Professional Documents

Culture Documents

Marking Non Electrical Equipment Ex PDF

Uploaded by

MMOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marking Non Electrical Equipment Ex PDF

Uploaded by

MMCopyright:

Available Formats

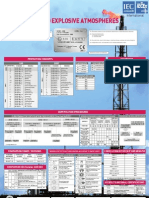

Marking of non-electrical equipment for use in potentially explosive atmospheres

Conditions and subdivisions Subdivisions of gases and vapours

Conditions and subdivisions Required marking on the usable operating equipment Gases and vapours Assignment Temperature Maximum Permissible

of gases and vapours accordance class surface temperature

Flammable Temporary behaviour Classification Group Equipment Equipment group Equipment

to the ignition temperature temperature classes

materials of explosive atmosphere of hazardous as defined in category as as defined in protection level

of equipment of equipment

areas directive defined in directive EN 60079-O (EPL) as defined in

2014/34/EU 2014/34/EU EN ISO 80079-36 EN ISO 80079-36 ammonia, town gas, hydrogen > 450 °C T1 450 °C T1 to T6

methane, ethane, acrylnitril

gases is present continuously or zone 0 II 1G II Ga

propane

vapours for long periods or frequently

ethyl alcohol, ethylene, ethine > 300 °C ... < 450 °C T2 300 °C T2 to T6

arises in normal zone 1 II 2G or 1G II Gb or Ga

cyclohexane, ethylene oxide (acetylene)

operation occasionally

n-butane

is not likely toarise in normal zone 2 II 3G or II Gc or

gasoline, ethylene glycol, > 200 °C ... < 300 °C T3 200 °C T3 to T6

operation, or if it does, will 2G or 1G Gb or Ga

n-hexane hydrogen sulphide

persist for a short time only

dusts is present in the form of a zone 20 II 1D III Da

cloud continuously, or for acetaldehyde ethyl-ether > 135 °C ... < 200 °C T4 135 °C T4 to T6

long periods or frequently > 100 °C ... < 135 °C T5 100 °C T5 to T6

occasionally develops zone 21 II 2D or 1D III Db or Da sulphide of carbon > 085 °C ... < 100 °C T6 85 °C T6

into a cloud during

normal operation

is not likely to develop into zone 22 II 3D or III Dc or

a cloud during normal operation, 2D or1D Db or Da

or if it does, for a short time only Explosion groups

methane operation where there is - I M1 I Ma IIA IIB IIC

carbon dust a risk of explosion

Permissible equipment groups

disconnection where there - I M2 or M1 I Mb or Ma

is a risk of explosion IIA, IIB, IIC IIB, IIC IIC

Gas NB* II 2G c Ex h IIB T4 Gb NB* 16 ATEX 1234 X

Dust NB* II 2D c Ex h IIIB T110 °C Db NB* 16 ATEX 1234 X

Protection principle/types of protection Use of the operating equipment

Applications Flammable materials Protection principle Type of protection Symbol Marking in accordance with the equipment protection level Norms Marking Conditions

EPL a EPL b EPL c

very high level of high level of pro- enhanced level of operating equipment can be used without

protection tection protection without

restriction

all applications gases, vapours (G) and dusts (D) – general requirements – + + + EN 13463-1

EN ISO 80079-36 X special conditions of use

EN 60079-0 U operating equipment with partial certificate,

CE-conformity is certified when it is installed

Coupling, belt drive, gases, vapours (G) and dusts (D) This protection principle ensures Constructional safety c c c EN 13463-5 into a complete item of operating apparatus

agitator, ventilator, mill that a source of ignition cannot

occur. Ex h Ex h Ex h EN ISO 80079-37

Ignition temperature of dust

Plain bearing, pump, agitator, gases, vapours (G) and dusts (D) This protection principle prevents Control of ignition sources b b b EN 13463-6

vacuum pump a source of ignition from becoming permissible temperature of Tadm. C = T 5 mm C - 75 K

effective. Ex h Ex h Ex h EN ISO 80079-37 the layer

permissible temperature of Tadm. nuage = 2/3 Tnuage

Gear gases, vapours (G) and dusts (D) This protection principle prevents Liquid immersion k k k EN 13463-8

the cloud

the hazardous atmosphere reaching

the source of ignition. Ex h Ex h Ex h EN ISO 80079-37 max. permissible surface Tadm. C > Tadm. < Tadm. nuage

temperature of the

Centrifuge, compressor, gases, vapours (G) and dusts (D) This protection principle prevents Pressurised enclosure – p – EN 13463-7 equipment

geared motor, the hazardous atmosphere reaching

complex assembly group the source of ignition. – Ex pxb, pyb Ex pzc EN 60079-2 2)

Centrifuge, compressor, gases and vapours (G) This protection principle prevents Protection by flow restricting – – – Ex fr EN 13463-2 Groups of dust

geared motor, the hazardous atmosphere reaching enclosure

complex assembly group the source of ignition. Marking Dusts Permissible

equipment group

Centrifuge, compressor, dusts (D) This protection principle prevents Protection by enclosure Ex ta Ex tb Ex tc EN 60079-31 2) combustible flyings

IIIA IIIA, IIIB, IIIC

geared motor, the hazardous atmosphere reaching

complex assembly group the source of ignition. IIIB non-conductive dust IIIB, IIIC

IIIC conductive dust IIIC

Brakes gases and vapours (G) This protection principle prevents Flame-proof enclosure – d – EN 13463-3

flame propagation through an

enclosure. Ex da Ex db Ex dc EN 60079-1 2)

Directive 2014/34/EU

* Notified Bodies’ identification number Norm EN 13463-1 ff / EN ISO 80079-36

e.g. BAM 0589 (Germany), DEKRA EXAM 0158 (Germany), EECS (BASEEFA) 0600 (Great Britain),

IBExU 0637 (Germany), KEMA 0344 (Netherlands), LCIE 0081 (France), PTB 0102 (Germany),

SIRA 0518 (Great Britain), TÜV 0044 (Germany), who – where required – have certified the QA system Application in hazardous area

or inspected the products (only with Category 1) Zone 0/20 Zone 1/21 Zone 2/22

Zone 1/21 Zone 2/22

Zone 2/22

E-D-WEG261010-04/2018-BARTECMarketing&Communications-306855

BARTEC GmbH Max-Eyth-Str. 16 97980 Bad Mergentheim Phone: +49 7931 597 0 info@bartec.de www.bartec.de

You might also like

- General Tolerances DIN ISO 2768Document2 pagesGeneral Tolerances DIN ISO 2768Vasil Gospodinov83% (23)

- Phonetics 101Document6 pagesPhonetics 101Marygrace Gan Sabanal0% (1)

- Netfabb Basic Documentation PDFDocument237 pagesNetfabb Basic Documentation PDF123indNo ratings yet

- ATEX Guidelines clarify Directive 2014/34/EUDocument238 pagesATEX Guidelines clarify Directive 2014/34/EUARTURONo ratings yet

- EN 15089-2009 Explosion Isolation Systems PDFDocument42 pagesEN 15089-2009 Explosion Isolation Systems PDFMohamed Adel100% (2)

- Offshore Containers: Standard For Certification No. 2.7-1Document30 pagesOffshore Containers: Standard For Certification No. 2.7-1Teknik MarinaNo ratings yet

- Sira Atex PosterDocument1 pageSira Atex PosterRiadh2012No ratings yet

- Iecex TCD 02 Scheme Ed 7.0Document103 pagesIecex TCD 02 Scheme Ed 7.0Bhavik PrajapatiNo ratings yet

- 201012182932953Document5 pages201012182932953Sanjay Singh100% (1)

- Houeix 80079 34 Ed PDFDocument22 pagesHoueix 80079 34 Ed PDFNabi HasanNo ratings yet

- Circular - Amendment To Fire Code - Implementation of Ss 578 - 2019 - Code of Practice For The Use and Maintenance of Portable Fire ExtinguishersDocument3 pagesCircular - Amendment To Fire Code - Implementation of Ss 578 - 2019 - Code of Practice For The Use and Maintenance of Portable Fire ExtinguishersAzmi NordinNo ratings yet

- Directive 75-324-EEC ADDDocument10 pagesDirective 75-324-EEC ADDGordan SanticNo ratings yet

- Ex Poster Bartec 2019 eDocument1 pageEx Poster Bartec 2019 eSubin ThomasNo ratings yet

- Begin Guitar - Douglas NobleDocument35 pagesBegin Guitar - Douglas NobleConstable & Robinson91% (23)

- Key combinations in Fusion 360Document4 pagesKey combinations in Fusion 360marccerdan9828No ratings yet

- One Side ACC With IPA SymbolsDocument1 pageOne Side ACC With IPA SymbolsSerena ReviewsNo ratings yet

- Key combinations in Fusion 360Document4 pagesKey combinations in Fusion 360marccerdan9828No ratings yet

- One Side ACC With IPA SymbolsDocument1 pageOne Side ACC With IPA SymbolsSerena ReviewsNo ratings yet

- (BS EN 12981 - 2005+A1 - 2009) - Coating Plants. Spray Booths For Application of Organic Powder Coating Material. Safety Requirements.Document54 pages(BS EN 12981 - 2005+A1 - 2009) - Coating Plants. Spray Booths For Application of Organic Powder Coating Material. Safety Requirements.Simon ThaonNo ratings yet

- Chemical Resistance Reference Guide: Thermo Scientific Nalgene Plastic LabwareDocument1 pageChemical Resistance Reference Guide: Thermo Scientific Nalgene Plastic LabwareMochamad Adi Saputro100% (1)

- Design Properties and Calculations for FRP Lining PanelsDocument5 pagesDesign Properties and Calculations for FRP Lining PanelsSubin AnandanNo ratings yet

- Ped 2014 - 68 - EuDocument96 pagesPed 2014 - 68 - EuperycabralNo ratings yet

- Speck Vacuum Pumps Vhc-SeriesDocument16 pagesSpeck Vacuum Pumps Vhc-Seriesmaxh blumNo ratings yet

- Resin R3X1080 - Material Safety Data Sheet - Part BDocument5 pagesResin R3X1080 - Material Safety Data Sheet - Part BRavie OuditNo ratings yet

- New European Standard for Fume Cupboards Handles High Heat and AcidsDocument28 pagesNew European Standard for Fume Cupboards Handles High Heat and AcidsCaleb ConnerNo ratings yet

- General Product Catalogue ENG WEBDocument50 pagesGeneral Product Catalogue ENG WEBJamdade LaxmanNo ratings yet

- Piping system design basisDocument6 pagesPiping system design basisDeden SobirinNo ratings yet

- Lcie Bureau Veritas Atex Poster PDFDocument1 pageLcie Bureau Veritas Atex Poster PDFAncaOniscuNo ratings yet

- Safety in Pressure TestingDocument12 pagesSafety in Pressure TestingrodofgodNo ratings yet

- PD CR 12953-14-2002Document16 pagesPD CR 12953-14-2002navaronefraNo ratings yet

- Ped Asme ComparisionDocument31 pagesPed Asme ComparisionJose A ManciniNo ratings yet

- Standardization Document, SEFA-7 Spec Gas EquipmentDocument5 pagesStandardization Document, SEFA-7 Spec Gas Equipmentveronica880No ratings yet

- Pressure Equipment - European Commission PDFDocument22 pagesPressure Equipment - European Commission PDFNavneet SumanNo ratings yet

- Heat Treatment: Eurotherm Flexible SolutionsDocument16 pagesHeat Treatment: Eurotherm Flexible SolutionsDarshan SunnyNo ratings yet

- FMEADocument7 pagesFMEAClarizza DiosoNo ratings yet

- ATEX DirectiveDocument4 pagesATEX DirectiveSergeNo ratings yet

- En954 1 PDFDocument16 pagesEn954 1 PDFmagtrolNo ratings yet

- Atex PosterDocument1 pageAtex PosteratumrakisNo ratings yet

- Fire ExplosionDocument15 pagesFire ExplosionMutiaraNo ratings yet

- Exemplo de Análise - HRNDocument10 pagesExemplo de Análise - HRNLucas Zarpelon SilvaNo ratings yet

- BS en 10203-1991 (1999)Document32 pagesBS en 10203-1991 (1999)Sainath AmudaNo ratings yet

- Hydraulic Machines Lecture NotesDocument31 pagesHydraulic Machines Lecture NotesPratik RaoNo ratings yet

- BZ 8009372 PDFDocument22 pagesBZ 8009372 PDFizia_2No ratings yet

- Product Date Sheet - Swagelok BrocureDocument6 pagesProduct Date Sheet - Swagelok BrocurejulianpirahNo ratings yet

- IECEX ATEX ComparisonDocument6 pagesIECEX ATEX ComparisonPilsner80No ratings yet

- Handbook Directive ATEX Compliant MotorsDocument18 pagesHandbook Directive ATEX Compliant MotorsE.ANANDANNo ratings yet

- Iec Hazardous Locations Certification DocumentsDocument2 pagesIec Hazardous Locations Certification DocumentsbubuluqNo ratings yet

- DNV Os-E201 - 2012-12Document1 pageDNV Os-E201 - 2012-12Muthu KumarNo ratings yet

- Igem-Up-20 Introduction and ScopeDocument11 pagesIgem-Up-20 Introduction and ScopeAleksandarNo ratings yet

- Meters SatamDocument12 pagesMeters SatamAnoop ChulliyanNo ratings yet

- EN 14373-2005 Explosion Suppression Systems PDFDocument46 pagesEN 14373-2005 Explosion Suppression Systems PDFMurray PeartNo ratings yet

- Astm C892Document5 pagesAstm C892deivisbtsNo ratings yet

- BS Iso 10961 - 2010Document32 pagesBS Iso 10961 - 2010Luís Silva100% (1)

- Catalogo Sensitiv TADocument12 pagesCatalogo Sensitiv TAFranGigaNo ratings yet

- Msds - Auto I.T KeroseneDocument6 pagesMsds - Auto I.T KeroseneCharith LiyanageNo ratings yet

- Norsok H-003Document22 pagesNorsok H-003ElmoNo ratings yet

- ATEX Requirements Adn EU Certification System PDFDocument37 pagesATEX Requirements Adn EU Certification System PDFtintucinbNo ratings yet

- Aqualung 2010Document84 pagesAqualung 2010Fuchsia BucurestiNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFNicolae VisanNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFAgus RianNo ratings yet

- Marking requirements for electrical equipment used in explosive gas atmospheresDocument1 pageMarking requirements for electrical equipment used in explosive gas atmospheresBinhvvNo ratings yet

- Marking Electrical Equipment ExDocument1 pageMarking Electrical Equipment ExFendy ShirahNo ratings yet

- Marking requirements for non-electrical explosion protected equipmentDocument1 pageMarking requirements for non-electrical explosion protected equipmentTurkish Medical CareNo ratings yet

- Marking Electrical Equipment Ex PDFDocument1 pageMarking Electrical Equipment Ex PDFrakacyuNo ratings yet

- ATEX For Non-ElectricalDocument1 pageATEX For Non-ElectricalRajesh KumarNo ratings yet

- 8.bartec Non-Electrical PosterDocument1 page8.bartec Non-Electrical PosteraungwinnaingNo ratings yet

- Marking IECEx Equipment ExDocument1 pageMarking IECEx Equipment Exadirocks89No ratings yet

- Krista Ann Brown ResumeDocument2 pagesKrista Ann Brown ResumeMMNo ratings yet

- Foglio Di Calcolo LinkDocument1 pageFoglio Di Calcolo LinkMMNo ratings yet

- 2007 SRM-WRC Meeting NotesDocument4 pages2007 SRM-WRC Meeting NotesMMNo ratings yet

- Word Shortcut Keys in 40 CharactersDocument4 pagesWord Shortcut Keys in 40 Characterssophia_stephy9478No ratings yet

- ANSI Flanges Dimensions Specs Grades ClassesDocument23 pagesANSI Flanges Dimensions Specs Grades ClassesVenkatesh GangadharNo ratings yet

- Tabella Colori HTML: Colore Nome Del Colore Valori Dei Tre Numeri RGB (Hex) Valori DecimaliDocument4 pagesTabella Colori HTML: Colore Nome Del Colore Valori Dei Tre Numeri RGB (Hex) Valori DecimaliMMNo ratings yet

- 5.tracks TracklistDocument1 page5.tracks TracklistMMNo ratings yet

- Marking requirements for electrical equipment used in explosive gas atmospheresDocument1 pageMarking requirements for electrical equipment used in explosive gas atmospheresBinhvvNo ratings yet

- Syllabus Course Description: Iandii YesDocument4 pagesSyllabus Course Description: Iandii YesMMNo ratings yet

- Acceptance LetterDocument3 pagesAcceptance LetterMMNo ratings yet

- Antioxidant and Antimicrobial Potential of Aspidistra Elatior ExtractsDocument7 pagesAntioxidant and Antimicrobial Potential of Aspidistra Elatior ExtractsMMNo ratings yet

- Word Shortcut Keys in 40 CharactersDocument4 pagesWord Shortcut Keys in 40 Characterssophia_stephy9478No ratings yet

- The International Phonetic Alphabet (Revised To 2015)Document1 pageThe International Phonetic Alphabet (Revised To 2015)sebasarauzoNo ratings yet

- SEW Motor Brake BMGDocument52 pagesSEW Motor Brake BMGPruthvi ModiNo ratings yet

- 1136 E01-ML01DP5 Usermanual EN V1.2Document11 pages1136 E01-ML01DP5 Usermanual EN V1.2HectorNo ratings yet

- Water Sampling and Borehole Inspection FormsDocument2 pagesWater Sampling and Borehole Inspection FormsSibanda MqondisiNo ratings yet

- Campbell Soup Case-StudyDocument3 pagesCampbell Soup Case-StudyraghudeepaNo ratings yet

- Sea Cities British English Teacher Ver2Document6 pagesSea Cities British English Teacher Ver2Kati T.No ratings yet

- Lab 01 - HCV and LCV by Gas CalorimeterDocument6 pagesLab 01 - HCV and LCV by Gas CalorimeterTakreem SindhuNo ratings yet

- Giraffe Juice GamesDocument32 pagesGiraffe Juice Gamesgwyn022100% (3)

- J05720020120134026Functions and GraphsDocument14 pagesJ05720020120134026Functions and GraphsmuglersaurusNo ratings yet

- Brake System PDFDocument9 pagesBrake System PDFdiego diaz100% (1)

- Superficial ConclusionDocument49 pagesSuperficial ConclusionIngrid ParissNo ratings yet

- The Production and Interpretation of Ritual Transformation Experience: A Study on the Method of Physical Actions of the Baishatun Mazu PilgrimageDocument36 pagesThe Production and Interpretation of Ritual Transformation Experience: A Study on the Method of Physical Actions of the Baishatun Mazu PilgrimageMinmin HsuNo ratings yet

- Influence of Oxygen in Copper - 2010Document1 pageInfluence of Oxygen in Copper - 2010brunoNo ratings yet

- Whirlpool FL 5064 (ET)Document8 pagesWhirlpool FL 5064 (ET)long_kongo100% (1)

- Employees' Job Satisfaction and Organizational Performance A Case of KSRTCDocument4 pagesEmployees' Job Satisfaction and Organizational Performance A Case of KSRTCEditor IJTSRDNo ratings yet

- Mohammad Abu-Radi ResumeDocument4 pagesMohammad Abu-Radi ResumeMohammad Abu-RadiNo ratings yet

- CHB1 Assignmen5Document2 pagesCHB1 Assignmen5anhspidermenNo ratings yet

- Y06209 November 2015Document28 pagesY06209 November 2015Fredy CoyagoNo ratings yet

- Hackathon Statements V1Document10 pagesHackathon Statements V1AayushNo ratings yet

- Exp-1. Evacuative Tube ConcentratorDocument8 pagesExp-1. Evacuative Tube ConcentratorWaseem Nawaz MohammedNo ratings yet

- 6.1.3 Final Exam - Exam (Exam)Document8 pages6.1.3 Final Exam - Exam (Exam)parker3poseyNo ratings yet

- Pop-Up SystemDocument4 pagesPop-Up Systemkothat82No ratings yet

- BA 302 Lesson 3Document26 pagesBA 302 Lesson 3ピザンメルビンNo ratings yet

- Transportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDocument11 pagesTransportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDaniel Juan De Dios OchoaNo ratings yet

- By Emile Alline: Technical Art by Fred WolffDocument4 pagesBy Emile Alline: Technical Art by Fred WolffJim100% (3)

- 9-Lesson 5 Direct and Indirect SpeechDocument8 pages9-Lesson 5 Direct and Indirect Speechlaiwelyn100% (4)

- CA Module Franklin Gari RDocument28 pagesCA Module Franklin Gari RFranklin GariNo ratings yet

- Sulzer MC EquipmentDocument12 pagesSulzer MC EquipmentsnthmlgtNo ratings yet

- Quiz 1Document3 pagesQuiz 1JULIANNE BAYHONNo ratings yet

- Tithi PRAVESHADocument38 pagesTithi PRAVESHAdbbircs100% (1)

- wt-and-fds-practical-slipsDocument32 pageswt-and-fds-practical-slipsRohidas SapkalNo ratings yet