Professional Documents

Culture Documents

Halvorsen IJ Skogestad S 2000 TheoryOfDistillation PDF

Uploaded by

Rodrigo Mazzarella0 ratings0% found this document useful (0 votes)

6 views18 pagesOriginal Title

Halvorsen_IJ_Skogestad_S_2000_TheoryOfDistillation.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views18 pagesHalvorsen IJ Skogestad S 2000 TheoryOfDistillation PDF

Uploaded by

Rodrigo MazzarellaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 18

IV/DISTILLATION/ Theory of Di

tion 1117

headspace concentration, the heat of sublimation can

be determined for various compounds.

Derivatization procedures carried out on crude

samples can produce materials with improved subli-

mation characteristics. This technique has been used

to produce volatile compounds of lanthanides and

actinides which have then been sublimed prior to

analytical determinations. Derivatives have been

made using f-diketones (hexafluoroacetylacetone or

acetylacetone), benzoyltrifluoroacetone and thenoy!

trifluoroacetonates.

Low-temperature sublimation, which in some cit-

cumstances is termed freeze-drying, has been used t0

separate water, as ice, from biological fluids such as

serum, urine or saliva. The technique has been parti-

cularly useful in paediatric cases where sample volumes

are extremely low. Determinations have then been ac

complished using IR. spectroscopy or mass spectro

metry. Preparation of physiological samples for deter

mination of deuterium oxide has included sublimation

techniques prior to spectrophorometric determinations.

Low-temperature sublimation has been used to pre

pare samples for cryo-scanning electron microscopy

(SEM) analysis in order to examine herbicide particles

in a water suspension. The sublimation of herbicide-

containing frozen water droplets provides a suitable

cexching of the surface for the SEM technique.

High-temperature sublimations are often the

methods of choice in sample preparations from min-

cral ores, particularly in the case of trace enrichment

of noble metals and the actinides and lanthanides

prior to activation methods. Temperatures of $00—

1200°C are typical. The procedure is carried out in

silica tubes with entrainment gases, for example air or

argon, being used to increase the sublimation process.

Polycyclic aromatic compounds have been separ-

ated using sublimation techniques from a variety of

samples including coal, solids derived from oil, coal

and petroleum processing, and residues (soots) result

ing from the use of such fossil fuels.

Theory of Di jation

|. J. Halvorsen and S. Skogestad, Nonwesian

University of Science and Technology (NTNU),

Trondheim, Norway

Copyright © 2000 Academic Press

Introduction

Distillation is a very old separation technology for

separating liquid mixtures that can be traced back to

A. variety of miscellaneous applications have

been developed for separation from difficult matrices

and purification of specific materials. These include:

‘® Mercury separated from impurities by conversion

to its iodide followed by sublimation.

¢ Isolation of proazulene and chamomile from the

flower heads of plants.

¢ Isolation of aroma compounds from wheat and rye

samples prior to determination using isotope dilu-

tion methods,

‘¢ Determination of tin in casserite.

Selective sublimation of molybdenum and tung-

sten.

Sublimation is used in some procedures for the

preparation of samples for SEM in which gold is

sublimed in vacuum from a heated tungsten filament

to the sample being examined.

See also: WDistillation: Freeze-Drying.

Further Reading

CChickos J (1987) Heats of sublimation, In: Liebman JF

‘and Greenberg A (eds) Molecular Structure and Ener-

-getics, vol. 2. Weinheim, Germany: VCH Publishers.

Davies M (compiler) (1991-1992) Sublimation pressure for

‘organic compounds. In: Lide DR (ed.) CRC Handbook

of Physics and Chemistry, 72nd edn, pp. S-91. Boca

Raton: CRC Press

isenbraun EJ, Moyer C] and Vuppalapaty P (1978) Subli-

mation apparatus: design improvement. Chemistry and

Industry 229-230.

Holden CA and Bryant HS (1969) Purification by sublima

tion, Separation Science 4(1): 1-13.

Somorjai GA (1968) Mechanism of sublimation. Science

162: 755-760.

Stahl E (1976) Advances in the field of thermal procedures

in direct combination with thin-layer chromatography

Accounts of Chemical Research 9: 75-80,

a Neagiapeebos eA Gepawrhy

Semcet VM peut nace hes,

2.008

the chemists in Alexandria in the first century ab.

Today distillation is the most important industrial

separation technology. It is particularly well suited

for high purity separations since any degree of

separation can be obtained with a fixed energy con-

sumption by increasing the number of equilibrium

stages.

To describe the degree of separation between two

components in a column or in a column section, we

1118

I//DISTILLATION/ Theory of Di

introduce the separation factor:

(xc lube

S Gauleids

tu

where x denotes mole fraction of a component, sub-

script L denotes light component, H heavy component,

T denotes the top of the section, and B the bottom.

It is relatively straightforward to derive models of

distillation columns based on almost any degree

of detail, and also to use such models to simulate

the behaviour on a computer. However, such simula-

tions may be time-consuming and often provide

limited insight. The objective of this article is to

provide analytical expressions that are useful for

understanding the fundamentals of distillation and

which may be used to guide and check more detailed

simulations:

1, minimum energy requirement and corresponding

internal flow requirements

2. minimum number of stages

3. simple expressions for the separation factor

The derivation of analytical expressions requires the

assumptions oft

1, equilibrium stages

2. constant relative volatility

3. constant molar flows

These assumptions may scem restrictive, but they are

actually satisfied for many real systems, and in any

case the resulting expressions yield invaluable in-

sights, also for systems where the approximations do

not hold.

Saturated vapour leaving the stage

with equilibrium mole fraction y

‘and molar enthalpy hy (7 x),

Vapour entering the stage (Yin My i)

Figure 1 Equilbriumstage concept

Fundamentals

‘The Equilibrium-Stage Concept

‘The equilibrium (theoretical)-stage concept (Fig-

ure 1) is central in distillation. Here we assume va-

pour-liquid equilibrium (VLE) on each stage and that

the liquid is sent to the stage below and the vapour to

the stage above. For some trayed columns this may be

a reasonable description of the actual physics, but itis

certainly not for a packed column. Nevertheless, itis

established that calculations based on the equilib-

rium-stage concept (with the number of stages ad-

justed appropriately) fits data from most real columns

very well, even packed columns.

One many refine the equilibrium stage concept,

by introducing back-mixing or a Murphee efficiency

factor for the equilibrium, but these ‘fixes’ often have

relatively little theoretical justification, and are not

used in this article

For practical calculations, the critical step is usu-

ally not the modelling of the stages, but to obtain

a good description of the VLE. In this area there has;

been significant advances in the last 25 years, espe-

cially after the introduction of equations of state for

VLE prediction. However, here we will use simpler

VLE models (constant relative volatility) which apply

to celatively ideal mixtures.

Vapour-Liquid Equilibrium

In a two-phase system (PH = 2) with N-nonre

components, the

cting

state is completely determined by

N, degrees of freedom { f ), according to Gibb’s phase

ral:

(2)

Liquid entering the stage 0%, i.)

‘Vapour phase

Perfect mixing

Ineach phase

Liquid phase

7

y

Saturated liquid leaving the stage

‘with equilibrium mole fraction x

and enthalpy A(T, x)

I/DISTILLATION/ Theory of Distillation 1119

If the pressure (P) and N. ~ 1 liquid compositions or

‘mole fractions (x) are used as degree of freedom, then

the mole fractions (y) in the vapour phase and the

temperature (T) are determined, provided that two

phases are present. The general VLE relation can then

be written:

Dyin Ya ee Yeats T] = FUP 15 82 BN)

bsTI=FP,x 81

Here we have introduced the mole fractions x and y in

the liquid and vapour phases respectively, and we

trivially have S*_,x)= Land Ff, y= 1

In ideal mixture’, the VLE can be derived from

Raoult’s law which’ states that the partial pressure

p, of a component (i) in the vapour phase is propor-

tional to the vapour pressure (p?) of the pure compon

ent (which is a function of temperature only:

p? =p'(T)) and the liquid mole fraction (x):

p= xpD) 41

For an ideal gas, according to Dalton’s law, the par-

tial pressure of a component is proportional to the

mole fraction p, = y,P and since the total pressure

P= py Pet +P =P Li xpllD) we derive:

pt __sptlT)

abe a (5)

POY x pitt)

‘The following empirical formula is frequently used to

compute the pure component vapour pressure:

b

InpiNrat Pptdin( eer (6)

The coefficients are listed in component property

databases. The case with d=e=0 is called the

Antoine equation,

‘K-values and Relative Volatility

The K-value for a component i is defined as:

K, = yisz. The K-value is sometimes called the equi-

librium constant, but this is misleading as it depends

strongly on temperature and pressure (or composi-

tion).

The cclative volatility between components i and

jis defined as:

7 7]

For ideal mixtures that satisfy Raoult’s law we have:

K _ px,

px)

(ous)

oi

[8]

Here pf(T) depends on temperature so the K-values

will actually be constant only close to the column

ends where the temperature is relatively constant. On

the other hand, the ratio pi(T)/pi(T) is much less

dependent on temperature, which makes the relative

volatility very attractive for computations. For ideal

mixtures, a geometric average of the relative volatil-

ities for the highest and lowest temperature in the

column usually gives sufficient accuracy in the com-

putations: ay = /op * Sin

‘We usually select a common reference component

1 (usually the least volatile or heavy component), and

define:

(TV PAT) (9

The VLE relationship (eqn [5]) then becomes:

ca

10}

Daa

For a binary mixture we usually omit the component

index for the light component, i.e, we write x =x;

(light component) and x, = 1—.x (heavy compon-

ent). Then the VLE relationship becomes:

Tea-dx (i)

y

This equilibrium curve is illustrated in Figure 2.

The difference y ~ x determines the amount of

separation that can be achieved on a stage. Large

relative volatilities imply large differences in boiling

points and easy separation. Close boiling points im-

ply relative volatility closer to unity, as shown below

quantitatively

Estimating the Relative Volatility from

Boiling Point Data

‘The Clapeyron equation relates the vapour pressure

temperature dependency to the specific heat of vapor-

ization (AH?) and volume change between liquid

and vapour phase (AV*")

de) _ A(T)

oF ~TAV() 7]

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- United States Patent: (45) Date of Patent: Nov.30, 2010Document8 pagesUnited States Patent: (45) Date of Patent: Nov.30, 2010Rodrigo MazzarellaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Sattler PDFDocument232 pagesSattler PDFRodrigo Mazzarella100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

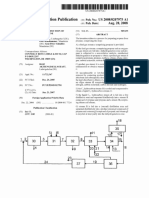

- Patent Application Publication (10) Pub. No.: US 2008/0207975 A1Document8 pagesPatent Application Publication (10) Pub. No.: US 2008/0207975 A1Rodrigo MazzarellaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Texto Integral PDFDocument374 pagesTexto Integral PDFRodrigo MazzarellaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Fundamentos SCILABDocument170 pagesFundamentos SCILABjoliveira_360212No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- US Patent for Increasing Olefin Recovery from Catalytic Cracker Gas PlantsDocument20 pagesUS Patent for Increasing Olefin Recovery from Catalytic Cracker Gas PlantsRodrigo MazzarellaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- ImagemDocumentoPdfController 2 PDFDocument37 pagesImagemDocumentoPdfController 2 PDFRodrigo MazzarellaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 2001 JChemEduc PDFDocument4 pages2001 JChemEduc PDFEuwan Tyrone PriasNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- US Patent for Increasing Olefin Recovery from Catalytic Cracker Gas PlantsDocument20 pagesUS Patent for Increasing Olefin Recovery from Catalytic Cracker Gas PlantsRodrigo MazzarellaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- ImagemDocumentoPdfController 2 PDFDocument37 pagesImagemDocumentoPdfController 2 PDFRodrigo MazzarellaNo ratings yet

- Process Propane DehydrogenationDocument4 pagesProcess Propane DehydrogenationRodrigo MazzarellaNo ratings yet

- 687-700 Ing3Document14 pages687-700 Ing3Misha ManoharNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- ImagemDocumentoPdfController 2 PDFDocument37 pagesImagemDocumentoPdfController 2 PDFRodrigo MazzarellaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Patent Application Publication (10) Pub. No.: US 2008/0207975 A1Document8 pagesPatent Application Publication (10) Pub. No.: US 2008/0207975 A1Rodrigo MazzarellaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- PROCESSO PARA CONVERSÃO DE ALCANO EM ALCENODocument39 pagesPROCESSO PARA CONVERSÃO DE ALCANO EM ALCENORodrigo MazzarellaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- PROCESSO PARA A CONVERSÃO DE PROPANO A PROPENODocument23 pagesPROCESSO PARA A CONVERSÃO DE PROPANO A PROPENORodrigo MazzarellaNo ratings yet

- Conversão Propano em Propileno PDFDocument46 pagesConversão Propano em Propileno PDFRodrigo MazzarellaNo ratings yet

- ImagemDocumentoPdfController PDFDocument32 pagesImagemDocumentoPdfController PDFRodrigo MazzarellaNo ratings yet

- Global Olefins Polyolefins ABIPLASTDocument31 pagesGlobal Olefins Polyolefins ABIPLASTRodrigo MazzarellaNo ratings yet

- Projeto Preliminar de Uma Unidade de Produção de PolipropilenoDocument132 pagesProjeto Preliminar de Uma Unidade de Produção de PolipropilenoDébora EirizNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pervaporação - ResumoDocument7 pagesPervaporação - ResumoRodrigo MazzarellaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Disserta Emanuele Hernandes PDFDocument96 pagesDisserta Emanuele Hernandes PDFRodrigo MazzarellaNo ratings yet

- BRASKEM RA2016 PT PDFDocument120 pagesBRASKEM RA2016 PT PDFRodrigo MazzarellaNo ratings yet

- Aula de Membranas 2014 (Completa)Document39 pagesAula de Membranas 2014 (Completa)jessicaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- APIMEC - Apresentação para Investidores - 01 - 03 - CVMDocument45 pagesAPIMEC - Apresentação para Investidores - 01 - 03 - CVMElizeu Ferreira Dos SantosNo ratings yet

- Mercado Brasileiro de Polipropileno Com Ênfase No Setor AutomobilísticoDocument35 pagesMercado Brasileiro de Polipropileno Com Ênfase No Setor AutomobilísticoTâmara PorfíroNo ratings yet

- Pervaporação - ResumoDocument7 pagesPervaporação - ResumoRodrigo MazzarellaNo ratings yet

- APIMEC - Apresentação para Investidores - 01 - 03 - CVMDocument45 pagesAPIMEC - Apresentação para Investidores - 01 - 03 - CVMElizeu Ferreira Dos SantosNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Mercado Brasileiro de Polipropileno Com Ênfase No Setor AutomobilísticoDocument35 pagesMercado Brasileiro de Polipropileno Com Ênfase No Setor AutomobilísticoTâmara PorfíroNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)