Professional Documents

Culture Documents

Hammer Service Log MC60

Uploaded by

Reza0 ratings0% found this document useful (0 votes)

64 views2 pagesThis document is a service analysis log for a Mincon MC60 hammer. It records observations made during inspection of the hammer's components prior to service or rebuild. Key observations included wear on the chuck, wear sleeve, backhead, piston, check valve, and other parts. The technician recommends replacing or rebuilding worn parts to return the hammer to working condition.

Original Description:

Hammer Service Log MC60

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a service analysis log for a Mincon MC60 hammer. It records observations made during inspection of the hammer's components prior to service or rebuild. Key observations included wear on the chuck, wear sleeve, backhead, piston, check valve, and other parts. The technician recommends replacing or rebuilding worn parts to return the hammer to working condition.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

64 views2 pagesHammer Service Log MC60

Uploaded by

RezaThis document is a service analysis log for a Mincon MC60 hammer. It records observations made during inspection of the hammer's components prior to service or rebuild. Key observations included wear on the chuck, wear sleeve, backhead, piston, check valve, and other parts. The technician recommends replacing or rebuilding worn parts to return the hammer to working condition.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

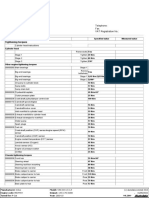

Customer Order No.

Mincon I/O No.

Mincon D/N No.

Leaders in Rock Drilling Technology

Hammer Service Analysis / Log

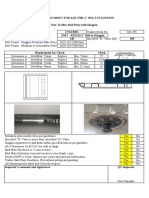

Date Hammer Model No. MINCON MC60 (MD601AS07)

Customer Hammer Ser. No.

Site Bit Used : Make

Rig Type Bit Used : Part No.

Rig No. Bit Used : Serial No.

Rig Operator Compressor Pressure Set At Psi / Bar

Site/Shift Supervisor Operating Pressure Psi / Bar

Site Manager Compressor Make / Model

Type of Drilling Done Compressor CFM

Meters done by Hammer prior to Service m Foam Used with this Hammer Yes No

Total Meters done by Hammer m Date of Previous Service

Reasons for this Service

Hammer Serviced / Rebuild By:

MD601BH01 ( Backhead)

MD625OK01 ( 6" O - Ring Kit)

MB611WS01 (Wear Sleeve)

MB502CV01 (Check Valve)

MD612PR02 (Piston Retaining Ring)

MB503SP01 (Spring)

MB613BB02 (Aligner Bush)

MD604SM01 (Steel Make Up Ring)

MD632PU01 (Polyurethane Chuck Ring)

MD605LR01 (Lock Ring)

MMD616CR01 (Chuck Ring)

MD607DR01 (Air Distributor)

MD608IC01 (Inner Cylinder) MB615CK04 (Chuck)

MD609SR01 (Seating Ring)

MD614BR01 (Bit Retaining Ring)

MD610PN04 (Piston)

Parts Replaced Marked as : MB631OK01 (6BH QL60 Outer Case Kit)

√

General Observations Prior to Service / Rebuild

1 Dirt inside Hammer Yes No

2 Hammer Lubricated Yes No

3 Any Corrosion Observed inside hammer or Parts Yes No

4 Chuck on this Hammer Yes No

5 Chuck Splines Worn more than 25% Yes No

6 Chuck Cracked Yes No

7 Any Impact/Hammering Marks on Chuck Yes No

8 Any Distortion of the Chuck Yes No

9 "Galling" on Chuck Splines Yes No

10 Wear-Sleeve Cracked at Backhead End Yes No

11 Wear-Sleeve Cracked at Chuck End Yes No

12 Any Impact/Hammering Marks on Wear-Sleeve Yes No

13 Any "Squeezing" Marks on Wear-Sleeve Yes No

14 Any Distortion of the Wear-Sleeve Yes No

15 Backhead on this Hammer Yes No

16 Backhead Excessively Worn due to "Stuck Equipment" Yes No

17 Backhead API Thread worn beyond safe Working Condition Yes No

18 Aligner Bush in this Hammer Yes No

19 Any "Galling" inside Aligner Bush Yes No

20 Did the Aligner Bush Move out-of Position (Chuck does not screw in tight) Yes No

21 Aligner Bush "Loose" inside Wear-Sleeve Yes No

22 Bit Retaining Rings with this Hammer Yes No

23 Bit Retaining Rings Worn Yes No

24 Any "Blue" Heat indication Marks on the Piston Yes No

25 Any "Scoring" - Marks on the Piston Yes No

26 Piston Strike Face Chipped or broken Yes No

27 Does the Piston moves "Freely" up and down inside Hammer Yes No

28 Make-Up Ring in this Hammer Yes No

29 Make-Up Ring Distorted Yes No

30 Lock-Ring in this Hammer Yes No

31 Lock-Ring Distorted Yes No

32 Were the Make-Up and/or Lock-Ring Inserted in Correct position/Order Yes No

33 Piston Retaining Ring Worn / Distorted / Broken Yes No

34 Seating Ring Worn / Distorted / Broken Yes No

35 Inner Cylinder - Cracked / Chipped / Broken Yes No

36 Any Visual worn marks on Air Distributor at Lock Ring- Area Yes No

37 Check Valve in this Hammer Yes No

38 Check Valve Visually Distorted / Melted Yes No

39 Check Valve Spring in this Hammer Yes No

40 Check Valve Spring Broken Yes No

41 Does the Check Valve Moves "Freely" Up and down inside the Distributor Yes No

Wear-Sleeve General

1 New Hammer Wear-Sleeve Outside Diameter 146.0 mm

2 Wear-Sleeve Discard Limit 128.5 mm

3 This Hammer OD at Chuck End mm

4 This Hammer OD at Backhead End mm

5 Wear-Sleeve Reversed Yes No

Conclusions - Recommendations - General Remarks

You might also like

- Hammer Service Log MP80Document2 pagesHammer Service Log MP80RezaNo ratings yet

- Machine Checkup Report SummaryDocument18 pagesMachine Checkup Report SummaryFERCHIU CRISTIANNo ratings yet

- ID0002 Rev FDocument1 pageID0002 Rev FJames ĐỗNo ratings yet

- AE No 2 Connection Rod InspectionDocument4 pagesAE No 2 Connection Rod InspectionMaxNo ratings yet

- McCulloch Gas Chain Saws Parts Manuals 11 600032 70 Silver Eagle 2012 IPL 211229 01Document18 pagesMcCulloch Gas Chain Saws Parts Manuals 11 600032 70 Silver Eagle 2012 IPL 211229 01grelfodNo ratings yet

- 40981Document23 pages40981Verdes CouchNo ratings yet

- Microsoft Word - WET GAS COMPRESSOR OVERHAULING REPORTDocument8 pagesMicrosoft Word - WET GAS COMPRESSOR OVERHAULING REPORTAbhi SharmaNo ratings yet

- LOP Steam WaterDocument4 pagesLOP Steam WaterJorge RuizNo ratings yet

- McCulloch Gas Blowers and Blower Vacs 16 400048 23 SUPER AIR STREAM XXV 06 94 To Current IPL 211569Document13 pagesMcCulloch Gas Blowers and Blower Vacs 16 400048 23 SUPER AIR STREAM XXV 06 94 To Current IPL 211569kotoNo ratings yet

- Excavator inspection checklistDocument2 pagesExcavator inspection checklistLeo FirstsonNo ratings yet

- Mould Check PoitsDocument2 pagesMould Check Poitspeerappa KoriNo ratings yet

- Additional Labor Diagnosis & RepairsDocument8 pagesAdditional Labor Diagnosis & Repairsterry zillerNo ratings yet

- Dog in The Woods - VFX BreakdownDocument5 pagesDog in The Woods - VFX BreakdownPhaNo ratings yet

- Discover 135 PDFDocument36 pagesDiscover 135 PDFHumberto RamosNo ratings yet

- Fork LiftsDocument4 pagesFork LiftslucienencreNo ratings yet

- Bicycle Repairs Park ToolsDocument86 pagesBicycle Repairs Park Toolsedlhy100% (1)

- MC 10173603 0001Document146 pagesMC 10173603 0001Ko KaneNo ratings yet

- Subaru Impreza Tightening TorquesDocument4 pagesSubaru Impreza Tightening TorquesChristianHuiscañancoPerezNo ratings yet

- PITBULL® 40 S&W / 9mm Lugar: Parts & PriceDocument1 pagePITBULL® 40 S&W / 9mm Lugar: Parts & PriceJohn McMullenNo ratings yet

- S.No Model JC No Advisor Tech. Job Type KMS: 1 XL100 3999 Ratnakar Ravi Paid /serviceDocument4 pagesS.No Model JC No Advisor Tech. Job Type KMS: 1 XL100 3999 Ratnakar Ravi Paid /serviceMani kumar MaddelaNo ratings yet

- Full Body Harness InspectionDocument1 pageFull Body Harness InspectionMohit KumarNo ratings yet

- 1y6QheLIpHsa3cc94uoqv jY5gz7udUivDocument27 pages1y6QheLIpHsa3cc94uoqv jY5gz7udUivANH LÊNo ratings yet

- Maintenance Instruction For The WB Valves: Spare PartsDocument7 pagesMaintenance Instruction For The WB Valves: Spare PartsagrovadoNo ratings yet

- Equipment Tyre Inspection FL075Document6 pagesEquipment Tyre Inspection FL075Robert DickNo ratings yet

- Oxygen Requirements For Bench BurnersDocument5 pagesOxygen Requirements For Bench BurnersDan George IonescuNo ratings yet

- Bilstein Rear E4-WM5-Y764A00Document15 pagesBilstein Rear E4-WM5-Y764A00AlzieNo ratings yet

- Safety Hrnss Check ListDocument1 pageSafety Hrnss Check ListAmit BhattNo ratings yet

- Telephone: Fax: VAT Registration No.Document2 pagesTelephone: Fax: VAT Registration No.Gustavo PérezNo ratings yet

- Checklist For NP CO2 Compressor Overhauling - Rev 0 PDFDocument6 pagesChecklist For NP CO2 Compressor Overhauling - Rev 0 PDFMohsin MurtazaNo ratings yet

- Piston Bumper Seal Option Now Available For Series 2A & 2AN: Sound Level ComparisonDocument2 pagesPiston Bumper Seal Option Now Available For Series 2A & 2AN: Sound Level ComparisonGonzalo AlvarezNo ratings yet

- DC16 Cylinder SequenceDocument1 pageDC16 Cylinder Sequencejengandxb100% (1)

- 360 BP'MCV, DisassDocument3 pages360 BP'MCV, DisassAimHighNo ratings yet

- Omega 3603 Technical GuideDocument29 pagesOmega 3603 Technical Guidechassenuage chassenuageNo ratings yet

- 2.how To Fix VS1295 LED - MBDocument41 pages2.how To Fix VS1295 LED - MBRichard emerson Lazcano barajasNo ratings yet

- Modification of Rocker Arm Bush Service Parts Unit for GE13 EngineDocument2 pagesModification of Rocker Arm Bush Service Parts Unit for GE13 EngineanggieNo ratings yet

- Form Report Overhaul TM 274 RevDocument14 pagesForm Report Overhaul TM 274 Revsersan darmin100% (1)

- Telephone: Fax: Número de Contribuinte:: Tightening TorquesDocument2 pagesTelephone: Fax: Número de Contribuinte:: Tightening TorquesJorge FrançaNo ratings yet

- Suspension and AxleDocument79 pagesSuspension and AxleАлександр СироижкоNo ratings yet

- BCC ComprasionDocument2 pagesBCC ComprasionAnjani kumarNo ratings yet

- Technical Specifications - EcoSportDocument1 pageTechnical Specifications - EcoSportBerg Auto Repairs100% (1)

- Iso Clearance ReportDocument1 pageIso Clearance ReportKarthikNo ratings yet

- Electronic Parts Catalog - Option DetailDocument3 pagesElectronic Parts Catalog - Option Detailnaya aninditaNo ratings yet

- CRV07 Service Manual CH 7 PDFDocument78 pagesCRV07 Service Manual CH 7 PDFPaoloPinardNo ratings yet

- Nissan FIFTH WHEEL TOWING HITCH WITH CONNECTOUSDocument55 pagesNissan FIFTH WHEEL TOWING HITCH WITH CONNECTOUSFrederikusNo ratings yet

- Maintenance Manual GeaDocument60 pagesMaintenance Manual GeageniusMAHINo ratings yet

- Ford Fiesta Futómű JavításDocument342 pagesFord Fiesta Futómű JavításAttila KissNo ratings yet

- SCHWING TrainingManual (262 303)Document42 pagesSCHWING TrainingManual (262 303)Petr KosNo ratings yet

- Trav 53108MH92 Shank - OrigDocument1 pageTrav 53108MH92 Shank - OrigTimur SonkayaNo ratings yet

- Z CraftsDocument22 pagesZ CraftslucienencreNo ratings yet

- 7,-Qad-28sample Inspection Report Mach. 74-100Document1 page7,-Qad-28sample Inspection Report Mach. 74-100azadsingh1No ratings yet

- Inspection Report PT LindeDocument1 pageInspection Report PT Lindesandy riadiNo ratings yet

- SGSB Gate Valve Technical Specifications and Parts ListDocument4 pagesSGSB Gate Valve Technical Specifications and Parts ListRicardo Paz SoldanNo ratings yet

- Huskystar 219 224 Manual enDocument56 pagesHuskystar 219 224 Manual enljubica100% (2)

- Assetsfilespdfshawkjaw Sr. Manual ALS Serial Numbers 1 To 100.PDF 4Document159 pagesAssetsfilespdfshawkjaw Sr. Manual ALS Serial Numbers 1 To 100.PDF 4Luis Alfredo Mean LaraNo ratings yet

- Nexxt Solutions Metalwork CompatibilityDocument2 pagesNexxt Solutions Metalwork CompatibilitynormNo ratings yet

- Aditek Catalogue Ed.04 - EnglishDocument64 pagesAditek Catalogue Ed.04 - EnglishhabeebNo ratings yet

- Mold Inspection SpecificationDocument6 pagesMold Inspection SpecificationNaukowyDrpNo ratings yet

- Rocker Bearing Weld Visual ReportDocument1 pageRocker Bearing Weld Visual ReportQUALITYNo ratings yet

- Technical Details For Adjusting The Bam b50 51 PDFDocument60 pagesTechnical Details For Adjusting The Bam b50 51 PDFJörgen100% (1)

- BLY NQ ValuesDocument1 pageBLY NQ ValuesRezaNo ratings yet

- 9 Disciplines of Successful EntrepreneursDocument11 pages9 Disciplines of Successful EntrepreneursBejetaNo ratings yet

- Incentive ProgramDocument9 pagesIncentive ProgramRezaNo ratings yet

- Reward ManagementDocument32 pagesReward ManagementRezaNo ratings yet

- Boost Productivity With An Effective Incentive Compensation PlanDocument11 pagesBoost Productivity With An Effective Incentive Compensation PlanRezaNo ratings yet

- Incentive Plan SeminarDocument17 pagesIncentive Plan SeminarRezaNo ratings yet

- Presentation On Types of Incentive PlansDocument11 pagesPresentation On Types of Incentive PlansRezaNo ratings yet

- Employee Incentive SchemeDocument13 pagesEmployee Incentive SchemeRezaNo ratings yet

- Pay For Performance Incentive RewardsDocument21 pagesPay For Performance Incentive RewardsReza100% (1)

- Employee Incentive FrameworkDocument21 pagesEmployee Incentive FrameworkRezaNo ratings yet

- How To Set Up A Sales Compensation PlanDocument7 pagesHow To Set Up A Sales Compensation PlanRezaNo ratings yet

- The Seven Steps of Sales Planning: by Alain WinandyDocument11 pagesThe Seven Steps of Sales Planning: by Alain WinandyRezaNo ratings yet

- Drum Line PercussionDocument25 pagesDrum Line PercussionHugo RochaNo ratings yet

- 08.metabolic Response To TraumaDocument34 pages08.metabolic Response To TraumaAloah12234667% (3)

- Complete hydraulic diagramDocument11 pagesComplete hydraulic diagramAstrit StratiNo ratings yet

- Alsangedy Bullets For Paces Charcot-Marie-Tooth DiseaseDocument2 pagesAlsangedy Bullets For Paces Charcot-Marie-Tooth DiseaseGhulamMemonNo ratings yet

- Swimming Times October 2015Document84 pagesSwimming Times October 2015danielwwcheong8981No ratings yet

- Yanmar TS-105 Industrial Engine Parts ListDocument1 pageYanmar TS-105 Industrial Engine Parts ListAhmad Ali Nursahidin100% (3)

- 10 Minutos de Exercicio - Mercola - Peak8 CardioDocument5 pages10 Minutos de Exercicio - Mercola - Peak8 CardioMarina SilvaNo ratings yet

- Chapter 16: Autonomic Nervous System: Multiple ChoiceDocument15 pagesChapter 16: Autonomic Nervous System: Multiple ChoiceGolf2153No ratings yet

- Dune - Adventures in The Imperium - Masters of DuDocument1 pageDune - Adventures in The Imperium - Masters of DuJustin Ulrey0% (3)

- ITM Session 3 Pivot TableDocument305 pagesITM Session 3 Pivot TableTUSHAR JAINNo ratings yet

- Black Tenting Trivia 2017Document10 pagesBlack Tenting Trivia 2017thedukechronicle100% (2)

- 4244071-Marching Band Dont Stop Til You Get EnoughDocument8 pages4244071-Marching Band Dont Stop Til You Get EnoughVitor Veloso da CostaNo ratings yet

- Geometry I: Pratyush at Toughest QuestionsDocument75 pagesGeometry I: Pratyush at Toughest QuestionsJaved Anwar100% (2)

- Young and UnafraidDocument43 pagesYoung and UnafraidShagel BetelgeuzeNo ratings yet

- Steven Hernandez 10125 Milan El Paso, Texas, 79924 (915) 216-2523Document3 pagesSteven Hernandez 10125 Milan El Paso, Texas, 79924 (915) 216-2523api-324394663No ratings yet

- Senior Project - Final ReportDocument80 pagesSenior Project - Final ReportJennNo ratings yet

- Hiking StretchesDocument1 pageHiking Stretchesliderj26No ratings yet

- (HSE-ForM-A.05) Form Inspection Rough Terrain CraneDocument6 pages(HSE-ForM-A.05) Form Inspection Rough Terrain CraneIvansyah SastrowardoyoNo ratings yet

- Musou Orochi Z English PatchDocument2 pagesMusou Orochi Z English PatchAlen Pobhenrhaj Chandra Mohan0% (1)

- HSN Code ListDocument2 pagesHSN Code ListShree Bhagwati InfrastructureNo ratings yet

- Standard Guitar TuningDocument1 pageStandard Guitar TuningVictor V AmadorNo ratings yet

- Woodlands ReglasDocument20 pagesWoodlands ReglasAriel Euripides Nunez BoddenNo ratings yet

- Guidelines For The Physiotherapy Management of Chronic Obstructive Pulmonary DiseaseDocument7 pagesGuidelines For The Physiotherapy Management of Chronic Obstructive Pulmonary DiseaseAyu AryaDewi PasyaViraNo ratings yet

- Moro 2020Document15 pagesMoro 2020Willian da costaNo ratings yet

- Canoeing and Kayaking REPORTDocument70 pagesCanoeing and Kayaking REPORTFreyjaa MabelinNo ratings yet

- Manual K3.86M - 2Document18 pagesManual K3.86M - 2servicio masisaNo ratings yet

- Sports History: BaseballDocument23 pagesSports History: BaseballHưng LêNo ratings yet

- Barangay CertificatesDocument75 pagesBarangay CertificatesJohn Paul MoradoNo ratings yet

- Fall Sports Preview (2022)Document24 pagesFall Sports Preview (2022)Watertown Daily TimesNo ratings yet

- English Civil War DBA Campaign (V Nov08)Document1 pageEnglish Civil War DBA Campaign (V Nov08)Bruno Friedrich KriegspielNo ratings yet