Professional Documents

Culture Documents

Calculation of GTG Shelter Rev 1

Uploaded by

Oky Mahertwo SeptianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation of GTG Shelter Rev 1

Uploaded by

Oky Mahertwo SeptianCopyright:

Available Formats

PetroChina International Jabung Ltd.

Betara Complex Development

Job No. : BCD-470R-CA

Detail Engineering Design

GTG & WHRU Additional Project

CALCULATION

GTG SHELTER STRUCTURAL ANALYSIS & FOUNDATION

Document No.

BCD3-690-45-CAL-4-102-00

Revision 1

CONTRACTOR DOCUMENT REVIEW

FOR CONFORMANCE WITH SPECIFICATIONS AND DESIGN DRAWINGS

Review Code

A Accepted as it is or with minor comments

B Accepted as noted – Resubmittal required

C Not Accepted

D Information Only

THIS REVIEW DOES NOT RELIEVE THE CONTRACTOR/VENDOR

OF ANY CONTRACTUAL OBLIGATION, INCLUDING THE

RESPONSIBILITY FOR ENGINEERING AND DETAIL DESIGN.

PetroChina International Jabung Ltd Date By

1 Re-Approved For Construction 08-FEB-2018 MI SEF JC/JND AAG/VK

0 Approved For Construction 12-SEP-2017 MI SEF JC/JND AAG/VK

C Issued For Approval 08-SEP-2017 MI SEF JC/JND AAG/VK

B Issued For Review 05-SEP-2017 MI SEF JC/JND AAG/VK

A Internal For Inter Discipline Check 04-SEP-2017 MI SEF JC/JND AAG/VK

Prepared Checked Reviewed Approved

Rev. Description Date

By By By By

PetroChina International Jabung Ltd. Calculation

GTG Shelter Structural Analysis &

Foundation

TABULATION OF REVISED PAGES

PAGE REVISIONS PAGE REVISIONS

A B C D 0 1 2 3 A B C D 0 1 2 3

1 51

2 52

3 53

4 54

5 55

6 56

7 57

8 58

9 59

10 60

11 61

12 62

13 63

14 64

15 65

16 66

17 67

18 68

19 69

20 70

21 71

22 72

23 73

24 74

25 75

26 76

27 77

28 78

29 79

30 80

31 81

32 82

33 83

34 84

35 85

36 86

37 87

38 88

39 89

40 90

41 ATTACHMENT/APPENDIX

42 1

43 2

44 3

45 4

46 5

47 6

48 7

49 8

50 9

BCD3-690-45-CAL-4-102-00 Rev 1 Page 2 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

Comments Response Sheet

Doc. No.: BCD3-690-45-CAL-4-102-00

GTG SHELTER STRUCTURAL ANALYSIS & FOUNDATION

Section/

No Company Comments Contractor Response Remark

Page Ref.

BCD3-690-45-CAL-4-102-00 Rev 1 Page 3 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

TABLE OF CONTENTS

Section Title Page

1.0 …………………………………………………………………………………… 6

INTRODUCTION

2.0 …………………………………………………………………………………… 6

ABBREVIATIONS

3.0 …………………………………………………………………………………… 6

DEFENITIONS

4.0 …………………………………………………………………………………… 7

GENERAL

4.1 ……………………………………………………………………………………….. 7

Scope

4.2 ………………………………………………………. 7

Codes, Standards and References

4.3 …………………………………………………………………………………………….

Unit 7

4.4 ……………………………………………………………………………. 7

Quality of Material

4.5 …………………………………………………………………………………. 8

Unit Weight

4.6 Pile Capacity……………………………………………………………………………. 8

5.0 DESIGN LOAD ……………………………………………………………………………………………

8

5.1 ………………………………………………………………………………...

Dead Load (D) 8

5.2 …………………………………………………………………………………

Live Load (L) 9

5.3 …………………………………………………………………………………

Wind Load (W) 9

5.4 ……………………………………………………………………. 12

Earthquake Load (EQ)

5.5 …………………………………………………………………………………. 13

Impact Load

5.6 ………………………………………………………………………… 14

Load Combination

5.7 Loading …………………………………………………………………………………

Data 15

6.0 …………………………………………………………………….. 16

COMPRESSOR SHELTER

6.1 ……………………………………………………………………………… 16

Summary Result

6.2 …………………………………………………………………………….. 17

Framing Modeling

6.3 ………………………………………………………………. 17

Joint and Member Numbering

6.4 …………………………………………………………………………. 19

Member Properties

6.5 ……………………………………………………………………………................. 19

Loading

7.0 FOUNDATION…………………………………………………………………………….

DESIGN 23

7.1 ……………………………………………………………………………. 23

Foundation Layout

7.2 …………………………………………………………………………….

Foundation Analysis F1 23

7.3 …………………………………………………………………………….

Foundation Analysis F2 33

7.4 …………………………………………………………………………….

Summary Foundation Analysis 42

7.5 ……………………………………………………………………………. 43

Foundation Sketch

8.0 ……………………………………………………………………………........... 45

RAIL DESIGN

8.1 …………………………………………………………………………..................…. 45

Loading

8.2 …………………………………………………………………………....................…. 45

Model

8.3 …………………………………………………………………………….... 46

Analysis Result

BCD3-690-45-CAL-4-102-00 Rev 1 Page 4 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

ATTACHMENT - 1 INPUT STAADPRO OF COMPRESSOR SHELTER

ATTACHMENT - 2 SOIL INVESTIGATION REPORT

ATTACHMENT - 3 CONNECTION CALCULATION

ATTACHMENT - 4 MATERIAL TAKE OFF

• ATTACHMENT - 3 : Shelter Drawing

BCD3-690-45-CAL-4-102-00 Rev 1 Page 5 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

1.0 INTRODUCTION

PetroChina International Jabung Ltd (PCIJL) is currently operating oil and gas field located in

Jabung Block in Jambi Province, Sumatra Indonesia.

In Betara Gas Processing (BGP) Facilities, PetroChina intend to extent its electric power

capacity by adding one set of Gas Turbine Generator (GTG) and Waste Heat Recovery Unit

(WHRU). Those equipment package are consisted of:

GTG Package consist of : (1). Gas Turbine (GT) complete with IC engine for starting system,

(2) Gas Turbine Generator (GTG), (3) Gearbox, (4) Lube Oil Console/System, (5) Radiator

and/or cooling system, (6) CO2 bottles, (7) Mist Eliminator and (8) Various Relevant Control

Panels

WHRU package consist of: (1) 1 set of WHRU include 2 coils and (2) Extension of ducting

system

This document is related to detail design of equipment foundation for those above

equipments and GTG shelter, that will be used by construction company as reference.

2.0 ABBREVIATIONS

BCD Betara Complex Development

BGP Betara Gas Plant

NGL Natural Gas Liquid

PCJL PetroChina Jabung Ltd.

POD Pursuant to Plant of Development

3.0 DEFENITIONS

● COMPANY is PETROCHINA JABUNG LTD shall mean firm or corporation which appoint

CONTRACTOR as the executor of the Project.

● CONTRACTOR is PT. Singgar Mulia shall mean firm or corporation as the executor of

the PROJECT.

● PROJECT is Front End Engineering Design (FEED) - Development of Non Associated

Gas from SABAR and NEB-UTAF Field.

BCD3-690-45-CAL-4-102-00 Rev 1 Page 6 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

4.0 GENERAL

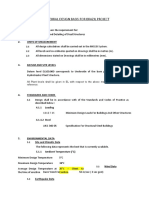

4.1 Scope

This document present detail engineering design calculation of GTG Shelter.

4.2 Codes, Standards and References

Applicable Documents and Reference

a. BCD4-000-45-CRT-4-001 : Civil & Structure Design

b. BCD4-000-45-CRT-4-101 : Civil & Structure Design Guide

c. BCD4-000-45-CRT-4-004 : Wind Load Design Guide

d. BCD3-01-00-45-SPC-003-1 : Specification for Structural Steel Construction

e. BCD4-000-45-SPC-4-122-00 : Project Specification Shelter

International Code

a. ASCE 7-05 : Minimum Design Loads for Buildings and other

structures

b. UBC 97 : Uniform Building Code

c. ACI 318-02 : Building Code Requirements for Reinforced Concrete

d. AISC-ASD 13th : American Institute of Steel Construction

4.3 Unit

All units are in Metric System.

4.4 Quality of Material

a) Concrete :

- Concrete Type class B, 28 days cylinder compressive strength (fc') = 280 kg/cm2

- Cement for upper and under ground portion : ASTM C150 Type I

- Cement for upper ground portion : ASTM C150 Type I

- Cement for under ground portion : ASTM C150 Type I/II/V

b) Rebar :

- Deformed steel bar (fy = 420 Mpa): ASTM A615 Gr. 60 or SII 0136 BJTD 40 or equal

- Plain round steel bar (fy = 280 Mpa): ASTM A615 Gr. 40 or SII 0136 BJTP 24 or equal

- Wiremesh (fy = 500 Mpa): ASTM A185

c) Lean Concrete

- Concrete Class D, 28 days cylinder compressive strength (fc') = 175 kg/cm2 (K-225)

- Cement as per ASTM C150 Type I

d) Steel Structure :

- High strength bolts shall conform to ASTM A325 type I

- Anchor bolts shall conform to ASTM A307 Grade A

- Structural steel shall conform to ASTM A36 or equivalent

BCD3-690-45-CAL-4-102-00 Rev 1 Page 7 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

4.5 Unit Weight

Unit weight of major construction materials shall be as follows :

- Steel : 7850 kg/m3

- Mortar : 2000 kg/m3

3

- Reinforcement Concrete : 2400 kg/m

3

- Plain Concrete : 2300 kg/m

4.6 Pile Capacity

Allowable Pile Capacity

Based on soil report data BCD3-600-45-CAL-4-001-00-0-IFR Design Basis For Pile and Soil

Bearing Capacity In Betara, Gemah, NEB-10 Plants. The allowable single pile bearing

capacity for size (300 mm diameter), 20 M penetration length for BGP area.

a. Pile bearing capacity for permanent, QA = 35 ton

Pile bearing capacity for temporary, QAt = 47 ton (increased 33%)

b. Pile lateral capacity for permanent, QL = 2.50 ton

Pile lateral capacity for temporary, QLt = 3.33 ton (increased 33%)

c. Pile tension capacity for permanent, QT = 35 ton

Pile tension capacity for temporary, QTt = 47 ton (increased 33%)

5.0 DESIGN LOAD

5.1 Dead Load ( D )

Dead load means the weight of structure it self, and all material permanently attached there to

or supported there by.

1). Self weight Structure (calculated by STAAD)

2). Roof Weight

- Roofing sheet = 6.5 kg/m2

- Miscellaneous item = 20.0 kg/m2

- Mech. Electrical, instrument = 5.0 kg/m2

- Purlins, Sagrod, & Girth = 8.50 kg/m2

+

= 40.0 kg/m2

Tributary Length (m) Uniform Load

Grid

Left Right (kg/m)

Edge 0.000 2.000 80.0

Inner 2.000 2.000 160.0

- PVC gutter 140 x 140 mm = 4.0 kg/m

Rainwater, 140x140x100x1000/10^6 = 2.0 kg/m

+

= 6.0 kg/m

(applied on the edge of roof) = 48 kg

3). Wall Weight

- Siding

2

Sagrod & siding frame struc. = 10.0 kg/m

BCD3-690-45-CAL-4-102-00 Rev 1 Page 8 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

5.2 Live Load ( L )

Live Loads shall means the moving or movable external loads on structure, floor, foundation

and building produced by people, tools, furnishings of building etc. which are not permanent.

Roof Length = 30 m

Roof Width = 12 m

2

Roof Area = 360 m

Basic live load = 100 kg/m2 (ASCE-7 Table 4-1 For ordinary roof)

1.0 for At 18.6 m2

Reduction factor = R 1.2-0.011At for 18.58 m2 < At < 55.74 m2

1 for At 55.7 m2

Roof Live Load = 60 kg/m2

Tributary Length (m) Uniform Load

Grid

Left Right (kg/m)

Edge 0.000 2.000 120.0

Inner 2.000 2.000 240.0

5.3 Wind Load (W)

Plan

A

qh G Cp

qh G Cp

L

qz G Cp

B = 30 m

A

BCD3-690-45-CAL-4-102-00 Rev 1 Page 9 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

Section A-A

qh G Cp

qh G Cp

15o

Z= 14 m

qzGCp qh G Cp

L = 12 m

Based on BCD6-000-45-CRT-4-004-00 : Wind Load Design Guide,

Wind pressure :

Wx, Wz = qz x G x Cf x Af

Where, qz = Velocity Pressure

= 0.613 x Kz x Kd x Kzt x V2 x I

Kz = 1.04 (Table 4-1 Wind Load Design Guide)

Kd = 0.85 (Building, ASCE 7-02 Table 6-4)

Kzt = 1.26 ASCE7-02 table 6-1

V = 28 m/s (Civil and Structural Design Criteria)

I = 1.15 (Category III) BCD3-000-45-CRT-4-004-00

Velocity pressure, qz = 0.613 x Kz x Kd x Kzt x V2 x I

= 0.613 x 1.04 x 0.85 x 1.26 x 28.00^2 x 1.15

2

= 615.60 N/m

= 62.82 kg/m2

Use Gust Effect Factor, G = 0.85

Cp = h/L = 14 / 30 = 0.467

for Angle = 15 Degrees

Winward

Cp = -0.7 Table 5-2 Wind Load Design Guide

Leeward

Cp = -0.5 Table 5-2 Wind Load Design Guide

So, Wind Pressure p

Windward

p = 62.82 x 0.85 x -0.7

= -37.38 Kg/m2

Leeward

p = 62.82 x 0.85 x -0.5

= -26.70 Kg/m2

BCD3-690-45-CAL-4-102-00 Rev 1 Page 10 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

Wall Load

Windward

p = qz.G.Cp

Where,

qz = 63 Kg/m2 Wind Load Design Guide Table 4-1

G = 0.9

Cp = 0.8 Wind Load Design Guide Table 5-1

So, Wind Pressure p

p = 63 x 0.85 x 0.8

= 42.84 Kg/m2

Leeward

p = qh x G x Cp

Cp = L/B = 12 / 30

= 0.4000

Cp = -0.5

p = 62.82 x 0.85 x -0.5

= -26.70 Kg/m2

Wind Load x - Dir

Rafter Load (Windward)

2

Pressure (kg/m ) Lenght of tributary (m) load (kg/m)

-37.38 2 -74.75

-37.38 4 -149.50

Wind Load x - Dir

Rafter Load (Leeward)

2

Pressure (kg/m ) Lenght of tributary (m) load (kg/m)

-26.70 2 -53.39

-26.70 4 -106.79

Wind Load x - Dir

Wall Load (WindWard)

Pressure (kg/m2) Lenght of tributary (m) load (kg/m)

42.84 2 85.68

42.84 4 171.36

Wind Load x - Dir

Wall Load (LeeWard)

2

Pressure (kg/m ) Lenght of tributary (m) load at rafter (kg/m)

-26.70 2 -53.39

-26.70 4 -106.79

BCD3-690-45-CAL-4-102-00 Rev 1 Page 11 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

Wind Load z - Dir

Wall Load (WindWard)

Pressure (kg/m2) Lenght of tributary (m) load (kg/m)

42.84 2 85.68

42.84 4 171.36

Wall Load (LeeWard)

Pressure (kg/m2) Lenght of tributary (m) load (kg/m)

-26.70 2 -53.39

-26.70 4 -106.79

5.4 Earthquake Load (EQ)

Based on UBC 1997, section 1630.2.1

The total design base shear,determined from the following formula

Cv x I x W

V1 =

RxT

The total design base shear need not exceed the following

2.5 x Ca x I x W

V2 =

R

The total design base shear shall not be less than the following

V3 = 0.11 x Ca x I x W

Where:

Seismic Zone = 2A BCD3-000-45-CRT-4-101-00

Seismic zone factor z = 0.15 (UBC Table 16-I)

Seismic importance factor I = 1.00 (UBC Table 16-K)

Soil profile type = SE (Soil Investigation Report)

Seismic coeficient factor Cv = 0.5 (UBC Table 16-R)

Seismic coeficient factor Ca = 0.22 (UBC Table 16-Q)

Numerical coeficient Rw = 4.5 (UBC Table 16-N & 16-P)

Numerical coeficient Ct = 0.035 (UBC Section 1630.2.2)

Height of structure hn = 14.3 m

Fundamental period T = Ct x (hn)^(3/4) (UBC Methode A)

= 0.26

The total design base shear

Cv x I x W 0.5 x 1

V1 = = W = 0.432 W

RxT 4.5 x 0.26

The total design base shear need not exceed the folowing

2.5 x Ca x I x W 2.5 x 1 x 0.22

V2 = = W = 0.122 W Govern

R 4.5

The total design base shear shall not be less than the following

V3 = 0.11 x Ca x I x W = 0.11 x 1 x 0.22 = 0.02 W

V1 = 0.432 W> V2 = 0.122 W

So the Total Design Base Shear = 0.122 W

BCD3-690-45-CAL-4-102-00 Rev 1 Page 12 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

5.5 Impact Load

Crane Data based on BCD6-550-43-DS-4-Y-101 Datasheet OH Crane.

Capacity of OH Crane = 15 ton

Weight of trolley = 0.42 ton (Assumed)

Weight of Bridge = 4 ton (Assumed)

- Vertical impact force = 25% (Civil and Structure Design Load)

- Lateral impact force :

- Transverse force = 20% of lift load (Civil and Structure Design Load)

- Longitudinal force = 10% of the maximum wheel loads.

(Civil and Structure Design Load)

Vertical Impact Force

Fy = (5+0.41+0.5*0.37)

= 17.42 ton

Total Fy= Fy + 25%Fy

= 17.42 + 4.36

= 21.78 ton

take only 75% of total Fy, for only one side of beam, thus

Fy = 16.33 ton (75%)

Fy = 5.44 ton (25%)

Longitudinal Force (longitudinal to the bridge)

FX = 10% x Total Fy

= 2.18 ton

take only 75% of total Fx, for only one side of beam, thus

Fx = 1.63 ton (75%)

Fx = 0.54 ton (25%)

Tranversal force (transversal to the bridge)

Fz = 20% x Fy

= 4.36 ton

take only 75% of total Fz, for only one side of beam, thus

Fz = 3.27 ton (75%)

Fz = 1.09 ton (25%)

So, the force applied to one side of beam (75%) To the other side of beam (25%)

Fx = 1.63 tons Fx = 0.54 tons

Fy = 16.33 tons Fy = 5.44 tons

Fz = 3.27 tons Fz = 1.09 tons

Moment load, due to Eccentricity of over head crane rail (0.65) :

Mx = 0 Mx = 0

My = Fz * e = 2.123 Ton.m My = Fz * e = 0.708 Ton.m

Mz = Fy * e = 10.615 Ton.m Mz = Fy * e = 3.538 Ton.m

BCD3-690-45-CAL-4-102-00 Rev 1 Page 13 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

5.6 Load Combination

All structural member must be designed based on some load combination bellow.

The critical condition will be used to determine member size of the structure.

Loading Combination for Allowable Stress Design

Unfactored Load for Allowable Stress Design (Steel Unity Check)

Loading Allowable stress

No Load comb Combinations of Load Condition

Conditions increasing factor

LC (DL + LL + CL) 1.00 Long term

LC 0.75 (DL + 0.5LL + CL + Wx) 1.00 Short term

Normal

1 LC 0.75 (DL + 0.5LL + CL + Wz) 1.00 Short term

Operation

LC 0.75 (DL + 0.5LL + CL + EQx) 1.00 Short term

LC 0.75 (DL + 0.5LL + CL + EQz) 1.00 Short term

Unfactored Load for Foundation Stability Check

Loading Allowable stress

No Load comb Combinations of Load Condition

Conditions increasing factor

LC DL + LL 1.00 Long term

LC DL + 0.5LL + CL + Wx 1.30 Short term

Normal

1 LC DL + 0.5LL + CL + Wz 1.30 Short term

Operation

LC DL + 0.5LL + CL) + EQx 1.30 Short term

LC DL + 0.5LL + CL + EQz 1.30 Short term

Factored Loads for Reinforcement Concrete Str. and Foundation

Allowable

Loading stress

No Load comb Combinations of Load Condition

Conditions increasing

factor

LC 1.4 DL + 1.7 LL 1.00 Long term

LC 1.4 DL + 1.7 (0.5LL+CL) 1.00 Long term

Normal LC 0.75(1.4 DL+ 1.7 (0.5LL+CL)+1.7 Wx 1.00 Short term

1

Operation LC 0.75(1.4 DL+ 1.7 (0.5LL+CL)+1.7 Wz 1.00 Short term

LC 0.75(1.4 (DL+CL) + 1.7 (0.5LL+CL)+1.87 EQx 1.00 Short term

LC 0.75(1.4 (DL+CL) + 1.7 (0.5LL+CL)+1.87 EQz 1.00 Short term

DL : Dead Load Wz : Wind Load in Z-Direction

LL : Live Load EQx : Earthquake Load in X-Direction

CL : Crane Load Eqz : Earthquake Load in Z-Direction

Wx : Wind Load in X-Direction

BCD3-690-45-CAL-4-102-00 Rev 1 Page 14 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

Load combination that are used in STAADPro are as follows :

Load Combination for Steel Design

LOAD COMB 9 DL+0.5LL

LOAD COMB 10 (DL+0.5LL+CL1)

LOAD COMB 11 (DL+0.5LL+CL2)

LOAD COMB 12 0.75(DL+0.5LL+CL1+WX)

LOAD COMB 13 0.75(DL+0.5LL+CL2+WX)

LOAD COMB 14 0.75(DL+0.5LL+CL1+WZ)

LOAD COMB 15 0.75(DL+0.5LL+CL2+WZ)

LOAD COMB 16 0.75(DL+0.5LL+CL1+QX)

LOAD COMB 17 0.75(DL+0.5LL+CL2+QX)

LOAD COMB 18 0.75(DL+0.5LL+CL1+QZ)

LOAD COMB 19 0.75(DL+0.5LL+CL2+QZ)

Load Combination for Concrete Design

LOAD COMB 20 1.4DL+1.7LL

LOAD COMB 21 1.4DL+1.7(0.5LL+CL1)

LOAD COMB 22 1.4DL+1.7(0.5LL+CL2)

LOAD COMB 23 1.05DL+1.275(0.5LL+CL1+WX)

LOAD COMB 24 1.05DL+1.275(0.5LL+CL2+WX)

LOAD COMB 25 1.05DL+1.275(0.5LL+CL1+WZ)

LOAD COMB 26 1.05DL+1.275(0.5LL+CL2+WZ)

LOAD COMB 27 1.05DL+1.275(0.5LL+CL1+QX)

LOAD COMB 28 1.05DL+1.275(0.5LL+CL2+QX)

LOAD COMB 29 1.05DL+1.275(0.5LL+CL1+QZ)

LOAD COMB 30 1.05DL+1.275(0.5LL+CL2+QZ)

Load Combination for Deflection

LOAD COMB 31 DL+LL

LOAD COMB 32 (DL+0.5LL+CL1)

LOAD COMB 33 (DL+0.5LL+CL2)

LOAD COMB 34 (DL+0.5LL+CL1+WX)

LOAD COMB 35 (DL+0.5LL+CL2+WX)

LOAD COMB 36 (DL+0.5LL+CL1+WZ)

LOAD COMB 37 (DL+0.5LL+CL2+WZ)

LOAD COMB 38 (DL+0.5LL+CL1+QX)

LOAD COMB 39 (DL+0.5LL+CL2+QX)

LOAD COMB 40 (DL+0.5LL+CL1+QZ)

LOAD COMB 41 (DL+0.5LL+CL2+QZ)

BCD3-690-45-CAL-4-102-00 Rev 1 Page 15 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

5.7 Loading Data

NO LOAD SOURCE LOAD

TYPE LOAD CALCULATION UNIT

VALUE

1 LOAD 1 (EARTHQUAKE LOAD X-DIRECTION) UBC X+1 by STAAD Pro

2 LOAD 2 (EARTHQUAKE LOAD Z-DIRECTION) UBC Z+1 by STAAD Pro

3 LOAD 3 ( DEAD LOAD = D)

SELFWEIGHT Y -1 by STAAD Pro

ROOF LOAD, EDGE RAFTER UNI GY 80 kg/m

ROOF LOAD, INNER RAFTER UNI GY 160 kg/m

WALL SIDING UNI GY 60 kg/m

ROOF GUTTER FY 48 kg

4 LOAD 4 ( LIVE LOAD = L)

ROOF LIVE LOAD, EDGE RAFTER YRANGE 120 kg/m

ROOF LIVE LOAD, INNER RAFTER YRANGE 240 kg/m

PLATFORM UNIFORM LOAD UNI GY 300 kg/m

5 LOAD 5 ( WIND LOAD X (+) DIR = WLX (+) )

MEMBER LOAD UNI GX - kg/m

6 LOAD 6 ( WIND LOAD Z (+) DIR = WLZ (+) )

MEMBER LOAD UNI GZ - kg/m

7 LOAD 7 (CRANE LOAD AT INNER COLUMN)

THE FORCE APPLIED TO ONE SIDE OF BEAM (75%)

LONGITUDINAL HORIZONTAL LOAD FX 1,633 kg

VERTICAL LOAD FY 16,331 kg

TRANSVERSAL HORIZONTAL LOAD FZ 3,266 kg

THE FORCE APPLIED TO ONE SIDE OF BEAM (25%)

LONGITUDINAL HORIZONTAL LOAD FX 544 kg

VERTICAL LOAD FY 5,444 kg

TRANSVERSAL HORIZONTAL LOAD FZ 1,089 kg

8 LOAD 8 (CRANE LOAD AT EDGE COLUMN)

THE FORCE APPLIED TO ONE SIDE OF BEAM (75%)

LONGITUDINAL HORIZONTAL LOAD FX 1,633 kg

VERTICAL LOAD FY 16,331 kg

TRANSVERSAL HORIZONTAL LOAD FZ 3,266 kg

THE FORCE APPLIED TO ONE SIDE OF BEAM (25%)

LONGITUDINAL HORIZONTAL LOAD FX 544 kg

VERTICAL LOAD FY 5,444 kg

TRANSVERSAL HORIZONTAL LOAD FZ 1,089 kg

BCD3-690-45-CAL-4-102-00 Rev 1 Page 16 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

6.0 COMPRESSOR SHELTER

6.1 Summary Result

Stress Ratio

No. Member Marking Beam No. LC Size Ratio

1 Column C1 7 13 H588X300X12 0.388

2 Column C2 1456 14 H200X100X5.5 0.562

3 Rafter RF1 1275 10 H450X200X9 0.844

4 Beam B1 1427 12 H150X150X7 0.688

5 Beam B2 1333 9 H300X150X6.5 0.811

6 Beam B3 1334 9 H250X125X6 0.6

7 Beam B4 1447 15 H200X200X8 0.783

8 Beam B5 1292 15 C100X50X5 0.768

9 Bracing VB1 1400 19 L80X80X6LD 0.416

*For detail location of the beam, see attachment A.

Beam Deflection

maximum vertical displacement dmax = 12.689 mm (Joint 124; LC 31)

Beam span L = 12000 mm

Allowable deflection dall = L/240 = 50.00 mm

Check deflection dmax < dall OK (BCD6-000-45-CRT-4-101-00-0)

Column sway

Column length L = 14000 mm

Sway limits Sl = L/200 = 70.00 mm (BCD6-000-45-CRT-4-101-00-0)

Sway X - Dir Dx = 69.578 mm OK (Dx < Sway limits) (Joint 113; LC 34)

Sway Z - Dir Dz = 18.104 mm OK (Dz < Sway limits) (Joint 738; LC 40)

∆Y ∆

∆Z X

BCD3-690-45-CAL-4-102-00 Rev 1 Page 17 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

6.2 Framing Modeling

+14.8

+13.6

+10.0

+6.67

+3.67

6M

8M

8M

6M

12 M

6.3 Joint and Member Numbering

Joint Numbering

BCD3-690-45-CAL-4-102-00 Rev 1 Page 18 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

Member Numbering

BCD3-690-45-CAL-4-102-00 Rev 1 Page 19 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

6.4 Member Properties

No. Member Marking Size

1 Column C1 H588X300X12

2 Column C2 H200X100X5.5

3 Rafter RF1 H450X200X9

4 Beam B1 H150X150X7

5 Beam B2 H300X150X6.5

6 Beam B3 H250X125X6

7 Beam B4 H200X200X8

8 Beam B5 C100X50X5

9 Bracing VB1 L80X80X6LD

B5

RF1

B2

B3

B1

B4

VB1 C1

VB1

BCD3-690-45-CAL-4-102-00 Rev 1 Page 20 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

6.5 Loading

1). Earthquake Load (X Direction)

2). Earthquake Load (Z Direction)

BCD3-690-45-CAL-4-102-00 Rev 1 Page 21 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

3). Dead Load

4). Live Load

BCD3-690-45-CAL-4-102-00 Rev 1 Page 22 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

5). Wind Load (X Direction)

6). Wind Load (Z Direction)

BCD3-690-45-CAL-4-102-00 Rev 1 Page 23 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

7). Crane Load (CL1)

8). Crane Load (CL2)

BCD3-690-45-CAL-4-102-00 Rev 1 Page 24 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

7.0 FOUNDATION DESIGN

7.1 Foundation Layout

F2 F1 F1 F1 F1

12 m

F1 F1 F1 F1 F1

6m 8m 8m 6m

7.2 Foundation Analysis F1

A.) Support Reaction (From output Staad pro)

Support reaction value are taken from output staad pro. This reaction occur on base plate of

pedestal and transferred to pile cap. Maximum support reaction for permanent & temporary

condition.

Permanent Load

Moment

Node L/C Fx kg Fy kg Fz kg

Mx kg-m My kg-m Mz kg-m

Max Fx 117 32 600.20 23818.1 6.0 0.0 0.0 0.0

Min Fx 116 32 -843.70 12715.0 2.0 0.0 0.0 0.0

Max Fy 117 32 600.20 23818.1 6.0 0.0 0.0 0.0

Min Fy 10 32 -355.70 3266.4 -648.0 0.0 0.0 0.0

Max Fz 11 31 -10.80 7327.9 136.2 0.0 0.0 0.0

Min Fz 95 33 -498.60 10848.4 -899.7 0.0 0.0 0.0

Max Mx 10 31 -6.10 7296.4 135.6 0.0 0.0 0.0

Min Mx 10 31 -6.10 7296.4 135.6 0.0 0.0 0.0

Max My 10 31 -6.10 7296.4 135.6 0.0 0.0 0.0

Min My 10 31 -6.10 7296.4 135.6 0.0 0.0 0.0

Max Mz 10 31 -6.10 7296.4 135.6 0.0 0.0 0.0

Min Mz 10 31 -6.10 7296.4 135.6 0.0 0.0 0.0

BCD3-690-45-CAL-4-102-00 Rev 1 Page 25 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

Temporary Load

Moment

Node L/C Fx kg Fy kg Fz kg

Mx kg-m My kg-m Mz kg-m

Max Fx 117 40 604.90 23845.2 5.9 0.0 0.0 0.0

Min Fx 11 35 -2540.50 12728.4 -755.2 0.0 0.0 0.0

Max Fy 117 40 604.90 23845.2 5.9 0.0 0.0 0.0

Min Fy 10 34 -2214.90 -1968.7 -649.5 0.0 0.0 0.0

Max Fz 117 36 598.50 23808.0 6.4 0.0 0.0 0.0

Min Fz 95 41 -495.70 14781.7 -1890.0 0.0 0.0 0.0

Max Mx 10 34 -2214.90 -1968.7 -649.5 0.0 0.0 0.0

Min Mx 10 34 -2214.90 -1968.7 -649.5 0.0 0.0 0.0

Max My 10 34 -2214.90 -1968.7 -649.5 0.0 0.0 0.0

Min My 10 34 -2214.90 -1968.7 -649.5 0.0 0.0 0.0

Max Mz 10 34 -2214.90 -1968.7 -649.5 0.0 0.0 0.0

Min Mz 10 34 -2214.90 -1968.7 -649.5 0.0 0.0 0.0

- Permanent Load - Temporary Load

V = 23.818 ton V = 23.845 ton

Fx = 0.844 ton Fx = 2.541 ton

Fz = 0.900 ton Fz = 1.890 ton

Mx = 0.000 ton.m Mx = 0.000 ton.m

Mz = 0.000 ton.m Mz = 0.000 ton.m

B). Pedestal Reinforcement

For Column (H 588x300x12)

Longitudinal Reinforcement

Height of pedestal, Hp = 0.600 m

Width of pedestal X-dir, Bp = 0.600 m

Width of pedestal Z-dir, Lp = 0.850 m

Pedestal Height 0.600

Ratio = = = 1.00 < 2.50 Pedestal

Width of pedestal 0.600

Concrete Strength, fc' = 280 kg/cm2 Effective Height, d

Reinforcement, fy = 4200 kg/cm2 (Bp - c - Ds - (0.5xDr)) = 529 mm

Concrete Cover, c = 50 mm For f'c < 4000 psi, b 1 = 0.9

Area of column, Ag = 5100 cm2 Re-bar dia., dr = 16 mm

Reduction Factor, fv = 0.85 Re-bar area, As = 2.01 cm2

Shear-bar, D = 13 mm

Take ρ = 0.5%

Ag = 5100 cm2

Asrequired = ρ * Ag

= 25.50 cm2 600 mm

D rebar = 1.6 cm2

As = 2.011 cm2

n rebar = 14.00 ea

Asused = As * n = 28.15 cm2 850 mm

Asused > Asrequired …..Ok

So, use 14 D 16 for longitudinal reinforcement.

BCD3-690-45-CAL-4-102-00 Rev 1 Page 26 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

Shear Reinforcement

Stirrup due to Shear

Necessity of Stirrups :

● When Vu < 1/2 øVc , Shear re-bar is not necessary.

● When øVc > Vu > 1/2 øVc , Min. shear re-bar is required.

● When Vu > ø Vc , Shear re-bar is required

Shear Reinforcement

Maximum base shear, Vu = 2.541 ton (Fx Temporary Load)

Maximum axial load, Nu = 25405 N

Nominal shear strength,ØVc = N u

.0.17.1 f c 'bw d (ACI 318-05, 11.3.1.2)

14 Ag

= 41.54 ton

0.5ϕVc > Vu = No reinforcement required

= Use Stirrup D13 with spacing max (d/2, ph/8, 300) = 150 mm

So, use : = D 13 - 150 for shear reinforcement.

C). Check Capacity of Pile

y

z

Gp x

Hp

x Bp Bf Dp

Df

Hf

Lp

PC conc. Pile

Lf

sx Ls sx

Pile Dimension

Pile Diameter = 0.300 m

Pile Length, L = 20 m

n Pile = 2 ea

Footing Dimension

Width of pile cap, BF = 1.20 m

Length of pile cap, LF = 2.20 m

Total thick. of pile cap, HF = 0.60 m

Height of pedestal above ground, Gp = 0.30 m

Height of pedestal below ground, Dp = 0.30 m

Depth of pile cap, DF = 0.90 m

Center to center of pile, Ls = 1.20 m

Length to edge of footing, Sx = 0.50 m

Area of pile cap, AF = 2.640 m2

Concrete Cover = 0.075 m

BCD3-690-45-CAL-4-102-00 Rev 1 Page 27 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

Structure Dead Load

Pedestal = BP * LP * HP * gc

= 0.6 * 0.85 * 0.6 * 2400 = 734 kg

Footing = BF * LF * HF * gc

= 1.2 * 2.2 * 0.6 * 2400 = 3802 kg

Soil at foundation = (((Lf*Bf)-((Lp*Bp)*np))*DP)* gso

= (((1.2 * 2.2) - ((0.6 * 0.85)* 1)) * 0.3 ) * 1800 = 1150 kg +

Total Weight of Foundation Wft = 5686 kg

Check Capacity of Pile

1. Axial Load

- Permanent

(V + Wft) 23.82 + 5.69

P = =

n pile 2.00

P = 14.75 ton < Pall = 35.00 ton …OK

- Temporary

(V + Wft) 23.85 + 5.69

P = =

n pile 2.00

P = 14.77 ton < Pall = 46.55 ton …OK

2. Lateral Load

- Base shear of Pedestal and Pile Cap

F pedestal, Fp = 0.228 x W ped x Ycog = 0.228 x 734.4 x 0.9 = 151 kg

F pile cap, Fpc = 0.228 x W pc x Ycog = 0.228 x 3801.6 x 0.3 = 260 kg

Total Base shear FTot = 411 kg

- Permanent

(Fx) + Ftot

Px =

n pile

0.844 + 0.411

= = 0.627 ton

2

(Fz) + Ftot

Pz = < Pall = 2.50 ton …OK

n pile

0.900 + 0.411

= = 0.655 ton

2

- Temporary

(Fx) + Ftot

Px =

n pile

2.541 + 0.411

= = 1.476 ton

2

(Fz) + Ftot

Pz = < Pall = 3.33 ton …OK

n pile

1.890 + 0.411

= = 1.150 ton

2

BCD3-690-45-CAL-4-102-00 Rev 1 Page 28 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

3. Moment Load

V

Fz Mx

Y

e

Z

P P

P1 P2

X c.o.g

0.60 0.60

Ls = 1.200 m

e = 1.200 m

Pile Xi Xi2 Zi Zi2

P1 -0.60 0.36 0.00 0

P2 0.60 0.36 0.00 0

∑= 0.7200 ∑= 0.0000

BCD3-690-45-CAL-4-102-00 Rev 1 Page 29 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

- Permanent Load

Moment due to Fz,

M1 = Fz x e

= 0.900 x 1.200

= 1.08 ton.m

Moment due to Mx

M2 = 0.00 ton.m

Axial Load V = Vstructure + W foundation

= 29.50 ton

V M1*X1 M2*X1

P1 = ± ±

n pile ∑Xi2 ∑Xi2

29.50 1.08*0.6 0*0

P1 = ± ±

2 0.7200 0.7200

P1max = 15.65 ton < Pall = 35.00 ton ...Satisfactory

P1min = 13.85 ton < Tall = 35.00 ton ...No Tension

- Temporary Load

Moment due to Fz,

M1 = Fz x e

= 1.890 x 1.200

= 2.27 ton.m

Moment due to Mx

M2 = 0.00 ton.m

Axial Load V = Vstructure + W foundation

= 29.53 ton

P1 = V M1*X1 M2*X1

± ±

n pile ∑Xi2 ∑Xi2

29.5 2.27*0.6 0*0

P1 = ± ±

2 0.7200 0.7200

P1max = 16.66 ton < Pall = 46.55 ton ...Satisfactory

P1min = 12.88 ton < Tall = 46.55 ton ...No Tension

For Moment in X direction (Mz)

Mz is held by Maximum Bending Moment Capacity of Pile

Based on soil investigation in Attachment 2

maximum moment capacity of 1 pile at BGP area for Free Head = 2.5 ton.m

maximum Mz from Staad Output :

- Permanent Load

Mz 1.08

Mz = = = 0.54 t.m < Mall = 2.50 t.m ...Satisfactory

n pile 2

- Temporary Load

Mz 2.27

Mz = = = 1.13 t.m < Mall = 3.25 t.m ...Satisfactory

n pile 2

BCD3-690-45-CAL-4-102-00 Rev 1 Page 30 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

D). Pile Cap/Footing Reinforcement

Support reaction value are taken from output staad pro. This reaction occur on base plate of

pedestal and transferred to pile cap. Maximum support reaction for permanent & temporary

condition with factor load combination.

Moment

Node L/C Fx kg Fy kg Fz kg

Mx kg-m My kg-m Mz kg-m

Max Fx 345 20 1567.00 17863.0 -2.0 0.0 0.0 0.0

Min Fx 154 23 -4769.00 27251.0 0.0 0.0 0.0 0.0

Max Fy 155 21 1135.00 45405.0 -3.0 0.0 0.0 0.0

Min Fy 703 23 -1740.00 3503.0 1.0 0.0 0.0 0.0

Max Fz 117 20 1266.00 19001.0 560.0 0.0 0.0 0.0

Min Fz 193 29 742.00 19457.0 -2057.0 0.0 0.0 0.0

Max Mx 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

Min Mx 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

Max My 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

Min My 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

Max Mz 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

Min Mz 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

- Summary

V = 45.405 ton

Fx = 4.769 ton

Fz = 2.057 ton

Mx = 0.000 ton.m

Mz = 0.000 ton.m

Pstr

Pp

qf

L

1.200

Wstructure = 45.4 ton Pstr = 45.4

= 45.4 ton

Wpedestal = 0.734 ton Pp = 0.734

= 0.734 ton

Wfooting+soil = 4.95 ton qf = 4.95 / 1.2

= 4.13 t/m

Mdl = 1/4 P L = 1/4 x 45.41 x 1.2 = 13.62 t.m

Mp = 1/4 P L = 1/4 x 0.73 x 1.2 = 0.22 t.m

Mf = 1/8 qf L2 = 1/8 x 4.13 x 1.2^2" = 0.74 t.m +

Mt = 14.58 t.m

Mux = 1.4 Mt = 20.42 t.m = 20418.43 kg m

BCD3-690-45-CAL-4-102-00 Rev 1 Page 31 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

Properties

Reinforce Bar fy = 4200 kg/cm2

Concrete strength fc' = 280 kg/cm2

Width of footing B = 1200 mm = 120 cm

Length of footing L = 2200 mm = 220 cm

Depth of pile cap H = 600 mm = 60 cm

Concrete cover d' = 75 mm = 7.5 cm

Effective depth d = 525 mm = 52.5 cm

Rebar required

fy

m = = 17.65 Ø= 0.9

0.85 fc'

Mux

Rn = = 6.859 kg/cm2

.Bf.d^2

1 1 - 2 m Rn

ro = 1- = 0.001657

m fy

β1 = 0.85

0.85 β1 f'c 600

rb = = 0.0283

fy 600+fy

r Shringkage = 0.0018 x H/d = 0.00206

r max = 0.75 x r b = 0.02125 (ACI 318, Section 7.12.2.1)

1.4

r min1 = = 0.00333

fy rused = Max (rShringkage, ro, Min (r r, max (rmin1,rmin2)))

fc'

r min2 = 4 fy = 0.00100 So, rused = 0.00206 < r max OK

rr = 1.33 x r req'd = 0.00220

r used = 0.00206

As = r used x Bf x d = 13.0 cm2

D = 16 mm ; Ab = 2.01 cm2

n = As / Ab = 7

As Used = Ab x n = 14.1 cm2

Spacing,s = 220 mm ; whichever is smaller. Use spacing, s = 200 mm

2d = 1050 mm

take : D 16 - 200 (Top and Bottom) About Z direction

D 16 - 200 (Top and Bottom) About X direction

BCD3-690-45-CAL-4-102-00 Rev 1 Page 32 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

Punching Shear Footing

Against Piling

v = Reduction factor for shear = 0.75

Vu = 227.03 kN per pile

bc = 1 f c' = 28 Mpa

bo = (p.(dp + Dpile)) dp = 400 mm bo

= 2199 mm D pile = 300 mm dp/2

as = 20 for edge pile

2 f c 'b o d

1 = 2327.32 kN

b c 6

dp

asd f c 'bo d

Vc = minimum 2 = 2186.84 kN c

b 12

o

f c 'b o d = 1551.55 kN

3

Vc = 1163.7 kN > Vu = 227.03 kN ...OK No shear reinforcement required

7.3 Foundation Analysis F2

A.) Support Reaction (From output Staad pro)

Support reaction value are taken from output staad pro. This reaction occur on base plate of

pedestal and transferred to pile cap. Maximum support reaction for permanent & temporary

condition.

Permanent Load

Moment

Node L/C Fx kg Fy kg Fz kg

Mx kg-m My kg-m Mz kg-m

Max Fx 703 31 -20.00 8056.0 -146.8 0.0 0.0 0.0

Min Fx 703 32 -376.80 8645.5 -904.6 0.0 0.0 0.0

Max Fy 703 32 -376.80 8645.5 -904.6 0.0 0.0 0.0

Min Fy 703 33 -274.00 6131.8 -274.3 0.0 0.0 0.0

Max Fz 703 31 -20.00 8056.0 -146.8 0.0 0.0 0.0

Min Fz 703 32 -376.80 8645.5 -904.6 0.0 0.0 0.0

Max Mx 703 31 -20.00 8056.0 -146.8 0.0 0.0 0.0

Min Mx 703 31 -20.00 8056.0 -146.8 0.0 0.0 0.0

Max My 703 31 -20.00 8056.0 -146.8 0.0 0.0 0.0

Min My 703 31 -20.00 8056.0 -146.8 0.0 0.0 0.0

Max Mz 703 31 -20.00 8056.0 -146.8 0.0 0.0 0.0

Min Mz 703 31 -20.00 8056.0 -146.8 0.0 0.0 0.0

BCD3-690-45-CAL-4-102-00 Rev 1 Page 33 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

Temporary Load

Moment

Node L/C Fx kg Fy kg Fz kg

Mx kg-m My kg-m Mz kg-m

Max Fx 703 37 -273.70 7827.1 -699.1 0.0 0.0 0.0

Min Fx 703 34 -2165.20 3758.0 -912.9 0.0 0.0 0.0

Max Fy 703 40 -377.70 12723.1 -1905.1 0.0 0.0 0.0

Min Fy 703 35 -2062.40 1244.3 -282.6 0.0 0.0 0.0

Max Fz 703 35 -2062.40 1244.3 -282.6 0.0 0.0 0.0

Min Fz 703 40 -377.70 12723.1 -1905.1 0.0 0.0 0.0

Max Mx 703 34 -2165.20 3758.0 -912.9 0.0 0.0 0.0

Min Mx 703 34 -2165.20 3758.0 -912.9 0.0 0.0 0.0

Max My 703 34 -2165.20 3758.0 -912.9 0.0 0.0 0.0

Min My 703 34 -2165.20 3758.0 -912.9 0.0 0.0 0.0

Max Mz 703 34 -2165.20 3758.0 -912.9 0.0 0.0 0.0

Min Mz 703 34 -2165.20 3758.0 -912.9 0.0 0.0 0.0

- Permanent Load - Temporary Load

V = 8.646 ton V = 12.723 ton

Fx = 0.377 ton Fx = 2.165 ton

Fz = 0.905 ton Fz = 1.905 ton

Mx = 0.000 ton.m Mx = 0.000 ton.m

Mz = 0.000 ton.m Mz = 0.000 ton.m

B). Pedestal Reinforcement

For Column (H 588x300x12)

Longitudinal Reinforcement

Height of pedestal, Hp = 0.600 m

Width of pedestal X-dir, Bp = 0.600 m

Width of pedestal Z-dir, Lp = 0.850 m

Pedestal Height 0.600

Ratio = = = 1.00 < 2.50 Pedestal

Width of pedestal 0.600

Concrete Strength, fc' = 280 kg/cm2 Effective Height, d

Reinforcement, fy = 4200 kg/cm2 (Bp - c - Ds - (0.5xDr)) = 529 mm

Concrete Cover, c = 50 mm For f'c < 4000 psi, b 1 = 0.9

Area of column, Ag = 5100 cm2 Re-bar dia., dr = 16 mm

Reduction Factor, fv = 0.85 Re-bar area, As = 2.01 cm2

Shear-bar, D = 13 mm

Take ρ = 0.5%

Ag = 5100 cm2

Asrequired = ρ * Ag

= 25.50 cm2 600 mm

D rebar = 1.6 cm2

As = 2.011 cm2

n rebar = 14.00 ea

Asused = As * n = 28.15 cm2 850 mm

Asused > Asrequired …..Ok

So, use 14 D 16 for longitudinal reinforcement.

BCD3-690-45-CAL-4-102-00 Rev 1 Page 34 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

Shear Reinforcement

Stirrup due to Shear

Necessity of Stirrups :

● When Vu < 1/2 øVc , Shear re-bar is not necessary.

● When øVc > Vu > 1/2 øVc , Min. shear re-bar is required.

● When Vu > ø Vc , Shear re-bar is required

Shear Reinforcement

Maximum base shear, Vu = 2.165 ton (Fx Temporary Load)

Maximum axial load, Nu = 21652 N

Nominal shear strength,ØVc = N u

.0.17.1 f c 'bw d (ACI 318-05, 11.3.1.2)

14 Ag

= 38.99 ton

0.5ϕVc > Vu = No reinforcement required

= Use Stirrup D13 with spacing max (d/2, ph/8, 300) = 150 mm

So, use : = D 13 - 150 for shear reinforcement.

C). Check Capacity of Pile

y

z

Gp x

Hp

x Dp

Bp Bf

Df

Hf

Lp

PC conc. Pile

Lf

sx Ls sx

Pile Dimension

Pile Diameter = 0.300 m

Pile Length, L = 20 m

n Pile = 2 ea

Footing Dimension

Width of pile cap, BF = 1.20 m

Length of pile cap, LF = 3.10 m

Total thick. of pile cap, HF = 0.60 m

Height of pedestal above ground, Gp = 0.30 m

Height of pedestal below ground, Dp = 0.30 m

Depth of pile cap, DF = 0.90 m

Center to center of pile, Ls = 2.10 m

Length to edge of footing, Sx = 0.50 m

Area of pile cap, AF = 3.720 m2

Concrete Cover = 0.075 m

BCD3-690-45-CAL-4-102-00 Rev 1 Page 35 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

Structure Dead Load

Pedestal = BP * LP * HP * gc

= 0.6 * 0.85 * 0.6 * 2400 = 734 kg

Footing = BF * LF * HF * gc

= 1.2 * 3.1 * 0.6 * 2400 = 5357 kg

Soil at foundation = (((Lf*Bf)-((Lp*Bp)*np))*DP)* gso

= (((1.2 * 3.1) - ((0.6 * 0.85)* 1)) * 0.3 ) * 1800 = 1733 kg +

Total Weight of Foundation Wft = 7825 kg

Check Capacity of Pile

1. Axial Load

- Permanent

(V + Wft) 8.65 + 7.82

P = =

n pile 2.00

P = 8.24 ton < Pall = 35.00 ton …OK

- Temporary

(V + Wft) 12.72 + 7.82

P = =

n pile 2.00

P = 10.27 ton < Pall = 46.55 ton …OK

2. Lateral Load

- Base shear of Pedestal and Pile Cap

F pedestal, Fp = 0.228 x W ped x Ycog = 0.228 x 734.4 x 0.9 = 151 kg

F pile cap, Fpc = 0.228 x W pc x Ycog = 0.228 x 5356.8 x 0.3 = 366 kg

Total Base shear FTot = 517 kg

- Permanent

(Fx) + Ftot

Px =

n pile

0.377 + 0.517

= = 0.447 ton

2

(Fz) + Ftot

Pz = < Pall = 2.50 ton …OK

n pile

0.905 + 0.517

= = 0.711 ton

2

- Temporary

(Fx) + Ftot

Px =

n pile

2.165 + 0.517

= = 1.341 ton

2

(Fz) + Ftot

Pz = < Pall = 3.33 ton …OK

n pile

1.905 + 0.517

= = 1.211 ton

2

BCD3-690-45-CAL-4-102-00 Rev 1 Page 36 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

3. Moment Load

V

Fz Mx

Y

e

Z

P P

P1 P2

X c.o.g

0.60 1.50

Ls = 2.100 m

e = 1.200 m

Pile Xi Xi2 Zi Zi2

P1 -0.60 0.36 0.00 0

P2 1.50 2.25 0.00 0

∑= 2.6100 ∑= 0.0000

BCD3-690-45-CAL-4-102-00 Rev 1 Page 37 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

- Permanent Load

Moment due to Fz,

M1 = Fz x e

= 0.905 x 1.200

= 1.09 ton.m

Moment due to Mx

M2 = 0.00 ton.m

Axial Load V = Vstructure + W foundation

= 16.47 ton

V M1*X1 M2*X1

P1 = ± ±

n pile ∑Xi2 ∑Xi2

16.47 1.09*1.5 0*0

P1 = ± ±

2 2.6100 2.6100

P1max = 8.86 ton < Pall = 35.00 ton ...Satisfactory

P1min = 7.61 ton < Tall = 35.00 ton ...No Tension

- Temporary Load

Moment due to Fz,

M1 = Fz x e

= 1.905 x 1.200

= 2.29 ton.m

Moment due to Mx

M2 = 0.00 ton.m

Axial Load V = Vstructure + W foundation

= 20.55 ton

P1 = V M1*X1 M2*X1

± ±

n pile ∑Xi2 ∑Xi2

20.5 2.29*1.5 0*0

P1 = ± ±

2 2.6100 2.6100

P1max = 11.59 ton < Pall = 46.55 ton ...Satisfactory

P1min = 8.96 ton < Tall = 46.55 ton ...No Tension

For Moment in X direction (Mz)

Mz is held by Maximum Bending Moment Capacity of Pile

Based on soil investigation in Attachment 2

maximum moment capacity of 1 pile at BGP area for Free Head = 2.5 ton.m

maximum Mz from Staad Output :

- Permanent Load

Mz 1.09

Mz = = = 0.54 t.m < Mall = 2.50 t.m ...Satisfactory

n pile 2

- Temporary Load

Mz 2.29

Mz = = = 1.14 t.m < Mall = 3.25 t.m ...Satisfactory

n pile 2

BCD3-690-45-CAL-4-102-00 Rev 1 Page 38 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

D). Pile Cap/Footing Reinforcement

Support reaction value are taken from output staad pro. This reaction occur on base plate of

pedestal and transferred to pile cap. Maximum support reaction for permanent & temporary

condition with factor load combination.

Moment

Node L/C Fx kg Fy kg Fz kg

Mx kg-m My kg-m Mz kg-m

Max Fx 345 20 1567.00 17863.0 -2.0 0.0 0.0 0.0

Min Fx 154 23 -4769.00 27251.0 0.0 0.0 0.0 0.0

Max Fy 155 21 1135.00 45405.0 -3.0 0.0 0.0 0.0

Min Fy 703 23 -1740.00 3503.0 1.0 0.0 0.0 0.0

Max Fz 117 20 1266.00 19001.0 560.0 0.0 0.0 0.0

Min Fz 193 29 742.00 19457.0 -2057.0 0.0 0.0 0.0

Max Mx 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

Min Mx 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

Max My 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

Min My 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

Max Mz 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

Min Mz 10 20 653.00 12741.0 2.0 0.0 0.0 0.0

- Summary

V = 45.405 ton

Fx = 4.769 ton

Fz = 2.057 ton

Mx = 0.000 ton.m

Mz = 0.000 ton.m

Pstr

Pp

qf

0.6 1.500

2.100

L

Wstructure = 45.4 ton Pstr = 45.4

= 45.4 ton

Wpedestal = 0.734 ton Pp = 0.734

= 0.734 ton

Wfooting+soil = 7.09 ton qf = 7.09 / 1.2

= 5.91 t/m

Moment at column point

Mdl = (1.5/2.1) x 0.6 x P = (1.5/2.1) x 0.6 x 45.405 = 19.46 t.m

Mp = (1.5/2.1) x 0.6 x P = (1.5/2.1) x 0.6 x 0.7344 = 0.31 t.m

Mf = (0.6 x 2.1 - 0.6^2) x q / 2 = (0.6 x 2.1 - 0.6^2) x 5.91 / 2 = 2.66 t.m +

Mt = 22.43 t.m

Mux = 1.4 Mt = 31.41 t.m = 31406 kg m

BCD3-690-45-CAL-4-102-00 Rev 1 Page 39 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

Properties

Reinforce Bar fy = 4200 kg/cm2

Concrete strength fc' = 280 kg/cm2

Width of footing B = 1200 mm = 120 cm

Length of footing L = 3100 mm = 310 cm

Depth of pile cap H = 600 mm = 60 cm

Concrete cover d' = 75 mm = 7.5 cm

Effective depth d = 525 mm = 52.5 cm

Rebar required

fy

m = = 17.65 Ø= 0.9

0.85 fc'

Mux

Rn = = 10.550 kg/cm2

.Bf.d^2

1 1 - 2 m Rn

ro = 1- = 0.002570

m fy

β1 = 0.85

0.85 β1 f'c 600

rb = = 0.0283

fy 600+fy

r Shringkage = 0.0018 x H/d = 0.00206

r max = 0.75 x r b = 0.02125 (ACI 318, Section 7.12.2.1)

1.4

r min1 = = 0.00333

fy rused = Max (rShringkage, ro, Min (r r, max (rmin1,rmin2)))

fc'

r min2 = 4 fy = 0.00100 So, rused = 0.00257 < r max OK

rr = 1.33 x r req'd = 0.00342

r used = 0.00257

As = r used x Bf x d = 16.2 cm2

D = 16 mm ; Ab = 2.01 cm2

n = As / Ab = 9

As Used = Ab x n = 18.1 cm2

Spacing,s = 170 mm ; whichever is smaller. Use spacing, s = 150 mm

2d = 1050 mm

take : D 16 - 150 (Top and Bottom) About Z direction

D 16 - 150 (Top and Bottom) About X direction

BCD3-690-45-CAL-4-102-00 Rev 1 Page 40 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

Punching Shear Footing

Against Piling

v = Reduction factor for shear = 0.75

Vu = 227.03 kN per pile

bc = 1 f c' = 28 Mpa

bo = (p.(dp + Dpile)) dp = 400 mm bo

= 2199 mm D pile = 300 mm dp/2

as = 20 for edge pile

2 f c 'b o d

1 = 2327.32 kN

b c 6

dp

asd f c 'bo d

Vc = minimum 2 = 2186.84 kN c

b 12

o

f c 'b o d = 1551.55 kN

3

Vc = 1163.7 kN > Vu = 227.03 kN ...OK No shear reinforcement required

BCD3-690-45-CAL-4-102-00 Rev 1 Page 41 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

7.4 Summary Foundation Analysis

7.4.1 Pile Capacity Check

Hor Vertical Allowable Capacity Safety Factor

n pile

Condition Lat. Comp. Tens. Lat. Comp. Tens. Check

Lat. Comp.Tens.

ton ton ton ea ton ton ton

Foundation (Type F1)

Long Term 0.66 14.75 - 2.50 35.00 35.00 3.8 2.4 35 OK!

2

Short Term 1.48 14.77 - 3.33 46.55 46.55 2.3 3.2 47 OK!

Foundation (Type F2)

Long Term 0.71 8.24 - 2.50 35.00 35.00 3.5 4.3 35 OK!

2

Short Term 1.34 10.27 - 3.33 46.55 46.55 2.5 4.5 47 OK!

7.4.2 Concrete and Reinforcement Design

Component As req. (cm2) As used (cm2) Check

Foundation (Type F1)

Pile Cap X Direction 12.96 14.07 OK!

Pile Cap Z Direction 12.96 14.07 OK!

Punching Shear No shear reinforcement required

Foundation (Type F2)

Pile Cap X Direction 16.19 18.10 OK!

Pile Cap Z Direction 16.19 18.10 OK!

Punching Shear No shear reinforcement required

Size 600 X 850

Pedestal Rebar 14 D 16

Ties D 13 - 150

BCD3-690-45-CAL-4-102-00 Rev 1 Page 42 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

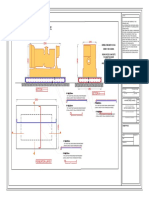

7.5 Foundation Sketch

a.) Foundation (Type F1)

0.50 1.20 0.50

0.85

A A

0.60

1.20

z

D 16 - 200 (Top and Bottom)

Foundation Plan

D 13 - 150 14 D 16

0.300

D 16 - 200 (Top and Bottom)

0.300

0.600

Ties : 3 D 13

y

2 PC Pile

x 0.50 1.20 0.50 300 mm Dia., 20 m Length

(Free head pile)

2.20

Section A - A

BCD3-690-45-CAL-4-102-00 Rev 1 Page 43 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. Process Piperack Structure &

Foundation

B.) Foundation (Type F2)

0.50 0.6 1.50 0.50

0.85

A A

0.60

1.20

z

D 16 - 150 (Top and Bottom)

Foundation Plan

D 13 - 150 14 D 16

0.300

D 16 - 150 (Top and Bottom)

0.300

0.600

Ties : 3 D 13

y

2 PC Pile

x 0.50 2.10 0.50 300 mm Dia., 20 m Length

(Free head pile)

3.10

Section A - A

BCD3-690-45-CAL-4-102-00 Rev 1 Page 44 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

8.0 RAIL DESIGN

8.1 Loading

- Dead load from selfweight.

- Impact Load as calculated before, including weight of crane bridge (calculated by vendor

during EPC) :

Fx = 1.63 tons

Fy = 16.33 tons

Fz = 3.27 tons

8.2 Model

8 M

BCD3-690-45-CAL-4-102-00 Rev 1 Page 45 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

8.3 Analysis Result

Ratio

Beam Deflection

maximum vertical deflection dmax = 3.460 mm

Beam span L = 8000 mm

Allowable deflection dall = L/240 = 33.33 mm

Check deflection dmax < dall OK (BCD6-000-45-CRT-4-101-00-0)

maximum horizontal deflection dmax = 4.107 mm

Beam span L = 8000 mm

Allowable deflection dall = L/240 = 33.33 mm

Check deflection dmax < dall OK (BCD6-000-45-CRT-4-101-00-0)

BCD3-690-45-CAL-4-102-00 Rev 1 Page 46 of 46 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

ATTACHMENT - 1

INPUT STAADPRO OF COMPRESSOR SHELTER

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 1 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

STAAD SPACE

START JOB INFORMATION

ENGINEER DATE 02-OCT-09

END JOB INFORMATION

INPUT WIDTH 79

UNIT METER KG

JOINT COORDINATES

10 0 0 10; 11 12 0 10; 12 0 10 10; 13 12 10 10; 14 0 13.6 10; 15 12 13.6 10;

17 12 6.675 10; 18 0 6.675 10; 81 5.99939 14.8 10; 89 0 10 16; 90 0 13.6 16;

91 12 10 16; 92 12 13.6 16; 93 0 6.675 16; 94 12 6.675 16; 95 12 0 16;

96 0 0 16; 105 5.99939 14.8 16; 110 0 10 24; 111 0 13.6 24; 112 12 10 24;

113 12 13.6 24; 114 0 6.675 24; 115 12 6.675 24; 116 12 0 24; 117 0 0 24;

124 5.99939 14.8 24; 129 0 10 32; 130 0 13.6 32; 131 12 10 32; 132 12 13.6 32;

133 0 6.675 32; 134 12 6.675 32; 135 12 0 32; 136 0 0 32; 143 5.99939 14.8 32;

148 0 10 38; 149 0 13.6 38; 150 12 10 38; 151 12 13.6 38; 152 0 6.675 38;

153 12 6.675 38; 162 5.99939 14.8 38; 381 12 3.675 32; 382 0 3.675 32;

389 0 3.675 38; 394 12 3.675 38; 652 12 5.17499 32; 671 12 8.175 16;

677 12 5.17499 10; 687 12 8.175 38; 691 4.99535 16.0992 38;

693 5.99535 16.3002 38; 694 7.00335 16.0992 38; 703 0 0 38; 730 12 0 38;

731 4.99535 14.5992 38; 732 7.00289 14.5993 38; 733 4.99535 14.5992 32;

734 4.99535 16.0992 32; 735 5.99535 16.3002 32; 736 7.00335 16.0992 32;

737 7.00289 14.5993 32; 738 4.99535 14.5992 24; 739 4.99535 16.0992 24;

740 5.99535 16.3002 24; 741 7.00335 16.0992 24; 742 7.00289 14.5993 24;

743 4.99535 14.5992 16; 744 4.99535 16.0992 15.9999;

745 5.99535 16.3002 15.9999; 746 7.00335 16.0992 15.9999;

747 7.00289 14.5993 16; 748 4.99535 14.5992 9.99995;

749 4.99535 16.0992 9.99993; 750 5.99535 16.3002 9.99993;

751 7.00335 16.0992 9.99993; 752 7.00289 14.5993 9.99995; 753 0 13.6 13;

755 12 13.6 13; 757 5.99939 14.8 13; 758 8.99969 14.2 13; 759 2.9997 14.2 13;

760 0 13.6 20; 761 2.9997 14.2 20; 762 12 13.6 20; 763 8.9997 14.2 20;

764 5.99939 14.8 20; 765 0 13.6 28; 766 2.99971 14.2 28; 767 12 13.6 28;

768 8.9997 14.2 28; 769 5.99939 14.8 28; 770 0 13.6 35; 771 2.99972 14.2 35;

772 12 13.6 35; 773 8.99971 14.2 35; 774 5.99939 14.8 35; 775 0 3.675 35;

776 12 3.675 35; 777 0 6.675 35; 778 12 6.675 35; 779 0 10 35; 780 12 10 35;

781 0 3.675 10; 782 0 6.675 13; 783 0 10 13; 784 0 3.675 13; 785 0 3.675 16;

786 12 3.675 10; 787 12 3.675 13; 788 12 3.675 16; 789 12 6.675 13;

790 12 10 13; 791 0 9 13; 792 4.99535 16.0992 16.9999;

794 7.00335 16.0992 16.9999; 795 4.99535 16.0992 23.0001;

796 7.00335 16.0992 23.0001; 797 12 9 13; 798 0 10 20; 799 0 9 20;

800 12 10 20; 801 12 9 20; 802 0 10 28; 803 0 9 28; 804 12 10 28; 805 12 9 28;

806 0 9 35; 807 12 9 35; 808 5.99972 10 10; 809 5.99972 10 38.0001;

810 7.99972 10 10; 812 7.99972 10 38; 814 3.99971 10 10;

816 3.99971 10 38.0001; 818 3.99942 14.4 38; 819 7.99942 14.4 38;

820 7.99942 14.4 9.99996; 821 3.99942 14.4 9.99996;

MEMBER INCIDENCES

7 12 14; 8 13 15; 9 18 12; 10 17 13; 11 17 677; 12 18 781; 138 89 90;

139 91 92; 140 93 89; 141 94 671; 142 94 788; 143 93 785; 163 18 782;

164 81 757; 165 17 789; 166 15 755; 167 110 111; 168 112 113; 169 114 110;

170 115 112; 171 115 116; 172 114 117; 186 93 114; 187 90 760; 188 94 115;

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 2 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

189 92 762; 190 129 130; 191 131 132; 192 133 129; 193 134 131; 194 134 652;

195 133 382; 232 133 777; 233 130 770; 234 134 778; 235 132 772; 472 382 777;

487 12 783; 488 13 790; 489 89 798; 490 91 800; 493 129 779; 494 131 780;

559 381 135; 560 382 136; 565 133 779; 568 816 149; 631 11 786; 655 136 775;

656 114 133; 657 111 765; 658 115 134; 659 113 767; 660 110 802; 661 112 804;

765 389 777; 767 152 779; 769 148 770; 771 703 775; 1087 652 381; 1114 671 91;

1132 148 149; 1133 150 151; 1134 152 148; 1135 153 687; 1136 153 394;

1137 152 389; 1138 149 818; 1139 691 731; 1140 691 693; 1144 151 819;

1145 694 732; 1158 389 703; 1160 394 730; 1205 687 150; 1209 81 758;

1210 105 758; 1211 14 759; 1212 90 759; 1233 143 773; 1235 130 766;

1248 149 771; 1256 162 773; 1265 731 162; 1266 732 162; 1267 130 733;

1268 734 733; 1269 734 735; 1272 736 737; 1273 733 143; 1274 737 143;

1275 111 738; 1276 739 738; 1277 739 740; 1280 741 742; 1281 738 124;

1282 742 124; 1283 90 743; 1284 744 743; 1285 744 745; 1288 746 747;

1289 743 105; 1290 747 105; 1291 14 821; 1292 749 748; 1293 749 750;

1295 15 820; 1296 751 752; 1297 748 81; 1298 752 81; 1299 14 753; 1300 105 764;

1301 143 774; 1302 124 769; 1303 753 90; 1304 753 783; 1305 755 92;

1306 755 758; 1307 757 105; 1308 758 92; 1309 758 15; 1310 759 105;

1311 759 81; 1312 759 757; 1313 758 757; 1314 760 111; 1317 760 761;

1318 762 113; 1321 762 763; 1322 764 124; 1323 761 764; 1324 763 764;

1325 765 130; 1328 765 766; 1329 767 132; 1332 767 768; 1333 769 143;

1334 766 769; 1335 768 769; 1336 770 149; 1337 771 162; 1338 766 143;

1339 770 771; 1340 772 151; 1341 773 151; 1342 773 132; 1343 772 773;

1344 774 162; 1345 771 774; 1346 773 774; 1347 382 775; 1348 381 776;

1349 775 389; 1350 776 394; 1351 135 776; 1352 730 776; 1353 777 152;

1354 778 153; 1355 381 778; 1356 394 778; 1357 779 148; 1358 780 150;

1359 134 780; 1360 153 780; 1361 131 772; 1362 150 772; 1363 750 751;

1364 751 746; 1365 745 746; 1367 735 736; 1369 740 741; 1371 749 744;

1374 693 694; 1375 744 792; 1376 746 794; 1377 734 691; 1378 739 734;

1379 736 694; 1380 741 736; 1381 781 10; 1382 782 93; 1383 781 782;

1384 783 89; 1385 18 783; 1386 12 753; 1387 10 784; 1388 785 96; 1389 785 782;

1390 93 783; 1391 89 753; 1392 96 784; 1393 781 784; 1394 786 677;

1395 786 787; 1396 784 785; 1397 788 95; 1398 787 788; 1399 11 787;

1400 95 787; 1401 789 94; 1402 786 789; 1403 788 789; 1404 790 91; 1405 17 790;

1406 94 790; 1407 13 755; 1408 91 755; 1409 783 791; 1410 753 759;

1411 792 795; 1412 792 743; 1413 794 796; 1414 794 747; 1415 795 739;

1416 796 741; 1417 795 738; 1418 796 742; 1419 755 790; 1420 790 797;

1421 798 110; 1422 760 798; 1423 798 799; 1424 800 112; 1425 762 800;

1426 800 801; 1427 802 129; 1428 765 802; 1429 802 803; 1430 804 131;

1431 767 804; 1432 804 805; 1433 770 779; 1434 779 806; 1435 772 780;

1436 780 807; 1438 12 814; 1439 13 810; 1441 809 812; 1442 148 816;

1443 810 808; 1445 812 150; 1446 812 819; 1447 814 808; 1449 816 809;

1450 816 818; 1451 818 731; 1452 819 732; 1453 820 752; 1454 810 820;

1455 821 748; 1456 814 821; 1457 129 770; 1460 814 14; 1461 810 15;

1462 812 151; 1466 111 766; 1467 766 124; 1468 111 761; 1469 761 124;

1470 90 761; 1471 761 105; 1472 92 747; 1474 113 742; 1475 132 737;

1477 132 768; 1478 768 143; 1479 113 768; 1480 768 124; 1481 113 763;

1482 763 124; 1483 92 763; 1484 763 105; 1485 130 771; 1486 771 143;

START GROUP DEFINITION

GEOMETRY

_C1 7 TO 12 138 TO 143 167 TO 172 190 TO 195 559 560 631 1087 1114 -

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 3 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

1132 TO 1137 1158 1160 1205 1381 1388 1394 1397

MEMBER

_MAINSTRUCTURE 7 TO 12 138 TO 143 167 TO 172 190 TO 195 559 560 631 1087 1114 -

1132 TO 1138 1144 1158 1160 1205 1265 TO 1267 1273 TO 1275 1281 TO 1283 1289 -

1290 TO 1291 1295 1297 1298 1381 1388 1394 1397 1451 TO 1453 1455 1472 1474 -

1475

_C2 1446 1450 1454 1456

_RF1 1138 1144 1265 TO 1267 1273 TO 1275 1281 TO 1283 1289 TO 1291 1295 1297 -

1298 1451 TO 1453 1455 1472 1474 1475

_B1 163 165 186 188 232 234 487 TO 490 493 494 656 658 660 661 1347 TO 1350 -

1353 1354 1357 1358 1382 1384 1393 1395 1396 1398 1401 1404 1421 1424 1427 -

1430

_B2 164 166 187 189 233 235 657 659 1299 TO 1303 1305 1307 1314 1318 1322 -

1325 1329 1333 1336 1340 1344

_B3 1306 1312 1313 1317 1321 1323 1324 1328 1332 1334 1335 1339 1343 1345 -

1346 1410

_B4 1438 1439 1441 TO 1443 1445 1447 1449

_VB1 472 565 568 655 765 767 769 771 1351 1352 1355 1356 1359 TO 1362 1383 -

1385 TO 1387 1389 TO 1392 1399 1400 1402 1403 1405 TO 1408 1457 1460 TO 1462

_VB2 568 1460 TO 1462

_B5 1139 1140 1145 1268 1269 1272 1276 1277 1280 1284 1285 1288 1292 1293 -

1296 1363 TO 1365 1367 1369 1371 1374 TO 1380 1411 1413 1415 1416

_MC 1138 1144 1267 1275 1283 1291 1295 1472 1474 1475

_SPLB 1265 1266 1273 1274 1281 1282 1289 1290 1297 1298

_BP 171 172 559 560 631 1158 1160 1381 1388 1392 1397

JOINT

END GROUP DEFINITION

DEFINE MATERIAL START

ISOTROPIC STEEL

E 2.09e+010

POISSON 0.3

DENSITY 7833.41

ALPHA 1.2e-005

DAMP 0.03

END DEFINE MATERIAL

MEMBER PROPERTY JAPANESE

7 TO 12 138 TO 143 167 TO 172 190 TO 195 559 560 631 1087 1114 1132 TO 1137 -

1158 1160 1205 1381 1388 1394 1397 TABLE ST H588X300X12

1138 1144 1265 TO 1267 1273 TO 1275 1281 TO 1283 1289 TO 1291 1295 1297 1298 -

1451 TO 1453 1455 1472 1474 1475 TABLE ST H450X200X9

163 165 186 188 232 234 487 TO 490 493 494 656 658 660 661 1347 TO 1350 1353 -

1354 1357 1358 1382 1384 1393 1395 1396 1398 1401 1404 1421 1424 1427 -

1430 TABLE ST H150X150X7

MEMBER PROPERTY JAPANESE

1446 1450 1454 1456 TABLE ST H200X100X5.5

166 187 189 233 235 657 659 1299 1303 1305 1314 1318 1325 1329 1336 -

1340 TABLE ST H300X150X6.5

1139 1140 1145 1268 1269 1272 1276 1277 1280 1284 1285 1288 1292 1293 1296 -

1363 1365 1367 1369 1374 TABLE ST C100X50X5

472 565 655 765 767 769 771 1351 1352 1355 1356 1359 TO 1362 1383 -

1385 TO 1387 1389 TO 1392 1399 1400 1402 1403 1405 TO 1408 -

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 4 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

1457 TABLE LD L80X80X6 SP 0.01

1306 1312 1313 1317 1321 1323 1324 1328 1332 1334 1335 1339 1343 1345 1346 -

1410 TABLE ST H250X125X6

1438 1439 1441 TO 1443 1445 1447 1449 TABLE ST H200X200X8

1364 1371 1375 TO 1380 1411 1413 1415 1416 TABLE ST C100X50X5

1412 1414 1417 1418 TABLE ST L50X50X5

MEMBER PROPERTY JAPANESE

1209 TO 1212 1233 1235 1248 1256 1308 TO 1311 1337 1338 1341 1342 -

1466 TO 1471 1477 TO 1486 PRIS YD 0.016

1304 1409 1419 1420 1422 1423 1425 1426 1428 1429 1431 TO 1435 -

1436 TABLE ST H100X100X6

568 1460 TO 1462 TABLE LD L80X80X6 SP 0.01

164 1300 TO 1302 1307 1322 1333 1344 TABLE ST H300X150X6.5

CONSTANTS

BETA 90 MEMB 1442 1446 1454

MATERIAL STEEL ALL

SUPPORTS

10 11 95 96 116 117 135 136 703 730 PINNED

*ENFORCED BUT MY

MEMBER RELEASE

163 TO 166 186 TO 189 232 233 235 487 TO 490 493 656 TO 661 1299 TO 1302 1306 -

1317 1321 1328 1332 1339 1343 1347 1364 1371 1375 TO 1380 1393 1395 1410 -

1446 1450 1454 1456 START MY MZ

186 188 656 658 1303 1305 1307 1312 TO 1314 1318 1322 TO 1325 1329 -

1333 TO 1336 1340 1344 TO 1346 1364 1371 1377 TO 1380 1382 1384 1398 1401 -

1404 1415 1416 1421 1424 1427 1430 1446 1450 1454 1456 END MY MZ

MEMBER TRUSS

472 565 568 655 765 767 769 771 1209 TO 1212 1233 1235 1248 1256 1308 TO 1311 -

1337 1338 1341 1342 1351 1352 1355 1356 1359 TO 1362 1383 1385 TO 1387 1389 -

1390 TO 1392 1399 1400 1402 1403 1405 TO 1408 1457 1460 TO 1462 1466 TO 1471 -

1477 TO 1486

DEFINE UBC LOAD

ZONE 0.15 I 1 RWX 4.5 RWZ 4.5 STYP 4 CT 0.035

SELFWEIGHT 1.15

JOINT WEIGHT

14 15 90 92 111 113 130 132 149 151 WEIGHT 48

MEMBER WEIGHT

1138 1140 1144 1291 1293 1295 1363 1374 1451 TO 1453 1455 UNI 80

1267 1269 1275 1277 1283 1285 1306 1312 1313 1317 1321 1323 1324 1328 1332 -

1334 1335 1339 1343 1345 1346 1365 1367 1369 1410 1472 1474 1475 UNI 160

166 187 189 233 235 487 TO 490 493 494 657 659 TO 661 1299 1303 1305 1314 -

1318 1325 1329 1336 1340 1357 1358 1384 1404 1421 1424 1427 1430 1438 1439 -

1441 TO 1443 1445 1447 1449 UNI 36

LOAD 1 UBC IN X - DIR

UBC LOAD X

LOAD 2 UBC IN Z - DIR

UBC LOAD Z

LOAD 3 DEAD LOAD ( DL )

SELFWEIGHT Y -1.15 LIST 7 TO 12 138 TO 143 163 TO 172 186 TO 195 232 TO 235 -

472 487 TO 490 493 494 559 560 565 568 631 655 TO 661 765 767 769 771 1087 -

1114 1132 TO 1140 1144 1145 1158 1160 1205 1209 TO 1212 1233 1235 1248 1256 -

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 5 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

1265 TO 1269 1272 TO 1277 1280 TO 1285 1288 TO 1293 1295 TO 1314 1317 1318 -

1321 TO 1325 1328 1329 1332 TO 1365 1367 1369 1371 1374 TO 1436 1438 1439 -

1441 TO 1443 1445 TO 1447 1449 TO 1457 1460 1461

MEMBER LOAD

1138 1140 1144 1291 1293 1295 1363 1374 1451 TO 1453 1455 UNI GY -80

1267 1269 1275 1277 1283 1285 1306 1312 1313 1317 1321 1323 1324 1328 1332 -

1334 1335 1339 1343 1345 1346 1365 1367 1369 1410 1472 1474 -

1475 UNI GY -160

166 187 189 233 235 487 TO 490 493 494 657 659 TO 661 1299 1303 1305 1314 -

1318 1325 1329 1336 1340 1357 1358 1384 1404 1421 1424 1427 1430 1438 1439 -

1441 TO 1443 1445 1447 1449 UNI GY -36

JOINT LOAD

14 15 90 92 111 113 130 132 149 151 FY -48

LOAD 4 LOADTYPE None TITLE LIVE LOAD

MEMBER LOAD

1138 1140 1144 1291 1293 1295 1363 1374 1451 TO 1453 1455 UNI GY -120

1267 1269 1275 1277 1283 1285 1306 1312 1313 1317 1321 1323 1324 1328 1332 -

1334 1335 1339 1343 1345 1346 1365 1367 1369 1410 1472 1474 -

1475 UNI GY -240

LOAD 5 WIND LOAD X DIR ( WX )

MEMBER LOAD

1138 1140 1291 1293 1451 1455 UNI Y 74.75

1267 1269 1275 1277 1283 1285 1312 1317 1323 1328 1334 1339 1345 -

1410 UNI Y 149.5

1144 1295 1363 1374 1452 1453 UNI Y 53.39

1306 1313 1321 1324 1332 1335 1343 1346 1365 1367 1369 1472 1474 -

1475 UNI Y 106.79

7 9 1132 1134 UNI GX 85.68

138 140 167 169 190 192 1304 1409 1422 1423 1428 1429 1433 1434 UNI GX 171.36

8 10 1133 1135 1205 UNI GX 53.39

139 141 168 170 191 193 1114 1419 1420 1425 1426 1431 1432 1435 -

1436 UNI GX 106.79

LOAD 6 WIND LOAD Z DIR ( WZ )

MEMBER LOAD

7 8 UNI GZ 85.68

1454 1456 UNI GZ 171.36

1132 1133 UNI GZ 53.39

1446 1450 UNI GZ 106.79

LOAD 7 LOADTYPE None TITLE CRANE LOAD 1 (CL1)

JOINT LOAD

110 FY -16330

112 FY -5440

110 FX 1630

112 FX 540

110 FZ 3270

112 FZ 1090

110 MY -2123 MZ -10615

112 MY 708 MZ 3538

LOAD 8 LOADTYPE None TITLE CRANE LOAD 2 (CL2)

JOINT LOAD

12 FY -16330

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 6 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

13 FY -5440

12 FX 1630

13 FX 540

12 FZ 3270

13 FZ 1090

12 MY -2123 MZ -10615

13 MY 708 MZ 3538

LOAD COMB 9 DL+0.5LL

3 1.0 4 1.0

LOAD COMB 10 (DL+0.5LL+CL1)

3 1.0 4 0.5 7 1.0

LOAD COMB 11 (DL+0.5LL+CL2)

3 1.0 4 0.5 8 1.0

LOAD COMB 12 0.75(DL+0.5LL+CL1+WX)

3 0.75 4 0.375 7 0.75 5 0.75

LOAD COMB 13 0.75(DL+0.5LL+CL2+WX)

3 0.75 4 0.375 8 0.75 5 0.75

LOAD COMB 14 0.75(DL+0.5LL+CL1+WZ)

3 0.75 4 0.375 7 0.75 6 0.75

LOAD COMB 15 0.75(DL+0.5LL+CL2+WZ)

3 0.75 4 0.375 8 0.75 6 0.75

LOAD COMB 16 0.75(DL+0.5LL+CL1+QX)

3 0.75 4 0.375 7 0.75 1 0.75

LOAD COMB 17 0.75(DL+0.5LL+CL2+QX)

3 0.75 4 0.375 8 0.75 1 0.75

LOAD COMB 18 0.75(DL+0.5LL+CL1+QZ)

3 0.75 4 0.375 7 0.75 2 0.75

LOAD COMB 19 0.75(DL+0.5LL+CL2+QZ)

3 0.75 4 0.375 8 0.75 2 0.75

LOAD COMB 20 1.4DL+1.7LL

3 1.4 4 1.7

LOAD COMB 21 1.4DL+1.7(0.5LL+CL1)

3 1.4 4 1.7 7 1.7

LOAD COMB 22 1.4DL+1.7(0.5LL+CL2)

3 1.4 4 0.85 8 1.7

LOAD COMB 23 1.05DL+1.275(0.5LL+CL1+WX)

3 1.05 4 0.6375 7 1.275 5 1.275

LOAD COMB 24 1.05DL+1.275(0.5LL+CL2+WX)

3 1.05 4 0.6375 8 1.275 5 1.275

LOAD COMB 25 1.05DL+1.275(0.5LL+CL1+WZ)

3 1.05 4 0.6375 7 1.275 6 1.275

LOAD COMB 26 1.05DL+1.275(0.5LL+CL2+WZ)

3 1.05 4 0.6375 8 1.275 6 1.275

LOAD COMB 27 1.05DL+1.275(0.5LL+CL1+QX)

3 1.05 4 0.6375 7 1.275 1 1.275

LOAD COMB 28 1.05DL+1.275(0.5LL+CL2+QX)

3 1.05 4 0.6375 8 1.275 5 1.275

LOAD COMB 29 1.05DL+1.275(0.5LL+CL1+QZ)

3 1.05 4 0.6375 7 1.275 2 1.275

LOAD COMB 30 1.05DL+1.275(0.5LL+CL2+QZ)

3 1.05 4 0.6375 8 1.275

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 7 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

LOAD COMB 31 DL+LL

3 1.0 4 1.0

LOAD COMB 32 (DL+0.5LL+CL1)

3 1.0 4 0.5 7 1.0

LOAD COMB 33 (DL+0.5LL+CL2)

3 1.0 4 0.5 8 1.0

LOAD COMB 34 (DL+0.5LL+CL1+WX)

3 1.0 4 0.5 7 1.0 5 1.0

LOAD COMB 35 (DL+0.5LL+CL2+WX)

3 1.0 4 0.5 8 1.0 5 1.0

LOAD COMB 36 (DL+0.5LL+CL1+WZ)

3 1.0 4 0.5 7 1.0 6 1.0

LOAD COMB 37 (DL+0.5LL+CL2+WZ)

3 1.0 4 0.5 8 1.0 6 1.0

LOAD COMB 38 (DL+0.5LL+CL1+QX)

3 1.0 4 0.5 7 1.0 1 1.0

LOAD COMB 39 (DL+0.5LL+CL2+QX)

3 1.0 4 0.5 8 1.0 1 1.0

LOAD COMB 40 (DL+0.5LL+CL1+QZ)

3 1.0 4 0.5 7 1.0 2 1.0

LOAD COMB 41 (DL+0.5LL+CL2+QZ)

3 1.0 4 0.5 8 1.0 2 1.0

PERFORM ANALYSIS

LOAD LIST 9 TO 19

*PRINT JOINT DISPLACEMENTS LIST 10 TO 15 17 18 89 TO 96 110 TO 117 129 TO 136 -

*148 TO 155 167 TO 174 186 TO 193 205 TO 212 224 TO 231 243 TO 250 -

*262 TO 269 281 TO 288 300 TO 307 319 TO 321 323 324 326 327 338 TO 345

PRINT SUPPORT REACTION LIST 10 11 95 96 116 117 135 136 703 730

PARAMETER 1

CODE AISC

UNL 1.2 MEMB 1138 1144 1265 TO 1267 1273 TO 1275 1281 TO 1283 1289 TO 1291 -

1295 1297 1298 1453 1455 1472 1474 1475

LY 1.2 MEMB 1138 1144 1265 TO 1267 1273 TO 1275 1281 TO 1283 1289 TO 1291 -

1295 1297 1298 1453 1455 1472 1474 1475

LX 1.2 MEMB 1138 1144 1265 TO 1267 1273 TO 1275 1281 TO 1283 1289 TO 1291 -

1295 1297 1298 1453 1455 1472 1474 1475

BEAM 1 MEMB 7 TO 11 138 TO 141 163 164 167 TO 170 186 TO 195 232 233 472 487 -

489 490 493 560 565 568 655 TO 661 765 767 769 771 1087 1114 1132 TO 1140 -

1144 1145 1158 1205 1265 TO 1269 1272 TO 1277 1280 TO 1285 1288 TO 1293 1295 -

1296 TO 1298 1307 1314 1318 1325 1329 1336 1347 1349 1351 TO 1353 -

1355 TO 1357 1359 TO 1365 1367 1369 1371 1374 1382 TO 1387 1389 TO 1393 1396 -

1399 1400 1402 1403 1405 TO 1408 1412 1414 1417 1418 1421 1424 1427 1430 -

1442 1446 1453 TO 1455 1457 1460 TO 1462 1472 1474 1475

FYLD 2.4e+007 MEMB 7 TO 12 138 TO 143 163 TO 172 186 TO 195 232 TO 235 472 -

487 TO 490 493 494 559 560 565 568 631 655 TO 661 765 767 769 771 1087 1114 -

1132 TO 1140 1144 1145 1158 1160 1205 1265 TO 1269 1272 TO 1277 1280 TO 1285 -

1288 TO 1293 1295 TO 1307 1312 TO 1314 1317 1318 1321 TO 1325 1328 1329 1332 -

1333 TO 1336 1339 1340 1343 TO 1365 1367 1369 1371 1374 TO 1436 1438 1439 -

1441 TO 1443 1445 TO 1447 1449 TO 1457 1460 TO 1462 1472 1474 1475

MAIN 1 MEMB 163 164 186 TO 189 232 233 487 489 490 493 656 TO 661 1307 1314 -

1318 1325 1329 1336 1347 1349 1353 1357 1364 1371 1377 TO 1380 1382 1384 -

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 8 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

1393 1396 1411 1413 1421 1424 1427 1430

LX 3 MEMB 568 1460 TO 1462

LY 3 MEMB 568 1460 TO 1462

LZ 3 MEMB 568 1460 TO 1462

CHECK CODE MEMB 7 TO 12 138 TO 143 163 TO 172 186 TO 195 232 TO 235 472 487 -

488 TO 490 493 494 559 560 565 568 631 655 TO 661 765 767 769 771 1087 1114 -

1132 TO 1140 1144 1145 1158 1160 1205 1265 TO 1269 1272 TO 1277 1280 TO 1285 -

1288 TO 1293 1295 TO 1307 1312 TO 1314 1317 1318 1321 TO 1325 1328 1329 1332 -

1333 TO 1336 1339 1340 1343 TO 1365 1367 1369 1371 1374 TO 1436 1438 1439 -

1441 TO 1443 1445 TO 1447 1449 TO 1457 1460 TO 1462 1472 1474 1475

*STEEL MEMBER TAKE OFF LIST 7 TO 12 44 46 71 TO 73 121 TO 123 125 130 TO 148 -

*153 TO 159 163 TO 184 186 TO 207 209 TO 230 232 TO 253 255 TO 276 -

*278 TO 299 301 TO 322 324 TO 345 347 TO 368 370 TO 391 393 TO 414 -

*416 TO 437 439 TO 460 462 TO 472 475 476 487 TO 599 601 TO 613 615 TO 627

*LOAD LIST 20 TO 30

*PRINT MAXFORCE ENVELOPE NSECTION 6 LIST 7 TO 12 44 46 71 TO 73 130 TO 136 -

*138 TO 148 153 TO 159 167 TO 184 190 TO 207 213 TO 230 236 TO 253 -

*259 TO 276 282 TO 299 305 TO 322 328 TO 345 351 TO 368 374 TO 391 -

*397 TO 414 420 TO 437 443 TO 460 515 TO 518 535 538 546 549 557 TO 560 577 -

*580 588 591

PARAMETER 2

CODE AISC

STEEL MEMBER TAKE OFF LIST 7 TO 12 138 TO 143 163 TO 172 186 TO 195 -

232 TO 235 472 487 TO 490 493 494 559 560 565 568 631 655 TO 661 765 767 -

769 771 1087 1114 1132 TO 1140 1144 1145 1158 1160 1205 1209 TO 1212 1233 -

1235 1248 1256 1265 TO 1269 1272 TO 1277 1280 TO 1285 1288 TO 1293 -

1295 TO 1314 1317 1318 1321 TO 1325 1328 1329 1332 TO 1365 1367 1369 1371 -

1374 TO 1436 1438 1439 1441 TO 1443 1445 TO 1447 1449 TO 1457 1460 TO 1462 -

1466 TO 1472 1474 1475 1477 TO 1486

FINISH

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 9 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

Member Location with The Maximum Ratio

1 Column - C1 -H588X300X12

Max ratio

2 Column - C2 -H200X100X5.5

Max ratio

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 10 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

3 Rafter - RF1 -H450X200X9

Max ratio

4 Beam - B1 -H150X150X7

Max ratio

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 11 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

5 Beam - B2 -H300X150X6.5

Max ratio

6 Beam - B3 -H250X125X6

Max ratio

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 12 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation

7 Beam - B4 -H200X200X8

Max ratio

8 Beam - B5 -C100X50X5

Max ratio

BCD3-690-45-CAL-4-102-00 Rev 1 Attachment - 1 - Page 13 08-Feb-2018

Calculation

PetroChina International Jabung Ltd. GTG Shelter Structural Analysis &

Foundation