Professional Documents

Culture Documents

CFD Investigation of 660MW Boiler Combustion

Uploaded by

Abdu M. HabsyiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CFD Investigation of 660MW Boiler Combustion

Uploaded by

Abdu M. HabsyiCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

CFD Investigation of Combustion in 660MW Tangential Fired

Boiler

Mr. P. V. Joshi,

Mr. AshishFande,

Professor,

PG SCHOLAR,

Department of Mechanical Engineering Department of Mechanical Engineering

S.S.C.E.T.,BHILAI S.S.C.E.T.,BHILAI

CHHATISGARH, India

Mr. Sachin Gabhane Mr. Mukesh Kumar Sahu

Assist. Manager At Adani Power Plant. Department of Mechanical Engineering

TIRORA.INDIA. S.S.C.E.T.,BHILAI

CHHATISGARH, India

RT

Abstract

IJE

Studies intothe effects of operating conditions in a tangential fired furnace using

commercial code FLUENT is explained in this paper. A 3-D combustor model is used to

determine the temperature, velocity and other thermal characteristics like O2mass fraction,

CO2mass fraction for a typical660 MW utility boiler firing medium volatile coal. Particle

trajectories are studied to identify the causes of operational problems such as fouling on burners,

and temperatures achieved in various parts of the boiler during the combustion process. In this

project peripheral air concentric to the primary air with coal in the furnace temperature pattern is

considered. For these we have done a numerical study of flow of reactive gas mixture with

pulverized coal combustion occurring in tangential fired furnace. Study Model calculations

showed good agreement with experimental measurements plant data.The experience obtained

Using these CFD model studies can improve the operation of a boiler by varying its flow

parameter inside the boiler, which built a foundation for the boiler operating expert system.

Keywords: tangential fired furnace, Grid generation, CFD, Turbulent flow, Multiphase flow,

Particle trajectories, temperature in various zones of boiler, species like O2&CO2distribution.

IJERTV3IS10356 www.ijert.org 892

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

1. Introduction

In recent years the interest on performance optimisation of large utility boilers has

become very relevant. All the optimisation thinking are directed at extending their lifetime, for

increasing the thermal efficiency and reducing the pollutant emissions from combustion.

Moreover, efficient use of pulverised coal is crucial to the utility industry. To get higher

combustion efficiency, the major influencing factors such as the particle size distribution, gas

and particle temperatures, local heat release, local oxygen concentration, kinetic parameters for

coal de-volatilization and char oxidation, char properties should be understood thoroughly [1,2].

In an engineering practice, it is very difficult to study the combustion processes of various kinds

of combustibles directly in the boiler than constructing real boilers and trying to these

characteristics, computers are used to experiment with models of the boilers.

One of the techniques to visualise parametric effects in boilers is computational fluid

dynamics (CFD) modelling, which potentially can be an accurate and cost effective tool. Over

the last 20 years, the CFD has gained its reputation of being an effective tool in identifying and

solving problems related to pulverized coal combustion [3–4]. In particular, it can provide

RT

insights into the combustion characteristics of unfamiliar coals and for this reason has been

IJE

extensively applied to evaluate the combustion performance of coals in bench-, pilot-and full-

scale furnaces.

In the present study, an attempt has been made to simulate and visualise the furnace

operation, based on parameters of interest to the combustion process through CFD modelling.

These parameters include temperatures achieved in various parts of the boiler, particle residence

time, particle velocity, O2and CO2distribution within the furnace. This paper concentrates on the

prediction of furnace performance for different boiler operating conditions. The boiler geometry

and operating conditions along with the mathematical model used are detailed in the following

section. Results simulated are based on real cases (different operating conditions used in the

industry), but the data sources have necessarily been disguised to the extent that industry

proprietary concerns are not infringed. It must be mentioned that the verification of the

computational simulations are expensive to obtain, but even if the user has experimental data

available, the comparison between these data and predictions leaves the user uncertain about

both the errors in the model and experimental data. Nevertheless, using the experience obtained

by a CFD model can significantly improve the operation of a boiler, regarding stability and local

material temperature of boiler.

IJERTV3IS10356 www.ijert.org 893

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

2.Furnace geometry and operating conditions

The boiler geometry is to be constructed in such a way that depending upon its

dimension as height, length and depth from ground .The width of the furnace is

19824mm,whilethe depth is 17640mm. Elevation of the water wall lower header is 9000mm;

elevation of centerline of roof is 77800mm, and elevation of the main girder bottom is

85700mm. Thirty two burners are arranged in the corner of boiler. Total 8 mills are located for

coal with primary air firing each mill having four burners and the mill are spaced at the certain

distance as 972.4 mm. with each other. In between mill there is some provision for firing

secondary air .Boiler combustion system is design according to medium speed pulverizers and

cold primary air direct-fired system. 32 direct air burners are arranged at the lower four corners

of the furnace in 8 layers, and power coal and air are loaded through the four corners to burn in

the furnace tangentially.The Nozzle center elevation of the top row of burner is 39780mm and is

20020mm far from the platen bottom. The Nozzle center elevation of the bottom row of burner

is 26150mm and is 5131mm far from the furnace hopper corner. Technology, quick ignition

RT

pulverized coal nozzle etc. burners in the corners. The velocity of coal+air is shown in table

1[9].

IJE

On upper part of the furnace platen superheater and high temperature superheater are

arranged. Platen superheater, high temperature superheater and reheater are fixed by fluid cooled

spacer tube along the furnace width direction. A fluid cooled spacer tube is led out from the

backpass extending side wall lower header, converging with the main pipe before entering the

secondary desuperheater. Superheater steam temperature is controlled by coal-water ratio

adjustment and two-stage spray water. The primary desuperheater is located at the low

temperature superheater outlet piping, while the secondary one is at the platen Geometry and

distribution of inlet sections along the height of each corner of the furnace Superheating and two

reheating sections are located. Economizers are located in the rear pass of combustion gases.

The coal used in this boiler based on the proximate and ultimate analysis shown in table 2[9].The

complete set of three dimensional arrangement of boiler and side view of tangential fired boiler is shown

in fig. 1.

IJERTV3IS10356 www.ijert.org 894

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

(a) (b)

Fig. 1 (a) Three dimensional arrangement of boiler (b) side view of tangential fired boiler

Fig.2. shows in detail the arrangement of air and coal nozzles. Different inlet sections are

RT

represented, corresponding to the mixture of primary air and pulverized-coal (PA + PC), the

secondary air (SA) and also the fuel-oil used during start-up (FO). Surrounding the primary air

IJE

and pulverized-coal entrance, a narrow square ring also introduces a small flow of peripheral

secondary air. Different orientations can be imposed for the entering streams, separately for

primary air + pulverized-coal and for secondary air.

The boiler furnace geometry of the simulated boiler can be seen in Fig. 3. The

3dimensional geometry is created using Ansys workbench software. The meshed-geometry

contained 1,72,640 nodes with tetrahedral cells throughout the geometry .In order to make

correct quantitative predictions about ignition behavior, it is necessary that an appropriate

geometry is created with convenient meshing techniques. A more refined mesh is provided near

the burner and air inlet. About 50% to 60% of the project time is involved in creating the model

geometry. Primary and secondary air inlet details are taken according to the actual burner

dimensions. The swirl angle is not considered for the present study.

IJERTV3IS10356 www.ijert.org 895

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

RT

IJE

Fig.2. Vertical arrangement of pulverized coal burners

IJERTV3IS10356 www.ijert.org 896

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

Fig.3. Grided geometry of boiler

Operating condition for CFD simulation

Table 2.Main boiler operating conditions in boiler[9].

RT

1st Mill (In 2nd Mill(In 3rd Mill(In 4rth Mill

5th Mill(In

IJE

Case description Each Each Each (In Each

Each Burner)

Burner) Burner) Burner) Burner)

P.A.velocity(m/s) 24.6m/sec 24.6m/sec 24.6m/sec 24.6m/sec 24.6m/sec

& temperature (K) &343k &343k &343k &343k &343k

S.A velocity(m/s) 37m/sec 37m/sec 37m/sec 37m/sec 37m/sec

& temperature (k) & 598k & 598k & 598k & 598k & 598k

P.S.A velocity(m/s) 19 m/sec 19 m/sec 19 m/sec 19 m/sec 19 m/sec

& temperature(K) &598k &598k &598k &598k &598k

Total coal feed rate

3.47 3.47 3.47 3.47 3.47

(kg/s)

Calorific value 1.64e+07 1.64e+07 1.64e+07 1.64e+07 1.64e+07

WHERE,

P.A.For Primary Air Velocity.

S.A. For Secondary Air Velocity.

P.S.A.For Peripheral Secondary Air Velocity.

IJERTV3IS10356 www.ijert.org 897

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

Table 3. Proximate and ultimate analysis of the coal-fired during the tests[9].

Proximate analysis (% db) Ultimate analysis (% daf)

Moisture 17 Carbon 74.42

Ash content 4 Hydrogen 4.9

Volatile matter 37 Nitrogen 1.5

Fixed carbon 43 Sulfur 1.0

Total sulphure 0.83 Oxygen 18.13

3. Mathematical model

The mathematical model implemented here is totally based on the commercial CFD

code, FLUENT , where the gas flow is described by the time averaged equations of global mass,

momentum, enthalpy and species mass fraction. The equations, which are elliptic and three-

dimensional,were solved to provide predictions of the flow pattern, thermaland pollution

RT

characteristics of reacting flows inside amodel of an industrial boiler. Operating parameters

includethe air to fuel ratio, combustion air temperature and swirlangle. The governing equations,

IJE

turbulence model, theboundary conditions and the solution procedure are presented

in the following sections.

𝜕 𝜕𝑦 𝜕𝜙

𝜕𝑥 𝑗

𝜌𝑈𝑗 ∅ + 𝜌𝑢𝑗 ∅ = 𝜕𝑥 Γ𝜙 𝜕𝑥 + 𝜌𝑆∅ (1)

𝑗 𝑗

Where, ∅ is the dependent variable and uj is the velocity component along the coordinate

direction xj.𝜌is the fluid density; Γ𝜙 is the diffusion coefficient and 𝑆∅ is the source term.Eq. (1)

stands for the mass conservation equation when ∅ = 1; the momentum conservation equation

when ∅ is a velocity component; the energy equation when ∅ is the stagnation enthalpy; or the

transport equation of a scalar when ∅ is a scalar variable such as mixture fraction.

The standard k-ε turbulence model, single mixture fraction probability density function

(PDF) and the P1 radiation models are used in the present simulations. For the bulk of

engineering combustion systems the mixing process proceeds much more slowly than the

chemistry and as a result the mixing rate almost always determines the rate of combustion [6].

IJERTV3IS10356 www.ijert.org 898

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

Therefore, for the predominant industry case of „diffusion‟ or non-premixed combustion for

example, it normally suffices to solve a conservation equation for a mixing variable called the

„mixture fraction‟ in order to determine the temperature and concentrations of major species. In

this study, a simplified coal combustion furnace is modeled using the non-premixed combustion

model for the reaction chemistry. The following steps describe the method followed, after

creating the required geometry.

1) A PDF table for a pulverized coal fuel using the PDFPre-processor has been prepared for

medium volatile coal.

2) FLUENT inputs for non-premixed combustion chemistrymodeling were estimated.

3) A discrete second phase of coal particles was defined.

4) Simulations which were carried out first without involving reactive mixture and discrete coal

particles and then once the solution convergence is achieved, furthermore simulations were

continued involving reacting discrete phase coal particles. The composition in terms of atom

fraction ofH, C, N, O, S along with the lower heat value and heat capacity of the fuel are defined

using the data provided by a 660MW power plant. The volatile release model is based on a

RT

single kinetic rate model [7,8]. This model states that the production rate of volatile gases is

given by a first order reaction, which correlates rates of weight loss with the temperature.

IJE

As in most practical fossil-fuel combustion simulations, the incompressible form of the

equations of motion using a finite volume form of the discretization equations are solved with

SIMPLE-based approaches. It is also assumed that the flow field is at a steady-state and the

solution procedure is simplified by solving a steady-state form of the equation of motion. For

many combustion processes, radiation is not only the dominant energy transport mechanism but

also one of the most complex problems. The accuracy of the radiation calculation depends on a

combination of the accuracy of calculation method and the accuracy to which the properties of

the radiating media and surrounding walls are known [4]. The P1 radiation model is used to

account for the exchange of radiation in furnace, which specifies a composition dependent

absorption coefficient. All thermodynamic data including density, specific heat, and formation

of enthalpies are extracted from the pre-PDF chemical database.

4. Results and discussion

The computational model has been applied to the furnace of 660 MW boiler fired with

high-ash, medium volatile coal. The input data for CFD simulations (including boiler

IJERTV3IS10356 www.ijert.org 899

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

operational conditions) is selected in correspondence with data related to the experimental tests

of the considered boiler. The properties and the lower heating value of fuel mass “as received”

basis at a local power station are assumed in calculations. The yield of volatile matter was taken

according to the data provided. Although, the full-scale boiler is equipped with 32 conventional

burners having eight mills of the swirling type arranged on each corner, here only five mills are

considered as full load (hereafter referred to as base case) for modelling the operation.

At first, only the gas flow equations are solved in order to achieve for stable calculations

and fast convergences for two-phase flow, combustion, heat-transfer and chemical reactions.

After the flow field converges, the trajectories of the coal particles interacting with the flue gas

are calculated. Next, the chemical reaction and enthalpy equations for coal combustion are taken

into account. Numerical calculations are repeated until the flow and temperature converge. A

convergence criterion is that the normalized residuals for all the variables need to be less than

10-3. Flow and temperature field convergence is obtained after more than 1465 iterations. Scaled

residuals for total combustion process including the discrete phase is shown in fig 4.

The predicted temperatures at the furnace exit are 1545K, while the measured

RT

temperatures are 1600K.The predicted molar fraction of O2(%)and CO2(%)at the boilerfurnace

exit are 0.7% and 16% respectively.

IJE

Table 3.Comparison of predicted outlet temperatures with measurements in experimental data.

Section name Plant measurement Predicted mesurement

Temperature[K] Furnace exit 1600 1545

O2[%,molefraction] Furnace exit - 0.7%

CO2[%, mole fraction] Furnace exit 12 % 16 %

IJERTV3IS10356 www.ijert.org 900

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

Fig.4.Scaledresidualsfortotalcombustionprocessincludingthediscretephase.

4.1Flow fields and coal particle trajectories

RT

IJE

(a) (b)

Fig.5.Flow fields of coal +airinlet (a) velocity magnitude(b) velocity vector

The velocity distribution and vectors in cross sections along the furnace height are shown

in Fig.5. The flows located near the burners show more activity than in other locations. A

clockwise swirling flow formed via the air and coal particles injected through the burner ports is

IJERTV3IS10356 www.ijert.org 901

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

found in the center of the furnace, as expected. The swirling flow is stronger in the lower level at

26.14 m from ground level than in the higher level at 30.07 m . In the upper region (at 34.01m

&39.8m), the swirling flow is remarkably reduced.The flue gas flows into theprimary super-

heater with a mean velocity of 8.01 m/s and standarddeviation of 3.32m/s. The upward velocity

distribution located downstream above the burner‟s inlet is relatively flat and the swirling flow

is very weak. This implies that the equipment like super-heaters and re-heaters installed

downstream help the flow to be even and the residual swirling flow to be reduced.

RT

(a) (b)

IJE

Fig.6.Streamline of the flue gas and coal particle (a) isometric view (b) top view

The streamlines of the flue gas and the trajectories of the coal particles are depicted in

Fig.6. The streamlines and trajectories show very complicated three-dimensional flow

characteristics which promote the mixing of the air and coal particles and enhancing heat

transfer via bulk motion. The coal particle trajectories are very similar to the flue gas path lines

but not coincident due to the different densities and turbulent fluctuations. The flue gas and coal

particles injected from the lower burners, initially circulate in the bottom of the furnace and the

ash hopper and eventually travel up through the high-temperature and swirling- flow region (so-

called fire-ball) formed in the central region of the furnace, while the flue gas and coal particles

from the higher burners pass around the surface of the fire-ball region.As a result, the residence

times of the flue gas, and coal particles injected from the higher burners are shorter

incomparison to the flue gas and coal particles injected from the lowerburners. The average

residence time and traveling length of theflue gas within the boiler are 22.2 s and 162 m,

respectively, andthese values are listed in Table 4.

IJERTV3IS10356 www.ijert.org 902

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

Table 4Summary of flue gas behavior

Avg. Residence time [s] 22.2

Flue gas

Traveling length [m] 162 m

Coal devolatilization and char combustion take place while thecoal particles are traveling

around the furnace, as shown in Fig. 6.Moreover, residence time and turbulence are always

considered together: the more turbulence inside furnace, the longer the residence time of the coal

particles. It is obvious that the residence time depended strongly on the height of the burner; the

residence time decreased with increasing height of burner positions. In general,it is known that

all fuel species except char are consumed very quickly in the furnace. However, char burns at a

slower rate and is consumed in the central region of the furnace. In this calculation, the

conversion ratio of the combusting particles is approximately 100%. This implies that the

present combustion processes offer sufficientresidence time even for char conversion.

4.2. Temperature distributions

The temperature distributions in the cross sections are shown in Fig. 7. The temperature

RT

of the flue gas is relatively high in the central region of the furnace where coal combustion

actively takes place. The change pattern of the flue gas temperature is clearly shown along the

IJE

furnace height in Fig. 7b. The temperature of the air injected from the burners corner is 343 K,

and it increases up to a maximum temperature of 1800 K in the central region of the furnace. A

noticeable temperature deviation is seen in the lower level of the furnace, but in the higher

levels, the temperature deviation decreases due to stronger swirling and increased mixing. Along

with the increased height, the average temperatures in each cross sections also increase because

of high combustion intensity. However, as the flue gas goes upward in the furnace , the

temperature of the flue gas decreases due to the heat transfer between the flue gas and furnace

walls via convection and radiation. Finally, the flue gas leaves the boiler furnace at an average

temperature of 1,545 K. The iso-surfaces at temperatures of 1800 K indicating high temperature

zones in the furnace are depicted in Fig. 10a. These high temperature regions are closely related

to NOx formation which is dependent on local temperature.

IJERTV3IS10356 www.ijert.org 903

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

(a) ( b)

Fig.7. Temperature fields in a coal fired furnace (a) along vertical section (b) along

horizontal section.

RT

4.3 O2 distributions

IJE

The mass fraction distributions of O2 aredepicted in Fig. 8.

(a) (b)

Fig.8O2 distribution in tangential fired boiler(a) along vertical section (b) along horizontal section.

IJERTV3IS10356 www.ijert.org 904

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

The O2 concentration in the furnace is relatively higher near the burners. The O2

contained in the air injected inside the furnace, where the temperature is relatively higher, is

quickly consumed during the combustion processes. Due to which, the O2 mass fraction rapidly

decreases. In particular, the O2 mass fraction remarkably decreases near the burners, where

combustion is more and more active, and the fuel volatile species are more rapidly consumed.

As depicted in Fig. 7, the high temperature regions in the furnace roughly correspond to the

regions of the lower O2 mass fraction. The iso-surfaces at O2 of 4.5% indicating high oxygen

containing zones in the furnace are depicted in Fig. 10b. These high oxygen regions are closely

related to increasing the temperature inside boilerand proper combustion of fuel.

4.4 CO2 distributions

The CO2 distributions in the cross sections are shown in Fig. 9.

RT

IJE

(a) (b)

Fig. 9 CO2 distribution in tangential fired boiler (a) along vertical section (b) along horizontal

section

In contrast to the O2 mass fraction, the CO2 mass fraction significantly increases as the

air moves from the burners due to the active combustion processes. high peaks of the O2 mass

fraction are shown in the middle zone of the furnace when the CO2 mass fraction is low, which

suggests that the sudden variation in their values is due to the supply of combustion air through

the burners. In Fig. 7b, as the temperature of the flue gas increases, the O2 mass fraction

decreases steeply while the CO2 mass fraction increases because volatile combustible contents

of the coal burn near the burners.

IJERTV3IS10356 www.ijert.org 905

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

(a) (b) (c)

Fig.10.(a) iso-surface indicating high temperature zone (1800k) (b) ) iso-surface indicating

high O2 mass fraction (4.5%) (c) ) iso-surface indicating high CO2 mass fraction (24%).

The iso-surfaces at CO2 of 25% indicating high CO2 containing zones in the furnace are

depicted in Fig. 10c. These high CO2regions are closely related to decreasing the oxygen mass

fraction inside boiler.

RT

The variation of species concentration and temperature along the furnace is shown in figure 11.

IJE

variation of predicted cross sectional mass weighted average of species

and temperature along the furnace elevation

0.3 2000

1802

1737

1644 1636 1800

0.25 1563 1545

1600

Species mass fraction in %

1374 0.25 0.25

0.24

Temperature in kelvin

1234 0.23 0.23 1400

0.2 O2 mass fraction

0.21 1200

0.2

CO2 mass fraction

0.15 0.21 1000

temperature in kelvin

800

0.1

600

0.038 0.038 0.045 400

0.05

0.009 0.007 200

0.001 0.0003

0 0.0002 0

10 20 30 Furnace

Boiler 40 Elevation

50 In Meter

60 70 outlet

Fig.11. variation of species concentration and temperature along the furnace

IJERTV3IS10356 www.ijert.org 906

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

5. Conclusions

Modelling of a tangential fired furnace is carried out using CFD commercial flow solver

FLUENT. Simulation results with different burners in operation suggested a significant impact

on the distribution of temperatures and furnace exit temperatures. This indicates that extreme

care must be taken in terms of maintenance and service of burners so as to minimize the effects

on combustion and continue smooth operation of boilers. Predicted particle trajectories indicate

differences in particle residence times within the boiler. In particular, particles emerging out

lower burner sections tend to reside within the boiler longer than the particles at other locations.

This may lead to poorcombustion, which is undesirable for efficient operation of power station

boilers.The simulation of this boiler using fluent we visualise what will be temperature in

various zones of boiler.The relation among the temperature, O2 mass fraction and CO2 mass

fraction has been clearly demonstrated based on the calculated distributions. Overall the model

results showed good agreement with measured and reported data, which provides a solid

foundation for future work. Data presented in the paper demonstrates the implications and

possible options for burner operations in terms of their maintenance and serviceability. The

RT

results obtained with such models would prove to be of practical value to optimize the

performance of boilers.

IJE

References

[1] MinghouXu, J.L.T. Azevedo, M.G. Carvalho, Modeling of a front wall fired utility boiler

for different operating conditions, Comput. Methods Appl. Mech. Eng. 190 (2001) 3581–

3590.

[2] S. Chapman, T.G. Cowling, The Mathematical Theory of Non-Uniform Gases, Cambridge

University Press, Cambridge, UK, 1990.

[3] S. Niksa, Coal Combustion Modelling, IEAPER/31, IEA Coal Research, London, 1996.

[4] M. Eaton, L.D. Smoot, S.C. Hill, C.N. Eatough, Components, formulations, solutions,

evaluation, and application of comprehensive combustion models, Prog.Energy.Combust. Sci.

25 (1999) 387–436.

[5] T. Abbas, P.G. Costen, F.C. Lockwood, 26th Symposium (International) on Combustion,

The Combustion Institute, 1996, p. 3041.

[6] P.G. Costen, D. Dajnak, M. Messina, F.C. Lockwood, T. Abbas, C. Bertrand, N.H.

Kandamby, V. Sakthitharan, I. Siera, S. Yousif, On the prediction and control of industrial

combustors by mathematical modelling, Paper presented at 2002 Australian Symposium on

IJERTV3IS10356 www.ijert.org 907

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 1, January - 2014

Combustion and The Seventh Australian Flame Days, Adelaide, February 2002.

[7] FLUENT, FLUENT 6.2 Users Guide, 2005 Lebanon, USA.

[8] Williams, R. Backreedy, R. Habib, J.M. Jones, M. Pourkashanian, Modelling coal

combustion: the current position, Fuel 81 (2002) 605–618.

[9]Shangai boiler works limited user manual.

RT

IJE

IJERTV3IS10356 www.ijert.org 908

You might also like

- Control of Ash Related Problems in A Large Scale Tangentially Fired Boiler Using CFD ModellingDocument9 pagesControl of Ash Related Problems in A Large Scale Tangentially Fired Boiler Using CFD ModellingRindra HosanovaNo ratings yet

- 2013p CavazzutiCorticelli PIMechECDocument23 pages2013p CavazzutiCorticelli PIMechECmap vitcoNo ratings yet

- Review Paper on Numerical Analysis of Induction FurnaceDocument7 pagesReview Paper on Numerical Analysis of Induction FurnaceUma KoduriNo ratings yet

- An Analysis of Different Methods For Major Energy Saving in Thermal Power PlantDocument9 pagesAn Analysis of Different Methods For Major Energy Saving in Thermal Power PlantRavikanth ReddyNo ratings yet

- CFD analysis of steam boiler tube used in power plantDocument10 pagesCFD analysis of steam boiler tube used in power plantADVOKASI PPI MALAYSIANo ratings yet

- Paper 1107Document7 pagesPaper 1107Dr. RISHA MALNo ratings yet

- 88MWDocument10 pages88MWVignesh AlagesanNo ratings yet

- An Investigation On Tube Temperature Distribution in A Water Tube BoilerDocument6 pagesAn Investigation On Tube Temperature Distribution in A Water Tube BoilerKelvinWongNo ratings yet

- Experimental Investigations On The Performance and Emissoin CharacteristicsDocument6 pagesExperimental Investigations On The Performance and Emissoin CharacteristicsIAEME PublicationNo ratings yet

- Design and CFD Analysis of Combustion Chamber in IDocument10 pagesDesign and CFD Analysis of Combustion Chamber in IRuvimboNo ratings yet

- Design and Analysis of Compact Boiler: July 2018Document11 pagesDesign and Analysis of Compact Boiler: July 2018Yash DumaswalaNo ratings yet

- Application of Eutectic Composites To Gas Turbine System and Fundamental Fracture Properties Up To 1700°CDocument9 pagesApplication of Eutectic Composites To Gas Turbine System and Fundamental Fracture Properties Up To 1700°CMikecz JuliannaNo ratings yet

- Design and Analysis of Gas Turbine Blade: ISSN: 2319-8753 I J I R S E TDocument7 pagesDesign and Analysis of Gas Turbine Blade: ISSN: 2319-8753 I J I R S E Tmaji heNo ratings yet

- CFD Analysis of Superheater in View of Boiler Tube Leakage: Ajay N. Ingale, Vivek C. Pathade, Dr. Vivek H. TatwawadiDocument3 pagesCFD Analysis of Superheater in View of Boiler Tube Leakage: Ajay N. Ingale, Vivek C. Pathade, Dr. Vivek H. Tatwawadidinesh23cbeNo ratings yet

- Analysis of Gas Turbine Combustor With Varying Air Inlet Velocity and Methane Fuel Inlet TemperatureDocument7 pagesAnalysis of Gas Turbine Combustor With Varying Air Inlet Velocity and Methane Fuel Inlet TemperatureGuruvenu KamanuruNo ratings yet

- Super Critical Thermal Power Plant Boiler Efficiency Calculation Using Imported CoalDocument9 pagesSuper Critical Thermal Power Plant Boiler Efficiency Calculation Using Imported CoalSomplak KudaNo ratings yet

- Super Critical Thermal Power Plant Boiler Efficiency Calculation Using Imported CoalDocument9 pagesSuper Critical Thermal Power Plant Boiler Efficiency Calculation Using Imported CoalSomplak KudaNo ratings yet

- Thermal Fatigue Analysis of Exhaust ManifoldDocument11 pagesThermal Fatigue Analysis of Exhaust ManifoldIJRASETPublicationsNo ratings yet

- Experimental Investigation To Improve Flame Intensity in 250MW Tangentially Firing FurnaceDocument11 pagesExperimental Investigation To Improve Flame Intensity in 250MW Tangentially Firing FurnaceSiddhant SatpathyNo ratings yet

- Energy Audit and Energy Efficient Recommendations With Payback Period For Industrial BoilerDocument7 pagesEnergy Audit and Energy Efficient Recommendations With Payback Period For Industrial BoilerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design Analysis of Shell Tube Type Heat Exchanger IJERTV9IS010215Document16 pagesDesign Analysis of Shell Tube Type Heat Exchanger IJERTV9IS010215Harshil ChangelaNo ratings yet

- Establishing Correct Coal Quality For Achieving Optimum Boiler Efficiency & Performance - A Case Study in The Indian Utility IndustryDocument12 pagesEstablishing Correct Coal Quality For Achieving Optimum Boiler Efficiency & Performance - A Case Study in The Indian Utility Industrystark2006No ratings yet

- Thermal Barrier Coating Effect on Diesel Engine PistonDocument5 pagesThermal Barrier Coating Effect on Diesel Engine PistonShreeram BakthaNo ratings yet

- IJEDR1703010Document8 pagesIJEDR1703010Belay AyalewNo ratings yet

- Experimental Investigation of Combustion, Performance and Emission Characteristics of Di Diesel Engine Under Hcci Mode With Porous Medium CombustionDocument10 pagesExperimental Investigation of Combustion, Performance and Emission Characteristics of Di Diesel Engine Under Hcci Mode With Porous Medium CombustionkannanjbrNo ratings yet

- IJTIMESV05I05150531142334Document8 pagesIJTIMESV05I05150531142334Sheila KorirNo ratings yet

- Structural Design and Analysis of Gas Turbine Blade Using Cae Tools IJERTV3IS100482Document6 pagesStructural Design and Analysis of Gas Turbine Blade Using Cae Tools IJERTV3IS100482Sai SushmaNo ratings yet

- International Journal of Thermal Sciences: SciencedirectDocument11 pagesInternational Journal of Thermal Sciences: SciencedirectAnubhav SinghNo ratings yet

- Application of CFD in Thermal Power PlantsDocument4 pagesApplication of CFD in Thermal Power PlantsAnonymous 4R6sDK8eNo ratings yet

- Contoh JurnalDocument9 pagesContoh JurnalMuhammad DaffaNo ratings yet

- Design of Advanced Industrial Furnaces Using Numerical Modeling MethodDocument153 pagesDesign of Advanced Industrial Furnaces Using Numerical Modeling MethodELFargaliMohamedNo ratings yet

- Design New Medium-Temperature Stirling Engine For Distributed Cogeneration ApplicationsDocument10 pagesDesign New Medium-Temperature Stirling Engine For Distributed Cogeneration ApplicationsLima CostaNo ratings yet

- Energy Integration of Fired Heater: IMEC04-2003Document17 pagesEnergy Integration of Fired Heater: IMEC04-2003Wejden YaakoubyNo ratings yet

- Exergy Analysis Back Pressure Turbine Rana Mehtadd IJMERDocument8 pagesExergy Analysis Back Pressure Turbine Rana Mehtadd IJMERSky 6794No ratings yet

- Thermal design of economizer for WHRBDocument7 pagesThermal design of economizer for WHRBKhushnood100% (1)

- Case Study of A Condemned Boiler & Methods To Re-Establish ItDocument43 pagesCase Study of A Condemned Boiler & Methods To Re-Establish Its sivaNo ratings yet

- Transient Heat Transfer Analysis of Induction Furnace by Using Finite Element AnalysisDocument5 pagesTransient Heat Transfer Analysis of Induction Furnace by Using Finite Element AnalysisMilion dugumaNo ratings yet

- Performance Enhancement of An Industrial Fire Tube BoilerDocument6 pagesPerformance Enhancement of An Industrial Fire Tube BoilerZaid YahyaNo ratings yet

- 52 - Paper ID IJ60606050Document7 pages52 - Paper ID IJ60606050reiferNo ratings yet

- IOP Conference Series: Materials Science and Engineering CFD analysis of temperature imbalance in superheater/reheater region of tangentially coal-fired boilerDocument10 pagesIOP Conference Series: Materials Science and Engineering CFD analysis of temperature imbalance in superheater/reheater region of tangentially coal-fired boilersvvsnrajuNo ratings yet

- Design Fabrication and Testing of Shell and Tube Heat Exchanger For Heat Recovery From Hydraulic Oil IJERTV6IS070289Document8 pagesDesign Fabrication and Testing of Shell and Tube Heat Exchanger For Heat Recovery From Hydraulic Oil IJERTV6IS070289PAPPU KUMARNo ratings yet

- 7 Viii August 2019Document11 pages7 Viii August 2019Ankush ChoudharyNo ratings yet

- A 3D Modelling of The In-Cylinder Combustion DynamDocument13 pagesA 3D Modelling of The In-Cylinder Combustion DynamPabloNo ratings yet

- Thermal Efficiency and Heat Balance of Reheating Furnace of Rolling MillsDocument15 pagesThermal Efficiency and Heat Balance of Reheating Furnace of Rolling MillsGidNo ratings yet

- Multi-Objective Heat Sink Optimization by Using Taguchi MethodDocument9 pagesMulti-Objective Heat Sink Optimization by Using Taguchi MethodIJRASETPublicationsNo ratings yet

- Ijet V4i3p38 PDFDocument10 pagesIjet V4i3p38 PDFInternational Journal of Engineering and TechniquesNo ratings yet

- Thermal Efficiency of Rolling Mill Reheating FurnacesDocument15 pagesThermal Efficiency of Rolling Mill Reheating FurnacesJorge Neyra MacedoNo ratings yet

- Machinability and Chip Morphology Study of Inconel 740H and Haynes 282 For Advanced-Ultra Supercritical ApplicationsDocument18 pagesMachinability and Chip Morphology Study of Inconel 740H and Haynes 282 For Advanced-Ultra Supercritical ApplicationsIJRASETPublicationsNo ratings yet

- Coke Chem 1710004 Lipunov KORDocument7 pagesCoke Chem 1710004 Lipunov KORchemamarNo ratings yet

- Design of Earth Tube Heat Exchanger: Devika Padwal, Tejaskumar Kharva, Jaiminkumar BhattDocument6 pagesDesign of Earth Tube Heat Exchanger: Devika Padwal, Tejaskumar Kharva, Jaiminkumar BhattAnuj MalewarNo ratings yet

- ADocument22 pagesAAntonio LoretoCortesNo ratings yet

- Ijiset V3 I10 10Document11 pagesIjiset V3 I10 10Diki PrayogoNo ratings yet

- Experimental and Comparison Study of Heat Transfer Characteristics of Wickless Heat Pipes by Using Various Heat InputsDocument12 pagesExperimental and Comparison Study of Heat Transfer Characteristics of Wickless Heat Pipes by Using Various Heat InputsIJRASETPublicationsNo ratings yet

- Assessment of Erosion resistance through CFD modelingDocument5 pagesAssessment of Erosion resistance through CFD modelingEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- How Furnace Model Predictive Control Forecasts Transitions To Enhance Strip Quality and ProductivityDocument12 pagesHow Furnace Model Predictive Control Forecasts Transitions To Enhance Strip Quality and ProductivityJJNo ratings yet

- Heat Transfer Enhancement Using Nanoparticles (Al2o3)Document6 pagesHeat Transfer Enhancement Using Nanoparticles (Al2o3)IJRASETPublicationsNo ratings yet

- Preprints201608 0029 v1Document14 pagesPreprints201608 0029 v1Juan Ignacio GonzálezNo ratings yet

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualFrom EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualNo ratings yet

- Handbook of Energy Data and Calculations: Including Directory of Products and ServicesFrom EverandHandbook of Energy Data and Calculations: Including Directory of Products and ServicesNo ratings yet

- Potensi Sumberdaya Logam Radioaktif di IndonesiaDocument23 pagesPotensi Sumberdaya Logam Radioaktif di IndonesiaAbdu M. HabsyiNo ratings yet

- Current Condition & Future Prediction of Oil Industry in MENADocument15 pagesCurrent Condition & Future Prediction of Oil Industry in MENAtrinaldyNo ratings yet

- Prof. Anatoliy Zolotukhin - Impact of Oil Price Fluctuations On RussiaDocument34 pagesProf. Anatoliy Zolotukhin - Impact of Oil Price Fluctuations On RussiatrinaldyNo ratings yet

- s0378 4347 (00) 86006 5 PDFDocument7 pagess0378 4347 (00) 86006 5 PDFAbdu M. HabsyiNo ratings yet

- Biochemj00782 0164 PDFDocument5 pagesBiochemj00782 0164 PDFBrillian AlfiNo ratings yet

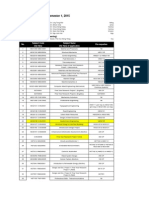

- Mr. Auli Kusuma - Current Condition and Future Prediction of Petroleum WorldDocument15 pagesMr. Auli Kusuma - Current Condition and Future Prediction of Petroleum WorldAbdu M. HabsyiNo ratings yet

- RD ArticleDocument6 pagesRD ArticleAbdu M. HabsyiNo ratings yet

- Biochemj00782 0164 PDFDocument5 pagesBiochemj00782 0164 PDFBrillian AlfiNo ratings yet

- FCC Process and CatalystDocument7 pagesFCC Process and CatalystAbdu M. HabsyiNo ratings yet

- Biochemj00782 0164 PDFDocument5 pagesBiochemj00782 0164 PDFBrillian AlfiNo ratings yet

- s0378 4347 (00) 86006 5 PDFDocument7 pagess0378 4347 (00) 86006 5 PDFAbdu M. HabsyiNo ratings yet

- Removal of Phospholipids From Crude Edible Oil by PVDF MembraneDocument6 pagesRemoval of Phospholipids From Crude Edible Oil by PVDF MembraneAbdu M. HabsyiNo ratings yet

- Processing of Machinery Reliability StatisticsDocument1 pageProcessing of Machinery Reliability StatisticsAbdu M. HabsyiNo ratings yet

- Ultrafiltration Membrane Dry DegummingDocument10 pagesUltrafiltration Membrane Dry DegummingAbdu M. HabsyiNo ratings yet

- Ultrafiltration Membrane Dry DegummingDocument10 pagesUltrafiltration Membrane Dry DegummingAbdu M. HabsyiNo ratings yet

- 1 Contoh Ini LangsungDocument97 pages1 Contoh Ini LangsungAbdu M. HabsyiNo ratings yet

- SPE-196494-MS Sumatera Operation SMO Integrated Optimisation Decision Support Center IODSC Success in Embracing Digitalisation and Innovation To Deliver Business ResultsDocument12 pagesSPE-196494-MS Sumatera Operation SMO Integrated Optimisation Decision Support Center IODSC Success in Embracing Digitalisation and Innovation To Deliver Business ResultsAbdu M. HabsyiNo ratings yet

- Encyclopedia ZeoliteDocument6 pagesEncyclopedia ZeoliteAbdu M. HabsyiNo ratings yet

- Homework on catalytic hydrodealkylationDocument1 pageHomework on catalytic hydrodealkylationAbdu M. HabsyiNo ratings yet

- Coal TechnologiesDocument22 pagesCoal TechnologiesAbdu M. HabsyiNo ratings yet

- Home assignment No4: Calculating Acrylonitrile Yield and Ethylene Feed RateDocument3 pagesHome assignment No4: Calculating Acrylonitrile Yield and Ethylene Feed RateAbdu M. HabsyiNo ratings yet

- AcidDocument5 pagesAcidAbdu M. HabsyiNo ratings yet

- Chra 1Document143 pagesChra 1Abdu M. Habsyi100% (1)

- Report No.: Determination of Thermo Physical Properties of Certec P-35Document13 pagesReport No.: Determination of Thermo Physical Properties of Certec P-35AliNo ratings yet

- Ex3 - Fire Under Concrete Slab - Compos PDFDocument64 pagesEx3 - Fire Under Concrete Slab - Compos PDFEmra MerdićNo ratings yet

- The Surface Fatigue Life of Contour Induction Hardened AISI 1552 TM-107017 (Nasa) PDFDocument11 pagesThe Surface Fatigue Life of Contour Induction Hardened AISI 1552 TM-107017 (Nasa) PDFmariannyNo ratings yet

- Thermotron CE Catalogue 2022 VOL10 - MidresDocument54 pagesThermotron CE Catalogue 2022 VOL10 - MidresChristy LaheteNo ratings yet

- Corning® LEAF® Optical Fiber: Product InformationDocument0 pagesCorning® LEAF® Optical Fiber: Product Informationhcdung18No ratings yet

- Ultrasonic Vortex Flowmeter "Ultra Yewflo-Uyf200": KAWANO Takashi MATSUNAGA Yoshinori ANDOH Tetsuo Yasumatsu AkioDocument4 pagesUltrasonic Vortex Flowmeter "Ultra Yewflo-Uyf200": KAWANO Takashi MATSUNAGA Yoshinori ANDOH Tetsuo Yasumatsu AkiohendrabudimanNo ratings yet

- Experimental and Numerical Investigation of Lower Limb Prosthetic Foot Made From Composite Polymer Blends1Document12 pagesExperimental and Numerical Investigation of Lower Limb Prosthetic Foot Made From Composite Polymer Blends1Jawad K. OleiwiNo ratings yet

- Units Offered S1 2015 Engineering DegreeDocument4 pagesUnits Offered S1 2015 Engineering DegreescytheVSNo ratings yet

- ANC20LA059 Structures Rudder Study-RelDocument16 pagesANC20LA059 Structures Rudder Study-RelFRRNo ratings yet

- Fellenius2019 Red Book PDFDocument487 pagesFellenius2019 Red Book PDF'Vanessa VogtNo ratings yet

- PT Statika Mitra Sarana Compressive Strength TestDocument6 pagesPT Statika Mitra Sarana Compressive Strength Testfajar sNo ratings yet

- 7 Climate Control Air Handling Unit 2020Document2 pages7 Climate Control Air Handling Unit 2020Fahri Husaini NstNo ratings yet

- Flare - Reduced Purge Rates in StacksDocument13 pagesFlare - Reduced Purge Rates in StacksGary JonesNo ratings yet

- Vincent PDFDocument4 pagesVincent PDFSarinKorthawornwongNo ratings yet

- F1 Chapter 5 MatterDocument13 pagesF1 Chapter 5 Matteralya sophiaNo ratings yet

- FEA Modal Analysis - MPF For Resonance Check, While Dealing Component Natural FrequenciesDocument3 pagesFEA Modal Analysis - MPF For Resonance Check, While Dealing Component Natural Frequenciesmatteo_1234No ratings yet

- Measuring Specific Heat CapacityDocument5 pagesMeasuring Specific Heat CapacityhernanNo ratings yet

- Lead Acid Battery LectureDocument76 pagesLead Acid Battery LectureChau Tran100% (2)

- WDM technology multiplies fiber capacity using laser wavelengthsDocument8 pagesWDM technology multiplies fiber capacity using laser wavelengthsAnkit SharmaNo ratings yet

- Surveying 2 SyllabusDocument3 pagesSurveying 2 Syllabussurendar17_raj3406No ratings yet

- Chem Grade 10 WK 3Document5 pagesChem Grade 10 WK 3Anasatcia Mcpherson 9c FNo ratings yet

- GCMS - K - MS TuneDocument4 pagesGCMS - K - MS TuneDaniel MoraNo ratings yet

- Materials Express: Low-Cycle Fatigue Behavior of 7075-T6 Aluminum Alloy at Different Strain AmplitudesDocument6 pagesMaterials Express: Low-Cycle Fatigue Behavior of 7075-T6 Aluminum Alloy at Different Strain Amplitudesadarshravindran1991No ratings yet

- Welding TMCP SteelsDocument7 pagesWelding TMCP SteelsElias Kapa100% (1)

- Proof Energy Geoscience - AnalysisofwellborestabilitybyporepressurepredictionusingsreismicvelocitiesDocument11 pagesProof Energy Geoscience - Analysisofwellborestabilitybyporepressurepredictionusingsreismicvelocitiesghassen laouiniNo ratings yet

- Asme Sec Viii Div-2Document31 pagesAsme Sec Viii Div-2Yash Rami100% (3)

- Physical Properties of Carton Box - A To ZDocument20 pagesPhysical Properties of Carton Box - A To ZPiyush MishraNo ratings yet

- X-Rays: Click To Add TextDocument43 pagesX-Rays: Click To Add TextAhmedNo ratings yet

- Quarterly Miller Welding Machine MaintenanceDocument3 pagesQuarterly Miller Welding Machine MaintenanceMuhammad RosihanNo ratings yet

- Garrison: Oceanography An Invitation To Marine Science, 8e FinalDocument22 pagesGarrison: Oceanography An Invitation To Marine Science, 8e FinalBagas IndiantoNo ratings yet