Professional Documents

Culture Documents

DS-1 Volumen 3 Adenda 7 PDF

Uploaded by

Ana JaimesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DS-1 Volumen 3 Adenda 7 PDF

Uploaded by

Ana JaimesCopyright:

Available Formats

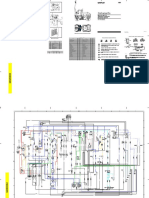

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

In this Volume 3 - Addendum 7, the following items have been modified or added:

Item Page Item Page

¶ 2.9.7............................................................... 2 ¶ 3.33.8.2 ....................................................... 23

Table 2.1.......................................................... 2 ¶ 3.33.5.1.b-c ................................................. 23

Table 2.2 (note)................................................ 2 Figure 3.37.1.................................................. 24

¶ 3.7.5.a ........................................................... 3 Table 3.7.1 .................................................... 25

¶ 3.11.5.b ......................................................... 3 Table 3.7.2 .................................................... 26

¶ 3.11.5.i .......................................................... 3 Table 3.7.3 .................................................... 30

¶ 3.11.6 ............................................................ 4 Table 3.7.4 .................................................... 34

¶ 3.11.6.b-c ...................................................... 4 Table 3.7.5 .................................................... 38

¶ 3.11.6.d-e ..................................................... 5 Table 3.7.6 .................................................... 41

Figure 3.11.2 ................................................... 6 Table 3.7.7 .................................................... 44

Figures 3.11.3.a-c ........................................... 6 Table 3.7.8 .................................................... 47

¶ 3.11.6.f .......................................................... 7 Table 3.7.9 .................................................... 49

¶ 3.11.7.a ......................................................... 7 Table 3.7.10 .................................................. 51

¶ 3.11.13........................................................... 8 Table 3.7.11 .................................................. 51

Figure 3.11.5.................................................... 9 Table 3.7.20 .................................................. 52

Figure 3.11.6.................................................... 9 Table 3.7.21 .................................................. 52

¶ 3.11.14 ........................................................ 10 Table 3.7.22 .................................................. 53

Figure 3.11.7.................................................. 10 Table 3.7.23 .................................................. 54

Figure 3.11.8.................................................. 10 Table 3.7.24 .................................................. 55

¶ 3.13.2.b-c .................................................... 11 Table 3.7.25 .................................................. 56

¶ 3.13.5.a-b ................................................... 12 Table 3.7.26 .................................................. 58

¶ 3.13.5.e ....................................................... 12 Table 3.7.27 .................................................. 62

¶ 3.13.5.h ....................................................... 13 Table 3.7.28 .................................................. 63

¶ 3.13.5.j ........................................................ 13 Table 3.7.29 .................................................. 67

Figure 3.13.2.................................................. 13 Table 3.7.30 .................................................. 70

¶ 3.13.6.b ....................................................... 14 Table 3.9.2..................................................... 71

¶ 3.13.6.e ....................................................... 14 Table 3.9.3..................................................... 71

¶ 3.13.6.h ....................................................... 14 Table 3.9.4..................................................... 72

¶ 3.13.6.j ........................................................ 14 Table 3.9.5..................................................... 72

Figure 3.13.3.................................................. 15 Table 3.9.6..................................................... 73

¶ 3.13.11.j ...................................................... 15 Table 3.9.7..................................................... 73

Figure 3.13.7.................................................. 15 Table 3.9.9..................................................... 74

¶ 3.13.12 ........................................................ 16 Table 3.12...................................................... 75

¶ 3.13.13 ........................................................ 18 ¶ 5.7.10 .......................................................... 82

Figure 3.13.10................................................ 18 ¶ 5.7.11 .......................................................... 82

Figure 3.13.11................................................ 18 ¶ 5.7.12 .......................................................... 82

¶ 3.14.2.b ....................................................... 19 ¶ 5.7.14 .......................................................... 82

¶ 3.14.5.a-b ................................................... 20 ¶ 5.7.15 .......................................................... 83

¶ 3.14.5.e ....................................................... 20 ¶ 5.7.16 .......................................................... 83

¶ 3.14.5.h ....................................................... 20 ¶ 5.7.17 .......................................................... 83

¶ 3.14.5.j ........................................................ 21 Appendix A.7.1.a-b ........................................ 84

¶ 3.14.6.b ....................................................... 21 Appendix A.7.3............................................... 84

¶ 3.14.8 .......................................................... 21

Issue Date: February 7, 2018 Page 1

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 6

¶ 2.9.7

CURRENT: CHANGE TO: (Amended text is underlined)

Recommended BSR Ranges Recommended BSR Ranges

Traditional Recommended Traditional Recommended

Drill Collar OD BSR Range BSR Range Drill Collar OD BSR Range BSR Range

< 6 inches 2.25-2.75 1.8-2.5 < 6 inches 2.25-2.75 1.8-2.5

6 - 7 7/8 inches 2.25-2.75 2.25-2.75 6 to < 8 inches 2.25-2.75 2.25-2.75

≥ 8 inches 2.25-2.75 2.5-3.2 ≥ 8 inches 2.25-2.75 2.5-3.2

Page 16

Table 2.1

CURRENT: (text to be deleted is underlined) CHANGE TO: (Amended text is underlined)

NAME OF METHOD: WHAT IS DONE: NAME OF METHOD: WHAT IS DONE:

8 Visual Connection Visual examination of 8 Visual Connection Visual examination of

connections, shoulders, and connections, shoulders, and

tool joints and profile check of tool joints and profile check of

threads, measurement of box threads, measurement of box

swell swell and pin lead, and check for

shoulder flatness

9 Dimensional 1 Measurement or Go-No-Go

gaging of box OD, pin ID, 9 Dimensional 1 Measurement or Go-No-Go

shoulder width, tong space, box gaging of box OD, pin ID,

counterbore shoulder width, tong space

10 Dimensional 2 Dimensional 1 requirements 10 Dimensional 2 Dimensional 1 requirements

plus measurement or Go-No-Go plus measurement or Go-No-Go

gaging of pin lead, counterbore gaging of counterbore depth, box

depth, box counterbore, pin flat counterbore, pin flat length, bevel

length, bevel diameter, seal width, diameter

and shoulder flatness

Page 19

Table 2.2, Note 1

CURRENT: CHANGE TO: (Amended text is underlined)

Note 1: FLUT is recommended for drill pipe in lieu of EMI Note 1: FLUT is recommended for drill pipe in lieu of EMI

when either the measured wall thickness is greater than when either the nominal wall thickness is greater than

0.400” or verification of wall thickness along the entire 0.500” or verification of wall thickness along the entire

tube length is critical. tube length is critical.

Issue Date: February 7, 2018 Page 2

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 35

¶ 3.7.5.a

CURRENT: (from Addendum 5) CHANGE TO: (Amended text is underlined)

3.7.5 Standardization of Flux Leakage Equipment: 3.7.5 Standardization of Flux Leakage Equipment:

a. The equipment shall be adjusted to produce a a. The equipment shall be adjusted to produce a

common reference amplitude (minimum 10 mm for common reference amplitude (minimum 10 mm

paper charts or a minimum of 80% of full screen for paper charts or a minimum of 40% of full digital

height for digital display) from each detector when screen height) from each detector when a hole is

a hole is scanned. Signal to noise ratio shall be a scanned. Signal to noise ratio shall be a minimum

minimum of 3 to 1. of 3 to 1.

Page 42

¶ 3.11.5.b

CURRENT: (from Addendum 6) CHANGE TO: (Amended text is underlined)

b. Thread Surfaces: For thread root and surface b. Thread Surfaces: For thread root pitting criteria

pitting criteria see A.7 in the Appendix for specific see A.7 in the Appendix for specific inspection

inspection requirements. Thread surfaces shall be requirements. Other thread surfaces, such as thread

free of other imperfections that appear to either crests, thread flanks, the box taper behind the last

penetrate below the thread root, occupy more than scratch with no stress-relief feature, and the area

1-1/2 inches in length along any thread helix or between the pin shoulder and the last scratch (i.e.

exceed 1/16 inch in depth or 1/8 inch in diameter. pin-neck flats) with no stress-relief feature, shall be

Raised protrusions must be removed with a hand free of imperfections that appear to either penetrate

file or “soft” (nonmetallic) buffing wheel. The thread below the thread root, occupy more than 1-1/2

profile shall be checked after any buffing or filing of inches in length along any thread helix or exceed

the threads. 1/16 inch in depth or 1/8 inch in diameter. Raised

protrusions must be removed with a hand file or

“soft” (nonmetallic) buffing wheel. The thread profile

shall be checked after any buffing or filing of the

threads

*Additional changes in A.7 are included in this Addendum 7.

Page 44

¶ 3.11.5.i

CURRENT: CHANGE TO: (Amended text is underlined)

i. Box Taper: The box taper at the back of the box i. Box Taper: The box taper at the back of the box

shall be visually inspected. All inner diameter tapers shall be visually inspected. All inner diameter tapers

originating from a box thread shall be at an angle originating from a box thread shall be at an angle

of 30° (+15°, -0°) from the centerline axis of the of 45 degrees maximum from the centerline axis of

connection. No burr, lip or edge greater than the the connection. No burr, lip or edge greater than the

allowable angle tolerance is acceptable. allowable angle tolerance is acceptable.

Issue Date: February 7, 2018 Page 3

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 44

¶ 3.11.6

CURRENT: CHANGE TO: (Amended text is underlined)

NOTE: When conflicts arise between this specification NOTE: Damages include, but are not limited to, the

and the manufacturer’s requirements, the manufacturer’s following conditions: galls, nicks, washes, fins, dents,

requirements shall apply. scratches, pits, or cuts. This does not include discol-

oration or other superficial anomalies that alter the

appearance only. When conflicts arise between this

specification and the manufacturer’s requirements, the

manufacturer’s requirements shall apply.

Page 45

¶ 3.11.6.b-c

CURRENT: CHANGE TO: (Amended text is underlined)

b. Primary Shoulder (Seal): The seal surfaces shall be b. Primary Shoulder (Seal): The seal surfaces shall be

free of raised metal or corrosion deposits detected free of raised metal or corrosion deposits detected

visually or by rubbing a metal scale or fingernail visually or by rubbing a metal scale or fingernail

across the surface. Any pitting or interruptions of the across the surface. Any pitting or interruptions of the

seal surface that are estimated to exceed 1/32 inch seal surface that are estimated to exceed 1/32 inch

in depth or cumulatively covers more than 1/3 of the

in depth or occupy more that 30% of the seal width

radial width at any given location are rejectable. No

at any given location are rejectable. No filing of the filing of the seal shoulders is permissible. See figure

seal shoulders is permissible. 3.11.2 for examples of acceptable and rejectable

damages.

c. Secondary Shoulder (Mechanical Stop): The

Secondary Shoulder is not a sealing surface. c. Secondary Shoulder (Mechanical Stop): The

Damage to this surface is not critical unless the Secondary Shoulder is not a sealing surface.

damage interferes with the make-up, driftability, or Damage to this surface is not critical unless the

torque capacity of the connection. Dents, scratches, damage interferes with the make-up, driftability, or

and cuts do not affect this surface unless these torque capacity of the connection. Dents, scratches,

exceed 1 inch in width and cause the connection and cuts are not acceptable if they exceed 1 inch

in length along the circumference or cause the

to be rejected due to shortening of the shoulder-

connection to be rejected due to shortening of the

to-shoulder length. Filing may be used to repair shoulder-to-shoulder length. Any metal protrusion

material protrusions, which extend from the face. above the seal surface is not acceptable and shall

Connection length readings shall not be taken in be removed by filing, soft wheel, or other buffing

damaged areas. method and protected by applying coating to the

repaired areas. Connection length readings shall

not be taken in damaged areas.

Issue Date: February 7, 2018 Page 4

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 45-46

¶ 3.11.6.d-e

CURRENT: CHANGE TO: (Amended text is underlined)

d. Refacing: For HT®, XT™, uXT™, TT® , GPDS™, d. Refacing: For HT™, XT™, uXT™, TT™ , GPDS™,

and uDS™, if refacing is necessary, the distance and uGPDS™, if refacing is necessary, the distance

from the primary shoulder to the secondary shoulder from the primary shoulder to the secondary shoulder

must be maintained as required in the Dimensional must be maintained as required in the Dimensional

2 Inspection. Refacing limits are 1/32 inch on any 2 Inspection. Refacing limits are 1/32 inch on any

one removal and 1/16 inch cumulatively. If existing

one removal and 1/16 inch cumulatively. If existing

benchmarks indicate that the shoulder has been

benchmarks indicate that the shoulder has been refaced beyond the maximum, the connection shall

refaced beyond the maximum, the connection shall be rejected.

be rejected.

• GPMark™ Benchmark: After refacing repair, a

minimum length of 1/16 inch (.062”) shall remain

• H-Series™ Benchmark: After refacing repair, a

on the box refacing benchmark, and 3/16 inch

minimum length of 1/16 inch (.062”) shall remain maximum (.188”) shall remain on the pin refac-

on the box refacing benchmark, and 3/16 inch ing benchmark. Rethreading is required if excess

maximum (.188”) shall remain on the pin refacing material is removed. See figure 3.11.3.a.

benchmark. Rethreading is required if excess

• Xmark™ Benchmarks: After refacing repair, a

material is removed. See figure 3.11.2.

visible step on the benchmark shall remain on the

primary shoulder. The step is a necessary indica-

• Xmark™ Benchmarks: After refacing repair, a tor that a benchmark is still present. Rethreading

visible step on the benchmark shall remain on the is required if there is no visible benchmark. See

primary shoulder. The step is a necessary indica- figure 3.11.3.b.

tor that a benchmark is still present. Rethreading Machine refacing in a lathe is the preferred method.

is required if there is no visible benchmark. See Portable field refacing units designed specifically

figure 3.11.3. for Grant Prideco connections are acceptable. A

minimum of four measurements shall be taken when

e. Threads: Thread flank surfaces shall be free of using a portable field refacing unit. The variability

damage that exceeds 1/16 inch in depth or 1/8 inch of face flatness and squareness is introduced and

in diameter. Thread roots shall be free of damage should be monitored. If any measurement is found

that extends below the thread root radius. Material to be outside the drawing limits, the connection shall

that protrudes beyond the thread profile should be be rejected.

removed using a round cornered triangle hand file

e. Threads: Thread flank surfaces shall be free of

or soft buffing wheel.

damage that exceeds 1/16 inch in depth or 1/8 inch

in diameter/width. For damage that is not round,

NOTE: For XT™, uXT™, XT-M™, TT® and TT®-M the 1/8 inch requirement applies to the width of

connections, ... the damage, and shall not apply to the length of

the damage along the circumference. See figure

3.11.3.c. Material that protrudes beyond the thread

profile shall be removed using a round cornered

triangle hand file or soft buffing wheel. Any damage

in the thread roots located within the Pit Free Zone

designated on the “Field Inspection Dimensions”

drawing, latest revision, is not acceptable. For

thread roots outside the designated Pit Free Zone,

damage that exceeds 1/32 inch in depth or 1/8 inch

in diameter is not acceptable and shall be repaired

by rethreading.

NOTE: For XT™, uXT™, XT-M™, TT™ and TT-M™

connections, ...

Issue Date: February 7, 2018 Page 5

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 45

Replace current with new Figure 3.11.2, 3.11.3.a, and 3.11.3.c (New)

NEW: NEW:

0.125" 0.031" 0.188"

(1/8") (1/32") (3/16")

0.125" 0.031" 0.063"

(1/8") (1/32") (1/16")

New Benchmark Max Removed Max Reface

per Reface

Figure 3.11.3.a GPMark™ Benchmarks.

CHANGE: Renumber 3.11.3 to 3.11.3.b

0.063" 0.031" 0.063"

(1/16") (1/32") (1/16")

0.063" 0.031" 0.063"

(1/16") (1/32") (1/16")

Acceptable Damage Rejectable Damage

W W

Ew + Fw ≤ Aw > New Benchmark Single Reface Max Reface

3 3 (with visible step)

Figure 3.11.3.b Xmark™ Benchmarks.

W

Gw + I w ≤

3 W

Bw + Cw + Dw >

(Hw is not loated at the same radial 3 NEW:

position as Gw and Iw, and is therefore not

added to the total width at this location)

Figure 3.11.2 Acceptable and rejectable seal damage.

Figure 3.11.3.c Dimensions of damage on thread flanks.

Issue Date: February 7, 2018 Page 6

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 46

¶ 3.11.6.f

CURRENT: CHANGE TO: (Amended text is underlined)

f. Thread Profile: The thread profile shall be verified f. Thread Profile: The thread profile shall be verified

along the full length of complete threads in two along the full length of complete threads in two

locations at least 90° apart. The profile gage locations at least 90° apart. The profile gage

should mesh evenly in the threads and show normal shall mesh evenly in the threads and show normal

contact. If the profile gage does not mesh evenly contact. If the profile gage does not mesh evenly

in the threads, lead measurements shall be taken. in the threads, lead measurements shall be taken.

Page 46

¶ 3.11.7.a

CURRENT: CHANGE TO: (Amended text is underlined)

a. 15° Seal: The 15° metal-to-metal sealing surfaces a. 15° Seal: The 15° metal-to-metal sealing surfaces

are allowed to contain round pit type defects in the are allowed to contain non-circumferential damage

contact area of the seal surface up to 1/32 inch in that is less than or equal to 1/32 inch in length,

diameter and not exceeding 1/32 inch in depth. width, diameter or depth. Multiple pits of this

Multiple pits of this type are acceptable provided there type are acceptable provided there is at least

is at least 1-inch circumferential separation between 1-inch circumferential separation between them.

them. Circumferential lines or marks are acceptable Circumferential lines or marks are acceptable in this

in this surface provided they cannot be detected by surface provided they cannot be detected by rubbing

rubbing a fingernail across the surface. The following a fingernail across the surface. The following “Pin

“Pin Seal” and “Box Seal” diagrams (figure 3.11.4) Seal” and “Box Seal” diagrams (figure 3.11.4) show

show areas of the seal that may contain damage areas of the seal that may contain damage exceeding

exceeding that previously stated in this procedure. that previously stated in this procedure. The area of

The area of the pin seal within 0.060 inch of the the pin seal within 0.060 inch of the minor pin nose

minor pin nose diameter is a not-contact surface and diameter is a not-contact surface and damage in this

damage in this area does not affect sealing. The area does not affect sealing. The area on the pin seal

area on the pin seal within 0.060 inch of the major pin within 0.060 inch of the major pin nose diameter may

nose diameter may also contain damage or pitting. also contain damage or pitting. Damages and pitting

Damages and pitting within these two areas of the within these two areas of the pin seal are permissible

pin seal are permissible provided the balance of the provided the balance of the pin seal contact surface

pin seal contact surface area meets the requirements area meets the requirements of this procedure.

of this procedure. Similarly, the area on the box seal Similarly, the area on the box seal within 0.188 inch

within 0.188 inch of the major box cylinder diameter of the major box cylinder diameter contains the non-

contains the non-contact portion of the box seal and contact portion of the box seal and that portion of the

that portion of the seal that corresponds to the first seal that corresponds to the first 0.060 inch of the pin

0.060 inch of the pin seal. Damage and pitting within seal. Damage and pitting within this area of the box

this area of the box seal are permissible provided the seal are permissible provided the balance of the box

balance of the box seal contact surface area meets seal contact surface area meets the requirements

the requirements of this section. of this section. Any metal protrusion above the seal

surface is not acceptable. Filing is not permitted on

any area of the radial metal-to-metal seal.

Issue Date: February 7, 2018 Page 7

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 49a

¶ 3.11.13 - Add new section

NEW:

3.11.13 Delta™ Connections: In addition to the re- • The cumulative total material removal from the

quirements of paragraph 3.11.4, Grant Prideco Delta™ primary make-up shoulder for all refacing opera-

connections shall meet the following requirements. tions shall not exceed 3/32 inch before rethreading

NOTE: Damages include, but are not limited to, the is required.

following conditions: galls, nicks, washes, fins, dents, • Repair by refacing methods shall only remove

scratches, pits, or cuts. This does not include discolor- sufficient material to repair the damage. However,

ation or other superficial anomalies that alter the appear- when damage is less than 1/32 inch deep, all dam-

ance only. When conflicts arise between this specification age shall be removed from the primary make-up

and the manufacturer’s requirements, the manufacturer’s shoulder.

requirements shall apply. • After the maximum reface allowance is met, any

remaining damage on the primary make-up shoul-

a. Preparation: All thread, make-up shoulder and seal der shall not be deeper than 1/64 inch and shall

surfaces shall be cleaned sufficiently to allow for meet all other requirements of this procedure.

visual inspection. The starting threads of the pin

and box connections should be cleaned using a “soft • If the connection cannot be brought back within

wheel” or other buffing method. the acceptable limits outlined in this procedure

without removing more than 1/32 inch of material

b. Primary Shoulder (Seal): The seal surface shall be from the primary shoulder, then rethreading shall

free of galls, nicks, washes, fins, or other conditions be required.

for which the damage exceeds 3/64 inch in depth, • Both the primary make-up shoulder and second-

cumulatively covers more than 1/3 of the radial ary make-up shoulder shall be skimmed/machined

width of the seal surface, or raised metal protrudes during a refacing operation for all double shoulder

above the seal surface (Filing on the primary make- connections.

up shoulder is not permitted). See figure 3.11.2 for

• Machine refacing in a lathe is the preferred

examples of acceptable and rejectable damages.

method.

c. Secondary Shoulder (Mechanical Stop): The • If the portable field refacing unit method is used,

Secondary Shoulder is not a sealing surface. the variability of face flatness and squareness is

Damage to this surface is not critical unless the introduced and shall be monitored by taking the

damage interferes with the make-up, driftability, or connection length measurements in a minimum

torque capacity of the connection. Dents, scratches, of four locations, equally spaced around the cir-

and cuts do not affect this surface unless the cumference. Each measurement shall be within

damage around the circumference prevents the the limits of the “Field Inspection Dimensions”

connection length from being accurately measured drawing, latest revision.

at two locations approximately 180 degrees apart or • GPMark™ + Benchmark: After refacing repair, a

any raised metal protruding above the seal surface minimum length of 1/16 inch (.063”) shall remain

that cannot be removed by filing, soft wheel, or on the box refacing benchmark, and 3/16 inch

other buffing method (Any repaired areas shall be maximum (.188”) shall remain on the pin refacing

protected by applying an acceptable coating). benchmark. Rethreading is required if excess

material is removed. See figure 3.11.5

d. Refacing: Repair by refacing may only be used

to attempt to repair shoulder damage less than • Xmark™ + Benchmarks: After refacing repair, a

or equal to 3/64 inch in depth, and/or connection visible step on the benchmark shall remain on the

length discrepancies that are less than 1/32 inch primary shoulder. The step is a necessary indica-

out of specification. tor that a benchmark is still present. Rethreading

is required if there is no visible benchmark. See

• As typical of the rotary shoulder connection reface figure 3.11.6.

process, a maximum of 1/32 inch of material may

be removed from the primary make-up shoulder e. Threads: Thread surfaces shall be free of any

during each refacing operation, after which the raised metal protruding above the thread surface

joint shall be placed back into service prior to that cannot be removed by filing, soft wheel, or

performing any additional refacing repair. other buffing method (Filing is not permitted in the

Issue Date: February 7, 2018 Page 8

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 49a

¶ 3.11.13 - Add new section (continued)

NEW:

0.094" 0.031" 0.188" thread roots.) Any repaired areas shall be protected

(3/32") (1/32") (3/16")

by applying an acceptable coating. Thread flank

surfaces shall be free of damage that exceeds

1/16 inch in depth or 1/8 inch in diameter/width. For

damage that is not round, the 1/8 inch requirement

applies to the width of the damage, and shall

not apply to the length of the damage along the

circumference. See figure 3.11.3.c. Thread roots

within the Pit Free Zone designated on the “Field

Inspection Dimension” drawing, latest revision, shall

0.156" 0.031" 0.063" be free of all damage. For thread roots outside of

(5/32") (1/32") (1/16") the designated Pit Free Zone, damage shall not

New Benchmark Max Removed Max Reface exceeds 1/32 inch in depth or 1/8 inch in diameter.

per Reface

Figure 3.11.5 Refacing with the GPmark™ + Benchmark f. Thread Profile: The thread profile shall be verified

for Delta™ connections. along the length of the full form threads in two

0.094" 0.031" 0.094" locations at least 90 degrees apart. The profile

(3/32") (1/32") (3/32") gauge shall mesh evenly in the threads and show

normal contact. If the profile gauge does not mesh

in the threads, lead measurements shall be taken.

g. Lead: If the profile gage indicates that thread stretch

has occurred, lead shall be measured over a 2-inch

0.094" 0.031" 0.094"

(3/32") (1/32") (3/32")

interval. Thread stretch shall not exceed 0.006 inch

over the 2-inch length. Connections failing this

inspection should be repaired by rethreading.

h. Coating: Threads and shoulders that are repaired by

filing or refacing shall be protected by hot phosphate

New Benchmark Max Removed Max Reface

per Reface

coating, or by using copper sulfate or other

commercially available effective surface etchant

products suitable for rotary shoulder connections.

Figure 3.11.6 Refacing with the Xmark™ + Benchmark All rethreaded connections shall be protected by

for Delta™ connections. hot phosphate coating.

i. Dimensional: Dimensional 2 (Section 3.13.12) is

required for drill pipe connections and Dimensional

3 (Section 3.14.8) is required for HWDP, drill collar

and sub connections.

Issue Date: February 7, 2018 Page 9

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 49b

¶ 3.11.14 - Add new section

NEW:

3.11.14 VAM® X-Force™: In addition to the Visual external shoulders to check whether the connector

Connection requirements of paragraph 3.11.4, VAM® can be re-faced or not. As shown in figure 3.11.7,

X-Force™ (VF) connections shall meet the following pin benchmark is a groove cut inside the external

requirements. shoulder that has the same depth as allowed re-

NOTE: When conflicts arise between this specification facing depth (1/16 inch). When the pin benchmark

and the manufacturer’s requirements, the manufacturer’s is no longer visible, it means that the connection

requirements shall apply. cannot be re-faced anymore. On the box end, as

shown in figure 3.11.8, the benchmark is a recess on

a. Preparation: All thread, make-up shoulder and seal the counter-bore diameter of the external shoulder.

surfaces shall be cleaned sufficiently to allow for This benchmark has twice the depth of allowed re-

visual inspection. facing depth. When box benchmark depth is equal

to or smaller than 1/16 inch, the box connection

b. Bevel Width: An approximate 45 degree OD bevel cannot be re-faced anymore. Measurement of box

at least 1/32 inch wide shall be present for the full benchmark depth is also an indicator of how much

circumference on both pin and box. re-facing was already carried out on the box part.

c. Box Swell: A straightedge shall be placed along g. Threads: Thread surfaces shall be free of damage

the longitudinal axis of the box tool joint. If a visible that exceeds 1/16 inch in depth or 1/8 inch in

gap exists between the straightedge and the tool diameter or that occupy more than 1-1/2 inch in

joint, the OD must be measured using calipers. length along the thread helix. Thread roots shall be

Compare the OD at the bevel to the OD 2 inches, free of damage that extends below the thread root

±1/2 inch away from the bevel. If the OD at the bevel radius. Material that protrudes beyond the thread

is greater by 1/32 inch or more, the connection shall profile should be removed using a round cornered

be rejected. triangle hand file or soft buffing wheel.

d. Primary Shoulder (Seal): Any pitting, interruptions,

galls, nicks, washes, fins or other conditions on the 0.0625" NEW

seal surface that are estimated to exceed 1/32 inch

in depth or occupy more that 30% of the seal width

at any given location are rejectable. No filing of the

seal shoulders is permissible.

e. Secondary Shoulder (Mechanical Stop): The

secondary shoulder is not a seal. This shoulder

must be free of raised metal or other imperfections

that could prevent proper make-up, driftability or

cause galling. Secondary shoulder damage can

be repaired with a hand file and should be used to Figure 3.11.7 Pin end benchmark.

remove protruding metal.

f. Refacing: If refacing is necessary, the distance from

the primary shoulder to the secondary shoulder

must be maintained as required in the Dimensional

2 Inspection. Shoulder refacing must be performed

in a machine repair shop. Refacing limits are 1/32

inch on any one removal and 1/16 inch cumulatively.

If existing benchmarks indicate that the shoulder has

been refaced beyond the maximum, the connection

shall be rejected. Drill pipe machined with VAM® 0.125" NEW

X-Force™ design have benchmark on pin and box

Figure 3.11.8 Box end benchmark.

Issue Date: February 7, 2018 Page 10

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 49b

¶ 3.11.14 - Add new section (continued)

NEW:

h. Thread Profile: The thread profile shall be verified box thread and shoulder areas. If this coating is

along the full length of complete threads in two slightly worn in some areas it is acceptable, however

locations at least 90 degrees apart. The profile gage if the coating is removed completely or if re-facing

should mesh evenly in the threads and show normal has been carried out, the connector requires re-

contact. If the profile gage does not mesh evenly coating with phosphate or with a Molybdenum

in the threads, lead measurements shall be taken. Disulfide (MoS2) repair kit (like Molykote® spray

products).

i. Lead: If the profile gage indicates that thread stretch

has occurred, lead shall be measured over a 2-inch k. Box Counterbore: The box counterbore radius shall

interval. Thread stretch shall not exceed 0.006 inch be free of any sharp edged defects caused by poor

over the 2-inch length. handling or stabbing. Such defects must be removed

by grinding prior to re-using the connection.

j. Coating: VAM® X-Force™ should always have a

phosphate coating (Mn or Zn) on both the pin and

Page 50

¶ 3.13.2.b-c

CURRENT: CHANGE TO: (Amended text is underlined)

b. Grant Prideco HI TORQUE™, eXtreme™ Torque, b. Grant Prideco HI TORQUE™, eXtreme™ Torque,

uXT™, eXtreme™ Torque-M, TurboTorque™, uXT™, eXtreme™ Torque-M, TurboTorque™,

TurboTorque-M™, Grant Prideco™ Double Shoulder TurboTorque-M™, Grant Prideco™ Double Shoulder

and uPDS™ Connections: In addtion... uGPDS™ and Delta™ Connections: In addtion...

... Dimensions provided in tables 3.7.2 - 3.7.9 and ... Dimensions provided in tables 3.7.2 - 3.7.9 , 3.7.20

3.7.20 - 3.7.24 are considered equivalent to the - 3.7.24, 3.7.28 and 3.7.30 are considered equivalent

dimensions provided in Grant Prideco field inspection to the dimensions provided in Grant Prideco field

drawings at the time of this document’s release. inspection drawings at the time of this document’s

Responsibility... release. Responsibility...

c. VAM Drilling VX, EIS, CDS and TM2 Connections: c. VAM VX, EIS, CDS, TM2 and VF Connections: In

In addition to... addition to...

Issue Date: February 7, 2018 Page 11

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 53

¶ 3.13.5.a-b

CURRENT: CHANGE TO: (Amended text is underlined)

a. Box Outside Diameter (OD): For NOV Grant a. Box Outside Diameter (OD): For Grant Prideco™ HI

Prideco HI TORQUE®, eXtreme™ Torque, uXT™ TORQUE™ and eXtreme™ Torque-M connections,

and eXtreme™ Torque-M connections, the OD of the OD of the tool joint box shall be measured at

the tool joint box shall be measured at a distance a distance of 2 inches ±1/4 inch from the primary

of 2 inches ±1/4 inch from the primary make-up make-up shoulder. Measurements shall be taken

shoulder. Measurements shall be taken around around the circumference to determine the minimum

the circumference to determine the minimum diameter. This minimum box diameter shall meet

diameter. This minimum box diameter shall meet the requirements in table 3.7.2, 3.7.4, or 3.7.20, as

the requirements in table 3.7.2 - 3.7.4, 3.7.8, 3.7.20 applicable.

- 3.7.21, or 3.7.24, as applicable. For Grant Prideco™ eXtreme™ Torque and uXT™

sizes 43 and smaller (e.g. XT43), the OD of the

For NOV Grant Prideco TurboTorque and ®

tool joint box shall be measured at a distance of

TurboTorque ®-M connections, the OD of the 5/8 inches ± 1/4 inch from the primary make-up

tool joint box shall be measured at a distance of shoulder. For sizes 46 and larger, the OD of the

5/8 inch to 7/8 inch from the primary make-up tool joint box shall be measured at a distance of

shoulder. Measurements shall be taken around 2 inches ± 1/4 inch from the primary make-up

the circumference to determine the minimum shoulder. Measurements shall be taken around

diameter. This minimum box diameter shall meet the circumference to determine the minimum

the requirements in table 3.7.6 - 3.7.7 or 3.7.22- diameter. This minimum box diameter shall meet

3.7.23, as applicable. the requirements in table 3.7.3, 3.7.8, 3.7.21, or

3.7.24, as applicable.

b. Pin Inside Diameter (ID): The pin ID shall be

measured under the last thread nearest the shoulder For Grant Prideco™ TurboTorque™ and

(±1/4 inch) and shall meet the requirements in table TurboTorque-M™ connections, the OD of the

3.7.2 - 3.7.8 or 3.7.20 - 3.7.24, as applicable. tool joint box shall be measured at a distance of

5/8 inch to 7/8 inch from the primary make-up

shoulder. Measurements shall be taken around

the circumference to determine the minimum

diameter. This minimum box diameter shall meet

the requirements in table 3.7.6 - 3.7.7 or 3.7.22-

3.7.23, as applicable.

b. Pin Inside Diameter (ID): The pin ID shall be

measured under the last thread nearest to the

shoulder (±1/4 inch) and referenced against the

values in table 3.7.2 - 3.7.8 or 3.7.20 - 3.7.24,

as applicable. The pin ID is used to define other

inspection dimensions.

Page 53

¶ 3.13.5.e

CURRENT: CHANGE TO: (Amended text is underlined)

e. Box Counterbore Diameter: The box counterbore e. Box Counterbore Diameter: The box counterbore

diameter shall be measured and shall meet the diameter shall be measured at two locations 90

requirements shown in table 3.7.2 - 3.7.8 or 3.7.20 degrees apart and shall meet the requirements

- 3.7.24, as applicable. This dimension is not used shown in table 3.7.2 - 3.7.8 or 3.7.20 - 3.7.24, as

to determine acceptance or rejection, but to test for applicable. If the diameter exceeds these limits, the

box swell and the need to verify connection length. connection shall be repaired by rethreading.

Issue Date: February 7, 2018 Page 12

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 53

¶ 3.13.5.h

CURRENT: CHANGE TO: (Amended text is underlined)

h. Pin Nose Diameter: For HT®, XT™, uXT™, TT® h. Pin Nose Diameter: For HT™, XT™, uXT™, TT™

connections, the outside diameter of the pin nose connections, the outside diameter of the pin nose

shall be measured and shall meet the requirements shall be measured at two locations 90 degrees apart

shown in table 3.7.2, 3.7.3, 3.7.6, 3.7.8, 3.7.20, and shall meet the requirements shown in table

3.7.21, 3.7.22 or 3.7.24, as applicable. This is not 3.7.2, 3.7.3, 3.7.6, 3.7.8, 3.7.20, 3.7.21, 3.7.22 or

required for XT-M™ or TT-M® connections. This 3.7.24, as applicable. Nonconforming connections

dimension is not used to determine acceptance or shall be rethreaded. This dimension is not used to

rejection, but to test for pin nose swell and the need determine acceptance or rejection for XT-M™ or

to verify connection length. TT-M™ connections, but to test for pin nose swell

and the need to verify connection length.

Page 53

¶ 3.13.5.j

CURRENT: CHANGE TO: (Amended text is underlined)

j. Pin Cylinder Diameter: The pin cylinder diameter j. Pin Cylinder Diameter: This is not required for Grant

shall be measured and shall meet the requirements Prideco connections.

shown in table 3.7.2 - 3.7.8 or 3.7.20 - 3.7.24, as

applicable.

Page 52

Figure 3.13.2

CHANGE TO: (Delete “J” from figure and legend)

G

I

H B A E F

DB DP

A BOX OUTSIDE DIAMETER

B PIN INSIDE DIAMETER

C BOX COUNTERBORE WALL

D B BOX TONG SPACE

D P PIN TONG SPACE

E BOX COUNTERBORE DIAMETER

F BEVEL DIAMETER

G BOX CONNECTION LENGTH

H PIN NOSE DIAMETER (DOES NOT APPLY TO

XT-M™ AND TT-M™)

DETAIL OF HT™, XT™, uXT™ AND TT™ DETAIL OF XT-M™ AND TT-M™ I PIN CONNECTION LENGTH

VOLUME 3 -

Figure 3.13.2 Tool joint dimensions for Grant Prideco™ HI TORQUE™, eXtreme™ Torque, uXT™, XT-M™, TurboTorque™, TurboTorque-M™ and Delta™

Figure 3.13.2 Tool joint dimensions for Grant Prideco™ HI TORQUE™, eXtreme™ Torque, uXT™, XT-M™,

Connections.

REDRAWN JAN-20-2018TurboTorque-M™ and Delta™ Connections.

TurboTorque™,

Issue Date: February 7, 2018 Page 13

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 55

¶ 3.13.6.b

CURRENT: CHANGE TO: (Amended text is underlined)

b. Pin Inside Diameter (ID): The pin ID shall be b. Pin Inside Diameter (ID): The pin ID shall be

measured under the last thread nearest the shoulder measured under the last thread nearest to the

(± 1/4 inch) and shall meet the requirements in table shoulder (±1/4 inch) and referenced against the

3.7.5 or 3.7.9, as applicable. values in table 3.7.5 or 3.7.9, as applicable. The pin

ID is used to define other inspection dimensions.

Page 55

¶ 3.13.6.e

CURRENT: CHANGE TO: (Amended text is underlined)

e. Box Counterbore Diameter: The box counterbore e. Box Counterbore Diameter: The box counterbore

diameter shall be measured and shall meet the diameter shall be measured at two locations 90

requirements shown in table 3.7.5 or 3.7.9, as degrees apart and shall meet the requirements

applicable. This dimension is not used to determine shown in table 3.7.5 or 3.7.9, as applicable. If the

acceptance or rejection, but to test for box swell and diameter exceeds these limits, the connection shall

the need to verify connection length. be repaired by rethreading.

Page 55

¶ 3.13.6.h

CURRENT: CHANGE TO: (Amended text is underlined)

h. Pin Nose Diameter: The outside diameter of the h. Pin Nose Diameter: The outside diameter of the pin

pin nose shall be measured and shall meet the nose shall be measured at two locations 90 degrees

requirements shown in table 3.7.5 or 3.7.9, as apart and shall meet the requirements shown in table

applicable. This dimension is not used to determine 3.7.5 or 3.7.9, as applicable.

acceptance or rejection, but to test for pin nose swell

and the need to verify connection length.

Page 55

¶ 3.13.6.j

CURRENT: CHANGE TO: (Amended text is underlined)

j. Pin Cylinder Diameter: The pin cylinder diameter j. Pin Cylinder Diameter: This is not required for Grant

shall be measured and shall meet the requirements Prideco connections.

shown in table 3.7.5 or 3.7.9, as applicable.

Issue Date: February 7, 2018 Page 14

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 54

Figure 3.13.3

CHANGE TO: (Delete “J” from figure and legend)

G

I

H B A E F

D B1 D P1

D B2 D P2

A BOX OUTSIDE DIAMETER DP1 PIN TONG SPACE (VAM CONNECTIONS)

B PIN INSIDE DIAMETER DP2 PIN TONG SPACE (GPDS & uGPDS)

C BOX SHOULDER WIDTH (VAM CONNECTIONS) E BOX COUNTERBORE DIAMETER

BOX COUNTERBORE WALL (GPDS & uGPDS) F BEVEL DIAMETER

VOLUME 3 - DB1 BOX TONG SPACE (VAM CONNECTIONS) G BOX CONNECTION LENGTH

Figure 3.13.3 ToolDjoint

dimensions

BOX TONG for Grant

SPACEPrideco™ Double

(GPDS Shoulder, uGPDS™, VAM® Express™,

& uGPDS) H VAMPIN

EIS®,NOSE

VAM® CDS, VAM TorqMaster 2™, and

DIAMETER

B2

VAM® X-Force™ Connections.

I PIN CONNECTION LENGTH

REDRAWN JAN-20-2018

Figure 3.13.3 Tool joint dimensions for Grant Prideco™ Double Shoulder, uGPDS™, VAM® Express™, VAM EIS®,

VAM® CDS, VAM TorqMaster 2™, and VAM® X-Force™ Connections.

Page 59b (from Addendum 6)

¶ 3.13.11.j

CURRENT: CHANGE TO: (Amended text is underlined)

j. Pin Cylindrical Diameter: The pin cylindrical diameter j. Pin Cylindrical Diameter: This is not required for

shall be measured as shown in figure 3.13.7. The DP-Master connections.

pin cylindrical diameter must meet the requirements

in tables 3.7.25 - 3.7.27, as applicable.

Page 59b (from Addendum 6)

Figure 3.13.7

CHANGE TO: (Delete “J” from figure and legend)

G

I

H B A E F

DB DP

A BOX OUTSIDE DIAMETER E BOX COUNTERBORE DIAMETER

VOLUMEB 3- PIN INSIDE DIAMETER F BEVEL DIAMETER

C Tool

Figure 3.13.7 BOX COUNTERBORE

joint dimensions for DPM-DS, WALL

DPM-MT and DPM High Torque PAC connections. G BOX CONNECTION LENGTH

D BOX TONG SPACE

REDRAWN BJAN-20-2018

H PIN NOSE DIAMETER

DP PIN TONG SPACE I PIN CONNECTION LENGTH

Figure 3.13.7 Tool joint dimensions for DPM-DS, DPM-MT and DPM High Torque PAC connections.

Issue Date: February 7, 2018 Page 15

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 59c

¶ 3.13.12 - Add new section

NEW:

3.13.12 Procedure and Acceptance Criteria for Grant g. Box Connection Length: The distance between the

Prideco™ Delta™ Connections: These features are il- primary and secondary make-up shoulders shall

lustrated in figure 3.13.2. In addition to the Visual Connec- be measured in two locations, 180 degrees apart,

tion requirements of 3.11.6, the Grant Prideco™ Delta™ and free from mechanical damage. Measurements

connections shall meet the following requirements. shall not be taken in areas where surface condition

NOTE: When conflicts arise between this specification prevents accurate measurements. This distance

and the manufacturer’s requirements, the manufacturer’s shall meet the requirements of table 3.7.28 or

requirements shall apply. 3.7.30, as applicable. Refer to 3.13.5.l for repair of

connection length non-conformances.

a. Box Outside Diameter (OD): The OD of the

tool joint box shall be measured at a distance h. Pin Nose Diameter: The outside diameter of the pin

5/8 inch (±1/4 inch) from the primary make-up nose shall be measured at two locations 90 degrees

shoulder. Measurements shall be taken around apart and shall meet the requirements shown in

the circumference to determine the minimum table 3.7.28 or 3.7.30, as applicable. If the diameter

diameter. This minimum box diameter shall meet exceeds the specified limit, the connection shall be

the requirements in table 3.7.28 or 3.7.30, as repaired by rethreading.

applicable.

i. Pin Connection Length: The distance between the

b. Pin Inside Diameter (ID): The pin ID shall be primary and secondary make-up shoulders shall

measured under the last thread nearest to the be measured in two locations, 180 degrees apart,

shoulder (±1/4 inch) and referenced against the and free from mechanical damage. Measurements

values in table 3.7.28 or 3.7.30, as applicable. The shall not be taken in areas where surface condition

pin ID is used to define other inspection dimensions. prevents accurate measurements. This distance

shall meet the requirements of table 3.7.28 or

c. Box Counterbore (CBore) Wall Thickness: The box 3.7.30, as applicable. Refer to 3.13.5.l for repair of

CBore wall thickness shall be measured by placing connection length non-conformances.

the straightedge longitudinally along the tool joint,

extending past the shoulder surface, and then j. Pin Cylinder Diameter: This is not required for

measuring the wall thickness from this extension to Delta™ connections.

the counterbore. The CBore wall thickness shall be

measured at its point of minimum thickness. Any k. Thread Compound and Protectors: Acceptable

reading that does not meet the minimum CBore wall connections shall be coated with an API Tool Joint

thickness requirement in table 3.7.28 or 3.7.30, as Compound over all thread and shoulder surfaces

applicable, shall cause the tool joint to be rejected. including the end of the pin. A copper-based thread

compound is recommended. Thread protectors

d. Tong Space: Box and pin tong space (including shall be applied and secured with approximately

the OD bevel) shall meet the requirements of 50 to 100 ft-lbs of torque. The thread protectors

table 3.7.28 or 3.7.30, as applicable. Tong space shall be free of debris. If additional inspection of

measurements on hardfaced components shall be the threads or shoulders will be performed prior to

made from the primary shoulder face to the edge pipe movement, application of thread compound

of the hardfacing. and protectors may be postponed until completion

of the additional inspection.

e. Box Counterbore Diameter: The box counterbore

diameter shall be measured at two locations 90 l. Refacing: Repair by refacing may only be used

degrees apart. The diameters shall meet the to attempt to repair shoulder damage less than or

requirements in table 3.7.28 or 3.7.30, as applicable. equal to 3/64 inch in depth, and/or connection length

If the limits are exceeded, the connection shall be discrepancies that are less than 1/32 inch out of

rethreaded. specification.

• As typical of the rotary shoulder connection reface

f. Bevel Diameter: The bevel diameter on both the process, a maximum of 1/32 inch of material may

box and pin shall be measured and shall meet the be removed from the primary make-up shoulder

requirements shown in table 3.7.28 or 3.7.30, as during each refacing operation, after which the

applicable.

Issue Date: February 7, 2018 Page 16

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 59c

¶ 3.13.12 - Add new section (continued)

NEW:

joint shall be placed back into service prior to cumference. Each measurement shall be within

performing any additional refacing repair. the limits of the “Field Inspection Dimensions”

• The cumulative total material removal from the drawing, latest revision.

primary make-up shoulder for all refacing opera- • GPMark™ + Benchmark: After refacing repair, a

tions shall not exceed 3/32 inch before rethreading minimum length of 1/16 inch (.063”) shall remain

is required. on the box refacing benchmark, and 3/16 inch

• Repair by refacing methods shall only remove maximum (.188”) shall remain on the pin refacing

sufficient material to repair the damage. However, benchmark. Rethreading is required if excess

when damage is less than 1/32 inch deep, all dam- material is removed. See figure 3.11.5.

age shall be removed from the primary make-up • Xmark™ + Benchmarks: After refacing repair, a

shoulder. visible step on the benchmark shall remain on the

• After the maximum reface allowance is met, any primary shoulder. The step is a necessary indica-

remaining damage on the primary make-up shoul- tor that a benchmark is still present. Rethreading

der shall not be deeper than 1/64 inch and shall is required if there is no visible benchmark. See

meet all other requirements of this procedure. figure 3.11.6.

• If the connection cannot be brought back within m. Rethreading: This method shall be used to repair

the acceptable limits outlined in this procedure connections that fail to meet the requirements

without removing more than 1/32 inch of material stipulated in this inspection procedure after field

from the primary shoulder, then rethreading shall repair is completed. Performance of this operation

be required. requires cropping the connection behind any fatigue

• Both the primary make-up shoulder and second- crack. Complete removal of the thread profile is not

ary make-up shoulder shall be skimmed/machined necessary if the connection has no fatigue cracks

during a refacing operation for all double shoulder and if sufficient material can be removed to comply

connections. with the NEW product requirements. In this case,

the connection does not have to be “reblanked,”

• Machine refacing in a lathe is the preferred however all torque shoulders, seal surfaces and

method. thread elements must be machined to 100%

• If the portable field refacing unit method is used, “bright metal”. This is not necessary for cylindrical

the variability of face flatness and squareness is diameters. After rethreading, the connection must

introduced and shall be monitored by taking the be phosphate coated. Copper sulfate is not an

connection length measurements in a minimum acceptable substitute for phosphate coating on

of four locations, equally spaced around the cir- rethreaded connections.

Issue Date: February 7, 2018 Page 17

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 59d

¶ 3.13.13 - Add new section

NEW:

3.13.13 Procedure and Acceptance Criteria for VAM® d. Tong Space: Box and pin tong space shall meet

X-Force™ Connections: The connections may be ab- the requirements of table 3.7.29. Tong space

breviated as VF. measurements on hardfaced components shall be

These features are illustrated in figure 3.13.3. In addition made from the bevel to the edge of the hardfacing.

to the Visual Connection requirements of 3.11.14, VAM

VF connections shall meet the following requirements. e. Box Counterbore Diameter: The box counterbore

diameter shall be measured and shall meet the

NOTE: When conflicts arise between this specification requirements shown in table 3.7.29. Since the box

and the manufacturer’s requirements, the manufacturer’s benchmark is a recess on the counter bore diameter

requirements shall apply. of the external shoulder, be sure to measure the

box end counter bore diameter and not the box

a. Tool Joint Box Outside Diameter (OD): The OD of benchmark diameter.

the tool joint box shall be measured 2 inches ± 1/4

inch from the primary shoulder. Measurements shall f. Bevel Diameter: The bevel diameter on both the

be taken around the circumference to determine the box and pin shall be measured and shall meet the

minimum diameter. This minimum box diameter requirements shown in table 3.7.29.

shall meet the requirements in table 3.7.29.

g. Box Connection Length: The distance between the

b. Pin Inside Diameter (ID): The pin ID shall be primary and secondary make-up shoulders shall

measured under the last thread nearest the shoulder be measured in two locations, 90 degrees apart,

(± 1/4 inch) and shall meet the requirements in table and free from mechanical damage. This distance

3.7.29. shall meet the requirements of table 3.7.29. If the

connection length exceeds the specified criteria,

c. Box Shoulder Width: The box shoulder width shall be repair may be made by refacing the primary

measured by placing the straightedge longitudinally shoulder. If the connection length is less than the

along the tool joint, extending past the shoulder specified criteria, refacing the secondary shoulder

surface, and then measuring the shoulder thickness may be adequate to repair the connection. Refacing

from this extension to the counterbore. The shoulder limits are the same as that performed for damaged

width shall be measured at its point of minimum shoulder faces. See figure 3.13.3.

thickness. Any reading that does not meet the

minimum shoulder width requirement in table 3.7.29

shall cause the tool joint to be rejected.

Figure 3.13.10 Two Methods of Box Connection Length Figure 3.13.11 Two Methods of Pin Connection Length

Inspection. Inspection.

Issue Date: February 7, 2018 Page 18

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 59d

¶ 3.13.13 - Add new section (continued)

NEW:

h. Pin Nose Diameter: The outside diameter of the should be applied to prevent the ingress of water

pin nose shall be measured and shall meet the into the connection. Thread protectors shall be

requirements shown in table 3.7.29. applied and secured with approximately 50 to 100

ft-lbs of torque. The thread protectors shall be free

i. Pin Connection Length: The distance between the of debris. If additional inspection of the threads or

primary and secondary make-up shoulders shall shoulders will be performed prior to pipe movement,

be measured in two locations, 90 degrees apart, application of thread compound and protectors may

and free from mechanical damage. This distance be postponed until completion of the additional

shall meet the requirements of table 3.7.29. If the inspection.

connection length exceeds the specified criteria,

repair may be made by refacing the secondary k. Rethreading: This method shall be used to repair

shoulder (pin nose). If the connection length is connections that fail to meet the requirements

less than the specified criteria, refacing the primary stipulated in this inspection procedure after field

shoulder may be adequate to repair the connection. repair is completed. Performance of this operation

Refacing limits are the same as that performed requires cropping the connection behind any fatigue

for damaged shoulder faces. that performed for crack. Complete removal of the thread profile is not

damaged shoulder faces. See figure 3.13.3. necessary if the connection has no fatigue cracks

and if sufficient material can be removed to comply

j. Thread Compound and Protectors: Acceptable with the NEW product requirements. In this case,

connections shall be coated with an API Tool Joint the connection does not have to be “reblanked,”

Compound (or a storage compound, if applicable) however all torque shoulders, seal surfaces and

over all thread and shoulder surfaces including the thread elements must be machined to 100%

end of the pin. A copper-based thread compound “bright metal”. This is not necessary for cylindrical

is recommended. Only thread protectors specially diameters. After rethreading, the connection must

designed for VAM® X-Force™ connectors may be be phosphate coated. Copper sulfate is not an

used. These protectors cover the whole thread acceptable substitute for phosphate coating on

section and box counter bore. Sufficient grease rethreaded connections.

Page 60

¶ 3.14.2.b

CURRENT: CHANGE TO: (Amended text is underlined)

b. NOV Grant Prideco HI TORQUE ®, eXtreme™ b. Grant Prideco™ HI TORQUE™, eXtreme™ Torque,

Torque, uXT™, XT-M™ and Grant Prideco Double uXT™, XT-M™, Delta™ and Grant Prideco Double

Shoulder™, uDS™ Connections: In addition to the Shoulder, uGPDS™ Connections: In addition to the

requirements ... requirements...

... A current field inspection drawing of the connection ...A current field inspection drawing of the connection

size to be inspected is recommended, which is size to be inspected is recommended, which is

available from NOV Grant Prideco, their web site available from Grant Prideco, their web site or a

or a licensed NOV Grant Prideco machine shop. licensed Grant Prideco machine shop. Dimensions

Dimensions provided in Tables 3.9.2 - 3.9.7 are provided in Tables 3.9.2 - 3.9.7 and 3.9.9 are

considered equivalent to the dimensions provided in considered equivalent to the dimensions provided

NOV Grant Prideco field inspection drawings at the in Grant Prideco field inspection drawings at the

time of this document’s release. Responsibility for time of this document’s release. Responsibility for

ensuring this document’s dimensions are equivalent ensuring this document’s dimensions are equivalent

to NOV Grant Prideco’s latest revision field to Grant Prideco’s latest revision field inspection

inspection drawing for the applicable connection drawing for the applicable connection remains with

remains with the inspector. the inspector.

Issue Date: February 7, 2018 Page 19

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 63

¶ 3.14.5.a-b

CURRENT: CHANGE TO: (Amended text is underlined)

a. Tool Joint Box Outside Diameter (OD): The OD of a. Tool Joint Box Outside Diameter (OD): For

the tool joint box shall be measured at a distance HT™ and XT-M™ connections, the OD of the

of 2 inches ±1/4 inch from the primary make-up tool joint box shall be measured at a distance

shoulder. Measurements shall be taken around of 2 inches ±1/4 inch from the primary make-up

the circumference to determine the minimum shoulder. Measurements shall be taken around

diameter. This minimum box diameter shall the circumference to determine the minimum

meet the requirements in table 3.9.2 - 3.9.4 or diameter. This minimum box diameter shall meet the

3.9.6, as applicable. (Note: Connection box OD requirements in table 3.9.2 or 3.9.4, as applicable.

requirements are the same for HWDP and other For XT™ and uXT™ sizes 43 and smaller (e.g.

BHA connections.) XT43), the OD of the tool joint box shall be

measured at a distance of 5/8 inches ± 1/4 inch

b. Pin Inside Diameter (ID): The pin ID shall be from the primary make-up shoulder. For sizes 46

measured under the last thread nearest the shoulder and larger, the OD of the tool joint box shall be

(±1/4 inch) and shall meet the requirements in table measured at a distance of 2 inches ± 1/4 inch from

3.9.2 - 3.9.4 or 3.9.6, as applicable. the primary make-up shoulder. Measurements shall

be taken around the circumference to determine

the minimum diameter. This minimum box diameter

shall meet the requirements in table 3.9.3 or 3.9.6,

as applicable.

Note: Connection box OD requirements are the

same for HWDP and other BHA connections.

b. Pin Inside Diameter (ID): The pin ID shall be

measured under the last thread nearest to the

shoulder (±1/4 inch) and referenced against the

values in table 3.9.2 - 3.9.4 or 3.9.6, as applicable.

The pin ID is used to define other inspection

dimensions.

Page 63

¶ 3.14.5.e

CURRENT: CHANGE TO: (Amended text is underlined)

e. Box Counterbore Diameter: The box counterbore e. Box Counterbore Diameter: The box counterbore

diameter shall be measured and shall meet the diameter shall be measured at two locations 90

requirements shown in table 3.9.2 - 3.9.4 or 3.9.6, as degrees apart and shall meet the requirements

applicable. This dimension is not used to determine shown in table 3.9.2 - 3.9.4 or 3.9.6, as applicable.

acceptance or rejection, but to test for box swell and If the diameter exceeds these limits, the connection

the need to verify connection length. shall be repaired by rethreading.

Page 63

¶ 3.14.5.h

CURRENT: CHANGE TO: (Amended text is underlined)

h. Pin Nose Diameter: For HT®, XT™ and uXT™ h. Pin Nose Diameter: For HT™, XT™ and uXT™

connections, the outside diameter of the pin nose connections, the outside diameter of the pin nose

shall be measured and shall meet the requirements shall be measured at two locations 90 degrees apart

shown in table 3.9.2 - 3.9.3 or 3.9.6, as applicable. and shall meet the requirements shown in table

This is not required for XT-M™ connections. This 3.9.2 - 3.9.3 or 3.9.6, as applicable. Nonconforming

dimension is not used to determine acceptance or connections shall be rethreaded. This dimension is

rejection, but to test for pin nose swell and the need not used to determine acceptance or rejection for

to verify connection length. XT-M™ connections, but to test for pin nose swell

and the need to verify connection length.

Issue Date: February 7, 2018 Page 20

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 63

¶ 3.14.5.j

CURRENT: CHANGE TO: (Amended text is underlined)

j. Pin Cylinder Diameter: The pin cylinder diameter j. Pin Cylinder Diameter: This is not required for Grant

shall be measured and shall meet the requirements Prideco connections.

shown in table 3.9.2 - 3.9.4 or 3.9.6, as applicable.

Page 64

¶ 3.14.6.b

CURRENT: CHANGE TO: (Amended text is underlined)

b. Pin Inside Diameter (ID): The pin ID shall be b. Pin Inside Diameter (ID): The pin ID shall be

measured under the last thread nearest the shoulder measured under the last thread nearest to

(± 1/4 inch) and shall meet the requirements in table the shoulder (± 1/4 inch) and shall meet the

3.9.5 or 3.9.7, as applicable. requirements in table 3.9.5 or 3.9.7, as applicable.

The pin ID is used to define other inspection

dimensions.

Page 66a

¶ 3.14.8 - Add new section

NEW:

3.14.8 Procedure and Acceptance Criteria for d. Tong Space: Box and pin tong space (including

Grant Prideco™ Delta™ Connections: In addition to the OD bevel) shall meet the requirements of table

the Visual Connection requirements of 3.11.13, Grant 3.9.9. Tong space measurements on hardfaced

Prideco™ Delta™ connections shall meet the following components shall be made from the primary

requirements. shoulder face to the edge of the hardfacing.

NOTE: When conflicts arise between this specification e. Box Counterbore Diameter: The box counterbore

and the manufacturer’s requirements, the manufacturer’s diameter shall be measured at two locations

requirements shall apply. 90 degrees apart. The diameters shall meet

the requirements in table 3.9.9. If the limits are

a. Tool Joint Box Outside Diameter (OD): The OD of exceeded, the connection shall be rethreaded.

the tool joint box shall be measured at a distance

5/8 inch (±1/4 inch) from the primary make-up f. Bevel Diameter: The bevel diameter on both the

shoulder. Measurements shall be taken around box and pin shall be measured and shall meet the

the circumference to determine the minimum requirements shown in table 3.9.9.

diameter. This minimum box diameter shall meet

the requirements in table 3.9.9. g. Box Connection Length: The distance between the

primary and secondary make-up shoulders shall

b. Pin Inside Diameter (ID): Pin Inside Diameter (ID): be measured in two locations, 180 degrees apart,

The pin ID shall be measured under the last thread and free from mechanical damage. Measurements

nearest to the shoulder (±1/4 inch) and referenced shall not be taken in areas where surface condition

against the values in table 3.9.9. The pin ID is used prevents accurate measurements. This distance

to define other inspection dimensions. shall meet the requirements of table 3.9.9. Refer

to 3.13.5.l for repair of connection length non-

c. Box Shoulder Width (also referred to as Box conformances.

Counterbore (CBore) Wall Thickness): The box

CBore wall thickness shall be measured by placing h. Pin Nose Diameter: The outside diameter of the pin

the straightedge longitudinally along the tool joint, nose shall be measured at two locations 90 degrees

extending past the shoulder surface, and then apart and shall meet the requirements shown in table

measuring the wall thickness from this extension to 3.9.9. If the diameter exceeds the specified limit, the

the counterbore. The CBore wall thickness shall be connection shall be repaired by rethreading.

measured at its point of minimum thickness. Any

reading that does not meet the minimum CBore wall i. Pin Connection Length: The distance between the

thickness requirement in table 3.9.9, shall cause the primary and secondary make-up shoulders shall

tool joint to be rejected. be measured in two locations, 180 degrees apart,

Issue Date: February 7, 2018 Page 21

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 66a

¶ 3.14.8 - Add new section (continued)

NEW:

and free from mechanical damage. Measurements • If the connection cannot be brought back within

shall not be taken in areas where surface condition the acceptable limits outlined in this procedure

prevents accurate measurements. This distance without removing more than 1/32 inch of material

shall meet the requirements of table 3.9.9. Refer from the primary shoulder, then rethreading shall

to 3.13.5.l for repair of connection length non- be required.

conformances. • Both the primary make-up shoulder and second-

ary make-up shoulder shall be skimmed/machined

j. Pin Cylinder Diameter: This is not required for during a refacing operation for all double shoulder

Delta™ connections. connections.

k. Thread Compound and Protectors: Acceptable • Machine refacing in a lathe is the preferred

connections shall be coated with an API Tool Joint method.

Compound over all thread and shoulder surfaces • If the portable field refacing unit method is used,

including the end of the pin. A copper-based thread the variability of face flatness and squareness is

compound is recommended. Thread protectors introduced and shall be monitored by taking the

shall be applied and secured with approximately connection length measurements in a minimum

50 to 100 ft-lbs of torque. The thread protectors of four locations, equally spaced around the cir-

shall be free of debris. If additional inspection of cumference. Each measurement shall be within

the threads or shoulders will be performed prior to the limits of the “Field Inspection Dimensions”

pipe movement, application of thread compound drawing, latest revision.

and protectors may be postponed until completion

of the additional inspection. • GPMark™ + Benchmark: After refacing repair, a

minimum length of 1/16 inch (.063”) shall remain

l. HWDP Center Upset: The OD of the center upset on on the box refacing benchmark, and 3/16 inch

HWDP shall meet the requirements of table 3.9.9. maximum (.188”) shall remain on the pin refacing

benchmark. Rethreading is required if excess

m. Refacing: Repair by refacing may only be used material is removed. See figure 3.11.5

to attempt to repair shoulder damage less than • Xmark™ + Benchmarks: After refacing repair, a

or equal to 3/64 inch in depth, and/or connection visible step on the benchmark shall remain on the

length discrepancies that are less than 1/32 inch primary shoulder. The step is a necessary indica-

out of spec. tor that a benchmark is still present. Rethreading

• As typical of the rotary shoulder connection reface is required if there is no visible benchmark. See

process, a maximum of 1/32 inch of material may figure 3.11.6.

be removed from the primary make-up shoulder

during each refacing operation, after which the n. Rethreading: This method shall be used to repair

joint shall be placed back into service prior to connections that fail to meet the requirements

performing any additional refacing repair. stipulated in this inspection procedure after field

repair is completed. Performance of this operation

• The cumulative total material removal from the requires cropping the connection behind any fatigue

primary make-up shoulder for all refacing opera- crack. Complete removal of the thread profile is not

tions shall not exceed 3/32 inch before rethreading necessary if the connection has no fatigue cracks

is required. and if sufficient material can be removed to comply

• Repair by refacing methods shall only remove with the NEW product requirements. In this case,

sufficient material to repair the damage. However, the connection does not have to be “reblanked,”

when damage is less than 1/32 inch deep, all dam- however all torque shoulders, seal surfaces and

age shall be removed from the primary make-up thread elements must be machined to 100%

shoulder. “bright metal”. This is not necessary for cylindrical

diameters. After rethreading, the connection must

• After the maximum reface allowance is met, any be phosphate coated. Copper sulfate is not an

remaining damage on the primary make-up shoul- acceptable substitute for phosphate coating on

der shall not be deeper than 1/64 inch and shall rethreaded connections.

meet all other requirements of this procedure.

Issue Date: February 7, 2018 Page 22

Standard DS-1® Fourth Edition, Volume 3 - ADDENDUM 7

Applies to First, Second and Third Printing

Page 115

¶ 3.33.8.2

CURRENT: (from Addendum 6) CHANGE TO: (Amended text is underlined)

3.33.8.2 Break in: It is recommended that all recut 3.33.8.2 Break in: It is recommended that all recut

connections should be made up three times at 60% connections should be made up three times at 60%

of the minimum torsional yield of the connection. After of the minimum torsional yield of the connection. After

final make-up, each connection shall be 100% visually final make-up, each connection shall be 100% visually

inspected. inspected. If the vendor does not perform this break-in

procedure, this must be communicated to the user in

Note: Performing shop break-in of recut connections writing.

on certain components, like drill collars, may not be

feasible due to the difficulty of handling full length Note: Performing shop break-in of recut connections

components. Shops in certain locations may not have on certain components, like drill collars, may not be

the capability to perform the recommended connection feasible due to the difficulty of handling full length

break-in. components. Shops in certain locations may not have

the capability to perform the recommended connection

break-in.

Page 120

¶ 3.37.5.1.b-c

CURRENT: (text to be deleted is underlined) CHANGE TO: (Amended text is underlined)

b. Tool Joint Taper Stamp: If a serial number is b. Tool Joint Taper Stamp: If a serial number is

stamped on the tool joint taper, it can be used in the stamped on the tool joint taper, it can be used in the

inspection report for traceability. If a serial number inspection report for traceability. If a serial number

is not found on the tool joint taper or if it is not used is not found on the tool joint taper or if it is not used

for traceability, a unique sequence number shall be for traceability, a unique sequence number shall