Professional Documents

Culture Documents

Attachment X Training

Uploaded by

waleed mohiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Attachment X Training

Uploaded by

waleed mohiCopyright:

Available Formats

Sudanese Thermal Power Generating

Co. Ltd.

Attachment X: Training

Training

1 INTRODUCTION ......................................................................................................................................... 2

2 TRAINING PROGRAM OVERVIEW ......................................................................................................... 2

3 TRAINING FOR POWER PLANT MANAGEMENT ................................................................................. 3

3.1 P OWER PLANT MANAGEMENT SEMINAR ........................................................................................................... 3

4 TRAINING PROGRAM BASICS FOR OPERATION & MAINTENANCE .............................................. 4

4.1 P OWER PLANT FUNDAMENTAL COURSE ............................................................................................................ 4

4.2 BASIC OPERATION TRAINING ............................................................................................................................. 5

5 TRAINING PROGRAM FOR OPERATION PERSONNEL...................................................................... 6

5.1 GAS POWER PLANT O PERATION TRAINING (MMI) ........................................................................................... 6

5.2 P ROTECTION AND TROUBLESHOOTING OPERATION TRAINING (SIMULATOR) ................................................. 6

5.3 TRIP AVOIDANCE AND MENTAL STRENGTH TRAINING ....................................................................................... 7

5.4 ON THE JOB TRAINING FOR OPERATORS ............................................................................................................ 7

6 TRAINING PROGRAM FOR MECHANICAL MAINTENANCE PERSONNEL (INCLUDED IN EPC

CONTRACT_FOR INFORMATION ONLY) ...................................................................................................... 8

GAS TURBINE MAINTENANCE TRAINING (INCLUDED IN EPC CONTRACT_ FOR INFORMATION ONLY)......................... 8

7 TRAINING PROGRAM FOR ELECTRICAL MAINTENANCE AND I&C PERSONNEL ...................... 9

7.1 OPERATION POWER P LANT FOR MAINTENANCE PERSONNEL ........................................................................... 9

7.2 GENERATOR MAINTENANCE TRAINING (INCLUDED IN EPC CONTRACT _ FOR INFORMATION ONLY) .......... 10

7.3 S YNCHRONIZATION AND P ROTECTION FOR ELECTRICAL MAINTENANCE (INCLUDED IN EPC CONTRACT_ FOR

INFORMATION ONLY) ...................................................................................................................................................... 11

7.4 SEE/SFC TRAINING (INCLUDED IN EPC CONTRACT _ FOR INFORMATION ONLY )......................................... 11

7.5 INSTRUMENTATION & CONTROL SPPA-T3000 MAINTENANCE TRAINING ................................................... 12

8 COMPLEMENTARY TRAININGS ...........................................................................................................13

8.1 WIN_TS WEB-BASED ........................................................................................................................................ 14

8.2 HSE ................................................................................................................................................................... 14

8.3 CERTIFICATION PROGRAM FOR O PERATION & MAINTENANCE PERSONNEL ................................................. 14

9 REFRESHER TRAINING .........................................................................................................................16

9.1 FASTRAMPUP & QUALIFICATION TRAINING PACKAGE DURING S ERVICE CONTRACT P HASE ...................... 16

10 PRICING AND PAYMENT CONDITIONS ..........................................................................................17

11 GENERAL CONSIDERATIONS ..........................................................................................................17

11.1 P RE-REQUISITES OF TRAINING ......................................................................................................................... 17

11.2 S COPE OF SERVICES .......................................................................................................................................... 17

11.3 TRAINING COORDINATION ................................................................................................................................ 18

11.4 INCLUSIONS AND EXCLUSIONS ......................................................................................................................... 18

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 1 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

1 Introduction

This training program is designed to provide a better understanding of the equipment and its associated

auxiliary systems of the Siemens scope of supply and will support the handling of the individual components

and of the systems.

Our training program is anticipated for power plant personnel and management with a general knowledge of

power plant technology or related areas and requires only orientation to the specifics of the plant.

Each trainee will get a personal training manual in English language and all lessons will be performed in

English too, if no other language is mentioned within the module description.

The training program takes into account the necessary qualification and number of participants as

described in the offer. It consists of general training on the one hand which applies for operation and

maintenance personnel as well. After the general training, specific training according to the particular needs

for operation and maintenance will complete the training.

2 Training Program Overview

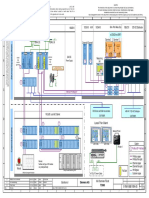

Chart description:

Chapter: detailed course description Participants: Number of max. participants

Days: Number of training days per course Execution: Number of executions of the course

Offsite: Training location in Germany Onsite: Training location at power station or next to

TRAINING PROGRAM SUMMARY

Particpants max.

Nr. of execution

Training topic Offsite Onsite

Days

No.

3. Training Power Plant Management

3.1. 8 5 1 Power Plant Managment Seminar X

4. Training Program Basics for Operation & Maintenance

4.1. 25 10 1 Power Plant Fundamental Course X

4.2. 25 15 2 Basic Operation Training X

5. Training Program for Operation Personnel

5.1. 8 5 3 Gas Power Plant Operator Training X

5.2. 8 5 3 Troubleshooting Operator Training X

5.3. 8 5 1 Trip avoidance and mental strength training X

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 2 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

5.5. 10 10 0 On the Job Training for Operators

5.4. 10 20 1 On the Job Training for Operators X

Training Program for Electrical Maintenance and I&C

7. Personnel

7.1. 8 5 2 Operation Power Plant for Maintenance X

7.5. 4 4 1 SPPA-T3000 Administration X

8. Complementary Training

8.1. 8 2 1 Win_TS X

8.2. 8 10 1 HSE X

8.3. 24 10 1 Certification program for operators personnel X

3 Training for Power Plant Management

Target Group

This course is recommended for power plant management personnel.

3.1 Power Plant Management Seminar

Learning Target

With the aid of the power plant simulator, participants can quickly and efficiently familiarize themselves with

the workflows encountered in a power plant. The simulator - analogous to a flight simulator for pilots - is the

most efficient way to see how a gas power plant works. Practical experiments conducted under the

supervision of a trainer help participants put themselves in the position of a real operator. A prior knowledge

of power plant operations management fundamentals is required. On successful completion of this course,

participants will have a solid basic understanding of the operation of a gas turbine power plant.

Course Contents

Simulator Part

∂ Siemens gas turbine power plant configuration

∂ Introduction in SPPA-T3000, familiarization and applications

∂ O&M displays, operator control elements and key characteristics

∂ Principles of function diagrams and logic elements

∂ Fundamentals of power plant operations management

∂ Startup and shutdown of a gas turbine power plant

Gas Turbine Part

∂ Visit of GT factory

∂ Gas turbine documentation

∂ Measuring instruments at GT

∂ Lube & lift oil system

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 3 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

∂ Fuel gas system

4 Training Program Basics for Operation & Maintenance

Target Group

This course is recommended for operation and maintenance personnel employed at the power plant.

4.1 Power Plant Fundamental Course

The power plant foundation course provides a theoretical knowledge of the systems and components in

regard to operate and maintain of the power plant.

Objective

This basic training course is designed to cover the following:

∂ Energy market and types of power plants

∂ Roles and people in a power plant (from station manager to shop keeper)

∂ Basic physics and mathematics for power plants

Course Contents

Gas Turbine Power Plant

∂ Overview

∂ single shaft, multi shaft,

∂ clutch

∂ bearings

Electrical System

∂ Generator & transformer principles and types

∂ Voltage levels, switchgears, bus bars

∂ circuit breaker

∂ Excitation, SFC/SEE

∂ grid mode, island mode, black start, frequency stabilization

Cycle Process of Thermal Power Plant

∂ Thermodynamic principles, thermodynamic cycle, efficiency

∂ Cooling

∂ Natural gas and fuel oil systems, emissions

∂ Start up and shutdown

Gas Turbine Overview

∂ Components of gas turbines

∂ Auxiliary systems of a gas turbine

∂ Start up and shutdown

Basics of Control Systems SPPA-T3000

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 4 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

∂ Hardware overview, cabinets

∂ Field components (like actors, sensors, valve types, pump types, ...)

4.2 Basic Operation Training

4.2.1 Basic Operation Training (E-I&C, GT)

General Part

∂ Introduction

∂ KKS system

∂ Siemens customer documentation (overview)

Electrical and I&C-Part

∂ Generator

∂ Excitation Equipment

∂ Static Frequency Converter

∂ Auxiliary Power Supply

∂ Auxiliary Systems

∂ Transformer

∂ I&C Concept

∂ Introduction to Siemens power plant automation and control system

∂ I&C Documentation

∂ Open-Loop Controls (group, subgroup and sub loop control, drive control)

Mechanical Part, Gas Turbine

∂ Gas turbine design

∂ Gas turbine fuel system

∂ Lube oil system

∂ Air filtration

∂ Gas turbine controller

∂ Gas turbine operation

Prerequisites

A working knowledge of basic power plant functions and the ability to interpret technical and operational

manuals is required.

Based on this training package all station employees can go to the next step of training program for their

particular job related training packages.

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 5 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

5 Training Program for Operation Personnel

Target Group

This course is recommended for control room engineers and technicians.

5.1 Gas Power Plant Operation Training (MMI)

Introduction

The power plant simulator course is designed to familiarize control room operators with the various features

of the DCS control system as its functions to control a simulated gas turbine power plant. Extensive and

repeated hands-on practice in normal plant start-up, operation, and shutdown procedures on a power plant

control simulator provides the vehicle for gaining the experience in controlling, recognizing and interpreting

the interactions between the various plant units. Upon completion of this training, the participants are

expected to be prepared to operate the power plant.

Course Contents

Simulated Power Plant Configuration

∂ Conditions of operation

∂ Simulation of operation

Control Room Operator Station (Thin clients)

∂ Level of access

∂ Plant displays

Process Displays (Trends)

∂ Pre-configured and user-configured trend

Introduction to Function Diagrams

∂ Display organization (hierarchically)

∂ Reading and navigate software diagrams

∂ Troubleshooting

Alarm Sequence Display (ASD)

∂ Alarm handling

∂ Filtering of alarms

Power Plant Control Operations

∂ Operational considerations

5.2 Protection and troubleshooting Operation Training (Simulator)

Introduction

Improvement of operation knowledge through intensive and interactive practice on power plant plant

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 6 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

simulator of system malfunctions.

Course Contents

The following is covered in the course.

∂ Analysis of GT, ST, BoP and HRSG startup and shutdown behavior

∂ Handling of malfunctions during startup operation and shutdown

∂ Gas and steam turbine trip and restart

∂ System and components trips

∂ Gas turbine protection shutdown

∂ Selection of actual plant events based on Siemens power diagnostic

∂ Discussion of functional diagrams based on selected problems

∂ Analysis of trip logics and consequences

Prerequisites

Participation in the course Operation MMI Training is recommended.

5.3 Trip avoidance and mental strength training

Introduction

This interactive training is designed to track and manage problems in a systematic way. Handling of

abnormal scenarios and troubleshooting under stress is essential for power plant personnel. Manage risks,

protect investment, reduce accidents and stress related mistakes to keep your power plant running. Drill

supports plant safety by effective operation. Use state of the art plant simulators and realistic practical

cases. The training helps to avoid trips and reduces shutdown periods. Be back in commercial operation

ahead of others.

Course Contents

∂ Troubleshooting based on realistic scenarios

∂ Self-analyzing stressful situation and own behavior

∂ Supporting other people under stress

∂ Tools and guidelines for stress handling

∂ SPPA-T3000 features used for troubleshooting and reporting

∂ Practical applications in stressful environment

Prerequisites

Participation in the course Operation MMI Training is recommended.

5.4 On the Job Training for Operators

Introduction

As the demand for operators continues to increase throughout the industry, we are faced with a shortage of

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 7 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

experienced personnel. With the need for operating personnel, plants are being staffed with people who

need more guidance and training attention than an operator who has previous power plant experience

and/or operation experience. Siemens has designed a support service that will provide an instructor to

assist the operation and partially maintenance personnel during the startup and commissioning phase of

the plant construction or for a plant currently in operation. An instructor will be available to support and

validate the actions of control room operators, equipment operators and maintenance personnel, as normal

day-to-day activities are conducted. The level of support will be customized to meet the individual plant

needs.

Course Contents

Course will consist of informal and impromptu onsite discussions and demonstrations.

Topics will cover the normal day-to-day operation and maintenance of customer plant systems during

equipment erection, startup/ commissioning phase or any trouble areas experienced at the plant.

Actual course contents conform to equipment and system availability as well as customer requirements.

Special Activities

Plant system operation and maintenance demonstrations may be supplemented by classroom instruction

as required.

Prerequisites

Participation in the course Operation MMI Training is recommended.

6 Training Program for Mechanical Maintenance Personnel

(included in EPC contract_for Information only)

Target Group

This course is recommended for plant mechanical maintenance personnel.

Gas Turbine Maintenance Training (included in EPC Contract_for Information

only)

Introduction

The gas turbine daily preventive maintenance training is designed to teach operation and maintenance

personnel the concepts of preventive maintenance, routine inspections, and site equipment specific

preventive maintenance recommendations of the Siemens gas turbine and its associated systems. This

course will use a combination of classroom instruction and plant walkabouts. Upon completion of this

course, the participants are expected to be prepared for on-the-job training in plant preventive maintenance

procedures and development of the site preventive maintenance program.

Course Contents

The following topics are representative of those covered in the course. Actual course content is customized

to the specific plant configuration.

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 8 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

Introduction

∂ Preventive maintenance philosophy

∂ Safety considerations

∂ Introduction to commissioning / operation

∂ Equivalent operating hours - EOH

∂ Overview gas turbine and auxiliary systems

System Preventive Maintenance of GT

∂ System function overview

∂ Identify equipment requiring preventive maintenance

∂ Periodicity guidelines

∂ Gathering specific component data

∂ Applying vendor recommended maintenance

∂ Developing site specific maintenance program

Administration

∂ Service bulletins

∂ Technical advisories

∂ Trending parameters

∂ Maintenance records documentation

∂ Equipment

∂ History

7 Training Program for Electrical Maintenance and I&C

Personnel

Target Group

This course is recommended for plant electrical and I&C maintenance personnel.

7.1 Operation Power Plant for Maintenance personnel

Introduction

The power plant simulator training is designed to familiarize maintenance personnel with the various

features of the DCS control system as it functions to control a simulated gas turbine power plant. Extensive

and repeated hands-on practice in normal plant start-up, operation and shutdown procedures on a power

plant control simulator provides the vehicle for gaining the experience in controlling, recognizing and

interpreting the interactions between the various plant units.

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 9 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

Course Contents

Simulated Power Plant Configuration

∂ Conditions of operation

∂ Simulation of operation

Control Room Operator Station (Thin clients)

∂ Level of access

∂ Plant displays

Process Displays (Trends)

∂ Pre-configured and user-configured trend

Introduction to Function Diagrams

∂ Display organization (hierarchically)

∂ Reading and navigate software diagrams

∂ Troubleshooting

Alarm Sequence Display (ASD)

∂ Alarm handling

∂ Filtering of alarms

Power Plant Control Operations

∂ Operational considerations

7.2 Generator Maintenance Training (included in EPC Contract _ for information

only)

Introduction

The generator preventive maintenance training is designed to teach operation and maintenance personnel

the concepts of preventive maintenance, routine inspections and site equipment specific preventive

maintenance recommendations of the generator and its associated systems. Upon completion of this

course, the participants are expected to be prepared for on-the-job training in plant preventive maintenance

procedures and development of the site preventive maintenance program.

Course Contents

∂ Preventive maintenance philosophy

∂ Safety considerations

∂ Overview generator and auxiliary systems

∂ Operating hour counter

∂ System function overview

∂ Identify equipment requiring preventive maintenance

∂ Periodicity guidelines

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 10 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

∂ Gathering specific component data

∂ Applying vendor recommended maintenance

∂ Developing site specific maintenance program

∂ Service bulletins & technical advisories

∂ Technical advisories

∂ Trending parameters

∂ Maintenance records

∂ Equipment history

7.3 Synchronization and Protection for electrical Maintenance (included in EPC

Contract_for information only)

Introduction

The participant learn the basics of synchronous generators, to operate the protection devices, tasks of the

components, basics of different protective functions and testing of it with a secondary injection kit

(OMICRON) and primary testing (generator model), handling of the operation software DIGSI. Introduction

to commissioning issues.

Course Contents

∂ basics of synchronous generators

∂ numerical protection devices from Siemens

∂ description and tasks of protective functions and protection circuits

∂ introduction to the operating software DIGSI and Testuniverse

∂ introduction to the commissioning documentation

∂ Execution of a secondary injection test (OMICRON) with exemplary protective functions under use

of the commissioning documentation (instructions, check lists, wiring diagrams, parameter lists) at

generator / transformer protection cubicle.

∂ Execution of a primary test (generator model) with exemplary protective functions under use of the

commissioning documentation (instructions, check lists, wiring diagrams, parameter lists) at a

generator / transformer protection cubicle.

∂ Exercises to hardware customization of SIPROTEC-devices

∂ Exercises to firmware-updates of SIPROTEC-devices

7.4 SEE/SFC Training (included in EPC Contract _ for information only)

Course Contents

SFC

∂ Basic of current source inverters

∂ Feedback control structure

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 11 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

∂ Start-up sequence and interlocks

∂ Software tools

∂ Operating and handling

∂ SFC Service, commissioning and maintenance information and tools

∂ Usage of the manuals and handbooks

∂ Trouble shooting (if possible)

SEE EXCITATION

∂ Basic of power generator control

∂ Feedback control structure

∂ Hardware and print boards

∂ Start-up sequence and interlock

∂ Software tools

∂ Safety concept

∂ Operating and handling

∂ Service, commissioning and maintenance information and tools

∂ Usage of the manuals and handbooks

∂ Trouble shooting (if possible)

7.5 Instrumentation & Control SPPA-T3000 Maintenance Training

7.5.1 I&C Maintenance SPPA-T3000 Training package

Introduction

On completion of this course, participants will be able to perform all activities required for

maintenance of the Siemens instrumentation and control (I&C) and the Automation System

used in power plants. They will learn how to detect and localize faults in the components of the

HMI system, eliminate these faults if applicable using simple inputs and use the hotline support.

Project-specific files in the Engineering System are also handled.

Course Contents

∂ Addressing of a Simatic CPU

∂ Starting up an application-/automation server

∂ Understanding and handling of dynamic FUP

∂ Simulation of binary and analog signals

∂ Fault analysis using diagnostic tools

∂ Tools for system analysis, administration, event handling

∂ Analysis of hardware and software errors

∂ Overview of controller functions

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 12 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

∂ Overview of fast digital control system

7.5.2 SPPA-T3000 Administration and Commissioning (T3ADM-1) (part of

package)

Introduction

This course applies to I&C staff and Siemens personnel responsible for administrative

tasks in SPPA-T3000 plants or for commissioning. The participants will learn how to do

project-specific modification of the basic installation, as well as how to verify network

settings and to configure a thin client. The participant will learn how to install a SIMATIC

license and SPPA-T3000 license as well as perform the thin client back-up & restore

procedure. They will learn how to swap out archive data and to engineer management

proxies. Furthermore, the emphasis is on the integration of new S7 Automation Servers,

systems analysis and the basics of the SPPA-T3000 safety concept

Prerequisite

T3K Basic and Advanced Engineering Certificate

Course Contents

∂ Basics of network engineering and specific aspects of network administration

∂ Configuring thin clients

∂ Modifying the fault-tolerant application server during commissioning

∂ Functional principle of the time synchronization on SPPA-T3000 devices

∂ Integration of S7 automation server

∂ System analysis tools

∂ Theory of data archiving and handling of data storage

∂ Backup and restore concept for the SPPA-T3000

∂ Functional principle of online SPPA-T3000 upgrade and patch installation

∂ Safety requirements and their implementation through the SPPA-T3000 safety concept

∂ Installing network printers

8 Complementary Trainings

Target Group

This course is recommended for operation and maintenance personnel employed at the power plant.

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 13 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

8.1 Win_TS web-based

Course Contents

∂ WIN_TSplus tasks

∂ WIN_TSplus hardware

∂ WIN_TSplus software structures

∂ WIN_TSplus Introduction

∂ Hardware overview

∂ System configuration and structures

∂ Integration of WIN_TS plus

∂ Basic components

∂ User interfaces

∂ WinCC interface (general overview)

∂ WEB interface

∂ Operation statistics GT, ST

∂ I&C interfaces

∂ Data analysis tools

∂ Messhaus

∂ TurbineTrendViewer TTV

∂ TurbineDataExplorer TDE

∂ ProfiSignal Flight recorder

∂ Overview, data acquisition, software overview

∂ View life (real-time) data trends, read historical data

Conditions

∂ Location: web based

8.2 HSE

Introduction / Course contents

HSE training of the complete power plant staff will be done to explain the general HSE policy of the

company and site, and to make the personnel aware of the regulations and procedures, which must be

followed in the power plant to assure safe and healthy working conditions, prevention of occupational

illnesses, injuries and pollution, and carrying out obligations under governing laws and regulations and

contract requirements.

8.3 Certification Program for Operation & Maintenance Personnel

Overview of Operator Certification Program:

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 14 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

8.3.1 Pre Assessment – web-based

Course Contents

∂ Administration including questionnaire

∂ Booking and assignment of participants

∂ Test & test analysis via internet

∂ Testing period: five working days

8.3.2 Operator Test – web-based

Course Contents

∂ Administration and questionnaire

∂ Booking and assignment of participants

∂ Test & test analysis via internet

∂ Period of test-availability: five working days

8.3.3 Five Days Operator Test – Based on remote power plant simulator

Course Contents

∂ Siemens auditor available during test period

∂ Test of all operational work steps to run an gas turbine power plant via simulation

∂ Test of critical situations e.g. trouble shooting via simulation

∂ Personal rotating test due to operational shift situation

8.3.4 On-site audit

Course Contents

∂ Siemens auditor available during test period

∂ Individual test of all operational issues to run an gas turbine power plant

∂ Test of cooperation between operation room and field

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 15 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

∂ Personal rotating test due to operational shift situation

Conditions for certification program:

∂ Number of participants: max. 20 test candidates (1 person per test slot - provided WEB Sim Part

(item 2) and the interview (item 3) will take place at onsite

∂ Course location: defined by Siemens O&M Training Center

∂ Schedule to be mutually agreed, latest three months before the start of the certification program

9 Refresher Training

Target Group

This course is recommended for new operation and maintenance personnel employed since the last 3

years at the power plant.

9.1 FastRampUp & Qualification Training Package during Service Contract Phase

Course Contents

During the live time of a power plant new employee hiring is essential to act against fluctuation. To ramp up

these new personnel during contract period as fast as possible some training courses are necessary.

Classroom training

∂ Electrical principles, components and I&C

∂ Physics, thermodynamics and mechanics

∂ GT systems and auxiliaries

∂ ST systems and auxiliaries *

∂ BoP and HRSG system *

∂ Cooling systems *

Simulator training

∂ Alarm sequence display

∂ Trend analysis and reports

∂ Function diagrams and logic structures

∂ Fundamentals of plant and system operation

∂ Start up and shut down of the plant and its systems

∂ Basics of troubleshooting

* applicable for combined cycle package only

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 16 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

10 Pricing and Payment Conditions

The prices quoted are fixed and firm prices, excluding VAT.

Any taxes, duties and/or charges levied by any authority outside Germany are not included. For the avoidance of doubt, withholding

tax is not included and shall be borne by the Customer.

In case of contractual coverage of trainees’ travel expenses by Siemens:

Travel expenses for trainees are limited to the following amounts per person:

∂ VISA 500€

∂ Daily allowance 100€

∂ Hotel Accommodation 150€/night

∂ Flight 2.000€/return flight

If the actual costs exceed the a.m. limits the difference shall be borne by the Customer.

11 General Considerations

11.1 Pre-Requisites of Training

The trainees have to be fluent in the English language (or any other language as agreed for the individual training) at least to such

degree that they are able to follow the lectures provided and read and answer the written tests.

11.2 Scope of Services

Division of Responsibility Service: Responsibility

Travelling and travel expenses of Siemens’ instructors Contractor

Provision of printed training materials to each trainee Contractor

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 17 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

Sudanese Thermal Power Generating

Co. Ltd.

Classroom facilities and required audio/visual aids for training courses held at site as per detailed description Customer

below.

Interpreter(s) for consecutive translation of training lessons. Customer

Training infrastructure for training courses held in Germany Contractor

Transportation of the Purchaser’s personnel (air fare, car rental, train fare, etc.) to Germany. Contractor

Purchaser’s personnel pick-up from and return to the airport as well as any transportation within Germany that is Contractor

relevant to the course.

Lunch for Customer’s personnel on those days when training is held in Germany. Contractor

Accommodations for the Purchaser’s personnel while in Germany for training Contractor

Daily allowance for the Purchaser’s personnel while in Germany for training Customer

Customs clearance and payment of customs duties and related costs of training manuals etc. for trainings held

outside Germany Customer

For cases of using the WEB Simulator during training modules, which is specified at chapter 3, the following technical hard- and

software prerequisites need to be provided by the customer in the classroom at site:

∂ 1 projector with VGA input.

∂ 4 desktops and 8 screens (each computer with two screens attached) with Windows operating, Internet Explorer, Java,

firewall and antivirus installation (screen sizes to measure at least 15 inch, preferably larger) and Ethernet network access

∂ Fast internet access router or switch with 5 RJ45 Ethernet connection / cables or WiFi

∂ Minimum Speed of internet connection is on average 256kbit/s upload per thin client and 1 Mbit/s download per thin

client)

∂ Please see system requirements (OS, Browser and Java versions) on this website

∂ Our login portal is: https://crsp-fth.siemens.com/dana-na/auth/url_6/welcome.cgi

During classroom training the classes are held daily (5 days a week) and are limited to 7 training hours (1 training hour, i.e. 50 min

training and 10 min break) per day.

Training documentation for each of the absolved courses as well as a “Certificate of Attendance” will be handed out to each trainee.

Should one or more participants decide to terminate their participation during the course, the cost of the course still has to be borne by

the customer. Should the training not be fully booked up to the respective limit of participants by the customer, Siemens reserves its

right to fill up the vacancies with other trainees. The price and payment condition remain unchanged.

11.3 Training Coordination

Siemens will always undertake their best possible efforts to accommodate customer requirements concerning the location of the

offered training courses. Nevertheless, Siemens reserves the right to finally decide about the actual training location, whether at the

customer's premises or at Siemens' in Germany. In case the anticipated training would need to be relocated, Siemens will inform the

customer respectively without delay and present an alternative option that would need to be separately agreed by the customer.

11.4 Inclusions and Exclusions

Any information or training material provided by Contractor in accordance with this document, Training, shall be regarded as

recommendations by the Contractor and Contractor shall have no liability with regard to such recommendations. Contractor shall not

be liable for the correctness or completeness of the information or materials provided and any recommendations hereunder.

Contractor shall not be liable for a certain result or success of the trainings, courses or programs described in this document, Training.

Training materials are exclusively for the use of Customer's personnel for the operation and maintenance of the Power Plant and

resale or reproduction without Contractor's prior permission is expressly forbidden. No audio or video recording of training sessions is

permitted unless Contractor grants permission in advance.

Unrestricted

Siemens Service Contract: Section: Attachment X: Training

Power Generation Services The reproduction, transmission or use of this document

Bid Ref. No.: SD 1002 or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, Page: 18 of 18

Rev. No.: DRAFT including rights created by patent grant or registration of

a utility model or design, are reserved.

You might also like

- TXPviewDocument65 pagesTXPviewsina20795No ratings yet

- Sppa D3000Document20 pagesSppa D3000Shahab AhmadaniNo ratings yet

- AC450 Testing Create PC Program and Download To AC450Document16 pagesAC450 Testing Create PC Program and Download To AC450Yeap Khai OnNo ratings yet

- Sic Her He Its Hand BuchDocument85 pagesSic Her He Its Hand BuchgnkameshNo ratings yet

- CM 104Document13 pagesCM 104Samuel Ramos MondragónNo ratings yet

- Siemens Sppa T3000 Training ManualDocument6 pagesSiemens Sppa T3000 Training ManualAkoKhalediNo ratings yet

- Prepared By: DR - Ahmed BaalehDocument14 pagesPrepared By: DR - Ahmed Baalehscribdkhatn100% (1)

- AddFEM A5E00075541C-05Document82 pagesAddFEM A5E00075541C-05jbecerra220568100% (1)

- Technical Training For Siemens SB5-17-0039-GT-EN-02cDocument5 pagesTechnical Training For Siemens SB5-17-0039-GT-EN-02cbabunidoniNo ratings yet

- Programming Guideline DOC v15 en PDFDocument120 pagesProgramming Guideline DOC v15 en PDFjuneNo ratings yet

- Spp2 Siemens TXP HW ManualDocument293 pagesSpp2 Siemens TXP HW ManualDiego Armando Vanegas RodriguezNo ratings yet

- RMG Gas Chromatograph ManualDocument21 pagesRMG Gas Chromatograph Manualtareq.sefatNo ratings yet

- GFK-1180h CIMPLICITY HMI Hmi-Base-System-Users-Manual PDFDocument765 pagesGFK-1180h CIMPLICITY HMI Hmi-Base-System-Users-Manual PDFSam eagle good100% (1)

- 07 - 94R300 - 2 - Configure SCE With I-O and LoopsDocument36 pages07 - 94R300 - 2 - Configure SCE With I-O and Loopsthillai312100% (2)

- PCS 7 - Configuration Manual Operator StationDocument326 pagesPCS 7 - Configuration Manual Operator StationvannhatquanNo ratings yet

- SIMATIC PCS 7 System OverviewDocument34 pagesSIMATIC PCS 7 System OverviewAmmar100% (1)

- I&C bus connections diagramDocument3 pagesI&C bus connections diagramDiego Armando Vanegas Rodriguez100% (3)

- T3 KviewDocument91 pagesT3 KviewHesham Hamdy100% (1)

- Speedtronic Mark Vie Training Course Section 8Document31 pagesSpeedtronic Mark Vie Training Course Section 8cucumelero barrios100% (1)

- CD Final 138039958 Mark VI Control Platform Upgrade - 1 of 2 - OtherPagesDocument255 pagesCD Final 138039958 Mark VI Control Platform Upgrade - 1 of 2 - OtherPagesAnis HamdaneNo ratings yet

- Turbine Outage Control Sppa r3000 enDocument2 pagesTurbine Outage Control Sppa r3000 enBharti ThakurNo ratings yet

- Software ArchitectureDocument17 pagesSoftware ArchitectureRandom NerdNo ratings yet

- Sequential Function Chart (SFC) : Application GuideDocument26 pagesSequential Function Chart (SFC) : Application Guideazizi reNo ratings yet

- DCS OvationDocument2 pagesDCS OvationJohn Noel TalandronNo ratings yet

- T3adm1-En 12Document32 pagesT3adm1-En 12Random NerdNo ratings yet

- GEA-S1212 Mark VIe IO Modules IndexDocument4 pagesGEA-S1212 Mark VIe IO Modules IndexjosseNo ratings yet

- AC450 Testing Create Data Base and Download To AC450Document25 pagesAC450 Testing Create Data Base and Download To AC450Yeap Khai On100% (1)

- Brochure SGT6 5000F TG 8Document25 pagesBrochure SGT6 5000F TG 8RUBEN DARIO AQUIZE PALACIOSNo ratings yet

- 50 1Document126 pages50 1Hass Moha Hass100% (4)

- GEH-6421 - Vol - I Mark VIDocument238 pagesGEH-6421 - Vol - I Mark VICharles WilsonNo ratings yet

- Customer Course CatalogDocument102 pagesCustomer Course Catalognabil160874No ratings yet

- Maxplant: Step by Step Tutorial Centum VPDocument6 pagesMaxplant: Step by Step Tutorial Centum VPAhmed KhairyNo ratings yet

- Ovation-OW352 R1100 PDFDocument597 pagesOvation-OW352 R1100 PDFHakan Bozkurt100% (2)

- Protect Your Power Plant With Continuous Security.: SPPA-T3000 R8.2Document8 pagesProtect Your Power Plant With Continuous Security.: SPPA-T3000 R8.2Melchor VasquezNo ratings yet

- Modbus TCP Wizard DOC enDocument45 pagesModbus TCP Wizard DOC enJasson ChavezNo ratings yet

- PCS7 Migration V6.1 to V8.0 with Batch Fox ControlDocument30 pagesPCS7 Migration V6.1 to V8.0 with Batch Fox Controlkrshna999100% (3)

- GTDocument122 pagesGTAnand Patel100% (1)

- What It Feels Like For A Turbine: DisclaimerDocument40 pagesWhat It Feels Like For A Turbine: DisclaimerBruno BrasilNo ratings yet

- Sic Her He Its Hand BuchDocument66 pagesSic Her He Its Hand Buchkatja kafkaNo ratings yet

- 02 OperatorStationDocument168 pages02 OperatorStationbmw316100% (1)

- HW Config: Simatic Pcs 7Document25 pagesHW Config: Simatic Pcs 7Ali PadaryamNo ratings yet

- SIS CHARMs Hardware InstallationDocument48 pagesSIS CHARMs Hardware InstallationSaad BroNo ratings yet

- Pcs 7Document34 pagesPcs 7Josh JoshNo ratings yet

- Sppa T3000Document6 pagesSppa T3000Dipti BhanjaNo ratings yet

- RTU560 COMPROTware EDocument17 pagesRTU560 COMPROTware Eparizad2500No ratings yet

- Hmi For Speedtronic™ Turbine Controls: Application ManualDocument332 pagesHmi For Speedtronic™ Turbine Controls: Application Manualemad0% (1)

- Project OverviewDocument3 pagesProject OverviewtungluongNo ratings yet

- 001 TXP Siemens 2007 EnglishDocument49 pages001 TXP Siemens 2007 EnglishwalterbishopNo ratings yet

- AdminManual TimeSynchronizationDocument108 pagesAdminManual TimeSynchronizationCesar Estrada Estrada MataNo ratings yet

- SCE - EN - 040-020 - R1209 - Startup S7-SCL PDFDocument30 pagesSCE - EN - 040-020 - R1209 - Startup S7-SCL PDFThiago NunesNo ratings yet

- SCOPE-1 SECTION-2 CommssinoingDocument109 pagesSCOPE-1 SECTION-2 Commssinoingahmed100% (1)

- GEH-6840.pdf Network PDFDocument94 pagesGEH-6840.pdf Network PDFMohammed Fares100% (1)

- 03-HMI Login, Default Accounts and Passwords - BDocument4 pages03-HMI Login, Default Accounts and Passwords - BjosseNo ratings yet

- Himatrix: Cpu 03 ManualDocument40 pagesHimatrix: Cpu 03 ManualFrancisco Javier Pinto EscalonaNo ratings yet

- PDF Teleperm Xs FeatDocument52 pagesPDF Teleperm Xs FeatooszachoooNo ratings yet

- Ics Powerplant of The FutureDocument64 pagesIcs Powerplant of The Futuretrung2iNo ratings yet

- Control: DSE7200 / DSE7300 Series Control ModuleDocument109 pagesControl: DSE7200 / DSE7300 Series Control ModuleMustika AlamNo ratings yet

- Control: DSE7200 / DSE7300 Series Control ModuleDocument109 pagesControl: DSE7200 / DSE7300 Series Control ModuleHo PhuNo ratings yet

- DSE Manual (057-074 7000 Series Operators Manual) Part 1.1 P1-18Document109 pagesDSE Manual (057-074 7000 Series Operators Manual) Part 1.1 P1-18Amborsius Sitorus100% (1)

- Wartsila Approval List 1Document17 pagesWartsila Approval List 1alevent100% (1)

- Voltage and Frequency Regulation To SupportDocument85 pagesVoltage and Frequency Regulation To Supportwaleed mohiNo ratings yet

- If The Generator Voltage Is Higher Than The Grid Voltage, This Means That TheDocument7 pagesIf The Generator Voltage Is Higher Than The Grid Voltage, This Means That Thewaleed mohiNo ratings yet

- What Is Negative Sequence Current and How Does It Affect Generator WorkDocument12 pagesWhat Is Negative Sequence Current and How Does It Affect Generator Workwaleed mohiNo ratings yet

- What Are The Reasons For Reverse Power To Occur in Generators While RunningDocument4 pagesWhat Are The Reasons For Reverse Power To Occur in Generators While Runningwaleed mohi100% (1)

- Applications of Capacitors in ElectronicsDocument3 pagesApplications of Capacitors in Electronicswaleed mohiNo ratings yet

- Reactive Power FundamDocument24 pagesReactive Power FundamNaveedNo ratings yet

- Lossofexcitation 130805045350 Phpapp01Document52 pagesLossofexcitation 130805045350 Phpapp01ahvaz1392bNo ratings yet

- Analysis of Salient-Pole Synchronous Generators Operating in Single-PhaseDocument7 pagesAnalysis of Salient-Pole Synchronous Generators Operating in Single-Phasewaleed mohiNo ratings yet

- Selecting Type GeneratorDocument4 pagesSelecting Type GeneratorMulugeta GgMichaelNo ratings yet

- Voltage Unbalance On AlternatorsDocument50 pagesVoltage Unbalance On Alternatorswaleed mohiNo ratings yet

- What Is Negative Sequence Current and How Does It Affect Generator WorkDocument12 pagesWhat Is Negative Sequence Current and How Does It Affect Generator Workwaleed mohiNo ratings yet

- 226 Electrical Machine-IIDocument99 pages226 Electrical Machine-IINuri BerishaNo ratings yet

- If An Alternator Is To Be Connected To An Infinite BusDocument4 pagesIf An Alternator Is To Be Connected To An Infinite Buswaleed mohiNo ratings yet

- SynchronousmachinesDocument51 pagesSynchronousmachineswaleed mohiNo ratings yet

- Generators and Back EmfDocument12 pagesGenerators and Back Emfwaleed mohiNo ratings yet

- What Is The Cause of Generator Overfluxing and OvercxcitationDocument2 pagesWhat Is The Cause of Generator Overfluxing and Overcxcitationwaleed mohiNo ratings yet

- Two Alternators Are Running in ParallelDocument1 pageTwo Alternators Are Running in Parallelwaleed mohiNo ratings yet

- Basic Concept of Diesel Power Plant DesignDocument4 pagesBasic Concept of Diesel Power Plant Designwaleed mohiNo ratings yet

- Analysis of Salient-Pole Synchronous Generators Operating in Single-PhaseDocument7 pagesAnalysis of Salient-Pole Synchronous Generators Operating in Single-Phasewaleed mohiNo ratings yet

- Lexe7582 06Document52 pagesLexe7582 06Daniel Alejandro Moreno HernándezNo ratings yet

- Fundamentals of Generator ProtectionDocument124 pagesFundamentals of Generator ProtectionZaks More100% (1)

- 3 2 Selection of Generator and Excitation SystemDocument54 pages3 2 Selection of Generator and Excitation SystemSalih Ahmed ObeidNo ratings yet

- Effects of Poor Synchronization of Two AC Generators or AlternatorsDocument5 pagesEffects of Poor Synchronization of Two AC Generators or Alternatorswaleed mohi100% (1)

- How Not To Select The Wrong Generator SetDocument12 pagesHow Not To Select The Wrong Generator Setwaleed mohiNo ratings yet

- Effects of Poor Synchronization of Two AC Generators or AlternatorsDocument5 pagesEffects of Poor Synchronization of Two AC Generators or Alternatorswaleed mohi100% (1)

- 3 Overcurrent Protective Device Ratings You MUST Properly SelectDocument11 pages3 Overcurrent Protective Device Ratings You MUST Properly Selectwaleed mohiNo ratings yet

- HashiCorp Packer in Production - John BoeroDocument246 pagesHashiCorp Packer in Production - John BoerostroganovborisNo ratings yet

- SWOT Analysis V1.21Document5 pagesSWOT Analysis V1.21depeNo ratings yet

- Training Course ContentsDocument3 pagesTraining Course ContentsmihaitimofteNo ratings yet

- Infineon-Future Requirements For Automotive Hardware Security-Whitepaper-V01 00-ENDocument18 pagesInfineon-Future Requirements For Automotive Hardware Security-Whitepaper-V01 00-ENRavindra BNo ratings yet

- Greatest Engineering Achievements of The 20th Century PDFDocument7 pagesGreatest Engineering Achievements of The 20th Century PDFArianna IsabelleNo ratings yet

- Financial Statements and Financial Analysis of ACC CemetDocument70 pagesFinancial Statements and Financial Analysis of ACC CemetAtul DubeyNo ratings yet

- Nikon D5500 Brochure PDFDocument9 pagesNikon D5500 Brochure PDFJeremy LermanNo ratings yet

- UMRN authorization formDocument1 pageUMRN authorization formPraneeth SrivanthNo ratings yet

- Direction of Industry A Literature Review On Industry 40Document10 pagesDirection of Industry A Literature Review On Industry 40Marko BrkicNo ratings yet

- Quiz 1 (It208)Document3 pagesQuiz 1 (It208)Glaiza Angel MacapagalNo ratings yet

- Advanced Java Interview QuestionsDocument9 pagesAdvanced Java Interview QuestionsparagNo ratings yet

- Robotic Grasping and Manipulation of Objects: András Fekete University of New HampshireDocument5 pagesRobotic Grasping and Manipulation of Objects: András Fekete University of New HampshirerNo ratings yet

- Farm Management Information SystemDocument45 pagesFarm Management Information SystemDivya VkNo ratings yet

- Promotional Strategy of Samsung Tablets: K.Kalyan SudhakarDocument17 pagesPromotional Strategy of Samsung Tablets: K.Kalyan Sudhakarratul_oneNo ratings yet

- IGCSE Business Studies Teacher's CD-ROM: Help NotesDocument8 pagesIGCSE Business Studies Teacher's CD-ROM: Help NotesReaz FiemNo ratings yet

- Azur 340A - Service ManualDocument21 pagesAzur 340A - Service ManualfabrizioNo ratings yet

- Ravindra PDocument3 pagesRavindra PRavi PujNo ratings yet

- System Flow Diagram and Level O-OE - SDocument3 pagesSystem Flow Diagram and Level O-OE - Ssunil bhandariNo ratings yet

- Companies Registry Online System FAQsDocument11 pagesCompanies Registry Online System FAQsVicard GibbingsNo ratings yet

- FC Vs FBDocument8 pagesFC Vs FBMiguel SanchesNo ratings yet

- Basics of Reversible Logic GatesDocument22 pagesBasics of Reversible Logic GatesRashika AggarwalNo ratings yet

- Photoshop green screen background removalDocument2 pagesPhotoshop green screen background removalJatiNo ratings yet

- Xilinx DCMDocument23 pagesXilinx DCMFitohdezNo ratings yet

- Chapter 1: Data Warehousing:: Dept of CSE, KLESCET - Shrikant AthanikarDocument23 pagesChapter 1: Data Warehousing:: Dept of CSE, KLESCET - Shrikant AthanikarshreyaNo ratings yet

- Battery Management Systems For Large Lithium Battery Packs (PDFDrive)Document303 pagesBattery Management Systems For Large Lithium Battery Packs (PDFDrive)Daniel Andres Gaitan ManriqueNo ratings yet

- RCS LITE Product Launch - Customer PresentationDocument24 pagesRCS LITE Product Launch - Customer PresentationPedro Miguel Moreira Pereira100% (2)

- Stalker ScriptDocument2 pagesStalker Scriptapi-528387861No ratings yet

- STEM Activity: Makey MakeyDocument14 pagesSTEM Activity: Makey Makeypreeti0505No ratings yet

- VolvoDocument220 pagesVolvoturbokolosabacNo ratings yet

- Unified Modeling Language (UML) : An OverviewDocument37 pagesUnified Modeling Language (UML) : An OverviewRaddad Al KingNo ratings yet