Professional Documents

Culture Documents

Design and Thermal Analysis of I.C Engin PDF

Uploaded by

Sai AbhinavOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Thermal Analysis of I.C Engin PDF

Uploaded by

Sai AbhinavCopyright:

Available Formats

IJSRD - International Journal for Scientific Research & Development| Vol.

3, Issue 09, 2015 | ISSN (online): 2321-0613

Design and Thermal Analysis of I.C Engine Piston

Siliveri naresh1 Mr. V. Srinivasa Rao2

1

M.Tech Student 2Assistant Professor

1,2

Department of Mechanical Engineering

1,2

J.B.Institute of Engineering &Technology, Telangana, India

Abstract— this project mainly deals with the design and density, high thermal conductivity, simple net-shape

analysis of I.C engine piston. Piston is a component of fabrication techniques casting and forging easy

reciprocating engines, reciprocating pumps, gas compressors machinability, high reliability and good recycling

and pneumatic cylinders among other similar mechanisms.in characteristics. Proper control of the chemical composition,

an engine, its purpose is to transfer force from expanding the processing conditions and the final heat treatment results

gas in the cylinder to the crankshaft via a piston rod or in a microstructure which ensures the required mechanical

connecting rod. Here the piston is designed, analysed and and thermal performance, in particular the high thermal

the manufacturing process has been studied. Piston fatigue resistance.

temperature has considerable influence on efficiency, Pistons are subjected to high mechanical and

emission, performance of the engine. Purpose of the thermal loads. The mechanical loads on the piston result

investigation is measurement of piston transient temperature from extreme pressure cycles with peak pressure up to 200

at several points on the piston, from cold start to steady bar in the combustion chamber and huge forces of inertia

condition and comparison with the results of finite element caused by extremely high acceleration during the

analysis.in this project the piston is modelled and assembled reciprocating motion of pistons. The thermal loads on the

with the help of CATIA software and component is meshed piston result from the combustion process with peak gas

and analysis is done in ANSYS software and the thermal temperatures in the combustion chamber 1800 and

and static behaviour is studied and the results are tabulated. 26000cdepending on type of engine, fuel, gas exchange,

The various two materials aluminium alloy A360 and alloy compression, fuel/gas ratio. Exhaust gases have

242.in this project work has been taken up on the following temperatures between 500 and 8000c.

aspects to cover the research gaps to present the results Pistons are produced from cast or forged, high-

based on the systematic studies. Temperature distribution temperature resistant aluminium silicon alloys there are 3

and heat flow through the piston of the engine, FEA analysis basic types of aluminium piston alloys. The standard piston

of the piston to measure temperature at the points where it is alloy is a eutectic al-12% Si alloy containing in addition

not possible to find out practically and to observe the heat approx.1% each of Cu, Ni and mg.

flow inside the piston. Composition of two aluminium alloys

Key words: ANSYS, CATIA, FEA, Heat Flow, Static,

A. Aluminium Alloy A360

Thermal Behavior, Temperature Distribution, And Transient

Temperature Element %

Copper 0.1 Max

I. INTRODUCTION Silicon 6.5-7.5

Magnesium 0.2-0.60

Piston is considered to be one of the most important part in a

reciprocating engine in which it helps to convert the Iron 5

chemical energy obtained by the combustion of fuel in to Manganese 3

useful mechanical power. The purpose of the piston is to Nickel 0.1

provide a means of conveying the expansion of the gases to Zinc 1

the crankshaft via the connecting rod, without loss of the gas Lead 1

from above or oil from below. Piston is essentially a Tin 0.05

cylindrical plug that moves up and down in the cylinder. Titanium 2 Max

It is equipped with piston rings to provide a good seal

Aluminium Remainder

between the cylindrical wall and piston. Although the piston

appears to be a simple part, it is actually quite complex from Table 1: Aluminium Alloy A360

the design standpoint. The piston must be as possible, B. Aluminium Alloy A242

however its weight should be minimized as far as possible in

Element %

order to reduce the inertia due to its reciprocating mass.

Aluminium Remainder

Magnesium 1.2-1.7

II. LITERATURE REVIEW

Silicon 0-0.6

In an internal combustion engines, pistons convert the Iron 0.8

thermal energy into mechanical energy. The functions of Copper 3.7-4.5

piston: to transmit the gas forces via connecting rod to the Zinc 0-0.1

crankshaft, to seal- in conjunction with the piston rings, to Titanium 0.07-0.2

dissipate the absorbed combustion heat to the cylinder linear

Manganese 0-0.1

and crankcase into the combustion chamber. Aluminium

Chromium 0.15-0.25

alloys are the preferred material for pistons both in gasoline

Others 0-0.15

and diesel engines due to their specific characteristics: low

Table 2: Aluminium Alloy A242

All rights reserved by www.ijsrd.com 316

Design and Thermal Analysis of I.C Engine Piston

(IJSRD/Vol. 3/Issue 09/2015/077)

III. GEOMETRIC MODELING AND FINITE ELEMENT

ANALYSIS

CATIA V5 R20 is an interactive computer aided

manufacturing system. The cad functions automate the

normal engineering, design and drafting capabilities found

in today’s manufacturing companies. Creation of a 3-D

model in CATIA V5 R20 can be performed using three

workbenches i.e.: sketcher, modelling and assembly.

A. Sketcher:

Sketcher is used to create two-dimensional representations

of associated within the part. We can a rough outline of

curves, and then specify conditions called constraints to

define the shapes more precisely and capture our design Fig. 3: 3-D model of I C engine piston

part. Each curve is referred to as a sketch object.to create a

new sketch, chose start to mechanical design and sketcher

then select the reference plane or sketch plane in which the

is to be created.

B. Sketch Plane:

The sketch plane is the plane that sketch is located on. The

sketch plane menu has the following options with this

option, we can use the attachment face/plane icon to select a

Table 3: Types

planner face or existing datum plane. If we select datum

Boundary conditions of Piston

plane we can use the reverse direction button to reverse the

Convective heat transfer coefficient

direction of the normal to the plane. XC-YC, YC-ZC and

In bowl h = 1.46 exp (25 (r) 1.5) / 1 + exp (25 (N) 1.5)

ZC-XC with these options, we can create a sketch on one of

Crown top h = 1.46 exp (25 (2N-r) 1.5) / 1+ exp (25 (N) 1.5)

the WCS planes. If we use this method, a datum plane and

Where N = D/3 D is piston diameter

two datum axes created as below.

R- Radial distance from the centre of the bowl

The following boundary conditions have been applied

Crown bowl T = 700 deg C, h = 0.6821 Kw/m2 k

Crown top T= 700 deg C, h= 0.91 Kw/m2 k

Top land T=180 deg C, h= 0.7 Kw/m2 k

2nd land & 3rd land T= 140 deg C, h= 0.7 Kw/m2 k

Fig. 1: Plane Skirt T= 120 deg C, h=0.7 Kw/ m2 k

Top groove bottom T= 140 deg C, h= 12 Kw/ m2 k

C. Modelling: The finite element method is numerical analysis

Feature is an all-encompassing term that refers to all solids, technique for obtaining approximate solutions to a wide

bodies and primitives used in CATIA V5 R20 form features variety of engineering problems. Basic approach for any

are used to supply detail to the model in the form of finite element analysis can be divided in to 3 parts 1) pre-

standard feature types these includes hole, slot, groove, processors2) solver3) post-processor pre- processor mainly

pocket, rib, and pad. we can create solid bodies by contains building material of the model, meshing, assigning

sweeping sketch and non- sketch geometry to create material properties etc. After assigning material properties

associative features or creating primitives for the basic and structural properties to the model, meshing is done.

building blocks, then adding more specific features. Meshing means divide the model in to number of finite

sized elements .FEA use complex system of points called

nodes, which make grid called mesh. This mesh is

programmed to contain material and structural properties,

which define how the structure will react to certain loading

conditions. Solver are geometric tsk oriented. These are

developed for specific applications. Solvers are designed

based on continuum approach where in in construction of

mass, momentum and energy equation of state,

thermodynamic equations. The post- processor read and

interpreted the results. They can be presented in the form of

the table, a counter plot, deformed shape of the component

to the mode shapes a natural frequencies.

Pre-Processor Post-Processor

Solution Phase

Phase Phase

Geometry Element matrix Post solution

definition formulation operations

Fig. 2: dimensions of the engine piston

Mesh Overall matrix Post data print

All rights reserved by www.ijsrd.com 317

Design and Thermal Analysis of I.C Engine Piston

(IJSRD/Vol. 3/Issue 09/2015/077)

generation triangularization outs

Material Wave point Post data

Scanning post

Definitions

data displays

Constraint Displacements, stress,

definitions etc.

Load definition Calculation

Model displays

Table 4: Description

IV. RESULT& DISCUSSIONS

A thermal analysis calculates the temperature distribution

and related thermal quantities in a system or component.

1) The temperature distribution

Fig 7: thermal gradient of piston

2) The amount of heat lost or gained

3) Thermal fluxes.

Fig 8: thermal flux of piston

Fig 4: 2D diagram of piston

Fig 5: mesh model of piston Fig 9: deformation of piston

A. Results of Aluminium Alloy A360

Fig 10: vonmises stress of piston

Fig. 6: nodal temperature of piston

All rights reserved by www.ijsrd.com 318

Design and Thermal Analysis of I.C Engine Piston

(IJSRD/Vol. 3/Issue 09/2015/077)

B. Results of Aluminium alloy A242

Fig 15: Vonmises Stress of piston

Aluminium alloy Aluminium alloy

Parameters

A360 A242

Fig 11: Nodal Temperature of piston Nodal temperature 3800c 3500c

Thermal gradient 139.025kelvin/m 128.432kelvin/m

Thermal flux 62.561 w/m2 44.951 w/m2

Deformation flux 0.418513 m 0.52374 m

Vonmises stress 648.35 N/mm2 301.14 /mm2

Table 5: Results of two materials

V. CONCLUSION

1) In our project we have designed a piston used for I.C

engine by using two aluminium alloys such as A360

and 242.

2) It was found that aluminium alloy 242 has around 73%

more permissible yield stress values when compared to

that of A360.

Fig 12: Thermal Gradient of the piston 3) Two models of piston are designed for two materials –

aluminium alloy A360 and 242. Coupled field analysis

is done on the models to validate structural and thermal

properties like displacement, vonmises stress, thermal

gradient, thermal flux and nodal temperature.

4) By observing the analysis results, von-misses stress and

nodal temperature values are less for material

aluminium alloy A360.when compare to aluminium

alloy 242.

5) Finally, from above results I am conclude that the

Aluminium alloy 242 is best material for manufacturing

of Piston.

A. Future Scope

1) 1.It should be noted that analysis of the piston pin

Fig 13: Thermal Flux of piston is beyond the scope of this work which can be

however achieved by an appropriate material

model for the piston pin and examinig the stresses

in the cross section of the pin.

2) 2. It is suggested to run the fatigue analysis on the

design to further optimize the shape and size.

3) 3. It is suggested to run the CFD analysis on the

design to get the better results.

REFERENCES

[1] Srecko Manasijevic, Radomir Radisa, Srdjan Markovic,

Zagorka Acimovic-Pavlovic, Karlo Raic, “Thermal

analysis and microscopic characterization of the piston

Fig 14: Deformation of piston alloy AlSi13Cu4Ni2Mg”, Intermetallics 19 (2011) 486

– 492.

All rights reserved by www.ijsrd.com 319

Design and Thermal Analysis of I.C Engine Piston

(IJSRD/Vol. 3/Issue 09/2015/077)

[2] Gudimetal P, Gopinath C.V, “Finite Element analysis of

Reverse Engineered Internal Combustion Engine

Piston”, AIJSTPME (2009) 2(4): 85-92.

[3] Esfahanian, A. Javaheri, M. Ghaffarpour, “Thermal

analysis of an SI engine piston using different

combustion boundary condition treatments”, Applied

Thermal Engineering 26(2006) 277

[4] Feng C.-X., 2003. Internet-Based Reverse Engineering,

Int. J. of Advanced Manufacturing Technology, 21(2):

138 – 144.

[5] Swanson J., Schok D., Kelley A. and Callow D., 2003.

Investigation of Reverse Engineering and Redesign of

Milkshake Maker, Internal report submitted for

Mechanical & Aerospace Engineering Department,

Arizona State University.

[6] C.H. Li., Piston thermal deformation and friction

considerations, SAE Paper 820086, 1982.

[7] Y. Liu. And R.D. Reitz, Multidimensional modeling of

combustion chamber surface temperatures, SAE Paper

971539, 1997.

[8] Handbook of Internal Combustion Engines, SAE

International

All rights reserved by www.ijsrd.com 320

You might also like

- The Stress Distribution and Thermal Stre PDFDocument5 pagesThe Stress Distribution and Thermal Stre PDFDamianCurcanNo ratings yet

- Couple Haru KoDocument8 pagesCouple Haru Koashesh bhattaraiNo ratings yet

- ANALYSIS OF IC ENGINE COMPONENTS USING ANSYSDocument65 pagesANALYSIS OF IC ENGINE COMPONENTS USING ANSYSRupender ShekhawatNo ratings yet

- IRJET-V4I11291 TBC PDFDocument7 pagesIRJET-V4I11291 TBC PDFAnand J LNo ratings yet

- Design and Analysis of Aluminium 6082-T6 PistonDocument9 pagesDesign and Analysis of Aluminium 6082-T6 PistonIJIRSTNo ratings yet

- Ansys PistonDocument8 pagesAnsys Pistonantedeguemon166No ratings yet

- Design and Analysis of Al-6081 T6 PistonDocument9 pagesDesign and Analysis of Al-6081 T6 PistonIJIRSTNo ratings yet

- A Review Paper on Design of Piston Using by Composite Material Al-SiC-Ni-Graphite - CopyDocument7 pagesA Review Paper on Design of Piston Using by Composite Material Al-SiC-Ni-Graphite - Copysandipjadhav18No ratings yet

- The Design and Analysis of Piston - Steady State Thermal Analysis Using "Ansys"Document8 pagesThe Design and Analysis of Piston - Steady State Thermal Analysis Using "Ansys"TJPRC PublicationsNo ratings yet

- IRJET Modeling and Analysis of A 100ccDocument6 pagesIRJET Modeling and Analysis of A 100ccDamianCurcanNo ratings yet

- Engineering Failure Analysis: Jivan Kumar, Swati Biswas, M.D. Ganeshachar, S.N. Narendra Babu, S. RamachandraDocument12 pagesEngineering Failure Analysis: Jivan Kumar, Swati Biswas, M.D. Ganeshachar, S.N. Narendra Babu, S. RamachandraAgy RandhikoNo ratings yet

- Design and Analysis of I.C. Engine PistoDocument13 pagesDesign and Analysis of I.C. Engine PistoDamianCurcanNo ratings yet

- Design and Analysis of Piston by Amc225xe AlloyDocument7 pagesDesign and Analysis of Piston by Amc225xe AlloyIJIRSTNo ratings yet

- Stress Analysis of Piston at Different P PDFDocument5 pagesStress Analysis of Piston at Different P PDFDamianCurcanNo ratings yet

- (1-8) Research Paper - Hashim Sheikh-FormatDocument8 pages(1-8) Research Paper - Hashim Sheikh-FormatAabal SyloNo ratings yet

- Material Final ProjectDocument23 pagesMaterial Final ProjectSami Onur VuralNo ratings yet

- Design and Static Structural Analysis of Crank Shaft: ISSN 2319-8885 Vol.04, Issue.07, March-2015, Pages:1393-1398Document6 pagesDesign and Static Structural Analysis of Crank Shaft: ISSN 2319-8885 Vol.04, Issue.07, March-2015, Pages:1393-1398Yuliantari YuliantariNo ratings yet

- Fs Piston DevelopmentDocument15 pagesFs Piston DevelopmentNir Azhar Abdul AzizNo ratings yet

- Design and Modal Analysis of Turbine Compressor BladeDocument8 pagesDesign and Modal Analysis of Turbine Compressor BladeReynaldi PrakasaNo ratings yet

- Irjet V4i5285 PDFDocument4 pagesIrjet V4i5285 PDFThiyagarajan TGNo ratings yet

- A Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993Document7 pagesA Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993ARUN VNo ratings yet

- Deepak TekhreDocument5 pagesDeepak TekhreasdfNo ratings yet

- IRJET-V7I5952Document5 pagesIRJET-V7I5952ds8123395No ratings yet

- Tanaka 1996 Development and Fabrication of CeraDocument8 pagesTanaka 1996 Development and Fabrication of Ceraabolfazl faramarziNo ratings yet

- IJRET ManuscriptTemplateDocument9 pagesIJRET ManuscriptTemplateGopal krishnaNo ratings yet

- ICE Engine Lab: Working/Function Material ManufacturingDocument4 pagesICE Engine Lab: Working/Function Material ManufacturingTarundeep SinghNo ratings yet

- Mechanical Properties Material and Desig PDFDocument7 pagesMechanical Properties Material and Desig PDFFida HussainNo ratings yet

- Design and Analysis of Aluminum Alloy For Gasoline Generator Piston Using Aluminum ScrapDocument8 pagesDesign and Analysis of Aluminum Alloy For Gasoline Generator Piston Using Aluminum ScrapEditor IJTSRDNo ratings yet

- Chromium Coated Piston Head Liner RingDocument56 pagesChromium Coated Piston Head Liner RingtechfiNo ratings yet

- Material Final ProjectDocument10 pagesMaterial Final ProjectSami Onur VuralNo ratings yet

- Optimizing The Heat Treatment Process of Cast Aluminium AlloysDocument25 pagesOptimizing The Heat Treatment Process of Cast Aluminium AlloysAndrei SorinNo ratings yet

- Design and Analysis of Cylinder and Cylinder Head of 4-Stroke SI Engine For Weight ReductionDocument7 pagesDesign and Analysis of Cylinder and Cylinder Head of 4-Stroke SI Engine For Weight ReductionPrashant NarwadeNo ratings yet

- Structural and Thermal Analysis of Turbo Charger BladesDocument8 pagesStructural and Thermal Analysis of Turbo Charger BladesTJPRC PublicationsNo ratings yet

- Eng-Effect of MG Enhancement in The Microstructure-Niyas SalimDocument10 pagesEng-Effect of MG Enhancement in The Microstructure-Niyas SalimImpact JournalsNo ratings yet

- KEYWORDS: Dissipation, Thermal Conductivity, Cylinder, Fins, 3D Model, CATIA V5, AnsysDocument1 pageKEYWORDS: Dissipation, Thermal Conductivity, Cylinder, Fins, 3D Model, CATIA V5, AnsysSravan Arimadla ArimadlaNo ratings yet

- Effect of Microstructure and Mechanical Properties of CNT Graphene Reinforced Al Hybrid Mmcs IJERTV9IS070452Document6 pagesEffect of Microstructure and Mechanical Properties of CNT Graphene Reinforced Al Hybrid Mmcs IJERTV9IS070452Sai TejaNo ratings yet

- Fabrication and Structural Analysis of Aluminium Alloy (Lm25) Reinforced With Silicon Carbide and Graphite ParticulateDocument10 pagesFabrication and Structural Analysis of Aluminium Alloy (Lm25) Reinforced With Silicon Carbide and Graphite ParticulateTJPRC PublicationsNo ratings yet

- Fabrication of Aluminium 6061-Sic-Al O MMC and HMMC by Strir Casting Technique and Comparing The Mechanical PropertiesDocument8 pagesFabrication of Aluminium 6061-Sic-Al O MMC and HMMC by Strir Casting Technique and Comparing The Mechanical PropertiesTJPRC PublicationsNo ratings yet

- 05 Chapter1Document10 pages05 Chapter1Khalid KhanNo ratings yet

- Engine cylinder fin thermal analysisDocument5 pagesEngine cylinder fin thermal analysisasdfNo ratings yet

- Precision Machining of An Aluminum Alloy Piston Reinforced With A Cast Iron InsertDocument8 pagesPrecision Machining of An Aluminum Alloy Piston Reinforced With A Cast Iron InsertrenatoeliegeNo ratings yet

- Determination of Optimum Percentage Addition of Magnesium in 319 Aluminum AlloyDocument10 pagesDetermination of Optimum Percentage Addition of Magnesium in 319 Aluminum Alloyvineesh VNo ratings yet

- IcatDocument122 pagesIcatViraj ParmarNo ratings yet

- 1352-Texto Del Artículo-6152-3-10-20200813Document18 pages1352-Texto Del Artículo-6152-3-10-20200813alexisNo ratings yet

- Design & Analysis of Radiator: M.DhanunjaiahDocument8 pagesDesign & Analysis of Radiator: M.DhanunjaiahvinodNo ratings yet

- 75 Ijmperdfeb201875Document6 pages75 Ijmperdfeb201875TJPRC PublicationsNo ratings yet

- IIPaperDocument11 pagesIIPaperPunit ShindeNo ratings yet

- Crankshaft Design and AnalysisDocument7 pagesCrankshaft Design and AnalysisNitin SinghNo ratings yet

- The Application of Ceramics To The Small Gas Turbine: A. F. McleanDocument10 pagesThe Application of Ceramics To The Small Gas Turbine: A. F. McleanRajan KumarNo ratings yet

- Modeling and Analysis of Steam Turbine Blade-Ijaerdv05i0451562n PDFDocument11 pagesModeling and Analysis of Steam Turbine Blade-Ijaerdv05i0451562n PDFGuruvenu KamanuruNo ratings yet

- Turbine Blade - Final Review-1Document30 pagesTurbine Blade - Final Review-1FAROOK FAKRUNo ratings yet

- AL Fueled GT ModelsDocument5 pagesAL Fueled GT ModelsMehulkumar PatelNo ratings yet

- Mathematical Analysis of Mid-Face Panel Crack Formation in Steel IngotsDocument11 pagesMathematical Analysis of Mid-Face Panel Crack Formation in Steel IngotsamitNo ratings yet

- Design and Analysis of Helical Gear With Different Materials by Using Pro/E and AnsysDocument7 pagesDesign and Analysis of Helical Gear With Different Materials by Using Pro/E and AnsysEditor IJTSRDNo ratings yet

- The Die-Cast Copper Motor RotorDocument17 pagesThe Die-Cast Copper Motor Rotoruuur35No ratings yet

- Materials Today: Proceedings: Experimental Analysis of AI-AIN-B4C Hybrid Composite Material For Automobile Disk BrakeDocument21 pagesMaterials Today: Proceedings: Experimental Analysis of AI-AIN-B4C Hybrid Composite Material For Automobile Disk BrakeramanathanNo ratings yet

- Static Stress Analysis of IC Engine Cylinder Head: Sreeraj Nair K., Kiran Robert and Shamnadh MDocument6 pagesStatic Stress Analysis of IC Engine Cylinder Head: Sreeraj Nair K., Kiran Robert and Shamnadh M1DS18ME014 Ashish RNo ratings yet

- As-Rolled Plate Product With Improved Yield Strength, Toughness, and Weldability For Pressurized Railroad Tank CarsDocument16 pagesAs-Rolled Plate Product With Improved Yield Strength, Toughness, and Weldability For Pressurized Railroad Tank CarssurendarNo ratings yet

- Surface Grinding Characteristics of Ti-6Al-4V Alloy: Aritras Roy, Kanchan Maji, Sudin Kumar KunduDocument10 pagesSurface Grinding Characteristics of Ti-6Al-4V Alloy: Aritras Roy, Kanchan Maji, Sudin Kumar KunduSudin Kumar KunduNo ratings yet

- Simulation of Convection Flow: Jntuh College of Engineering ManthaniDocument18 pagesSimulation of Convection Flow: Jntuh College of Engineering ManthaniSai AbhinavNo ratings yet

- Efficycle 2018 Rulebook PDFDocument52 pagesEfficycle 2018 Rulebook PDFSai AbhinavNo ratings yet

- Design and Thermal Analysis of I.C Engin PDFDocument5 pagesDesign and Thermal Analysis of I.C Engin PDFSai AbhinavNo ratings yet

- FOUR WHEEL STEERING SYSTEM IMPROVES HANDLINGDocument9 pagesFOUR WHEEL STEERING SYSTEM IMPROVES HANDLINGSai AbhinavNo ratings yet

- Baudouin 12M33 SpecSheetDocument2 pagesBaudouin 12M33 SpecSheetMartin KratkyNo ratings yet

- QSK45C HTC2500Document137 pagesQSK45C HTC2500Nova kurniawan 34No ratings yet

- MAN Piston RingDocument14 pagesMAN Piston RingDavison Thomas100% (3)

- RM250 Owners Service Manual 1991Document122 pagesRM250 Owners Service Manual 1991Anonymous hdApZGIhfi100% (2)

- Powerseal Catalog PDFDocument305 pagesPowerseal Catalog PDFSutikno100% (1)

- Whitlock-A-10753 DNFTDocument4 pagesWhitlock-A-10753 DNFTmarbbanNo ratings yet

- Hydraulic Seals LinearDocument154 pagesHydraulic Seals LinearThivanka Nirushan WithanageNo ratings yet

- Spare Parts Manual: Engine: ART - NO.: 3CM089861KENDocument32 pagesSpare Parts Manual: Engine: ART - NO.: 3CM089861KENKeine AngbeNo ratings yet

- Ape City Training Handout FinalDocument92 pagesApe City Training Handout FinalJosafat Rodriguez valverdeNo ratings yet

- Ukrainian - IMKAS - Suppressors With Floating BafflesDocument20 pagesUkrainian - IMKAS - Suppressors With Floating BafflesyuehanNo ratings yet

- Spare List - Caterpillar-3512: PLOT NO-103Document5 pagesSpare List - Caterpillar-3512: PLOT NO-103Balar PrakashNo ratings yet

- PASSION PRO Parts CatalogDocument129 pagesPASSION PRO Parts Catalogsarinr59No ratings yet

- Two-Stroke Piston Diagnosis GuideDocument5 pagesTwo-Stroke Piston Diagnosis Guidenebnik100% (2)

- Manual de Partes A40HP REED V004Document55 pagesManual de Partes A40HP REED V004sandalio canaviriNo ratings yet

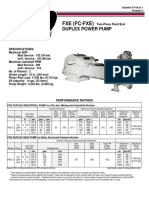

- FXE Duplex Pump Specs and PerformanceDocument2 pagesFXE Duplex Pump Specs and PerformanceBahman MatouriNo ratings yet

- Working of SI & CI Engines (2S & 4S) : Power Unit (Engine)Document12 pagesWorking of SI & CI Engines (2S & 4S) : Power Unit (Engine)Satish BheleNo ratings yet

- Pump DatasheetDocument10 pagesPump DatasheetPaulusIwan100% (1)

- Compressed Breathing Air: Industrial Hygiene Field Operations Manual Technical Manual NMCPHC-TM6290.91-2 12 MAR 2020Document11 pagesCompressed Breathing Air: Industrial Hygiene Field Operations Manual Technical Manual NMCPHC-TM6290.91-2 12 MAR 2020Abdus SamadNo ratings yet

- The Ball Piston EngineDocument38 pagesThe Ball Piston EngineAbhishek Rai0% (1)

- K&T Saw Shop 606-678-9623 or 606-561-4983Document13 pagesK&T Saw Shop 606-678-9623 or 606-561-4983NickNo ratings yet

- How A Discharge Relief Valve Controls PressureDocument6 pagesHow A Discharge Relief Valve Controls Pressureمحمد مجديNo ratings yet

- Compression Ignition EngineDocument7 pagesCompression Ignition Engineurmale50% (2)

- MLT Preparation Handbook Section 1Document22 pagesMLT Preparation Handbook Section 1BHOOPALA KRISHNAN MOTHILAL100% (2)

- 1.automobile Lab ManualDocument44 pages1.automobile Lab Manualharshita gupta100% (1)

- JIMMA UNIVERSITY INTERNS' MANUFACTURING EXPERIENCEDocument41 pagesJIMMA UNIVERSITY INTERNS' MANUFACTURING EXPERIENCEAmanuelNo ratings yet

- Speed Breaker Electric GenerationDocument72 pagesSpeed Breaker Electric Generationparas bhogulkarNo ratings yet

- 2007 Manitou Shock Service Manual - Rev NCDocument35 pages2007 Manitou Shock Service Manual - Rev NCMaikelNo ratings yet

- Conversion ContiMaster PowerMaster IIIDocument26 pagesConversion ContiMaster PowerMaster IIIVictor Edy Facundo DelzoNo ratings yet

- Nano Ic EngineDocument24 pagesNano Ic EngineUjjwal Kumar0% (1)

- C 94720 1 Engine BOMDocument28 pagesC 94720 1 Engine BOMStephen KokoNo ratings yet