liquid EjectorsDocument2 pagesQuestionnaire For: Liquid Jet Liquid EjectorsdonyaNo ratings yet

- Processes MTP 03 00684 v2Document15 pagesProcesses MTP 03 00684 v2akshaykgNo ratings yet

- 4244 12672 1 PB PDFDocument15 pages4244 12672 1 PB PDFVinh Do ThanhNo ratings yet

- 1975163Document2 pages1975163donyaNo ratings yet

- 291-Questionnaire-Jet and Venturi scrubbers-EN-161202-STDocument2 pages291-Questionnaire-Jet and Venturi scrubbers-EN-161202-STdonyaNo ratings yet

- 2D Fourier Transform: A Concise ExplanationDocument2 pages2D Fourier Transform: A Concise ExplanationJiveshNo ratings yet

- Internal Model ControlDocument12 pagesInternal Model ControlhimasailajaNo ratings yet

- Petrofacies Analysis A Petrophysical Tool For Geologic Engineering Reservoir Characterization PDFDocument18 pagesPetrofacies Analysis A Petrophysical Tool For Geologic Engineering Reservoir Characterization PDFJody Van RensburgNo ratings yet

- Optimization of Chemical SynthesisDocument3 pagesOptimization of Chemical SynthesisFahrudin MarbulakNo ratings yet

- Leybold FundamentalsDocument199 pagesLeybold FundamentalsJako MishyNo ratings yet

- Topic 1-Shear StrengthDocument69 pagesTopic 1-Shear StrengthFatin Naqiya RoslanNo ratings yet

- Solution To Problem 403 - Shear and Moment Diagrams - Strength of Materials ReviewDocument2 pagesSolution To Problem 403 - Shear and Moment Diagrams - Strength of Materials ReviewimrancenakkNo ratings yet

- Implementation of The Behavior of A Particle in A Double-Well Potential Using The Fourth-Order Runge-Kutta MethodDocument3 pagesImplementation of The Behavior of A Particle in A Double-Well Potential Using The Fourth-Order Runge-Kutta MethodCindy Liza EsporlasNo ratings yet

- X and y Are Related by The Equation: Linear Law Paper 1Document5 pagesX and y Are Related by The Equation: Linear Law Paper 1Loh Chee WeiNo ratings yet

- NMR of Nano ParticlesDocument19 pagesNMR of Nano ParticlessohailNo ratings yet

- Efficient FE Model ConnectionsDocument24 pagesEfficient FE Model Connectionsjejep4No ratings yet

- Physics 9C Midterm SolutionsDocument7 pagesPhysics 9C Midterm SolutionsTiffany LeeNo ratings yet

- Capacitor CompensatorDocument7 pagesCapacitor Compensatorranjith120198No ratings yet

- Ebook - Guide To The Measurement of Pressure and Vacuum PDFDocument81 pagesEbook - Guide To The Measurement of Pressure and Vacuum PDFAdindra Vickar EgaNo ratings yet

- FOURIER TRANSFORM PROBLEMSDocument57 pagesFOURIER TRANSFORM PROBLEMSAbdulhadi SafadiNo ratings yet

- Shape of Relativistically Moving ObjectsDocument9 pagesShape of Relativistically Moving ObjectsDalimil MazáčNo ratings yet

- Calculation of Properties of Pure FluidsDocument143 pagesCalculation of Properties of Pure FluidsArdila Hayu TiwikramaNo ratings yet

- Ladybird Beetle-Inspired Compliant Origami - Science RoboticsDocument1 pageLadybird Beetle-Inspired Compliant Origami - Science RoboticsMuhammadimran AliNo ratings yet

- FED 5 Instruction ManualDocument6 pagesFED 5 Instruction ManualAnonymous XOZfkNNo ratings yet

- Andritz Hydro 2015 Om Pelton Mnto.Document7 pagesAndritz Hydro 2015 Om Pelton Mnto.Christian Daniel ViveroNo ratings yet

- 2012 ENGG317 Midterm SolutionDocument4 pages2012 ENGG317 Midterm SolutionEmmanuel ConstantinidisNo ratings yet

- Astm For RealDocument4 pagesAstm For RealDeepakNo ratings yet