Professional Documents

Culture Documents

Sitren PSR 100 0209 en 2000 If

Uploaded by

Suryasai RednamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sitren PSR 100 0209 en 2000 If

Uploaded by

Suryasai RednamCopyright:

Available Formats

SITREN® PSR 100

Product Data Sheet

Product description Dosage and handling

SITREN® PSR 100 is a powdered shrinkage Recommended dosage rates are between 0.1 –

reducing additive. The active components are 2.0 wt.-% with respect to the solid content of the

organic alcohols on an inorganic carrier. mortar, dry-mix or concrete formulations.

Physical properties It is recommended to pre-mix the SITREN®

PSR 100 powder with all other dry components

Appearance white, free flowing powder by using standard mixing devices.

Density [g/l] approx. 550

The resulting powder blend should be added

Carrier inorganic

into water under gentle stirring to obtain a

homogeneous dispersion. Before application of

Application the wet blend the mixture should be given some

SITREN® PSR 100 reduces the drying shrinkage time (1 - 5 minutes) to settle for complete

and the autogenous shrinkage of cementitious, wetting of the solids.

dry-mix and specialty mortar formulations,

that can occur when the formulation is losing Registration status

moisture during the drying process. The ingredients of SITREN® PSR 100 are listed in

the following chemical inventories:

Properties

EINECS; TSCA; NDSL; ENCS; ECL; CHINA; PICCS;

In cementitious and concrete formulations NZIOC (New Zealand)

SITREN® PSR 100 reduces the surface tension of

pore fluids. As a result it provides the following Further information is available on request.

benefits,

Storage stability:

• SITREN® PSR 100 reduces significantly the SITREN® PSR 100 may be stored in closed bags

drying shrinkage and the autogenous for at least 6 months; storage temperature

shrinkage should not exceed 35 °C. Longer storage times

• SITREN® PSR 100 reduces the magnitude of may cause lumping which normally does not

capillary stresses and shrinkage strains affect the performance of the product.

• SITREN® PSR 100 improves the crack

resistance

• SITREN® PSR 100 can significantly improve

the resistance to chloride ion diffusivity

• SITREN® PSR 100 has no negative effect on

the workability

Packaging Hazardous goods classification

15 kg paper bags with PE inliner Information concerning

pallet size 450 kg (30 x 15 kg)

- Classification and labelling according to

regulations for transport and for dangerous

substances

Safety information

- Protective measures for storage and handling

Dust may be explosive if mixed with air in critical - Measures in case of accidents and fire

proportions and in the presence of an ignition - Toxicity and ecological effects

source.

is given in our material safety data sheets.

02/2009

This information and all further technical advice is based on our present knowledge and experience. However, it implies no liability or

other legal responsibility on our part, including with regard to existing third party intellectual property rights, especially patent rights. In

particular, no warranty, whether express or implied, or guarantee of product properties in the legal sense is intended or implied. We

reserve the right to make any changes according to technological progress or further developments. The customer is not released from

the obligation to conduct careful inspection and testing of incoming goods. Performance of the product described herein should be

verified by testing, which should be carried out only by qualified experts in the sole responsibility of a customer. Reference to trade

names used by other companies is neither a recommendation, nor does it imply that similar products could not be used. (Status: January

2008)

Evonik Goldschmidt GmbH Goldschmidtstr. 100 45127 Essen Germany

PHONE EUROPE +49 201 173 2175

PHONE ASIA +86 21 61191 125

PHONE AMERICAS +1 804 541 8658

is@evonik.com | www.goldschmidt-is.com

You might also like

- Aerated Autoclaved Concrete: Prepared by Ankit Patel SD 1110Document26 pagesAerated Autoclaved Concrete: Prepared by Ankit Patel SD 1110devNo ratings yet

- Sist en 459 1 2015Document15 pagesSist en 459 1 2015AnelNo ratings yet

- ASTM D3359 Standard Test Methods For Measuring Adhesion by Tape TestDocument2 pagesASTM D3359 Standard Test Methods For Measuring Adhesion by Tape TestEdgarDavidDiazCamposNo ratings yet

- Insta SBC en 1401-1 January2017 - UkDocument17 pagesInsta SBC en 1401-1 January2017 - UkDharmarajah Xavier IndrarajanNo ratings yet

- Instruments For Various TestsDocument14 pagesInstruments For Various TestsReshmita PallaNo ratings yet

- 10 - TDS - Emaco S22 NBDocument3 pages10 - TDS - Emaco S22 NBaahtagoNo ratings yet

- Micrasil TDSDocument2 pagesMicrasil TDSAmmarNo ratings yet

- Astm C 772-2003Document2 pagesAstm C 772-2003zeqs9No ratings yet

- BS en 480-1+a1-2011Document14 pagesBS en 480-1+a1-2011Abey VettoorNo ratings yet

- Din en Iso 1798 2008 PDFDocument16 pagesDin en Iso 1798 2008 PDFmakineci_67No ratings yet

- En 934 3Document7 pagesEn 934 3Temur LomidzeNo ratings yet

- Mortar TestingDocument4 pagesMortar TestingSasanka SekharNo ratings yet

- BS en 14190-2014Document36 pagesBS en 14190-2014Stefano PerelliNo ratings yet

- ISO - 7783 - 2 - 1999 - EN - FR PermeabilityDocument6 pagesISO - 7783 - 2 - 1999 - EN - FR Permeabilityaloka0% (1)

- Etag 004 February 2013Document143 pagesEtag 004 February 2013Ganka PeevaNo ratings yet

- En 13263-1 CommentsDocument6 pagesEn 13263-1 CommentsLefteris AnastasiouNo ratings yet

- BS 12-1989Document8 pagesBS 12-1989U Thaung MyintNo ratings yet

- GGBSDocument20 pagesGGBSratnakar0% (1)

- En 13108-20 (2016) (E)Document8 pagesEn 13108-20 (2016) (E)tavi9050% (2)

- Phu Gia The He Moi Cho Xi MangDocument109 pagesPhu Gia The He Moi Cho Xi Mangminhhuan0101No ratings yet

- BS en 1767 1999 Infrared AnalysisDocument8 pagesBS en 1767 1999 Infrared AnalysispboliverNo ratings yet

- BS en 01744-6-2006 (2007)Document10 pagesBS en 01744-6-2006 (2007)Mahendra Singh BudhathokiNo ratings yet

- 2918 Mapeproof 1k Turbo UkDocument4 pages2918 Mapeproof 1k Turbo UkFloorkitNo ratings yet

- Product Profile For Concrete Repair ProductsDocument10 pagesProduct Profile For Concrete Repair ProductshemantrulzNo ratings yet

- en 12004-2-2017 CenDocument35 pagesen 12004-2-2017 CenMalak Hindi100% (2)

- Din 30670 - 2012Document35 pagesDin 30670 - 2012jirawatNo ratings yet

- C156 PDFDocument5 pagesC156 PDFMateriales FicNo ratings yet

- En 12274-2-2003 - Part 2 Bitumen ResidualDocument9 pagesEn 12274-2-2003 - Part 2 Bitumen Residual30papNo ratings yet

- CEN TS 12390 9 2006 en PreviewDocument5 pagesCEN TS 12390 9 2006 en PreviewVivi GouriotiNo ratings yet

- prEN 12697-33 CompacteurDocument18 pagesprEN 12697-33 CompacteurDamouh MohamedNo ratings yet

- Astm C 22C 22MDocument2 pagesAstm C 22C 22MProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNo ratings yet

- En 1097-5Document5 pagesEn 1097-5silverware1No ratings yet

- Isobond: SBR Bonding AdmixtureDocument3 pagesIsobond: SBR Bonding AdmixtureHussain MarzooqNo ratings yet

- Nitoprime 31Document2 pagesNitoprime 31Balasubramanian AnanthNo ratings yet

- Tylose MH 60001 P4 TDSDocument1 pageTylose MH 60001 P4 TDSMaha MuflehNo ratings yet

- Testing Epoxy Resin Adhesive: Standard Method of Test ForDocument13 pagesTesting Epoxy Resin Adhesive: Standard Method of Test ForCasey Ryback100% (1)

- BS en 196-9-2010Document24 pagesBS en 196-9-2010Anime TinNo ratings yet

- Fineness TestDocument25 pagesFineness TestlailaNo ratings yet

- SCCDocument10 pagesSCCPrakash NanthagopalanNo ratings yet

- BS en 679-2005Document10 pagesBS en 679-2005adhi ymNo ratings yet

- ISO TC 074 Cement and LimeDocument5 pagesISO TC 074 Cement and Limehrd_managerNo ratings yet

- MasterBrace ADH 2200Document2 pagesMasterBrace ADH 2200EngTamerNo ratings yet

- TDS - Sonoshield ParkcoatDocument2 pagesTDS - Sonoshield ParkcoatVenkata RaoNo ratings yet

- Automatic binder extraction using InfraTest Asphalt AnalyzerDocument22 pagesAutomatic binder extraction using InfraTest Asphalt AnalyzerSupriyo PNo ratings yet

- Qcs 2010 Section 13 Part 2 Mortar and GroutDocument6 pagesQcs 2010 Section 13 Part 2 Mortar and Groutbryanpastor106No ratings yet

- Iso 8339 2005Document9 pagesIso 8339 2005Tâm Nguyễn ĐồngNo ratings yet

- Chemcure WPDocument2 pagesChemcure WPICPL-RWPNo ratings yet

- Ilnas-En 12390-1:2021Document8 pagesIlnas-En 12390-1:2021HaniAminNo ratings yet

- BS en 1323-2007 Piezas de Concreto A PrepararDocument12 pagesBS en 1323-2007 Piezas de Concreto A PrepararClaudia CarhuaniNo ratings yet

- European Standard for IG UnitsDocument7 pagesEuropean Standard for IG UnitsKhurshed Alam IndiaNo ratings yet

- Astm F3059-2015Document24 pagesAstm F3059-2015Khải TrươngNo ratings yet

- Sist en 13892 3 2015Document9 pagesSist en 13892 3 2015AnelNo ratings yet

- TCVN 6260 - 2009 Portland Blended Cement SpecificationsDocument4 pagesTCVN 6260 - 2009 Portland Blended Cement SpecificationsLong LêNo ratings yet

- CSA#20 Shrinkage Reducing Concrete AdditiveDocument2 pagesCSA#20 Shrinkage Reducing Concrete AdditiveThai Hai LyNo ratings yet

- (BS 4887-1-1986) - Mortar Admixtures. Specification For Air-Entraining (Plasticizing) AdmixturesDocument12 pages(BS 4887-1-1986) - Mortar Admixtures. Specification For Air-Entraining (Plasticizing) AdmixturesHung LeNo ratings yet

- BS EN 772 Part 20-2000-Determination of Flatness of Faces of Masonary BlocksDocument10 pagesBS EN 772 Part 20-2000-Determination of Flatness of Faces of Masonary Blocksjerin sam kurianNo ratings yet

- High Performance Microsilica Concrete AdmixtureDocument2 pagesHigh Performance Microsilica Concrete AdmixtureTori Small100% (1)

- Din en 12087-2013Document15 pagesDin en 12087-2013Casey RybackNo ratings yet

- C426 Contraccion Bloques 2010Document6 pagesC426 Contraccion Bloques 2010Javier MendezNo ratings yet

- Sitren P 750 0715 en Oi ConDocument2 pagesSitren P 750 0715 en Oi ConRama KrishnanNo ratings yet

- Bhagwan Ko Dekhne Ka SukhDocument1 pageBhagwan Ko Dekhne Ka SukhSuryasai RednamNo ratings yet

- Mera Baba BookDocument15 pagesMera Baba BookSuryasai RednamNo ratings yet

- Electric-Resistance-Welded Steel Pipe: Standard Specification ForDocument9 pagesElectric-Resistance-Welded Steel Pipe: Standard Specification ForSuryasai RednamNo ratings yet

- DET Confirmation Review Meet 18th Aug'17Document1 pageDET Confirmation Review Meet 18th Aug'17Suryasai RednamNo ratings yet

- 08 07 19-EDocument3 pages08 07 19-ESuryasai RednamNo ratings yet

- The Power of TruthDocument4 pagesThe Power of TruthSuryasai RednamNo ratings yet

- New Rich Text DocumentDocument1 pageNew Rich Text DocumentSuryasai RednamNo ratings yet

- 08 07 19-EDocument3 pages08 07 19-ESuryasai RednamNo ratings yet

- Govt 2 BHK Housing Scheme 1Document1 pageGovt 2 BHK Housing Scheme 1Suryasai RednamNo ratings yet

- C 18 Fee ParticularsDocument8 pagesC 18 Fee ParticularsSuryasai RednamNo ratings yet

- Science and Spirituality by BK Jagadeesh Chandra - RealityDocument230 pagesScience and Spirituality by BK Jagadeesh Chandra - RealitySuryasai Rednam100% (1)

- C 18 Fee ParticularsDocument8 pagesC 18 Fee ParticularsSuryasai RednamNo ratings yet

- C 18 Fee ParticularsDocument14 pagesC 18 Fee ParticularsSuryasai RednamNo ratings yet

- Is 10262-2019Document44 pagesIs 10262-2019ਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟ96% (141)

- Kesoram Industries Limited: Cement DivisionDocument10 pagesKesoram Industries Limited: Cement DivisionSuryasai Rednam100% (1)

- Modern Road Makers Private Limited: Po No: PO DateDocument2 pagesModern Road Makers Private Limited: Po No: PO DateSuryasai RednamNo ratings yet

- शिवचरित्र PDFDocument1,676 pagesशिवचरित्र PDFAnand78% (18)

- BS 5328 Part1 PDFDocument28 pagesBS 5328 Part1 PDFSuryasai RednamNo ratings yet

- SSC JE CorrigendumDocument1 pageSSC JE CorrigendumKabya SrivastavaNo ratings yet

- C 18 Fee ParticularsDocument8 pagesC 18 Fee ParticularsSuryasai RednamNo ratings yet

- BCA 9-Making SlumpDocument20 pagesBCA 9-Making SlumpSuryasai RednamNo ratings yet

- ESIC recruitment for Junior EngineersDocument16 pagesESIC recruitment for Junior EngineersChandra SekaranNo ratings yet

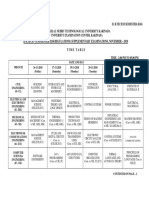

- JNTUK II B.Tech II Semester Nov 2018 Time TableDocument4 pagesJNTUK II B.Tech II Semester Nov 2018 Time TableSuryasai RednamNo ratings yet

- IS Latest For Aggregates SpecificationsDocument21 pagesIS Latest For Aggregates SpecificationsSuryasai RednamNo ratings yet

- शिवचरित्र PDFDocument1,676 pagesशिवचरित्र PDFAnand78% (18)

- Indian Standard of Accelerate Curing of ConcreteDocument17 pagesIndian Standard of Accelerate Curing of ConcreteAlberto Tupa OrtizNo ratings yet

- BS 5328 Part1 PDFDocument28 pagesBS 5328 Part1 PDFSuryasai RednamNo ratings yet

- Indian Institute of Technology MadrasDocument41 pagesIndian Institute of Technology MadrasNakul YadavNo ratings yet

- Sci+TG Module 4 Acid&BasesDocument10 pagesSci+TG Module 4 Acid&BasesRjvm Net Ca Fe100% (1)

- Glycerol Colorimetric EstimationDocument2 pagesGlycerol Colorimetric EstimationAJNo ratings yet

- D891Document4 pagesD891gwinnruNo ratings yet

- A Two - Year Seasonal Survey of The Quality of Shea Butter Produced in Niger State of NigeriaDocument11 pagesA Two - Year Seasonal Survey of The Quality of Shea Butter Produced in Niger State of NigeriaOgwu Charles KanayoNo ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2016-12-30T18:17Z Check The Source To Verify That This Is The Current Version Before UseDocument89 pagesSource: Https://assist - Dla.mil - Downloaded: 2016-12-30T18:17Z Check The Source To Verify That This Is The Current Version Before UseYotam ShalemNo ratings yet

- Fluid MechanicsDocument21 pagesFluid Mechanicspavankumar001No ratings yet

- PS Ball - TDSDocument2 pagesPS Ball - TDSMunawwar Mukhtar100% (1)

- Origin of Life On EarthDocument47 pagesOrigin of Life On EarthCharismaLeonaEvangelioEnderinaNo ratings yet

- CoA Flower: DeathstarDocument1 pageCoA Flower: DeathstarLauren HendersonNo ratings yet

- Thermal AnalysisDocument8 pagesThermal AnalysisSURESHNo ratings yet

- Module 2 Combustion ThermodynamicsDocument29 pagesModule 2 Combustion ThermodynamicsDESHRAJ MEENA100% (2)

- Chemistry Lesson PlanDocument11 pagesChemistry Lesson PlanWilliam BaileyNo ratings yet

- MUCLecture 2022 42023102Document11 pagesMUCLecture 2022 42023102Farhan TaufiqurrahmanNo ratings yet

- Pile SpringDocument6 pagesPile SpringHamidAffandyNo ratings yet

- Non Clogging PumpsDocument15 pagesNon Clogging PumpsSouvik SingharoyNo ratings yet

- Cellrespphotopuzzle Pre ApDocument2 pagesCellrespphotopuzzle Pre Apapi-155864611No ratings yet

- The Chemical Engineering Journal Volume 24 Issue 2 1982 (Doi 10.1016/0300-9467 (82) 80037-3) K. Turton - Centrifugal Pump Clinic - by Igor J. Karassik, Published by Marcel Dekker, New York, 1981, PDFDocument1 pageThe Chemical Engineering Journal Volume 24 Issue 2 1982 (Doi 10.1016/0300-9467 (82) 80037-3) K. Turton - Centrifugal Pump Clinic - by Igor J. Karassik, Published by Marcel Dekker, New York, 1981, PDFvcockscribdNo ratings yet

- Igcse 71 Atoms&RadioactivityDocument29 pagesIgcse 71 Atoms&RadioactivityHany ElGezawy100% (3)

- Stocking DensityDocument6 pagesStocking DensityKartikkeyyan LoganathanNo ratings yet

- Section 1928 - Alternative Load-FactorDocument20 pagesSection 1928 - Alternative Load-FactorminedataNo ratings yet

- Chem 114Document12 pagesChem 114lesliemarie272No ratings yet

- 09 Samss 069Document10 pages09 Samss 069Pratik GurungNo ratings yet

- SOFCs Osamu YamamotoDocument13 pagesSOFCs Osamu YamamotoMehran IsgandarliNo ratings yet

- Advanced Excel® For Scientific Data Analysis: OxtordDocument7 pagesAdvanced Excel® For Scientific Data Analysis: OxtordKatarzyna AdamowiczNo ratings yet

- 0-En 14509 PDFDocument175 pages0-En 14509 PDFHamada Shoukry MohammedNo ratings yet

- Tousif Thesis 2010Document158 pagesTousif Thesis 2010Kristine Dwi PuspitasariNo ratings yet

- Mars 1968Document12 pagesMars 1968Minh Trần Nguyễn NhựtNo ratings yet

- Portable Cooling Using Peltier EffectDocument35 pagesPortable Cooling Using Peltier Effectvaibhav bothraNo ratings yet

- DS TEGO Amid S 18 eDocument4 pagesDS TEGO Amid S 18 eYole IstaNo ratings yet

- The Production of Acetylsalicylic Acid Project - Barbra Dozier's BlogDocument43 pagesThe Production of Acetylsalicylic Acid Project - Barbra Dozier's BlogAnonymous 4EWKYOzJeNo ratings yet