Professional Documents

Culture Documents

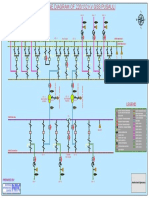

North Eastern Electricity Supply Company of Orissa Limited Technical Specification

Uploaded by

RajeshYadavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

North Eastern Electricity Supply Company of Orissa Limited Technical Specification

Uploaded by

RajeshYadavCopyright:

Available Formats

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

SECTION - III

TECHNICAL SPECIFICATION

OF

ELECTRICAL

MATERIALS

“ GROUP – B ”

Specification: TN/3722/14.3.11/ Gr.B

-1–

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

1. Single Pole Transformer Mounting Quantity

Bracket. 195 Nos.

TECHNICAL SPECIFICATION

Single Pole Transformer mounting Bracket suitable for installation of single Phase 11/.23 KV

10KVA and 16 KVA and 25KVA 11/0.4KV Transformers made out of 75x40x6 mm MS

channel,65x65x6 mm & 50x50x6mm MS Angle as per drawing REC Standard is to be

followed. The mounting bracket will be painted with two coats of red-oxide paints.

Bill of materials :

1. 75x40x6 mm M.S channel – 2 nos.(transformer mounting channel) with 50x8 mm -2 nos. M.S

flat flange welded for fixing of transformer base channel.

2. 65x65x6 mm M.S angle – 2 nos.(cantilever)

3. 50x50x60 mm M.S angle – 2nos. ( fixing with pole)

Approved drawing enclosed.

Specification: TN/3722/14.3.11/ Gr.B

-2–

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

2.i) 33 KV ‘V’ Cross arm (MS) Quantity

33 KV ‘V’ cross arm made out of 100x50x6 mm M.S Channel 300 Nos.

as per REC Standard M-1. The cross arm shall be fabricated out

of 100x50x6 mm size channel having 9.2 Kg/mtr. . After

fabrication the cross arm shall be painted with two coats of Red

Oxide primer, conforming to REC construction standard &

drawing.

Guaranteed Technical Particulars of 33 KV 'V' Cross Arm

Sl.

No. Description Specified Bidders Offer

1 Type of Cross Arm ISMC 100x50

2 Channel Weight 9.2 Kg/mtr

3 Grade of Steel FY 250

4 Steel Standard IS:2062-1992

5 Fabrication Standard IS:802 (part - 2) - 1978

6 Dimension (100x50x6)mm

Size of M S Flat welded at both

7 ends 50x8mm

8 Steel Tensile Strength 1500kgf/cm²

9 Working Load 400/ 450/ 550/600Kg

10 Total Weight 19.7 Kg (approx.)

Specification: TN/3722/14.3.11/ Gr.B

-3–

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

2.ii) 11 KV ‘V’ Cross arm (MS) Quantity

11 KV ‘V’ cross arm made out of 75x40x5 mm M.S Channel as 500 Nos.

per REC Standard A6. The cross arm shall be fabricated out of

75x40x5 mm size channel having 6.8 Kg/mtr. with 50mmx6mm

flat as per drawing on top & bottom flange of the channel where

the insulator pin is to be mounted. After fabrication the cross

arm shall be painted with two coats of Red Oxide primer,

conforming to REC construction standard & drawing.

Guaranteed Technical Particulars of 11KV 'V' Cross Arm

Sl.

No. Description Specified Bidders Offer

1 Type of Cross Arm ISMC 75x40

2 Channel Weight 6.8Kg/mtr

3 Grade of Steel FY 250

4 Steel Standard IS:2062-1992

5 Fabrication Standard IS:802 (part - 2) - 1978

6 Dimension (75x40x5)mm

Size of M S Flat welded at both

7 ends 50x8mm

8 Steel Tensile Strength 1500kgf/cm²

9 Working Load 200/300/350/400Kg

10 Total Weight 10.88 Kg (approx.)

Specification: TN/3722/14.3.11/ Gr.B

-4–

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

2.iii) 3 Ph. 4 W LT Cross arm Quantity

LT cross arm (3 –phase ,4 wire) made out of 75mm x40 mm 300 Nos.

Channel . The cross arm shall be fabricated out of (75x40) mm

channel with 50mmx6mm cleats as per drawing on top & bottom

flange of the channel where the insulator pin to be mounted,

conforming to REC Construction Standard & drawing..

2.iv) 3 Ph. 5 W LT Cross arm Quantity

LT cross arm (3 –phase ,5 wire) made out of 75mm x40 mm 200 Nos.

Channel . The cross arm shall be fabricated out of (75x40) mm

channel with 50mmx6mm cleats as per drawing on top & bottom

flange of the channel where the insulator pin to be mounted,

conforming to REC Construction Standard & drawing.

Specification: TN/3722/14.3.11/ Gr.B

-5–

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

3.i) Back Clamp for 33 KV ‘V’ Cross arm Quantity

Back clamp for 33 KV’V’ cross arm made out of 50x8 mm MS 1000 Nos.

Flat with two coat of red-oxide primer suitable for HT poles

confirming to REC Construction Standard & drawing.

3.ii) Back Clamp for 11 KV ‘V’ Cross arm Quantity

Back clamp for 33 KV’V’ cross arm made out of 50x8 mm MS Flat 800 Nos.

with two coat of red-oxide primer suitable for HT PSC poles

confirming to REC Construction Standard & drawing.

3.iii) Back Clamp for LT Cross arm Quantity

Back clamp for LT cross arm made out of 50x8 mm MS Flat 500 Nos.

with two coat of red-oxide primer suitable for PSC poles

confirming to REC Construction Standard & drawing.

3.iv) HT Stay Side Clamp Quantity

HT stay clamp suitable for PSC poles made out of 50x8 mm MS 300 Pairs

Flat with two coat of red-oxide primer , confirming to REC

Construction Standard & drawing.

Specification: TN/3722/14.3.11/ Gr.B

-6–

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

4. 11KV Pole Top Bracket Quantity

11 KV line pole top bracket made out of 50x8 mm M.S Flat with 500 Nos.

two coat of red-oxide primer , confirming to REC Construction

Standard.A-7 & drawing .

GUARANTEED TECHNICAL PARTICULARS FOR 11KV POLE TOP BRACKET

Sl.No. Constructional Features Specified Bidders

Offer

1. Material used 50x8 mm MS Flat

2. Overall height 385 mm

3. Flange Width (one welded & 60 mm

one bent)

4. Spacing between two flanges 75mm

5. Spacing of 2 nos of 18mm holes 100mm

for fixing on pole top

6. C/L Distance of 2nos of 22mm 25mm from edge

holes on top flanges of the of the flange

bracket

7. ISS 2062

8. Drawing enclosed

Specification: TN/3722/14.3.11/ Gr.B

-7–

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

5.i) 1-Ph. 2W LT spacer (Composite Type) Quantity

LT Spacer suitable for 1-phase, 2 wire LT line made of 1500 Nos.

polypropylene single mould , confirming to REC Construction

Standard.B-18 & drawing.

5.ii) 3-Ph. 3W LT spacer (Composite Type) Quantity

LT Spacer suitable for 3-phase, 3 wire LT line made of 2000 Nos.

polypropylene single mould , confirming to REC Construction

Standard.B-18 & drawing.

5.iii) 3-Ph. 4W LT spacer (Composite Type) Quantity

LT Spacer suitable for 3-phase, 4 wire LT line made of 2000 Nos.

polypropylene single mould , confirming to REC Construction

Standard.B-18 & drawing.

5.iv) 3-Ph. 5W LT spacer (Composite Type) Quantity

LT Spacer suitable for 3-phase, 5 wire LT line made of 3000 Nos.

polypropylene single mould , confirming to REC Construction

Standard.B-18 & drawing..

Specification: TN/3722/14.3.11/ Gr.B

-8–

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

6.i) 11 KV G.I Pin Quantity

11 KV hot-dipped galvanizing Pin suitable for 11 KV pin 1300 Nos.

insulator , confirming to REC Construction Standard. C- 1.

GUARANTEED TECHNICAL PARTICULARS FOR 11KV G.I PIN

Sl.No. Description Specified Bidders Offer

1 Manufacturer Name & Address To be specified by

Bidder

2 Type of Pin 11KV

3 Applicable International Standard IS:2486 (part-II)

4 Grade Steel HDG Steel

5 Steel Specification HDG Steel

6 Specification of Bolt & Nut As per ISS

7 Specification of Bolt Threads As per ISS

8 Mechanical falling load (MFL) 10 KN

9 Elongation at MFL As per ISS

10 Maximum deflection of Pin Top at 1.5 mm

MFL

11 Galvanising Specification IS- 2633

12 Minimum weight of Steel deposited 610 g/m²

on steel surface

13 Pin Length 315 mm

14 Shank Length 150 mm

15 Stalk Length 165 mm

16 Type of Thread As per ISS

17 Thread Length As per ISS

18 Drawing enclosed

Specification: TN/3722/14.3.11/ Gr.B

-9–

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

6.ii) LT G.I Pin Quantity

LT hot-dipped galvanizing Pin suitable for LT pin insulator , 800 Nos.

confirming to REC Construction Standard. D-2.

GUARANTEED TECHNICAL PARTICULARS FOR LT G.I PIN

Sl. Description Specified Bidders Offer

No.

1 Manufacturer Name & Address To be specified by

Bidder

2 Type of Pin LT

3 Applicable International Standard IS:2486 ( Part-II)

4 Grade Steel HDG Steel

5 Steel Specification HDG Steel

6 Specification of Bolt & Nut As per ISS

7 Specification of Bolt Threads As per ISS

8 Mechanical falling load (MFL) 10 KN

9 Elongation at MFL As per ISS

10 Maximum deflection of Pin Top at 1.5 mm

MFL

11 Galvanising Specification IS- 2633

12 Minimum weight of Steel deposited 610 g/m²

on steel surface

13 Pin Length 260 mm

14 Shank Length 125 mm

15 Stalk Length 135 mm

16 Type of Thread As per ISS

17 Thread Length As per ISS

18 Drawing enclosed

Specification: TN/3722/14.3.11/ Gr.B

- 10 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

7.i) 33 KV H/W Fittings (B&S) Quantity

33 KV Hard Ware fittings Ball and socket type ,confirming to 500 Sets

IS: 2486 (Part-II) latest amendment and as per drawing.

ii) 11 KV H/W Fittings (T&C) Quantity

11 KV Hard Ware fittings Tongue & Clevis type ,confirming 500 Sets

to REC Construction Standard C-2 and as per drawing.

TECHNICAL SPECIFICATION

T & C and B & S Hardware Fittings

The hardware fittings for B & S and T & C Strain Disc Insulator. For use in 33 KV and

11 KV Overhead power lines shall comply IS:2486 (Part-I) 1971 and 2486 (Part-II) /

1974 and IS:2486 (Part-III) 1974 IS:12048 /1987 and REC Specification 24/84 or the

latest revision thereof. All Forging and Casting shall be good finish and free from flows

and other defects. The edges on the outside of fittings such as at the Eye, Cleaves and

Holes shall be rounded.

All parts of different fittings, which provide for Inter-connection shall be made such that

sufficient clearance is provided at the Connection Point to ensure free movement &

suspension of the Insulator string Assembly.All eye and cleaves shall be free in this

manner but care shall be taken that too much clearance between Eye & Tongs of the

cleaves is avoided.

All ferrous fittings and parts other than those of Stainless steel shall be hot dip

galvanized as per ISS: 2633 / 1964.Small fittings like Spring washer , Nuts etc. may be

Electro-galvanized as per

IS-6745 / 72.The threads of nuts and topped holes when cut after

Galvanizing shall be well cited & grassed.

(A) Ball & Socket type Hardware fittings(Conversional

/ Performed ) for B & S type Strain Insulators

The hardware fittings (Ball and Socket type) shall be suitable for fixing on 100 mmx50

mm channel cross arms and for accommodation of 55 mm² / 100 mm² Conductor.

The set shall complete with following components

(i) Cross-arms straps with Bolts & Nuts, Brass split and Spring Washer.

(ii) Two numbers forged cotter pins,Brass split pins,Plain washer.

Specification: TN/3722/14.3.11/ Gr.B

- 11 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

(iii) One number Ball Eye of malleable cast iron

(iv) One number of socket eye complete with security clips made of Phosphor bronze

made cut of alluminium alloys-A/6.

(v) Halically formed Dead and Conductor grip having a Pre-fabricate loop to fit into the

proved contour of the thimbles on one end and for application over the conductor at the

other end for 55 mm²/100mm² conductors.

(vi) Strain clamps shall be suitable for above ACSR / AAAC.The ultimate strength

of clamp should not be less than 4500 Kg and Slipping strength shall not be less

than 90% of these figures.

(B) Tongue & Clevics type Hardware Fittings (Conventional / ¼ Performed ) for T

& C type Strain Insulators

The Hardware fittings ( Tongue & Clevis type) shall be suitable for fixing on 75 mmx40

mm Channel Cross Arm an accommodation 34mm²/55mm²/100mm² Conductors.

The set shall comply of the following components :-

(i) Cross arms straps (Dead & Straps) with Bolt (16mm) Nut and Spring Washer.

(ii) Two Nos. forged cotter pints and spring washer to suit the tongue and the clevics.

(iii) Formed helical fittings should be of suitable materials i.e all alloy aluminum steel

suitable for 34mm²/55mm²/100mm² ACSR/AAAC.

(iv) Strain clamps shall be suitable for the above ACSR

conductor or AAAC.The ultimate strength of the clamp

should not be less than 3000 Kg and slipping strength

shall not be less than 90% of this figure.The clamp

should be malleable cast iron/All alloy A-6.

Tests :

String insulator fittings shall comply with the following tests as per IS: 2486 (Part.I)

Type Tests:

a) Visual examination test

ii) Verification of dimensions

iii) Slip strength test

iv) Mechanical test

v) Electrical resistance test

vi) Heating cycle test

vii) Galvanising test.

Acceptance/ Routine Test :

i)Verification of dimensions

ii) Mechanical test

iii) Galvanising test

iv) Vidual examination test

v) Routine mechanical test.

Marking :

The caps and clamps shall have marked on them as trade mark & year of

manufacturing.

Specification: TN/3722/14.3.11/ Gr.B

- 12 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

Packing :

All hardware fittings shall be packed in bags or boxes suitable for rough

handling. Packing shall be marked with the strength and KV rating.

Guaranteed Technical Particulars :

The bidders are required to furnish the guaranteed technical particulars duly filed

in the proforma along with the bid.

GUARANTEED TECHNICAL PARTICULARS FOR 11 KV H/W

FITTINGS ( T&C )

Sl.No. Description Specified Bidders Offer

1. Manufacturer Name & To be specified by Bidder

Address

2. Standard Specification to IS: 2486 (Part-I,II &II)

which Hard ware Fittings

shall confirm.

3 Ultimate strength 3000 Kg (min)

4. Dimensions in accordance IS: 2486(Part-II)

with

5 Type of washer thickness

a) Spring 2.5 mm

b)Flat 2.5 mm

6. Type of Clamp size Tension Clamp suitable for

Squiral/Weasel/ Rabbit

7. Galvanised conform to IS 2633 , IS: 4759-1996 &

IS: 6747

8. Weight of Fittings ..

9. Tolerance in dimension if + 5%

any

10. Manufacturer trade mark to be Specified by the Bidder

embossed on the sets

11. Specific drawing to be Enclosed

enclosed.

NB. All ferrous fittings and the parts other than those of stainless steel , shall be

galvanized.

Specification: TN/3722/14.3.11/ Gr.B

- 13 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

GUARANTEED TECHNICAL PARTICULARS FOR 33 KV H/W

FITTINGS ( B&S )

Sl.No. Description Specified Bidders Offer

1. Manufacturer Name & To be specified by Bidder

Address

2. Standard Specification to IS: 2486 (Part-I,II &II)

which Hard ware Fittings

shall confirm.

3 Ultimate strength 4500 Kg (min.)

4. Dimensions in accordance IS: 2486(Part-II)

with

5 Material used and reference to

Standard:

i) Cross arm Strap G.I as per IS:1570

ii) Ball Eye Forged Steel IS:2004

iii) Socket Eye Malleable Cast Iron IS:

2108/1962

iv) Bolted type tension clamp & Aluminium Alloy LM-6,

its keeper

IS: 617

6. Galvanised conform to IS 2633 , IS: 4759-1996 &

IS: 6747

7. Weight of Fittings not less than 2.5 Kg.

8. Tolerance in dimension if + 5%

any

9. Manufacturer trade mark to be Specified by the Bidder

embossed on the sets

10. Specific drawing to be Enclosed

enclosed.

NB. All ferrous fittings and the parts other than those of stainless steel , shall be

galvanized.

Specification: TN/3722/14.3.11/ Gr.B

- 14 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

8. M16 M.S Nuts & Bolts Quantity

16 mm diameter M.S Nuts and Bolts black hexagonal As

per IS: 1387 (Part-II) Gr.-4/4.6 of following size

i) 16x40 mm ( Fully threaded) 400 Kg

ii) 16x125 mm ( Treaded length – 70 mm) 1140 Kg

iii) 16x150 mm ( Treaded length – 70 mm) 1070 Kg

iv) 16x175 mm ( Treaded length – 70 mm) 1210 Kg

v) 16x200 mm ( Treaded length – 70 mm) 930 Kg

vi) 16x225 mm ( Treaded length – 70 mm) 3000 Kg

vii) 16x250 mm ( Treaded length – 80 mm) 840 Kg

viii) 16x275 mm ( Treaded length – 80 mm) 850 Kg

ix) 16x 300 mm ( Treaded length – 80 mm) 1000 Kg

x) 16x350 mm ( Treaded length – 80 mm) 920 Kg

SPECIFICATION OF FINISHED PRODUCTS :

1. The bolts & Nuts shall be ISI Marked Mild Steel of Black Grade “B” and shall be

round with hexagonal head.

(i) The Bolts and Nuts shall be manufactured by Hot/Cold forging process neatly and

cleanly finished and shall have metric threads as per IS : 4218/1967 with its latest

amendments.

(ii) The dimensions of the bolts & nuts and tolerances should conform to IS: 1363 with

their latest amendments in all respect. The eccentricity and angular errors of various

elements shall be within specified limits as per IS: 1367/1967 with its latest

amendments the bolts & nuts shall be free from forging and threading defects such as

cuts, spats. burns, bulging taper eccentricity, loose fill etc. which may affect their

serviceability.

(iii) The colt heads and nuts shall be chamfered on one face only and other face shall be

machined made.

(iv) Mechanical property requirement of tester shall conform to IS: 1367 (Part-III)

Specification: TN/3722/14.3.11/ Gr.B

- 15 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

1979 property class 4.6 for bolts & property class-5 for nuts as per

IS: 1367 (Part VI) —1980.

(v) The bolts & nuts shall be supplied in well-cleaned conditions and suitably protected

against corrosion in individual bags of 50 kgs.

2. ACCEPTANCE TESTS:

The bidder should furnish test certificate from his awn/recognized Govt. Laboratory giving

the results of tests as per IS: 1367 (Part-Ill) —1979 & IS: 1367 (Part-VI) 1980 The test

certificate shall be in respect of the following for all sizes of both bolts & nuts as applicable

given below:-

i) Dimensional particulars (Sampling Ifl accordance with IS: 2614 for both bolts & nuts

(tolerance as per drawing).

ii) Tensile strength test on full size (for bolts minimum 400 NI Sq.mm and for Nuts Proof

Stress test Mm 610 N/Sq. mm).

iii) Power load test on full size bolts and M-12-51400 N for 15 Sec.

iv) Head soundness tests for bolts (no fracture).

v) Brinell hardness tests or Rockwell Hardness or Vickers’s Hardness tests for bolts min-

114 &max. 209 or mm. 67 & max. 95 or mm. 120 & max. 220 respectively. For nuts

Vickers’s Hardness mm. 130 & max. 302.

3. PRE-DESPATCH INSPECTION AND TEST

The bidder shall arrange to carryout acceptance tests in presence of owners inspecting

officer in his own laboratory. In case testing facilities are not available at works he will

make necessary arrangements for carrying out these tests at a Govt. recognized lab at his

own expense(s) and will provide all testing arrangement for Board’s representative to

witness the tests.

4. Markings:

On the bolt head, there shall be identification marking of the manufacturer as well as

property class ‘4.6”. If possible property class “5” shall be marked on Nuts also. Further

‘ISI’ mark shall be marked on

Sunny Bags for proper identification.

Specification: TN/3722/14.3.11/ Gr.B

- 16 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

9. 16 mm LT Stay Set ( Galvanized) Quantity

200 Sets

TECHNICAL SPECIFICATION OF

LT STAY SET

1. SCOPE

This specification covers design, manufacture, testing of 1 6 m m GI Stay Sets .

2. GENERAL REQUIREMENTS

i) 16 MM Dia Stay sets (Galvanized) – LT Stay Set

This stay sets (Line Guy set) will consist of the following components:-

ii) Anchor Rod with one washer and Nut

Overall length of rod should be 1800 mm to be made out of 16 mm dia GS Rod,

one end threaded up to 40 mm length with a pitch of 5 threads per cm and

provided with one square GS washer of size 40X40x1.6mm and one GS

hexagonal nut conforming to IS:1367:1967 & IS:1363:1967. Both waster and nut

to suit threded rod of 16 mm dia. The other end of the rod to be made into a round

eye having an inner dia of 40mm with best quality welding.

iii) . Anchor Plate Size 200 x 200 x6 mm

To be made out of GS plate of 6 mm thickness. The anchor plate should have at

its centre 18 mm dia hole.

iv) Turn Buckle & Eye Bolt with 2 Nuts

To be made of 16 mm dia GS Rod having an overall length of 450mm, one end of

the rod to be threaded up to 300 mm length with a pitch of 5 threads per cm and

provided with two GS Hexagonal nuts of suitable size conforming toIS:1363:1967

& IS:1367:1967. The other end of rod shall be rounded into a circular eye of

40mm inner dia with proper and good quality welding.

v) Bow with Welded Angle

To be made out of 16mm dia GS rod. The finished bow shall have an over all

length of 995 mm and eight of 450 mm, the apex or top of the bow shall be bent at

an angle of 10 R. The other end shall be welded with proper and good quality

welding to a GS angle 180 mm long having a dimension of 50x50x6mm. The

angle shall have 3 holes of 18 mm dia each.

vi) Thimble

Specification: TN/3722/14.3.11/ Gr.B

- 17 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

To be made on 1.5 mm thick GS sheet into a size of 75x22x40mm and shape as

per standard shall be supplied.

Average Weight of Finished 16mm Stay Sets shall be at least 7.702 KG

(Minimum) (Excluding Nuts Thimbles and Washer) 8.445 Kg. (Maximum)

3. Galvanizing

The complete assembly shall be hot dip galvanized as per ISS.

4. Welding

The minimum strength of welding provided on various components of 16mm

shall be 3100 kg . Minimum 6mm filet weld or its equivalent weld area should be

deposited in all positions of the job i.e. at any point of the weld length. The

welding shall be conforming to relevant IS:823/1964 or its latest amendment.

5. Threading

The threads on the Anchor Rods, Eye Bolts and Nuts shall be as per specification

IS; 4218:1967 (ISO Metric Screw Threads). The Nuts shall be conforming to the

requirements of IS: 1367:1967 and have dimension as per IS 1363:1967. The

mechanical property requirement of fasteners shall confirm to the properly clause

4.6 each for anchor rods and Eye bolt and property clause 4 for nuts as per IS:

1367:1967.

6. TESTS

The contractor shall be required to conduct testing of materials at

Govt./Recognized testing laboratory during pre-dispatch inspection for Tensile

Load of 3100 Kg applied for one minute on the welding and maintained for one

minute for 16 mm dia stay sets .

7. IDENTIFICATION MARK

All stay sets should carry the identification mark of the Purchaser

NESCO as applicable. This should be engraved on the body of stay rods to

ensure proper identification of the materials.

The nuts should be of a size compatible with threaded portion of rods and there

should be not play or slippage of nuts.

Welding wherever required should be perfect and should not give way after

erection.

8. TOLERANCES

The tolerances for various components of the stay sets are indicated below

subject to the condition that the average weight of finished stay sets of 16mm dia

excluding nuts, thimbles and washers shall not be less than the weight specified

above:-

Specification: TN/3722/14.3.11/ Gr.B

- 18 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

GURANTEED TECHNICAL PARTICULARS OF LT STAY SETS

Item Specified Parameters

Sl Descript

No. ion Section Material Bidder’s

Tolerances Fabrication offer

Tolerances

1. Anchor 6mm thick 200x200mm+1% GS Plate 6

Plate +2.5%-5% mm thick

2. Anchor 16mmdia Length1800mm+0.5% GS Round

Rod +5%- 3% 16mm dia

Rounded Eye 40 mm inside GS Round

dia +3% Threading 16mm dia

40mm+11%-5%

3. Turn Buckle 16mm dia 995mm+1% 16mm dia GS Round

Bow +5%-3% 16mm dia.

Length180mm +1% GS Angle

50x50x6mm

4. Eye Bolt 16mm dia Length 450mm + 1% GS Round

Rod +5%-3% 16 mm dia

Threading 300mm

+1% Round Eye 40mm

inside dia+3%

5 Galvanisatio

n thickness

a Anchor

All galvanization shall be carried out in accordance with IS: 2629 . The weight of Zinc

Plate

deposited shall be in accordance with IS: 2629 and shall not less than 0.61 kg/m² with a

b Anchor

minimum thickness of 86 microns for items of thickness more than 5 mm, 0.46kg/m²(64

Rod microns) for items of thickness between 2 mm & 5 mm& 0.33kg/m²(47 microns) for

c TurnBuckle items less than 2 mm thickness.

Bow

d Eye Bolt

Rod

6 Thimble 2 nos. to be made of 1.5 mm thick G.S Sheet into a size 75x22x40 mm & shape as per standard.

One G.S Hexagonal Nut confirming to IS:1363 & 1367 with one square washer of size 50x50x6

mm (G.S) along with Anchor Rod.

Two G.S Hexagonal Nuts of suitable size along with Eye Bolt Rod.

Specification: TN/3722/14.3.11/ Gr.B

- 19 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

10. 7/12 SWG G.I Stay Wire Quantity

1300 Kg

TECHNICAL SPECIFICATIONS

STAY WIRE (7/12 SWG)

1. Application Standards

Except when they conflict with the specific requirements of this specification, the

G.I Stay Stranded Wires shall comply with the specific requirements of IS: 2141-

1979. IS: 4826-1979 & IS: 6594-1974 or the latest versions thereof.

2. Application and Sizes

a) The G.I. stranded wires covered in this Specification are intended for use on

the overhead power line poles, distribution transformer structures etc.

b) The G.I stranded wires shall be of 7/12 SWG 7/2.5 mm for LT lines standard

sizes.

3. Materials

The wires shall be drawn from steel made by the open hearth basic oxygen or

electric furnace process and of such quality that when drawn to the size of wire

specified and coated with zinc, the finished strand and the individual wires shall

be of uniform quality and have the properties and characteristics as specified in

this specification. The wires shall not contain sulphur and phosphorus exceeding

0.060% each.

3.1 Tensile Grade

The wires shall be of tensile grade 4, having minimum tensile strength of 700

N/mm² conforming to 1S:2141.

3.2 General Requirements

a) The outer wire of strands shall have a right-hand lay.

b) The lay length of wire strands shall be 12 to 19 times the strand diameter.

Specification: TN/3722/14.3.11/ Gr.B

- 20 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

3.3 Minimum Breaking Load & Galvanising

The minimum breaking load of the wires before and after stranding shall be as

follows:

Min. breaking

load of the

Single wire Min. breaking load

No. of Wires Wire Dia before of the standard

& Const. (mm) stranding (KN) wire (KN)

7 (6/1) 2.5 3.44 21.40

Minimum

weight of

zinc coating 490 gm/mm2 490 gm/mm2 490 gm/mm2

before

stranding

Minimum

weight of

zinc coating 475 gm/mm2 475 gm/mm2 475 gm/mm2

before

stranding

4. Construction

a) The galvanized stay wire shall be of 7-wire construction. The wires shall be so

stranded together that when an evenly distributed pull is applied at the ends of

completed strand, each wire shall take an equal share of the pull.

b) Joints are permitted in the individual wires during stranding but such joints

shall not be less than 15 metres apart in the finished strands.

c) The wire shall be circular and free from scale, irregularities, imperfection,

flaws, splits and other defects.

5. Tolerances

A tolerance of (+) 2.5% on the diameter of wires before stranding shall be

permitted.

6. Sampling Criteria

The sampling criteria shall be in accordance with IS :2141.

Specification: TN/3722/14.3.11/ Gr.B

- 21 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

7. Tests on Wires before Manufacture

i) The wires shall be subjected to the following tests in accordance with IS :2141.

a) Ductility Test

b) Tolerance on Wire Diameter

ii) Tests on Completed Strand

The completed strand shall be tested for the following tests in accordance with

IS:2141.

a) Tensile and Elongation Test: The percentage elongation of the

stranded wire shall not be less than 6%.

b) Chemical analysis

c) Galvanizing Test

The Zinc Coating shall conform to "Heavy Coating" as laid down in 1S:4826

8. Marking

Each coil shall carry a metallic tag, securely attached to the inner part of the coil

bearing the following information:

a) Manufacturers name or trade mark

b) Lot number and coil number

c) Size

d) Construction

e) Tensile Designation

f) Lay

g) Coating

h) Length

i) Mass

j) ISI certification mark, if any

9. Packing

The wires shall be supplied in 75-100 Kg. coils. The packing should be done in

accordance with the provisions of IS:6594

Specification: TN/3722/14.3.11/ Gr.B

- 22 –

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

GURANTEED TECHNICAL PARTICULARS STAY

WIRE (7/12 SWG)

Sl. GENERAL TECHNICAL Specified Bidder’s

No. PARTICULARS offer

1 Nominal diameter of wire in mm 2.5

2 Tolerance in diameter in mm 2.5%

3 Minimum breaking load in Kg 2331.07

4 Tensile strength Kgf/mm² 71.40

5 Overall diameter of stranded wire in mm 7.50

6 Sectional Area (in mm².) 44.19

7 Coating Test

a Type of zinc coating whether heavy or light Heavy

b Weight of coating in g/m² 476

8a Length of wire in each coil in mtr. 298

b Tolerance + 5%

9 No. of dips the coating is able to withstand 3 dip in min.

as 18 ± 20ºC

10 Adhesion Test (Wrap Test at 1 turn per

second coiling while stress not exceeding

% nominal tensile strength)

a Min. complete turn of wrap To be

specified by

bidder

b Dia of mandrel on which wrapped - do -

11 Bend Test

a Angle - do -

b Dia round a format to be bent - do -

12 Freedom from defect - do -

13 Chemical composition the MS Wire used

shall not exceed

a Sulphur 0.060% - do -

b Phosphorous 0.065% - do -

14a Weight of wire in Kg/Km 310

b Tolerance + 5%

Specification: TN/3722/14.3.11/ Gr.B

23

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

11. Aluminium cable Socket Quantity

Cable Lugs of Aluminium tubular terminal end of any

reputed make with ISI mark for crimping to all

conductors of following sizes.

i) 120 Sq. mm 500 nos.

ii) 185 Sq. mm 700 nos.

iii) 240 Sq. mm 500 nos.

iv) 300 Sq. mm 1000 nos.

12. Aluminium Binding Wire Quantity

EC grade hard drawn Aluminium rods of 3.53mm diameter 500 Kg.

complying with IEC : 1089/IS-398

TECHNICAL SPECIFICATION ALUMINIUM BINDING WIRE

Sl. Particulars Specified Bidders Offer

No.

1. Binding Wire IEC : 1089/IS-398

2. Chemical composition of Aluminium 99.5% minimum.

Binding Wire Copper, silicon and iron

0.5% maximum.

3. The surface of the wire shall be

smooth and free from all

irregularities and imperfections.

Its cross section shall closely

approximate that of a true circle.

4. Diameter of Wire (mm)

Minimum 3.51

Nominal 3.53

Maximum 3.55

5. Weight of 26.45

wire kg/km

6. Breaking load (KN) 1.57

Specification: TN/3722/14.3.11/ Gr.B

24

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

13. Tinned Copper Fuse Quantity Size of T.C Fusing

in Kg. wire (dia. in current

Wire SWG /mm) (Approx.) in

Amp.

Annealed Tinned Copper Fuse Wire Specified by Specified by

conforming to IS: 9926/1981 of Capacity, Bidder Bidder

diameter in SWG & mm ,approximate

fusing current in Amp. mentioned

against tabulation of the following rating

:

i) 5 Amp. 100 Kg.

ii) 10 Amp. 200 Kg.

iii) 63 Amp 250 Kg.

iv 102 Amp. 250 Kg

v) 200 Amp. 200 Kg.

14. Kit-Kat Fuse Quantity

Kit Kat Fuse unit with porcelain base & carrier of

reputed brand complete with extended terminals as per

relevant ISS : 2086/1993, Amendment-I of following

ratings:

i) 300 Amp. 500 nos.

ii) 400 Amp. 700 nos.

15.i) 33 KV Danger Board Quantity

500nos.

ii) 11 KV Danger Board Quantity

1310 nos.

Specification: TN/3722/14.3.11/ Gr.B

25

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

ECHNICAL SPECIFICATION 33KV/ 11KV DANGER BOARD

Sl.No. Particulars Specified Bidders Offer

1. Design of Danger plate IS: 2551/1982

shall be as per

2. Letters and Bone skulls Red Vitreous

marks Enameled

3. Back Ground White Vitreous

Enameled

4. Back Side Black Vitreous

Enameled

5. Material 1.6mm Thick Mild

Steel Plate

6. Letter Language Oriya / English / Hindi

7. 2 nos of 2mm Thick

lead washer and 2 nos of

6mm dia. Bolts and Nuts

to be supplied with each

number plate

8. Drawing Enclosed

Name & Signature of tenderer with seal

NOTE: -

1. On asking, after opening of tenders , the qualified bidders should be submitted specific

samples to the SDO, Stores for finalization of the Tender.

2. The Manufacturer and Authorized Dealer of reputed company shall be given

priority on production of Documentary Evidence.

3. The material when ordered should be dispatched to the Stores Balasore by Road

Transport.

4. Tenderer should put their signature with seal in all the above pages.

5. The undersigned reserves the right to reduce or increase the quantity at time of

placing orders and right to reject any or all quotations without assigning any

reason thereof.

6. Price variation clause is not allowed.

General Manager (Works)

NESCO, Balasore.

Specification: TN/3722/14.3.11/ Gr.B

26

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

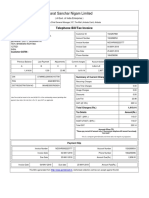

Price Schedule

GROUP - B

Excise Duty Rs. (@

Sale Tax/ VAT Rs.

Total Landed Price

Total Amount in

Entry Tax Rs. (@

Offered quantity

Description of

Unit Ex-works

materials

Sl. No.

(@ …..%)

Freight &

Insurance

…..%)

…. %)

Total

price

(Rs.)

Unit

Rs.

1. Single phase transformer No

mounting bracket.

2. i) 33 KV ‘V’ cross arm (MS)

ii) 11 KV ‘V’ cross arm(MS)

iii) LT 3ph 4 wire cross arm

iv) LT 3ph 5 wire cross arm

3 i) Back clamp for 33 KV ‘V’

cross arm.

ii) Back clamp for 11 KV ’V’

cross arm.

iii) Back clamp for LT cross

arm.

iv)

HT stay set side clamp

4. 11 KV Pole Top bracket

5. LT spacers

i) Suitable for 1-ph,2w

ii) Suitable for 3-ph,3w

iii) Suitable for 3-Ph, 4w

iv) Suitable for 3-ph, 5w

6 i) 11 KV GI pin

ii) LT GI pin

7 i) 33 KV H/W fittings(B&S)

ii) 11KV H/W fittings (T&C)

8 MS Nuts & Bolts

i) 16x40 mm

ii) 16x125mm

Specification: TN/3722/14.3.11/ Gr.B

27

NORTH EASTERN ELECTRICITY SUPPLY COMPANY OF ORISSA LIMITED

iii) 16x150mm

iv) 16x175mm

v) 16x200mm

vi) 16x225mm

vii) 16x250mm

viii) 16x275mm

ix) 16x300mm

x) 16x350mm

9. 16 mm LT Stay Set

10. 7/12 SWG G.I Stay wire

11. Aluminium cable socket

i) 120 mm²

ii) 185 mm²

iii) 240 mm²

iv) 300 mm²

12. Aluminium binding wire

13. Tinned Copper Fuse Wire

i) 5 Amp.

ii) 10 Amp.

iii) 63 Amp.

iv) 102 Amp.

v) 200 Amp.

14. Kit-Kat Fuse

i) 300 Amp

ii) 400 Amp.

15. i) 33 KV Danger Board

ii) 11 KV Danger Board

Name and Signature

of the Tenderer with Seal

Specification: TN/3722/14.3.11/ Gr.B

28

You might also like

- Gym Area Boq For Nri Club HouseDocument5 pagesGym Area Boq For Nri Club HouseSantosh ThakurNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Current Carrying Capacity of Overhead Transmission Line ACSR ConductorDocument8 pagesCurrent Carrying Capacity of Overhead Transmission Line ACSR Conductorrgoyal200867% (6)

- Chinnamasta Sadhana PDFDocument1 pageChinnamasta Sadhana PDFSayan Majumdar100% (2)

- Electrical Boq for Sulphuric Handling at EnclosureDocument2 pagesElectrical Boq for Sulphuric Handling at EnclosureKrishNo ratings yet

- Proposed Prices ForPGCIL - MonubolluDocument4 pagesProposed Prices ForPGCIL - MonubolluRaghavendar ReddyNo ratings yet

- Schedule-I (Price & Quantity)Document10 pagesSchedule-I (Price & Quantity)Pratik987No ratings yet

- Volume IIpart IIItechnicalspecificationDocument245 pagesVolume IIpart IIItechnicalspecificationtejzabNo ratings yet

- Rhomboidal Steel Wire Rope Net Panels SpecificationDocument5 pagesRhomboidal Steel Wire Rope Net Panels SpecificationSOMNATH JANANo ratings yet

- Schedule of QuantityDocument9 pagesSchedule of Quantityexecutive engineerNo ratings yet

- Bill of Quantity Sub Station & External Electrification Work S No Description of Item Unit Qty Rate Amount (RS)Document26 pagesBill of Quantity Sub Station & External Electrification Work S No Description of Item Unit Qty Rate Amount (RS)haider ahmedNo ratings yet

- Earthing Boq DapaongDocument4 pagesEarthing Boq DapaongCam HomeNo ratings yet

- Providing Lift EstimateDocument11 pagesProviding Lift EstimateTapan MishraNo ratings yet

- Construction of 33/11 KV Substation in HardoiDocument10 pagesConstruction of 33/11 KV Substation in HardoiRicky ChangNo ratings yet

- WPMSFILES 3414004606f1Document3 pagesWPMSFILES 3414004606f1sse power ws bknNo ratings yet

- PROFORMA OF SCHEDULES ELECTRICAL INSTALLATIONDocument13 pagesPROFORMA OF SCHEDULES ELECTRICAL INSTALLATIONAmit SharmaNo ratings yet

- SOW & Price - IBS Works S N Activity Description UOM RF ServicesDocument8 pagesSOW & Price - IBS Works S N Activity Description UOM RF ServicesmanojNo ratings yet

- Sr. No. - 19 Ward No - 18 Providing & Installing Electric Pole Near Bhagat Singh NagarDocument5 pagesSr. No. - 19 Ward No - 18 Providing & Installing Electric Pole Near Bhagat Singh Nagarnajuka ghodvindeNo ratings yet

- Specification For 33kV SwitchgearDocument2 pagesSpecification For 33kV SwitchgearSudharsan SDNo ratings yet

- Deogarh Court Boq Garden LightDocument7 pagesDeogarh Court Boq Garden Lighttsadkans59No ratings yet

- Construction of District Court Complex Electrical WorksDocument76 pagesConstruction of District Court Complex Electrical WorkssunilrauloNo ratings yet

- SOSOHbyUGMD MJsectionDocument18 pagesSOSOHbyUGMD MJsectionSushant RathiNo ratings yet

- Price ScheduleDocument12 pagesPrice ScheduleAkd DeshmukhNo ratings yet

- BOQ For PRMS Instrumentation, Electrical & Automation Job B.O.Q Project: PRMS Job, Visakhapatnam Steel PlantDocument31 pagesBOQ For PRMS Instrumentation, Electrical & Automation Job B.O.Q Project: PRMS Job, Visakhapatnam Steel Plantkoushik42000No ratings yet

- Cross Arm Galvanized StandardDocument19 pagesCross Arm Galvanized StandardprabathnilanNo ratings yet

- Galsi RRIDocument56 pagesGalsi RRISourendra KaranNo ratings yet

- Techinical Specification For 11 KV XLPEDocument14 pagesTechinical Specification For 11 KV XLPEVennila MAHADEVANNo ratings yet

- Supply Erection & CommissioningDocument5 pagesSupply Erection & CommissioningChethan GowdaNo ratings yet

- BOQ ElectricalDocument2 pagesBOQ ElectricalSachin ShindeNo ratings yet

- Annexure 2Document2 pagesAnnexure 2Anoop DamodaranNo ratings yet

- Natsteel BRCDocument8 pagesNatsteel BRClwin_oo2435No ratings yet

- 35MW plant's 110kV electrical packageDocument32 pages35MW plant's 110kV electrical packageganesh_dgNo ratings yet

- Electric Fencing bill of MalerkotlaDocument14 pagesElectric Fencing bill of MalerkotlaSumit gargNo ratings yet

- Electrical Estimate: SL - No Electrical SR 2018-19, P.No. & Item Nos. Unit Qty., Rate AmountDocument19 pagesElectrical Estimate: SL - No Electrical SR 2018-19, P.No. & Item Nos. Unit Qty., Rate AmountshivakumarNo ratings yet

- 24mw MSW Based Power Plant Boq - r0Document5 pages24mw MSW Based Power Plant Boq - r0pvpavan100% (1)

- PART-IV ELECTRICAL WORKS APWD Schedule of Rate 2013-14Document17 pagesPART-IV ELECTRICAL WORKS APWD Schedule of Rate 2013-14sumita sinhaNo ratings yet

- Massanjore SCDA Building EstimateDocument47 pagesMassanjore SCDA Building Estimatesourendra prasad karanNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityRenieNo ratings yet

- Draft Barbed Wire Is CodeDocument7 pagesDraft Barbed Wire Is Codekavi_prakash6992No ratings yet

- BOQ Jabalpur - 6 LotDocument15 pagesBOQ Jabalpur - 6 Lotvipinkr_2000No ratings yet

- Tendernotice 2Document3 pagesTendernotice 2neilagxicarNo ratings yet

- 6.0 Electrical KumbhrajDocument70 pages6.0 Electrical KumbhrajFaisal KhanNo ratings yet

- talcher estimate detailsDocument1 pagetalcher estimate detailssouvikbesu89No ratings yet

- RATNA 7016: A Hydrogen Controlled Basic Coated Electrode For Welding High and Medium Tensile SteelsDocument1 pageRATNA 7016: A Hydrogen Controlled Basic Coated Electrode For Welding High and Medium Tensile SteelsiabdillahNo ratings yet

- EB BOQ for HP substation transformer installationDocument2 pagesEB BOQ for HP substation transformer installationAshok KumarNo ratings yet

- Schedule of Quantity: Indian Institute of Technology Kanpur Tender Notice No. 27/elect./2019Document6 pagesSchedule of Quantity: Indian Institute of Technology Kanpur Tender Notice No. 27/elect./2019pradeep tangiralaNo ratings yet

- Spec 11kV 3 Core CablesDocument5 pagesSpec 11kV 3 Core CablessasikalaNo ratings yet

- Project Subject DateDocument68 pagesProject Subject DateMohammad SaquibNo ratings yet

- Cross Arm Un Galvanized StandardDocument17 pagesCross Arm Un Galvanized StandardprabathnilanNo ratings yet

- 228 Specificationofworks Annexure AFinalDocument19 pages228 Specificationofworks Annexure AFinalRoshanNo ratings yet

- JMR Ksba20Document2 pagesJMR Ksba20Ashok KumarNo ratings yet

- L1-CHE-SPE-059 Hard-Drawn Copper Solid Dropper Wire 21.15mm 2Document6 pagesL1-CHE-SPE-059 Hard-Drawn Copper Solid Dropper Wire 21.15mm 2CK TangNo ratings yet

- Electrical BOQDocument22 pagesElectrical BOQSAI ASSOCIATENo ratings yet

- Boq For Lig & Ews FlatsDocument42 pagesBoq For Lig & Ews FlatsHiteshNo ratings yet

- Technical Specification of Lattice Steel PolesDocument9 pagesTechnical Specification of Lattice Steel PolesCalinB.ACNo ratings yet

- IS 2026,1977/75,1852/79 Etc or Equivalent IEC.)Document38 pagesIS 2026,1977/75,1852/79 Etc or Equivalent IEC.)Milan SapkotaNo ratings yet

- Electrical BOQDocument7 pagesElectrical BOQpavanNo ratings yet

- RMU, Transformer, Cable Installation for SubstationDocument7 pagesRMU, Transformer, Cable Installation for SubstationpavanNo ratings yet

- مواصفات اعمده كهرباء الضغط العاليDocument8 pagesمواصفات اعمده كهرباء الضغط العاليAL-Kafaji HaithamNo ratings yet

- Electrical WorksheetDocument19 pagesElectrical Worksheetnitin yadavNo ratings yet

- Works FormatDocument12 pagesWorks FormatnikithayagantiNo ratings yet

- Insights from Ramcharit ManasDocument1 pageInsights from Ramcharit ManasRajeshYadavNo ratings yet

- Setting Calculation for IDMT RelaysDocument2 pagesSetting Calculation for IDMT Relaysrefaate100% (2)

- Final Grid CodeDocument182 pagesFinal Grid CodeRajeshYadavNo ratings yet

- Substation Details Dec-12Document151 pagesSubstation Details Dec-12RajeshYadavNo ratings yet

- EconomicSurvey2013 14Document271 pagesEconomicSurvey2013 14RajeshYadavNo ratings yet

- Volume 3 - 2Document413 pagesVolume 3 - 2RajeshYadavNo ratings yet

- Conductor Parameters SI UnitsDocument17 pagesConductor Parameters SI UnitsRajeshYadavNo ratings yet

- Pusauli SLD PDFDocument1 pagePusauli SLD PDFRajeshYadavNo ratings yet

- WBSEB TUBULAR STEEL POLES TECHNICAL SPECIFICATIONDocument8 pagesWBSEB TUBULAR STEEL POLES TECHNICAL SPECIFICATIONVarun SharmaNo ratings yet

- FinalGridCode PDFDocument332 pagesFinalGridCode PDFRajeshYadavNo ratings yet

- Gumla Soil AnalysisDocument18 pagesGumla Soil AnalysisRajeshYadavNo ratings yet

- BANKADocument1 pageBANKARajeshYadavNo ratings yet

- Essel Infra & Smart Utilities: Online Reimbursement RequestDocument1 pageEssel Infra & Smart Utilities: Online Reimbursement RequestRajeshYadavNo ratings yet

- Interim Arrangements For Restoration of Barh Motihari Ckt-1 and Motihari-Gorakhpur Ckt-1Document1 pageInterim Arrangements For Restoration of Barh Motihari Ckt-1 and Motihari-Gorakhpur Ckt-1RajeshYadavNo ratings yet

- Mobile Feb18Document3 pagesMobile Feb18RajeshYadavNo ratings yet

- 2019 Part B DCHB RanchiDocument1 page2019 Part B DCHB RanchiRajeshYadavNo ratings yet

- NDCHR0002223777Document1 pageNDCHR0002223777RajeshYadavNo ratings yet

- Statutory Clearance: Total Remarks Power Lines Railway NH SH Forest-HR Forest-RJ Approval ReceivedDocument2 pagesStatutory Clearance: Total Remarks Power Lines Railway NH SH Forest-HR Forest-RJ Approval ReceivedRajeshYadavNo ratings yet

- Before The Himachal Pradesh Electricity Regulatory Commission, ShimlaDocument41 pagesBefore The Himachal Pradesh Electricity Regulatory Commission, ShimlaRajeshYadavNo ratings yet

- HP Commission Order on IQU Hydro Power EvacuationDocument3 pagesHP Commission Order on IQU Hydro Power EvacuationRajeshYadavNo ratings yet

- CM PPT 4 PrintDocument110 pagesCM PPT 4 PrintRajeshYadavNo ratings yet

- Andhra-Nogli Zone Power Infrastructure ProjectsDocument8 pagesAndhra-Nogli Zone Power Infrastructure ProjectsRajeshYadavNo ratings yet

- Manual de Autocad BasicoDocument17 pagesManual de Autocad Basicoinfected521No ratings yet

- CSC33 AgDocument80 pagesCSC33 AgRajeshYadavNo ratings yet

- 69-UP SmallDocument5 pages69-UP SmallarvindNo ratings yet

- 2011Document11 pages2011RajeshYadavNo ratings yet

- 2 Amendment No. 4Document18 pages2 Amendment No. 4RajeshYadavNo ratings yet

- D2 Pre-Board Prof. Ed. - Do Not Teach Too Many Subjects.Document11 pagesD2 Pre-Board Prof. Ed. - Do Not Teach Too Many Subjects.Jorge Mrose26No ratings yet

- Fuzzy Logic - Wikipedia PDFDocument69 pagesFuzzy Logic - Wikipedia PDFannie joseNo ratings yet

- Nurses Assigned in Covid-19 Isolation Facilities. in This ConnectionDocument4 pagesNurses Assigned in Covid-19 Isolation Facilities. in This ConnectionDan HizonNo ratings yet

- Silent SpringDocument28 pagesSilent Springjmac1212No ratings yet

- Text Detection and Recognition in Raw Image Dataset of Seven Segment Digital Energy Meter DisplayDocument11 pagesText Detection and Recognition in Raw Image Dataset of Seven Segment Digital Energy Meter DisplaykkarthiksNo ratings yet

- Lecture 9-EVENT BUDGETDocument19 pagesLecture 9-EVENT BUDGETAlbina AbilkairNo ratings yet

- Thompson Industrial Products Inc Is A DiversifiedDocument4 pagesThompson Industrial Products Inc Is A DiversifiedKailash KumarNo ratings yet

- Student Teaching Edtpa Lesson Plan TemplateDocument7 pagesStudent Teaching Edtpa Lesson Plan Templateapi-3531253350% (1)

- Mcquillin Murphy ResumeDocument1 pageMcquillin Murphy Resumeapi-253430225No ratings yet

- Lesson 1 Intro - LatinDocument11 pagesLesson 1 Intro - LatinJohnny NguyenNo ratings yet

- OF Ministry Road Transport Highways (Road Safety Cell) : TH THDocument3 pagesOF Ministry Road Transport Highways (Road Safety Cell) : TH THAryann Gupta100% (1)

- Times Leader 04-10-2013Document37 pagesTimes Leader 04-10-2013The Times LeaderNo ratings yet

- Dance Manual W. Learning Outcomes PDFDocument8 pagesDance Manual W. Learning Outcomes PDFJoshua Quijano LamzonNo ratings yet

- Revised Answer Keys for Scientist/Engineer Recruitment ExamDocument5 pagesRevised Answer Keys for Scientist/Engineer Recruitment ExamDigantNo ratings yet

- Review Activity For The Final Test - 6 Level: 1. Match Phrasal Verbs and Match To The MeaningDocument3 pagesReview Activity For The Final Test - 6 Level: 1. Match Phrasal Verbs and Match To The MeaningGabrielle CostaNo ratings yet

- TIA Portal v11 - HMI ConnectionDocument4 pagesTIA Portal v11 - HMI ConnectionasdasdasdasdasdasdasadaNo ratings yet

- Global GovernanceDocument20 pagesGlobal GovernanceSed LenNo ratings yet

- Module 1: Overview of Implementation of The NSTP (Activities)Document3 pagesModule 1: Overview of Implementation of The NSTP (Activities)RonnelNo ratings yet

- Brinker Insider Trading SuitDocument5 pagesBrinker Insider Trading SuitDallasObserverNo ratings yet

- Reviewer in Intermediate Accounting IDocument9 pagesReviewer in Intermediate Accounting ICzarhiena SantiagoNo ratings yet

- 5.3.2 Generation of Dislocations: Dislocations in The First Place!Document2 pages5.3.2 Generation of Dislocations: Dislocations in The First Place!Shakira ParveenNo ratings yet

- Modern Dental Assisting 11Th Edition Bird Test Bank Full Chapter PDFDocument37 pagesModern Dental Assisting 11Th Edition Bird Test Bank Full Chapter PDFRichardThompsonpcbd100% (9)

- ENTH 311 Course Video ReflectionDocument2 pagesENTH 311 Course Video ReflectionJeshua ItemNo ratings yet

- Plusnet Cancellation FormDocument2 pagesPlusnet Cancellation FormJoJo GunnellNo ratings yet

- Chrome Settings For CameraDocument6 pagesChrome Settings For CameraDeep BhanushaliNo ratings yet

- Dwnload Full Fundamentals of Human Neuropsychology 7th Edition Kolb Test Bank PDFDocument12 pagesDwnload Full Fundamentals of Human Neuropsychology 7th Edition Kolb Test Bank PDFprindivillemaloriefx100% (12)

- HDFDJH 5Document7 pagesHDFDJH 5balamuruganNo ratings yet

- Redminote5 Invoice PDFDocument1 pageRedminote5 Invoice PDFvelmurug_balaNo ratings yet

- Schumann Op15 No5 PsuDocument1 pageSchumann Op15 No5 PsuCedric TutosNo ratings yet