Professional Documents

Culture Documents

APU 131-9A SIC-OIC Troubleshooting Guide 2016 PDF

Uploaded by

Permadi Ari SandyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APU 131-9A SIC-OIC Troubleshooting Guide 2016 PDF

Uploaded by

Permadi Ari SandyCopyright:

Available Formats

131-9A Auxiliary Power Unit Smell/Odour In

Cabin (SIC/OIC) Troubleshooting Guide

Honeywell Report 31-18899

Smell In Cabin - Troubleshooting Guide

The aim of this presentation is to summarise existing AMM

and TSM recommendations, providing operators with

inspection and maintenance recommendations to be followed

in case odour/smell in cabin is experienced and the APU is

suspected to be the contamination source

Refer to applicable Trouble Shooting Manual (TSM) and Aircraft Maintenance Manual

(AMM) for further information

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Smell In Cabin - Troubleshooting Guide

• Possible sources of smell in cabin from the APU

External Fumes ingested by the APU (i.e. Main Engines

Exhaust Gas fumes)

A/C external fluid leakages ingested by the APU

De-icing fluid ingestion, further to A/C de-icing operation

Hydraulic leaks ingestion (i.e. from A/C landing gear)

APU external fuel/oil leakages re-ingested by the APU

APU internal oil leakages reaching APU pneumatic system

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Smell In Cabin - Troubleshooting Guide

• In case of A/C smell in cabin and APU is suspected to be the source of

contamination, next steps should be followed:

Inspect the APU for presence of contaminants

If contaminants evidenced:

Identify source of contaminants

Identify contaminants path followed to reach the APU pneumatic system

Eliminate source of contaminants as per AMM instructions

If re-ingestion confirmed, inspect condition of APU doors/duct sealing and

drains, and restore them if required

Clean contaminated APU and compartment

Decontaminate A/C as per AMM 21-00-00 and ISI 21.00.00018

Note: Refer to Airbus SIL 49-032 “Aircraft/APU bleed air oil contamination/Aircraft smoke

warning” which compiles recommendations in case of APU suspected to be the

contaminant source (oil, de-icing fluid ingestion…)

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Smell In Cabin - Troubleshooting Guide

• Possible sources of smell in cabin from the APU

External Fumes ingested by the APU (i.e. Main Engines

Exhaust Gas fumes)

A/C external fluid leakages ingested by the APU

De-icing fluid ingestion, further to A/C de-icing operation

Hydraulic leaks ingestion (i.e. from A/C landing gear)

APU external fuel/oil leakages re-ingested by the APU

APU internal oil leakages reaching APU pneumatic system

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

External Fumes Ingested by the APU

• In case of external fumes (i.e. Exhaust Gas fumes from main

engines) present on the vicinity of the APU intake, they could be

ingested leading to smell in cabin

Smell will stop with fumes origin

No further inspections will be required on the APU

Perform cabin ventilation to eliminate any residual smell before next

revenue flight

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Smell In Cabin - Troubleshooting Guide

• Possible sources of smell in cabin from the APU

External Fumes ingested by the APU (i.e. Main Engines

Exhaust Gas fumes)

A/C external fluid leakages ingested by the APU

De-icing fluid ingestion, further to A/C de-icing operation

Hydraulic leaks ingestion (i.e. from A/C landing gear)

APU external fuel/oil leakages re-ingested by the APU

APU internal oil leakages reaching APU pneumatic system

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

A/C external fluid leakages

• If A/C external fluid leakage re-ingestion by the APU is suspected

Inspect the external surfaces of the APU doors, APU Air Intake Housing and

APU duct inner walls for presence of contaminants

If contaminants evidences, identify source of contaminants (i.e. hydraulic

leak, oil, de-icing fluid further to de-icing operation)

Eliminate source of contaminant as per AMM instructions

Clean contaminated surfaces (APU doors, intake duct air flow path)

Decontaminate A/C as per AMM 21-00-00 and ISI 21.00.00018

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

A/C external fluid leakages – De-icing fluid

• Check for de-icing fluid contamination

Further to A/C de-icing operation inspect the external surfaces of APU doors

for presence of de-icing fluid

Check for presence of de-icing fluid on the APU inlet duct to confirm re-

ingestion

Refer to AMM task 49-00-00-200-804-A : “Inspection of the APU (131-9(A))

for De-Icing Contamination” for further information

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

A/C external fluid leakages – Hydraulic fluid

• Check for possible hydraulic leaks ingestion

Inspect A/C fuselage from the nose landing gear up to the APU inlet and

vertical stabilizer up to the APU inlet for presence of hydraulic leak

Check for presence of hydraulic fluid on the APU inlet duct to confirm re-

ingestion, by using ultra-violet / black light

During visual inspection, any hydraulic leakage from the landing gear must

be fixed. Refer to Airbus ISI 29.00.00004 for further information

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Smell In Cabin - Troubleshooting Guide

• Possible sources of smell in cabin from the APU

External Fumes ingested by the APU (i.e. Main Engines

Exhaust Gas fumes)

A/C external fluid leakages ingested by the APU

De-icing fluid ingestion, further to A/C de-icing operation

Hydraulic leaks ingestion (i.e. from A/C landing gear)

APU external fuel/oil leakages re-ingested by the APU

APU internal oil leakages reaching APU pneumatic system

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

APU external fluid leakages

• If APU external fluid leakage re-ingestion by the APU is suspected

Inspect the APU compartment, APU external surfaces and the APU duct

inner walls for presence of contaminants

If contaminants evidenced

Identify source of contaminants by following APU and APU compartment

inspections described hereafter

Identify contaminants path followed to reach the APU pneumatic system

Eliminate source of contaminants as per AMM instructions

If re-ingestion confirmed, inspect condition of APU doors/duct sealing/drains

and restore them if required

Clean contaminated APU and compartment

Decontaminate A/C as per AMM 21-00-00 and ISI 21.00.00018

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

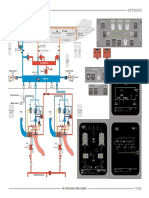

APU and APU Compartment Inspection

APU tubes and tube fittings

• Perform General Inspection of APU for leakage in all tubes and Tube Fittings

Inspect all external fittings for evidence of leaks and check for rightness

Special attention should be paid to the fittings of APU fuel manifolds and fuel lines (Inlet

Guide Vane Actuator (IGVA) / Surge Control Valve (SCV) Supply & Return lines (A and

B) and Fuel Supply Tube (C)), and drain lines (FCU Drain Tube (D)), LC Scroll Witness

Drain Tube (E), Turbine Drain Tube (F), IGV & SCV Drain Tubes (G and H)

Aircraft fuel supply line and interface to APU Fuel Control Unit (FCU)

C H E

C

F

A B G D

Fuel Manifolds APU Drain Mask

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

APU and APU Compartment Inspection

Gearbox Vent tube

• Inspect area around Gearbox vent tube (from air oil separator to exhaust)

Check fittings and tubes

Gearbox vent tube

Air Oil separator

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

APU and APU Compartment Inspection

Oil Supply & Oil Scavenge Tube at Turbine Bearing Cavity

• Check for evidence of Oil Leak at Turbine Bearing Cavity:

Inspect area around turbine bearing scavenge tube

Inspect area around turbine bearing oil supply tube

Check fittings

Oil supply

tube

Scavenge tube

• If oil is present in the bearing cavity, it’s likely caused by turbine seal leak.

Remove APU, if turbine seal leak is suspected

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

APU and APU Compartment Inspection

Oil Fill Cap, Lube Module, Fuel Control Unit, Low Oil

Level Switch & De-Oil solenoid

• Check for evidence of leak (oil, fuel) around:

Oil Fill Cap (for oil gravity filling)

Lube Module (Oil Pump)

Fuel Control Unit (FCU)

Low Oil Level Switch (LOL) Oil Fill Cap

De-Oil solenoid De-Oil solenoid

Lube Module

LOL

FCU

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

APU and APU Compartment Inspection

Generator Mount Flange

• Check for evidence of leak around circumference of generator to gearbox mount

Generator to Gearbox Mount

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

APU and APU Compartment Inspection

Load Compressor Scroll Housing to Gearbox Split-line

• Check for evidence of leak around Load Compressor Scroll Housing to Gearbox

Split line

Inspection Gearbox to Scroll Housing split line. If there is any evidence of leakage, use

black light to verify oil leak. Clean, degrease, run APU and inspect again to confirm oil

leak

APU assembly fluid can be present at the split line area, not to be mistaken with oil

leak

Split line

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

APU and APU Compartment Inspection

Magnetic plug and Hot Oil Temperature (HOT) sensor

• Check for evidence of leak around Magnetic Plug and Hot Oil Temperature (HOT)

Sensor

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

APU and APU Compartment Inspection

Starter Motor, Pressure Oil Port, Air Oil Separator, Low

Oil Pressure (LOP) Sensor

• Check for Evidence of Leak Around:

Starter Motor Flange

Pressure Oil Servicing

Air oil separator

Low Oil Pressure (LOP) Sensor

Starter motor

LOP

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

APU and APU Compartment Inspection

Drain Tubes and Bellows

• Check the alignment of the drain tube bellows on the door with the drain

tubes on the bottom of the APU

Check alignment by closing right APU door and observing from the open left

door. If they are not aligned, adjust spring adapter assembly on door

Please refer to AMM TASK 49-17-00-200-802-A "General Visual Inspection of

APU Compartment Draining System (131-9(A))”

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Identify contaminants path to reach the APU Bleed

APU compartment seals

• Any damages on APU compartment seals could lead to contaminants re-ingestion

Check APU firewall and elbow seals condition

Inspect APU plenum inlet seal condition

A visible contact pattern should be observed around the entire circumferential inlet plenum

flange to confirm alignment with APU intake duct

Check alignment/adjustment between APU intake duct and APU inlet plenum by

closing right APU door and observe from the open left door

Refer to AMM task 49-13-00-200-003-A “General Visual Inspection of all Fire Seals and

Walls (Rear, FWD, Sides, Upper and Compartment Doors) for condition”

Refer to AMM task 49-16-45-400-003-A “Installation of the Air Intake Diffuser and Elbow”

APU Intake Housing seal APU elbow seal APU seal contact flange

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Identify contaminants path to reach the APU Bleed

APU compartment seals

• Any damages on APU compartment seals could lead to contaminants re-ingestion

• Check APU doors rubber sealing condition

Refer to AMM task 49-13-00-200-003-A “General Visual Inspection of all Fire Seals

and Walls (Rear, FWD, Sides, Upper and Compartment Doors) for condition.”

APU doors rubber sealing (FR80)

• Refer to SB A320-49-1049 “INTRODUCE A DRAIN SYTEM AND SEALING ON

R/L ACCESS DOORS” and SB A320-49-1050 “INTRODUCE A MODIFIED

INTAKE ELBOW SEAL AND AIRCRAFT INTAKE BOX SEAL”

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Identify contaminants path to reach the APU Bleed

APU compartment seals

• Check alignment between the Oil cooler discharge duct and the APU door

Alignment is critical to minimise external cooling fan / oil cooler leaks that could

contaminate the APU compartment

Check alignment of oil cooler discharge duct by closing left APU door and

observe from the open right door

Oil Cooler discharge duct

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Smell In Cabin - Troubleshooting Guide

• Possible sources of smell in cabin from the APU

External Fumes ingested by the APU (i.e. Main Engines

Exhaust Gas fumes)

A/C external fluid leakages ingested by the APU

De-icing fluid ingestion, further to A/C de-icing operation

Hydraulic leaks ingestion (i.e. from A/C landing gear)

APU external fuel/oil leakages re-ingested by the APU

APU internal oil leakages reaching APU pneumatic system

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

APU internal oil leak reaching APU pneumatic system

• If APU internal oil leak is suspected

• Inspect the APU bleed duct for presence of oil

• If contaminants evidenced, identify source of contaminants

(i.e. Load Compressor Carbon seal, Cooling fan...)

• Eliminate source of contaminants as per AMM instructions

• It may require APU removal depending on the source identified

• Decontaminate A/C as per AMM 21-00-00 and ISI 21.00.00018

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

APU Bleed Duct Inspection

Load Control Valve (LCV) Inspection

• If oil ingestion is suspected and no external leak is evident, inspect pneumatic

duct downstream with black light for oil contamination

If oil is evident, there is a possibility of an internal APU oil leak or ingested oil leak

Inspect the APU drain system and APU cooling fan ducts as described in next

slides to identify source of contaminants

APU bleed air duct

LCV

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Identify Source of Contaminants

Check LC Witness Drain

• An oil leak witness drain is located aft of the seal to collect any oil leakage. The

oil is drained directly overboard through the drain mast

• Failure of the load compressor carbon seal would result in oil being present at

the seal cavity witness drain

• Check the 6 o’clock Load Compressor

(LC) witness drain with black light to

determine if there is oil. Presence of

excessive amount of oil indicates LC

seal leak

• APU should be removed, if LC seal

leak is suspected

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Identify Source of Contaminants

Oil cooler, cooling fan & discharge duct

fan ducts

• Inspect the inside of the fan ducts for evidence of oil. If oil

is present and the inside of the plenum is clean, further

inspection of the oil cooler and fan is required

Oil cooler

Inspect Oil Cooler Lines

• External contamination or cooling fan oil leak can

leave residue on cooling fan housing

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Identify Source of Contaminants

Check oil quantity

• Check Oil Quality – DO NOT Over Fill:

Confirm APU normal shutdown by checking fully closed APU air intake. If the

shutdown is unknown operate the APU at no-load for 5 minutes followed by a normal

shut down

Complete de-oiling during normal APU shutdown should be performed prior to

checking the oil level

Wait for at least 15 min after last APU shutdown prior to checking and eventually

completing the oil level

It is also best practice to determine the need for oil service by utilizing the aircraft

ECAM warning for low oil level

Oil sight glass

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Smell In Cabin - Troubleshooting Guide

• Once inspections have been carried out, source of contaminant has been

eliminated and APU compartment/duct sealing condition has been

restored, next step will be:

Clean contaminated APU and compartment

Decontaminate A/C pneumatic system as per AMM 21-00-00 and ISI

21.00.00018

• Failure to do so will lead to ineffective or only partial decontamination and

therefore the risk of future reports of smoke or odours in the cabin

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Clean APU plenum and duct

APU Inlet Plenum

• Inspect Inlet Plenum for Oil Contamination

If oil has accumulated in the plenum, clean using degreaser and/or steam cleaner (refer

to AMM 49-16-00 for further information).

Perform APU compressor cleaning as per AMM task 49-20-00-100-004-A

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Clean APU plenum and duct

APU inlet duct inspection

• Inspect the interior of the inlet duct for cleanliness. If it is contaminated, the duct

must be cleaned

Refer to AMM Task 49-00-00-790-008-A “Check APU compartment and air intake

duct for oil contamination”

Check AMM 49-00-00 PB 501 “Check APU compartment and air intake duct for oil

contamination” and TSM 49-00-00 “Fumes in the cabin / Oil Smoke at APU Exhaust” for

further information

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Smell In Cabin - Troubleshooting Guide

• Further to an APU removal associated to a Smell/Odour in

Cabin event, refer to the following workscope guide to be

followed during APU shop visit

Perform visual inspection

Perform black light inspection to look for traces of oil

Perform borescope inspection to verify if there is oil leak

at LC cavity

Determine if there is evidence of

External oil leak

Internal oil leak

External ingestion

Photo document findings & condition of the APU

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Airbus Documentation

Airbus SIL / ISI

Reference Description

ISI 21.00.00018 Environmental Control System (ECS) decontamination procedure

ISI 21.21.00011 Cabin Air Quality Troubleshooting Advice

ISI 29.00.00004 Preventing external hydraulic leaks

SIL 49-032 Aircraft/APU bleed air oil contamination/Aircraft smoke warning

Airbus Service Bulletins (SB)

SB Number Description Released date

A320-49-1049 Introduce a drain system and sealing on R/L access doors Jan 1997

A320-49-1050 Introduce a modified intake elbow seal and aircraft intake Feb 1997

box seal

A320-49-1068 APU starter Motor and Air Intake System Inspection Jun 2005

Cleaning

A320-52-1152 Introduce additional seals and guttering on the APU doors Sep 2010

to prevent water ingress

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

Honeywell Documentation

Vendor Service Bulletins (VSB)

VSB Description Released Date APU Effectivity

Number

131-49-7562 Gasket material change from BlueGuard to January 2000 R-2161

Grafoil

131-49-7845 Turbine Seal March 2006 R-2298

131-49-7947 Replace L/C carbon seal and rotor PN August 2007 P-3072

3827350-3 and PN 3842418-1 with PN

3827608-3 and PN 3822635-2

131-49-7944 Change of Turbine Scavenge Tube to January 2008 P-3630

Incorporate Conical Seal

131-49-7989 Turbine Aft cover Gasket April 2010 P-4477

131-49-8063 First Stage Dual Alloy Turbine* September 2011 P-4956

* First turbine blade walking can lead to rotor imbalance and turbine oil scavenge tube leak

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document. This document and all information contained herein is the sole property of AIRBUS S.A.S. No intellectual property rights are granted by the

delivery of this document or the disclosure of its content. This document shall not be reproduced or disclosed to a third party without the express written consent of AIRBUS S.A.S. This document and its content shall not be

used for any purpose other than that for which it is supplied. The statements made herein do not constitute an offer. They are based on the mentioned assumptions and are expressed in good faith. Where the supporting

grounds for these statements are not shown, AIRBUS S.A.S. will be pleased to explain the basis thereof.

AIRBUS, its logo, A300, A310, A318, A319, A320, A321, A330, A340, A350, A380, A400M are registered trademarks.

© AIRBUS S.A.S. All rights reserved. Confidential and proprietary document.

You might also like

- A319/A320/A321 APU Technical Training ManualDocument172 pagesA319/A320/A321 APU Technical Training ManualSelcuk GuncanNo ratings yet

- 49 Honeywell 131-9A Diff L3 Aug09 XDocument36 pages49 Honeywell 131-9A Diff L3 Aug09 XHo Viet Thang100% (1)

- CFM56 5C - Ang 2Document2 pagesCFM56 5C - Ang 2pullu p joseNo ratings yet

- Leap IntroductionDocument15 pagesLeap IntroductionAvinash Shetty100% (1)

- Iae Engine: Oat Colder ThenDocument1 pageIae Engine: Oat Colder ThenBharat Bhushan100% (1)

- APU 131-9A: Vibhu Agrawal Ets/Cte, Ial, HydDocument105 pagesAPU 131-9A: Vibhu Agrawal Ets/Cte, Ial, HydAnirban MukherjeeNo ratings yet

- PW1100Document12 pagesPW1100Brayan RobertoNo ratings yet

- Airbus 320 APUDocument136 pagesAirbus 320 APUSelcuk GuncanNo ratings yet

- Pw4000-100 - Opencowl Inspection GuideDocument63 pagesPw4000-100 - Opencowl Inspection Guidegayathrisicwai100% (8)

- Ctc-214 Basic EngineDocument365 pagesCtc-214 Basic Engineernesto rodriguezNo ratings yet

- Lgciu Ts GuideDocument34 pagesLgciu Ts GuidePankaj KhondgeNo ratings yet

- V2500-RR-Line and Base Maintenance - Course NotesDocument541 pagesV2500-RR-Line and Base Maintenance - Course NotesM AliNo ratings yet

- Airbus A320neo Family Project - Docx-1Document54 pagesAirbus A320neo Family Project - Docx-1ashik hussainNo ratings yet

- CFM Technical DataDocument2 pagesCFM Technical DataArturoACE100% (6)

- A320Document16 pagesA320allen donNo ratings yet

- 70 Power Plant Iae V2500 PDFDocument310 pages70 Power Plant Iae V2500 PDFNeorace67% (6)

- A320 Flight Control System Maintenance GuideDocument59 pagesA320 Flight Control System Maintenance GuideAgustin Guzman100% (2)

- Apu 01Document109 pagesApu 01flyingbeauty100% (2)

- Elac Sec Efcs Trouble Shooting Tips Booklet PDFDocument57 pagesElac Sec Efcs Trouble Shooting Tips Booklet PDFGenaro Rodriguez100% (1)

- 30 A320 ATA Ice and RainDocument88 pages30 A320 ATA Ice and Rainrajesh100% (2)

- The Rolls-Royce Trent 7000 Engine: Key Facts at A GlanceDocument3 pagesThe Rolls-Royce Trent 7000 Engine: Key Facts at A GlanceAshwiniNo ratings yet

- Apu White SmokeDocument3 pagesApu White SmokeGoutam SahaNo ratings yet

- 49 Honeywell 36-300 - Diff - L3 - Aug09 - X PDFDocument24 pages49 Honeywell 36-300 - Diff - L3 - Aug09 - X PDFHo Viet ThangNo ratings yet

- Atr72 Hydraulic SystemDocument8 pagesAtr72 Hydraulic SystemBernhard DallnAirNo ratings yet

- IAE V2500 Under Cowl GuideDocument61 pagesIAE V2500 Under Cowl GuideWalter Radzewicz100% (1)

- 131-9a ApuDocument4 pages131-9a Apuavianova40% (5)

- Avionics Ventilation SystemDocument6 pagesAvionics Ventilation SystemIbrahim AyyilNo ratings yet

- A320 30 Rain and Ice ProtectionDocument72 pagesA320 30 Rain and Ice ProtectionBahador100% (2)

- Line Maintenance Services Price List 2014Document7 pagesLine Maintenance Services Price List 2014Estevam Gomes de AzevedoNo ratings yet

- Ctc-071 Borescope InspectionDocument135 pagesCtc-071 Borescope InspectionJorge Farias Gomez100% (2)

- GE90 Engine Data With 3D CutawayDocument19 pagesGE90 Engine Data With 3D CutawayjauuulNo ratings yet

- PW1500G TRM Supplemental Material - Combustion Chamber Borescope Pictures - PWA115622 Rev CDocument2 pagesPW1500G TRM Supplemental Material - Combustion Chamber Borescope Pictures - PWA115622 Rev CaliNo ratings yet

- DMC Leap 1a 73 00 0023 01a 930a D - I 3 PDFDocument21 pagesDMC Leap 1a 73 00 0023 01a 930a D - I 3 PDFPanneer Selvam100% (1)

- 70 Power Plant Iae v2500Document466 pages70 Power Plant Iae v2500Joydeep Sengupta100% (1)

- CFM56-5A-5B CO-063 Basic Engine Feb2014Document27 pagesCFM56-5A-5B CO-063 Basic Engine Feb2014Kelik Arif100% (1)

- A 320321 Mel CDLDocument765 pagesA 320321 Mel CDLMustafa Direk100% (2)

- CFM56 NDT ManualDocument103 pagesCFM56 NDT Manualmanishprajapati707100% (3)

- A320 - 38 Water and Waste - GFC-1Document8 pagesA320 - 38 Water and Waste - GFC-1belinda koyaiyeNo ratings yet

- A321 Ata21-00 PDFDocument1 pageA321 Ata21-00 PDFkpilNo ratings yet

- Cf6 80c2 Engine.Document7 pagesCf6 80c2 Engine.Harsh Ambhore100% (1)

- LEAP Brochure 2015Document15 pagesLEAP Brochure 2015KITTU75% (4)

- Engine MaintenanceConceptsPresentation PDFDocument46 pagesEngine MaintenanceConceptsPresentation PDFEnrico Gambini100% (1)

- IAE V2500 BeamerDocument478 pagesIAE V2500 Beamerashufriendlucky92% (12)

- GE CF6-80C2 high-bypass turbofan engineDocument2 pagesGE CF6-80C2 high-bypass turbofan enginebbarry138No ratings yet

- MAINTENANCE PLANNING DOCUMENT OVERVIEWDocument31 pagesMAINTENANCE PLANNING DOCUMENT OVERVIEWAhrarNo ratings yet

- A319/A320 Component Location Manual Zones & FiguresDocument13 pagesA319/A320 Component Location Manual Zones & Figuresdiablohuno100% (1)

- Undercowl Guide v2500-1Document63 pagesUndercowl Guide v2500-1SAIBIN100% (1)

- FAST52Document21 pagesFAST52Vahid AlimoradiNo ratings yet

- Trip Check A330Document4 pagesTrip Check A330Omair Aziz RabbaniNo ratings yet

- Transit 737-400 19th September 2016Document4 pagesTransit 737-400 19th September 2016Iftikhar JawedNo ratings yet

- Effective From 17.07.19 PFI Boeing 737NG & MAX Issue 5, Rev-8Document3 pagesEffective From 17.07.19 PFI Boeing 737NG & MAX Issue 5, Rev-8Naresh Kumar PrajapatNo ratings yet

- AirbusnotesDocument139 pagesAirbusnotesANDRESXOXNo ratings yet

- 5 Cabin Conditioning & PressurisationDocument91 pages5 Cabin Conditioning & PressurisationIvan Milosevic100% (1)

- Transit Pre Flight Task Card AirbusDocument8 pagesTransit Pre Flight Task Card AirbusAbhijeet ChinchaneNo ratings yet

- Overhauled Airbrone Pump DAP UserManual022608Document25 pagesOverhauled Airbrone Pump DAP UserManual022608Kamal Jit DhimanNo ratings yet

- A 380 MaintenanceDocument43 pagesA 380 Maintenancesolnegro7100% (2)

- FAA issues SAIB on water contamination of fuel systemsDocument4 pagesFAA issues SAIB on water contamination of fuel systemsJesus Martin Muñante RamosNo ratings yet

- Sistemas de Aeronaves II: I.A. Allain Felipe Cely RamirezDocument41 pagesSistemas de Aeronaves II: I.A. Allain Felipe Cely RamirezMauricio Acevedo GarciaNo ratings yet

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Towing precautions for ATR 42 and 72 aircraftDocument3 pagesTowing precautions for ATR 42 and 72 aircraftPermadi Ari SandyNo ratings yet

- Abstrak InggrisDocument1 pageAbstrak InggrisPermadi Ari SandyNo ratings yet

- 8051 DatasheetDocument140 pages8051 DatasheetDharishNo ratings yet

- 8051 DatasheetDocument140 pages8051 DatasheetDharishNo ratings yet

- Apu Troubleshoot Tree: Abbreviations & DefinitionsDocument8 pagesApu Troubleshoot Tree: Abbreviations & DefinitionsAde YahyaNo ratings yet

- Gas Turbine Engine 1 of 2021Document16 pagesGas Turbine Engine 1 of 2021lintoNo ratings yet

- User Manual PA A320 FD Special Version V3 PDFDocument59 pagesUser Manual PA A320 FD Special Version V3 PDFaviation310300100% (1)

- A 33 eDocument462 pagesA 33 eGraham Waterfield100% (1)

- Aircraft Cost Calculator BBJ Vs B737-700Document13 pagesAircraft Cost Calculator BBJ Vs B737-700Harry NuryantoNo ratings yet

- ATA 36 PneumaticsDocument58 pagesATA 36 PneumaticsBao HuynhNo ratings yet

- Afman 11-2C-130H V3 Operations ProceduresDocument209 pagesAfman 11-2C-130H V3 Operations ProceduresAndrés SarmientoNo ratings yet

- Falcon - 2000 - PTM - V2r2 - MCD Description Des Systemes PDFDocument387 pagesFalcon - 2000 - PTM - V2r2 - MCD Description Des Systemes PDFRodrigo Alvarenga100% (2)

- Fokker 50-Aircraft GeneralDocument36 pagesFokker 50-Aircraft GeneralNishanth L100% (2)

- Q 400 SYSTEM BestDocument9 pagesQ 400 SYSTEM BestTeddy EshteNo ratings yet

- Accessories of A Gas Turbine EngineDocument20 pagesAccessories of A Gas Turbine EngineJames VillezaNo ratings yet

- B-777 RutDocument20 pagesB-777 Rutgeorgetown600No ratings yet

- DMW Project PDFDocument34 pagesDMW Project PDFAnonymous kE9DhY0zNo ratings yet

- MPP3914 - 36 11 01 05 1Document20 pagesMPP3914 - 36 11 01 05 1clebersjcNo ratings yet

- BP Turbo Oil Doc - Technique - Bpto2380Document14 pagesBP Turbo Oil Doc - Technique - Bpto2380Marc TapsonNo ratings yet

- V3N4Document16 pagesV3N4Fayçal MahieddineNo ratings yet

- Ata 28 - Fuel R1Document70 pagesAta 28 - Fuel R1Meda100% (2)

- A320 ATA 24 Electrical PowerDocument474 pagesA320 ATA 24 Electrical PowerDavid MF CocNo ratings yet

- TASK 49-00-00-811-901-A APU Shutdown During APU Start Normal OperationDocument7 pagesTASK 49-00-00-811-901-A APU Shutdown During APU Start Normal OperationEduardo FabianNo ratings yet

- Module 15 B1 Gas Turbines 0403Document548 pagesModule 15 B1 Gas Turbines 0403ArabyAbdel Hamed Sadek90% (10)

- B767 - Fuel SystemDocument41 pagesB767 - Fuel SystemTarik Benzineb100% (7)

- A320 Family Line Maintenance Task Card - Weekly Check: CockpitDocument4 pagesA320 Family Line Maintenance Task Card - Weekly Check: CockpitSuman BajracharyaNo ratings yet

- Special Applications Need Special Know-How: Engines and Systems Made in GermanyDocument9 pagesSpecial Applications Need Special Know-How: Engines and Systems Made in Germany임학진No ratings yet

- Aircraft Maintenance Engineer - Sample LetterDocument3 pagesAircraft Maintenance Engineer - Sample LetterBeing AirWindNo ratings yet

- Apu Comparison in Igo Fleet PDFDocument19 pagesApu Comparison in Igo Fleet PDFRahul UnnikrishnanNo ratings yet

- Checklist PMDG 737Document0 pagesChecklist PMDG 737prot291No ratings yet

- Aircraft Specifications - Model A320-212Document7 pagesAircraft Specifications - Model A320-212simon100% (1)

- R11 Segment 5 PDFDocument63 pagesR11 Segment 5 PDFFlorin Stancu100% (1)

- Aircraft Fuelling Operation - Risk Assessment Case StudyDocument9 pagesAircraft Fuelling Operation - Risk Assessment Case StudyDavid GrimaNo ratings yet

- Hawker 800 800XP FlashCardsDocument485 pagesHawker 800 800XP FlashCardsPolo Soto100% (3)