Professional Documents

Culture Documents

SRP - Flooded Battery Spec VF10516JDB PDF

Uploaded by

foufou79Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SRP - Flooded Battery Spec VF10516JDB PDF

Uploaded by

foufou79Copyright:

Available Formats

48 VOLT AND 125 VOLT

FLOODED LEAD-ACID BATTERIES

USED IN ELECTRICAL SUBSTATIONS

1. SCOPE

1.1 This specification covers the physical and electrical requirements for flooded, vented,

lead-acid, stationary batteries and racks, having ratings and accessories as detailed in

this document.

1.2 The vendor shall manufacture, test, package, and deliver the batteries described herein

with the required documentation to SRP’s specified warehouse location.

2. APPLICABLE STANDARDS

2.1 Except as modified by this specification; the batteries and battery racks shall be

designed, manufactured, and tested in accordance with the applicable requirements of

the latest ANSI, IEEE, NEMA, and UL standards.

2.2 The following specific standards shall apply except as modified herein:

2.2.1 IEEE-450, Recommended Practice for Maintenance, Testing and Replacement

of Large Lead Storage Batteries for Generating Stations and Substations

2.2.2 IEEE-484, Recommended Practice for Installation Design and Installation of

Vented Lead-Acid Batteries for Stationary Applications

2.2.3 IEEE-693, Recommended Practices for Seismic Design of Substations

2.2.4 IEEE-1578, Recommended Practice for Stationary Battery Electrolyte Spill

Containment and Management

3. SERVICE CONDITIONS

Typical service conditions are as follows:

3.1 Flooded battery installations are typically located inside a ventilated, climate controlled

control houses with dedicated battery rooms.

3.2 Temperature in battery installation areas is controlled within the following range: 80°F

maximum ambient, 65°F minimum ambient and 75°F average 24 hour ambient.

3.3 Relative humidity in battery installation areas is: 50% maximum ambient, 5% minimum

ambient, and 30% average 24 hour relative humidity.

3.4 Seismology: Battery installation racks specified herein shall be designed to conform to

IEEE Practices for Seismic Design of Substations, IEEE Standard 693. The seismic

design shall be per Annex J. The seismic level shall be classified as ‘Low Level’.

3.5 Altitude (feet above sea level): Less than 3,000 feet above sea level.

EXTENSIVE REVISIONS Page 1 of 8

Standard Material SUBSTATION MATERIAL ISSUE DATE: 08-03-92

Specifications

48 VOLT & 125 VOLT REV. DATE: 10-23-14

FLOODED LEAD-ACID BATTERIES

USED IN ELECTRICAL SUBSTATIONS APPROVAL: T.A. Keels

PROPRIETARY MATERIAL SM-260010 – 30 (5016215 – 5075340) SM-260010.doc

4. MANUFACTURER'S QUALIFICATIONS

4.1 Approved manufacturers shall have on file, with the Electric System Planning &

Engineering Department of Salt River Project (SRP) or shall submit with their bid, their

latest qualification test reports in accordance with the latest edition of the applicable

standards listed in Section 2.2 of this specification and as listed below:

4.1.1 8 hour capacity test report

4.1.2 Seismic qualification report

4.2 Any manufacturer who has not previously provided batteries and battery racks under

this specification or who proposes to furnish batteries and racks differing from that

supplied on previous orders shall submit copies of test reports in accordance with the

latest edition of the applicable standards listed in Section 2.2 of this specification and as

listed below:

4.2.1 8 hour capacity test report

4.2.2 Seismic qualification report

4.3 Manufacturers shall employ a documented, on-going process, of quality control and

continuous quality improvement, approved by SRP, to ensure the quality of incoming

materials and monitor the manufacturing process. Evidence of the quality assurance

program shall be submitted with the bid for SRP’s evaluation.

5. BATTERY DESIGN AND CONSTRUCTION REQUIREMENTS

5.1 General Design Requirements

5.1.1 Battery shall be designed for switchgear control applications and shall be

capable of meeting the performance ratings in Section 6, regardless of the amp-

hour rating as stated in this specification. Amp-hour ratings stated in this

specification are presented for item differentiation purposes only.

5.1.2 Battery shall have a design life of at least 20 years, assuming a maximum of 150

deep discharge cycles over the entire service life

5.1.3 Battery shall be comprised of a single series string. Parallel strings shall not be

allowed for the standard material sizes given in Section 6.

5.1.4 Each cell or jar shall contain a permanent label that indicates the battery type,

model, nominal Amp-Hour capacity at the 8 hour rate to 1.75vpc at 77 deg. F,

recommended float voltage, and nominal specific gravity. In addition, each cell

or jar shall be permanently marked with the Date Of Manufacture and specific

identification number of the cell.

5.1.5 The battery shall be equipped with catalyst recombination caps or other Engineer

approved method of gas recombination for minimizing venting/water loss. All

batteries purchased under this specification shall be so equipped or they will not

be considered.

EXTENSIVE REVISIONS Page 2 of 8

Standard Material SUBSTATION MATERIAL ISSUE DATE: 08-03-92

Specifications

48 VOLT & 125 VOLT REV. DATE: 10-23-14

FLOODED LEAD-ACID BATTERIES

USED IN ELECTRICAL SUBSTATIONS APPROVAL: T.A. Keels

PROPRIETARY MATERIAL SM-260010 – 30 (5016215 – 5075340) SM-260010.doc

5.1.6 The battery shall be designed to withstand a short circuit across the output

terminals for one minute without a failure of the jar, jar top, or post seals.

Manufacturer shall clearly state the short circuit rating of each battery size

supplied according to this specification.

5.1.7 The maximum weight of any single-cell jar shall not be more than 100 pounds.

75 pounds maximum weight per single-cell jar is preferred. The maximum

weight of any multi-cell jar shall not be more than 150 pounds.

5.2 Cell Design Requirements

5.2.1 Cell jars shall be constructed of one-piece molded high impact transparent

thermoplastic, with all walls of equal thickness and strength, with a mechanically

sealed top cover. Styrene-Acrylonitrile thermoplastic jars are preferred.

5.2.2 Cell jar tops shall be constructed of flame retardant material which can pass the

requirements in UL94-V0 and have an oxygen index of 28% or higher.

5.2.3 Cell jars shall be transparent to allow for visual inspection of plates, plate

separators, and electrolyte level. Cell jar shall have maximum and minimum

electrolyte level marks clearly visible from 2 sides of the jar.

5.2.4 Cell jars shall allow sufficient space for cell growth and sloughed material at the

bottom of the jar to prevent bridging.

5.2.5 Positive electrodes shall be constructed with a tubular grid design with a gauntlet

tube surrounding the positive grid. (OPzS type) Positive flat plate designs will

not be accepted for substation applications.

5.2.6 Battery plates shall be constructed from Lead-Calcium alloy. All lead alloys shall

have less than 2% Antimony content. Lead-Selenium alloys are also acceptable.

5.2.7 The electrolyte shall be an aqueous solution of sulfuric acid in water with a

nominal specific gravity of 1.240.

5.2.8 There shall be an ample reserve of electrolyte in the cell to minimize

maintenance.

6. BATTERY PERFORMANCE RATING

6.1 All batteries shall have capacities rated in Amp-Hours at 77°F (25° C) at the 8-hour

discharge rate to an end voltage of 1.75 VPC.

6.2 Batteries shall deliver a minimum of 90% of nameplate amp-hour capacity when

commissioned according to manufacturer’s instructions, and tested according to IEEE

standards at time of installation, and deliver 100% of nameplate amp-hours after three

months of float charging.

EXTENSIVE REVISIONS Page 3 of 8

Standard Material SUBSTATION MATERIAL ISSUE DATE: 08-03-92

Specifications

48 VOLT & 125 VOLT REV. DATE: 10-23-14

FLOODED LEAD-ACID BATTERIES

USED IN ELECTRICAL SUBSTATIONS APPROVAL: T.A. Keels

PROPRIETARY MATERIAL SM-260010 – 30 (5016215 – 5075340) SM-260010.doc

6.3 Batteries supplied under this specification shall consist of the following sizes and

ratings:

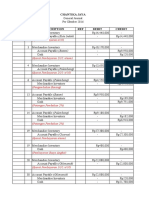

Flooded-Vented Battery - Standard Material Sizes

SRP Battery String Number of Jars Amp-Hour

1

Stock Code Nominal Voltage per String Rating

5077768 48 4 or 8 150

5077756 48 24 250

5077749 48 24 350

5077750 48 24 450

5077775 48 24 650

5077757 125 60 250

5077758 125 60 350

5077751 125 60 450

5077752 125 60 650

Note1 - Nominal Amp-Hour rating is based on an 8Hr discharge rate to 1.75VPC @ 77°F (25°C)

7. ACCESSORIES

7.1 The battery shall be supplied complete with the following: All necessary inter-cell

connecting links with holes properly drilled for ease of assembly, catalyst/gas re-

combiner caps for each cell, O-rings and gaskets as required.

7.2 All hardware fasteners shall be either metric or SAE size. Batteries and racks supplied

with mixed hardware sizes are not acceptable and shall be returned. Manufacturer shall

state in its proposal whether it will supply metric or SAE hardware for both the battery

and the rack.

7.3 The following spare parts shall be provided with EACH battery bank:

(1) Set of Cell Numbers

(2) Spare Insulated Post Covers

(1) Spare Catalyst Vent Caps

(2) Spare Inter-cell Connectors

(2) Spare Battery Terminal Screws

(2) Spare Wave Washers

(2) Spare Terminal Lugs

7.4 A copy of the manufacturer recommended battery installation procedures, owner’s

manual, applicable MSDS, and assembly drawings shall be included with every battery

and rack.

EXTENSIVE REVISIONS Page 4 of 8

Standard Material SUBSTATION MATERIAL ISSUE DATE: 08-03-92

Specifications

48 VOLT & 125 VOLT REV. DATE: 10-23-14

FLOODED LEAD-ACID BATTERIES

USED IN ELECTRICAL SUBSTATIONS APPROVAL: T.A. Keels

PROPRIETARY MATERIAL SM-260010 – 30 (5016215 – 5075340) SM-260010.doc

7.5 The accessories and spare parts for each battery shall be clearly labeled, packaged

separately, and be shipped together with the battery as required by the packaging and

shipping requirements of this specification.

7.6 Battery price provided shall include the cost of the accessories listed in herein.

8. BATTERY RACK

8.1 Battery rack(s) shall be either a 2-step, a 2-tier, or a 2-step & 2-tier design and shall

conform to the IEEE standards listed in section 2. The rack shall be designed with front

and back rails so that batteries will not become dislodged if the rack is bumped. All 2-

tiered racks shall have bracing, similar to a light duty seismic rack design.

8.2 Battery rack(s) shall be of steel construction and shall be painted or powder coated with

acid resistant epoxy not less than 3 mills thick. Racks are to include plastic channel rail

insulation, steel angle support frames, sway braces and all necessary hardware.

8.3 Battery rack(s) for flooded cells shall be constructed so as to allow access for viewing

electrolyte level of all cells from one side and for testing and maintenance while all cells

are in place. Racks shall be designed for cell installation such that edges of plates are

visible from the front.

8.4 Two-tiered battery racks shall be designed with sufficient height to accommodate the

installation and operation of a catalyst recombination cap, and allow for cell removal

from the lower tier without tipping the cell, and without disassembly of the rack.

8.5 Vendor shall provide with the rack the correct length cables appropriate for

interconnecting battery rows and tiers within the rack. Connecting cables between rows

and tiers shall be insulated 3/0 AWG copper welding cable, at a minimum.

8.6 Battery rack(s) for 48 volt battery shall conform to the following total maximum combined

space limitations: 7 feet long, 2 1/2 feet wide, and 5 feet high, or as specified.

8.7 Battery rack(s) for 125 volt battery shall conform to the following maximum total

combined space limitations: 12 feet long, 2 1/2 feet wide and 5 feet high, or as

specified.

8.8 Battery racks and spill containment system shall be quoted and ordered as a separate

line item from the battery when a rack and spill containment system is specified.

8.9 Battery rack(s) shall be packaged individually, be clearly labeled, and shipped as

required by the packaging and shipping requirements of this specification. Each rack

shall come with complete, intelligible, assembly drawings.

EXTENSIVE REVISIONS Page 5 of 8

Standard Material SUBSTATION MATERIAL ISSUE DATE: 08-03-92

Specifications

48 VOLT & 125 VOLT REV. DATE: 10-23-14

FLOODED LEAD-ACID BATTERIES

USED IN ELECTRICAL SUBSTATIONS APPROVAL: T.A. Keels

PROPRIETARY MATERIAL SM-260010 – 30 (5016215 – 5075340) SM-260010.doc

8.10 All equipment specified herein shall be designed to conform to IEEE Standard 693 -Annex

J. The seismic qualification level for Arizona shall be considered ‘Low Level’.

8.11 A spill containment system per IEEE-1578 shall be quoted with every flooded battery rack.

The spill containment system shall include a free-standing tray with electrolyte absorbing

and neutralizing agents. The spill containment system shall be classified as non-

flammable and shall be NFPA and UL-94 compliant.

8.12 This specification applies to the following SRP standard material racks for flooded-vented

lead-acid batteries:

Racks for Flooded-Vented Batteries - Standard Material Sizes

Battery String Size Number of Jars Battery Rack Configuration

Voltage Capacity per String 2-Step 2-Tier 2-Step/2-Tier

150 4 or 8 NA

250 24

48 350 24

450 24

650 24

250 60

350 60

125

450 60

650 60

9. PACKING AND SHIPPING

9.1 All materials and articles shall be prepared for shipment in such manner as to protect

them from damage and allow for easy sorting of the packages upon arrival. Equipment

damaged in transit shall not be accepted and shall be returned.

9.2 All packages shall clearly display the SRP Purchase Order #, and Item # from the PO on

the outside of the packaging. Each group of packages, consisting of battery, rack, and

accessories, shall be clearly labeled so that upon receipt, the different groups can be

readily sorted and assembled.

9.3 All packages containing batteries shall be strapped to a new forklift pallet and secured in

all three axis (X,Y,& Z) with non-metallic pallet straps.

9.4 Each battery shall be packaged separately. Heavy corrugated cardboard or foam or

other shock absorbing material shall be placed between the battery and the pallet, and

between each cell or jar.

9.5 One set of accessories shall be packaged separately and shipped with each battery.

When a battery rack is specified it shall be packaged separately and shipped with each

EXTENSIVE REVISIONS Page 6 of 8

Standard Material SUBSTATION MATERIAL ISSUE DATE: 08-03-92

Specifications

48 VOLT & 125 VOLT REV. DATE: 10-23-14

FLOODED LEAD-ACID BATTERIES

USED IN ELECTRICAL SUBSTATIONS APPROVAL: T.A. Keels

PROPRIETARY MATERIAL SM-260010 – 30 (5016215 – 5075340) SM-260010.doc

battery.

9.6 Each battery and rack shall be shipped complete. Partial shipments and/or short

shipments shall not be accepted.

9.7 Batteries requested under terms of a contract shall be prepared and shipped within two

weeks of receipt of a release to ship notification from SRP.

9.8 All bidders shall submit examples of their packaging (either drawings or photographs) to

demonstrate compliance with the above requirements as part of their proposal. Failure

to comply with the packaging and shipping provisions of this specification shall

constitute grounds for cancelation of the purchase contract.

10. WARRANTIES

10.1 Battery and rack(s) shall be warranted free from defects for 5 years from the date of

shipment. Defective cells and components shall be replaced free of charge within this

time.

10.2 Battery post sealing system and jar top shall be warranted free from defects, cracking,

or electrolyte leaks for a period of 10 years from date of manufacturer.

10.3 Battery shall be designed and warranted to deliver 80% of rated capacity for 20 years

for flooded-vented batteries from the date of shipment from the factory. The vendor

must provide a prorated adjustment to the warranty based on remaining service life

toward the purchase of another battery. A copy of the manufacturer’s warranty shall be

submitted with the bidder’s proposal. Alternate warranty provisions may be considered.

11. RECYCLING

All components of the batteries provided under this specification shall be recyclable using

standard recycling equipment and techniques. This includes the lead, acid, and plastic

components. Documentation verifying the recyclability of all battery components shall be supplied

on all proposals.

EXTENSIVE REVISIONS Page 7 of 8

Standard Material SUBSTATION MATERIAL ISSUE DATE: 08-03-92

Specifications

48 VOLT & 125 VOLT REV. DATE: 10-23-14

FLOODED LEAD-ACID BATTERIES

USED IN ELECTRICAL SUBSTATIONS APPROVAL: T.A. Keels

PROPRIETARY MATERIAL SM-260010 – 30 (5016215 – 5075340) SM-260010.doc

12. REQUIRED TECHNICAL DATA

12.1 The following information shall be supplied with each bid proposal:

12.1.1 Jar or block dimensions in inches

12.1.2 Weight per jar in pounds

12.1.3 Number of jars per step and/or tier on a rack

12.1.4 Fully dimensioned rack drawings with dimensions in inches

12.1.5 Weight of each battery rack (fully loaded) in pounds

12.1.6 List of accessories and spare parts to be provided

12.1.7 Cell jar material and oxygen rating

12.1.8 Documentation describing the catalyst recombination cap

12.1.9 Documentation describing the spill containment system

12.1.10 Quality assurance program details

12.1.11 Battery recyclability documentation

12.1.12 Warranty documentation for battery and rack

12.2 Drawings in AutoCAD or Microstation format shall be supplied which shall include

projected floor space, overall height, terminal pad heights, foundation requirements,

center of gravity, assembly, and anchor bolt drawings. The vendor shall submit this

information within 30 days after a receipt of order.

12.3 Certified test reports (design life and performance tests for the type and size of cell)

showing that the batteries to be supplied can meet or exceed the performance ratings

published by the manufacturer. The vendor shall submit certified test reports within 30

days after a receipt of order.

12.5 Required documentation shall be submitted to:

US Postal Service Courier

Document Coordinator Document Coordinator

Mail Station XCT317 Mail Station XCT317

Salt River Project OR Salt River Project

P. O. Box 52025 2727 East Washington St.

Phoenix, AZ 85072-2025 Phoenix, AZ 85034-1403

EXTENSIVE REVISIONS Page 8 of 8

Standard Material SUBSTATION MATERIAL ISSUE DATE: 08-03-92

Specifications

48 VOLT & 125 VOLT REV. DATE: 10-23-14

FLOODED LEAD-ACID BATTERIES

USED IN ELECTRICAL SUBSTATIONS APPROVAL: T.A. Keels

PROPRIETARY MATERIAL SM-260010 – 30 (5016215 – 5075340) SM-260010.doc

You might also like

- 3 Phase Short Circuit PDFDocument124 pages3 Phase Short Circuit PDFAriel ToroNo ratings yet

- Microgrid Lessons Learned: Will Edwards (SEL Engineering Services Division)Document24 pagesMicrogrid Lessons Learned: Will Edwards (SEL Engineering Services Division)Divya NaikNo ratings yet

- I-SMART: Integrated Curriculum For Smart Power Engineering: The Ohio State UniversityDocument1 pageI-SMART: Integrated Curriculum For Smart Power Engineering: The Ohio State Universityfoufou79No ratings yet

- Ml11238a234 PDFDocument21 pagesMl11238a234 PDFfoufou79No ratings yet

- Effects of Ac Ripple Current On Vrla Battery LifeDocument8 pagesEffects of Ac Ripple Current On Vrla Battery Lifebomberl3k4No ratings yet

- General-Purpose Relays: Competitive Cross Reference CC04901003EDocument16 pagesGeneral-Purpose Relays: Competitive Cross Reference CC04901003Efoufou79No ratings yet

- ConEd Profile Casestudy PDFDocument3 pagesConEd Profile Casestudy PDFfoufou79No ratings yet

- Wonderlogix Studio User Guide PDFDocument130 pagesWonderlogix Studio User Guide PDFchdiNo ratings yet

- 103-18 Appendix A Autotransformer 240 MVA Spec 2018-01-25Document31 pages103-18 Appendix A Autotransformer 240 MVA Spec 2018-01-25foufou79No ratings yet

- 2018 04 16 Tertiary Winding in Transformers PRCDocument17 pages2018 04 16 Tertiary Winding in Transformers PRCSaurav Kafle100% (1)

- Chapter 2 Circuit Breaker Mechanical Operation and Operation ML11238A227 PDFDocument14 pagesChapter 2 Circuit Breaker Mechanical Operation and Operation ML11238A227 PDFclaudia_baca_3No ratings yet

- ML11238A234Document21 pagesML11238A234foufou79No ratings yet

- Toa4 Basic Features 2 PDFDocument24 pagesToa4 Basic Features 2 PDFfoufou79No ratings yet

- Maintaining Power Circuit BreakersDocument14 pagesMaintaining Power Circuit BreakersChaikrit ChinaditNo ratings yet

- Insulator TestingDocument28 pagesInsulator TestingadnanNo ratings yet

- Netzwerkloesungen Mit IEC 61850-3 - IEEE 1613 Von MoxaDocument68 pagesNetzwerkloesungen Mit IEC 61850-3 - IEEE 1613 Von MoxaJessica DeanNo ratings yet

- Advanced Distribution Management - IT & OT ConvergenceDocument16 pagesAdvanced Distribution Management - IT & OT Convergencefoufou79No ratings yet

- Section 1.1 Per Unit System: 1 Power DistributionDocument4 pagesSection 1.1 Per Unit System: 1 Power Distributionfoufou79No ratings yet

- General Publication 100 g102 PDFDocument104 pagesGeneral Publication 100 g102 PDFfoufou79No ratings yet

- Calisto - Brochure and Technical SpecificationsDocument12 pagesCalisto - Brochure and Technical SpecificationsSlobodan PetrovicNo ratings yet

- R-DGA Quick Start Guide 20190627 2Document12 pagesR-DGA Quick Start Guide 20190627 2foufou79No ratings yet

- Duke EnergyDocument4 pagesDuke Energyfoufou79No ratings yet

- Spec Calisto501901 EN 072017 20170706162030Document4 pagesSpec Calisto501901 EN 072017 20170706162030foufou79No ratings yet

- ArrestersDocument4 pagesArrestersSibtain Ul HassanNo ratings yet

- ADI 0012am 1 Substation Automation SystemDocument33 pagesADI 0012am 1 Substation Automation Systemfoufou79No ratings yet

- IEEE 2014 Paper - Infrared Windows Applied in Switchgear Assemblies - Taking Another Look PDFDocument6 pagesIEEE 2014 Paper - Infrared Windows Applied in Switchgear Assemblies - Taking Another Look PDFAnonymous V6y1QL6hnNo ratings yet

- DMV Duplicate Title ApplicationDocument2 pagesDMV Duplicate Title Applicationfoufou79100% (1)

- Rely I Protection of FeedersDocument47 pagesRely I Protection of Feedersfoufou79No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Partnership Formation EssentialsDocument2 pagesPartnership Formation EssentialsRodolfo ManalacNo ratings yet

- Display Kit GuideDocument9 pagesDisplay Kit GuidemfabianiNo ratings yet

- Communicating Corporate Social Responsibility: Perspectives and PracticeDocument26 pagesCommunicating Corporate Social Responsibility: Perspectives and PracticeAndiMuhammadIrwanNo ratings yet

- ImcfDocument64 pagesImcfHʌɩɗɘʀ AɭɩNo ratings yet

- Playlist ArchacDocument30 pagesPlaylist ArchacMartin JánošíkNo ratings yet

- Donate Your Corneas PleaseDocument19 pagesDonate Your Corneas PleaseRahul PinnamaneniNo ratings yet

- Local Budget Memorandum No. 75 PDFDocument21 pagesLocal Budget Memorandum No. 75 PDFArnold ImbisanNo ratings yet

- Occurrence of Black Soldier Fly HermetiaDocument2 pagesOccurrence of Black Soldier Fly HermetiaMarcelo Geraldo TeixeiraNo ratings yet

- TANG - Remedial Law Activity 4Document23 pagesTANG - Remedial Law Activity 4Nathaniel Niño TangNo ratings yet

- Prop. Solution For India Asset and Tax DepreciationDocument8 pagesProp. Solution For India Asset and Tax DepreciationJit Ghosh100% (1)

- Manual Aeroccino 3Document30 pagesManual Aeroccino 3UltrabetoNo ratings yet

- Page 34-45 BLK PicDocument12 pagesPage 34-45 BLK PicMihir MehraNo ratings yet

- WEG Rectifier User Manual 10005817193 enDocument37 pagesWEG Rectifier User Manual 10005817193 endjunaedi djNo ratings yet

- Aurora Diesel Engine Driven FP SelectionDocument48 pagesAurora Diesel Engine Driven FP Selectionsyed mustafa aliNo ratings yet

- A Tidy GhostDocument13 pagesA Tidy Ghost12345aliNo ratings yet

- Rule 11-Time To File Responsive PleadingsDocument6 pagesRule 11-Time To File Responsive PleadingsAnne DemNo ratings yet

- Torts - Damages by UribeDocument4 pagesTorts - Damages by UribeJolas BrutasNo ratings yet

- 131b0314 - Im Danffos VLT ManualDocument108 pages131b0314 - Im Danffos VLT ManualMery Helen Barraza DelgadoNo ratings yet

- Life of A Loan, GM FinancialDocument12 pagesLife of A Loan, GM Financialed_nycNo ratings yet

- PT Amar Sejahtera General LedgerDocument6 pagesPT Amar Sejahtera General LedgerRiska GintingNo ratings yet

- Approved Local Government Taxes and Levies in Lagos StateDocument5 pagesApproved Local Government Taxes and Levies in Lagos StateAbū Bakr Aṣ-Ṣiddīq50% (2)

- Data Sheet Sylomer SR 28 ENDocument4 pagesData Sheet Sylomer SR 28 ENlpczyfansNo ratings yet

- QRHDocument12 pagesQRHNwe OoNo ratings yet

- Ausat Final Set 1Document13 pagesAusat Final Set 1Rajiv RanjanNo ratings yet

- Self-Certification and Medical Examiner's Certificate ReportingDocument2 pagesSelf-Certification and Medical Examiner's Certificate ReportingcatrutterNo ratings yet

- PahaDocument2 pagesPahaSeyfeAlemayehuNo ratings yet

- FINAL REPORT WV Albania Buiding Futures PotentialDocument30 pagesFINAL REPORT WV Albania Buiding Futures PotentialVasilijeNo ratings yet

- Docu31515 VNXe3100 VNXe3150 Replacing A Solid State Disk (SSD)Document6 pagesDocu31515 VNXe3100 VNXe3150 Replacing A Solid State Disk (SSD)john malloyNo ratings yet

- Effect of Organization Climate On Innovative Work BehaviourDocument8 pagesEffect of Organization Climate On Innovative Work BehaviourRaja .SNo ratings yet

- Complete Bar Bending Schedule For Different Structure (Free E-Book)Document20 pagesComplete Bar Bending Schedule For Different Structure (Free E-Book)Prakhar PatidarNo ratings yet