Professional Documents

Culture Documents

Understanding MIG Welding Nozzles

Uploaded by

ahmed0 ratings0% found this document useful (0 votes)

25 views2 pagesUnderstanding MIG Welding Nozzles

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUnderstanding MIG Welding Nozzles

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views2 pagesUnderstanding MIG Welding Nozzles

Uploaded by

ahmedUnderstanding MIG Welding Nozzles

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

246

Understanding MIG Welding Nozzles

Welding gun nozzles play a critical role in the welding operation. Having the right nozzle for the job can help reduce

weld defects, rework and associated downtime — while also extending consumable life. All of these factors impact

the bottom line.

Unfortunately, like other MIG welding consumables, the importance of

selecting the right nozzle is often overlooked. In any welding application, the

right shape and style of nozzle, however, can have a significant impact on the

quality, productivity and overall cost of the welding operation. Knowing how to

store and handle nozzles properly can also help improve their overall

performance. Consider these tips to get the best results.

Selecting the Right Shape of Nozzle

There are several shapes of nozzles available, including straight, bottleneck

and short or long taper nozzles. Straight nozzles typically have larger inside Nozzles that feature a fiberglass insulator and brass

diameters (e.g., 3/4 inch), but don’t offer as good of joint access. If greater insert, as shown in this cut-away, can help extend

the life of the consumable. The brass insert,

joint access is critical, a bottleneck nozzle may be the better option. These in particular, helps maintain the inner diameter

of the nozzle and reduce wear.

nozzles are particularly good for automated welding applications. A common

inside diameter for a bottleneck nozzle is 1/2 inch.

Short and long taper nozzles are also common choices for gaining good joint access. Note, that long taper nozzles

typically have a smaller inside diameters and may collect spatter more readily. When possible, using a short taper

nozzle can help prevent such a problem.

When selecting a nozzle, it is important to find one that provides the best joint access for the application. It is also

imperative that the nozzle allows for the proper gas flow to the weld puddle in order to keep contaminants away. The

best choice is to use as large of a nozzle as possible that still allows access to the weld joint. Doing so helps ensure

the greatest shielding gas flow. Larger nozzles are also less prone to collecting spatter compared to those with

smaller inside diameters.

Welding

Application Nozzles Considerations

The higher the welding current, the larger the bore size of the nozzles should be.

Welding Current Consider standard duty nozzles for low welding current applications to save money

Use a heavy-duty, copper nozzle for the high heat1 applications.

Brass nozzles have good spatted resistance and can take more manual abuse than copper

nozzles at medium and low heat applications.

High Heat Brass loses most merits when the temperature is above 450 degrees Celsius (840 F).

The general rule of thumb is to use as long a nozzle as possible to save gas and get sufficient

gas coverage. However, if weld access is an issue, use a short nozzle.

Taper or bottleneck nozzles shapes can also help.

Limited Weld Access

If heavy spatter is expected (i.e. galvanized base metal, or, oily surface, or, short circuit weld,

Heavy Spatter

100% CO2, etc.), use a short nozzle with a larger bore size

Generation Brass material is also a good choice depending on head (see above).

Straight bore nozzles are recommended to achieve the most effective cleaning with a robotic

Using Nozzle Cleaning

Stations nozzle cleaning station or reamer.

1

For extreme heat applications, consider water cooled nozzles/guns.

Selecting the Best Material

Nozzles are typically available in heavy-duty or standard styles, and in slip-on or thread-on varieties. Heavy-duty

nozzles have thicker walls, as well as thicker insulators, and are designed for use in applications ranging from 400

to 600 amps. Due to their heavier construction, these nozzles resist heat better than standard varieties. Standard

nozzles tend to have a thinner wall and are better for 100- to 300-amp applications. Slip-on nozzles, as their name

implies, simply slip on to the front end of the MIG gun. These nozzles are quite prevalent in the industry, compared

to thread-on nozzles that need to be twisted to install, and they offer the advantage of being able to change over

more quickly. A note of caution: when installing slip-on nozzles, be certain that they are fully seated on the retaining

head to prevent shielding gas leaks that could lead to poor weld quality.

Nozzles are typically available in brass or copper, although chrome-plated nozzles are also available. Brass nozzles

tend to resist spatter well and are good for lower-amperage applications (100 to 300 amps), whereas copper

nozzles are better for high-amperage applications (above 300 amps) or for those with longer arc-on time.

For high-amperage water-cooled applications, there are also nozzles available that circulate coolant around the

nozzles, but these tend to be much more expensive.

Proper Storage, Handling and Maintenance

It is important to handle, store and maintain nozzles properly to gain consistent

welding performance and prevent premature failure. Selecting high quality

nozzles can help these consumables last longer, too.

Look for nozzles that are engineered with a smooth surface finish and edges, as

these resist spatter build-up compared to nozzles that have an uneven surface

or burrs on the edges. Nozzles that have some mass to them are also more

desirable than lighter or thinner ones since they tend to resist heat better. Also,

consider purchasing nozzles that feature a brass insert. This insert helps the

nozzle maintain its inner diameter, and prevents the nozzle from rocking and

Checking the nozzle periodically for spatter wearing prematurely. The addition of a high-temperature fiberglass insulator can

build-up, as seen here, and cleaning it

properly can help extend the life of the also help extend nozzle life. Finally, look for heavy-duty crimping on the nozzle

consumable. Adding anti-spatter can also

help prevent build-up.

— the crimping holds the layers together and is an indication that the nozzle has

been built for longevity.

When storing nozzles, keep them in their original packaging, usually a small plastic bag. Removing them from that

packaging and placing them in a bin can lead to scratches or dents that allow spatter to adhere and will ultimately

shorten the life of the nozzle. Use gloves when handling nozzles or replacing nozzles to prevent dirt, oil or other

contaminants from adhering to them and inadvertently entering the weld puddle.

Periodically inspect the nozzle for spatter build-up and clean it using the tool recommended by the manufacturer as

needed and/or consider using an anti-spatter compound to protect against spatter.

As with any front-end consumable, nozzles play an important role in maintaining good weld quality and can have a

measurable impact on productivity and costs, too. Take the time to select the right ones for each application and

maintain them properly. Careful selection and maintenance can minimize downtime and keep your welding

operation running more smoothly in the long run.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Assignment No. 4 BlankDocument15 pagesAssignment No. 4 BlankahmedNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grade Structure Revamping TemplateDocument1 pageGrade Structure Revamping TemplateahmedNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Fuel TrimsDocument6 pagesFuel TrimsahmedNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- 5S PrincipleDocument53 pages5S PrincipleAmir M. VillasNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- YIC Materials Testing Lab Equipment and ExperimentsDocument2 pagesYIC Materials Testing Lab Equipment and ExperimentsahmedNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Illness Caused by Welding Fume and GasesDocument2 pagesIllness Caused by Welding Fume and GasesahmedNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Department OF Mechanical Engineering Technology: Heat Engines LaboratoryDocument2 pagesDepartment OF Mechanical Engineering Technology: Heat Engines LaboratoryahmedNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

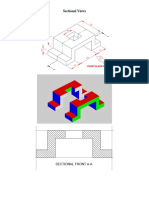

- Sectional ViewDocument2 pagesSectional ViewahmedNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Science Answer KeyDocument1 pageScience Answer KeyahmedNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Abdullah - Book Appointment With Consulate General of Pakistan, Jeddah PDFDocument1 pageAbdullah - Book Appointment With Consulate General of Pakistan, Jeddah PDFahmedNo ratings yet

- Measuring Metal Strength (Tensile & Impact Strength)Document5 pagesMeasuring Metal Strength (Tensile & Impact Strength)ahmedNo ratings yet

- 6 Mistakes That Can Lead To Cracked WeldsDocument4 pages6 Mistakes That Can Lead To Cracked WeldsahmedNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Drill Bit Size ChartDocument22 pagesDrill Bit Size ChartahmedNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 7 Ways You Are Violating Welding Procedures and Don't Know ItDocument2 pages7 Ways You Are Violating Welding Procedures and Don't Know ItahmedNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Plasma 2Document13 pagesPlasma 2ahmedNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Btus, CFMS, and Gges DemystifiedDocument2 pagesBtus, CFMS, and Gges DemystifiedahmedNo ratings yet

- Tip Data For OFWDocument1 pageTip Data For OFWahmedNo ratings yet

- Deposition Rates For Stick ElectrodesDocument3 pagesDeposition Rates For Stick ElectrodesahmedNo ratings yet

- PlasmaDocument8 pagesPlasmaahmedNo ratings yet

- PlasmaDocument7 pagesPlasmaahmedNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Why Is "Cold Cutting" Superior To Plasma Cutting?Document9 pagesWhy Is "Cold Cutting" Superior To Plasma Cutting?ahmedNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Plasma 2Document14 pagesPlasma 2ahmedNo ratings yet

- CGA Selection Chart for Pure & Mixed Industrial GasesDocument1 pageCGA Selection Chart for Pure & Mixed Industrial GasesSadot GutierrezNo ratings yet

- Grinding Wheel SpecificationsDocument2 pagesGrinding Wheel SpecificationsahmedNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- ASGEpg187 PDFDocument3 pagesASGEpg187 PDFbkprodhNo ratings yet

- Help Welding Calculation - WeldingDocument14 pagesHelp Welding Calculation - Weldingahmed100% (1)

- Method of Calculating The Cooling Rate in HAZ During WeldingDocument6 pagesMethod of Calculating The Cooling Rate in HAZ During WeldingahmedNo ratings yet

- To Be Free From Oil and Dirt ADAPTOR, CGA-022 To 1/4 NPT GDG PSMDocument1 pageTo Be Free From Oil and Dirt ADAPTOR, CGA-022 To 1/4 NPT GDG PSMahmedNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- UNCUNF Threads - SizeDocument1 pageUNCUNF Threads - SizeahmedNo ratings yet

- A Complete Guide To Pipe SizesDocument25 pagesA Complete Guide To Pipe SizesahmedNo ratings yet

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- Hse Powerpoint - pptx1Document161 pagesHse Powerpoint - pptx1Gbenga Mobolade100% (3)

- Barangay Skills Need Survey Form 2-TADIAN MUNICIPALITYDocument230 pagesBarangay Skills Need Survey Form 2-TADIAN MUNICIPALITYshell liwagNo ratings yet

- A020 PDFDocument32 pagesA020 PDFsolrac4371No ratings yet

- Residualstresslaserwelding 141216211007 Conversion Gate02Document18 pagesResidualstresslaserwelding 141216211007 Conversion Gate02mostafaNo ratings yet

- Double-Wall, Flat Oval Duct and Fittings DimensionsDocument46 pagesDouble-Wall, Flat Oval Duct and Fittings DimensionsShaun SullivanNo ratings yet

- List Applicable WPS StructureDocument7 pagesList Applicable WPS StructureFerdie OSNo ratings yet

- A10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsDocument9 pagesA10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsXNo ratings yet

- Saw Wire& Flux......Document41 pagesSaw Wire& Flux......Arul ChinnapillaiNo ratings yet

- SMAW NC I Safety ModuleDocument30 pagesSMAW NC I Safety ModuleCelso Amoto100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 005 Plate PDFDocument22 pages005 Plate PDFnice guyNo ratings yet

- GIS 18 012 31 October 2007Document11 pagesGIS 18 012 31 October 2007Jose Carlos100% (1)

- 14.99.90.6915 Rev. 2 RADIOGRAPHY EXAMINATION PROCEDURE PDFDocument22 pages14.99.90.6915 Rev. 2 RADIOGRAPHY EXAMINATION PROCEDURE PDFMANIGANDANNo ratings yet

- EDO WMS Fuel Storage Tank R01Document29 pagesEDO WMS Fuel Storage Tank R01ocayli100% (1)

- Ansi-Aws d1.2 PDFDocument208 pagesAnsi-Aws d1.2 PDFzokytoNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationGodwin A.udo-akanNo ratings yet

- Centrifugal Pumps Specification Provides Design RequirementsDocument20 pagesCentrifugal Pumps Specification Provides Design RequirementsRochdi SahliNo ratings yet

- Presentation Lightning Protection System by JMV LPSDocument62 pagesPresentation Lightning Protection System by JMV LPSMahesh Chandra ManavNo ratings yet

- 8 Tips MIG Welding BeginnersDocument7 pages8 Tips MIG Welding BeginnerspeterNo ratings yet

- Welding and Joining ProcessesDocument4 pagesWelding and Joining ProcessesImran AliNo ratings yet

- E1416-96 Radioscopic Exam of WeldmentsDocument5 pagesE1416-96 Radioscopic Exam of WeldmentssanthakumarNo ratings yet

- Process Planning AssimentDocument9 pagesProcess Planning Assimentዮሐንስ ታደሰNo ratings yet

- CoorsTek SmWedgeDocument60 pagesCoorsTek SmWedgeRonnie MagsinoNo ratings yet

- CWS-Certified Welding Supervisor 9-Yr Recertification / Re-Exam ApplicationDocument5 pagesCWS-Certified Welding Supervisor 9-Yr Recertification / Re-Exam Applicationwilliam cordero valverdeNo ratings yet

- Booklet Weldcap Weldline Eng 4148400610414924156 PDFDocument4 pagesBooklet Weldcap Weldline Eng 4148400610414924156 PDFMilan RadosavljevicNo ratings yet

- 405HTR - EnvirolineDocument4 pages405HTR - EnvirolineEdinsonNo ratings yet

- Ccsviiid1 2156Document2 pagesCcsviiid1 2156DieguitoOmarMoralesNo ratings yet

- Summary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTDocument14 pagesSummary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTTin Aung KyiNo ratings yet

- DEP 31.10.00.10 Material Control and Verification (PMI)Document25 pagesDEP 31.10.00.10 Material Control and Verification (PMI)MN VenkatesanNo ratings yet

- Erection of DPC Clinker Silo Extraction-2Document7 pagesErection of DPC Clinker Silo Extraction-2RajuNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)