Professional Documents

Culture Documents

Hameg Hm1004-3 Oscilloscope Um

Uploaded by

prasongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hameg Hm1004-3 Oscilloscope Um

Uploaded by

prasongCopyright:

Available Formats

P & S Technical Consultant and Serviced Co.,Ltd.

Install fabric expansion joint procedure

A. Purpose

1. The purposes of this procedure were about site installation of fabric expansion joint. Our standard

fabric expansion joint are consist with three layers, first from innermost was ceramic fiber

(accumulation barrier), second is fabric cloth and third is PTFE fiberglass coat. The fabric expansion

joint will be installing at ABPR 4 plant. Fabric expansion joints perform a function of compensating

for hot pipe misalignment and thermal growth typical in power plants and other hot pipe systems.

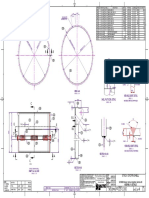

2. Drawing

.

B. Installation instruction

1. Pre-fabricated fabric retainer flange by welding and machining.

2. Blasting to Sa2.5 standard and primed with Interzince22.

3. Prepare fabric belt, insulation and fiberglass cloth.

4. Prepare all tools and equipment needed to get safety inspection before entering to site.

5. Removed aluminum sheet covers in needed area for flange installation.

6. Removed existing paint on the bottom side and drain pipe.

7. Fit-up haft circle (two pieces) of outboard flanges (upper and lower) to bottom of casing and drain

pipe.

P & S Technical Consultant and Serviced Co.,Ltd

129/113 Moo2 T.Tubma A.Muangrayong Rayong Province 21000

Tel/Fax : (038) 034097 E-mail : pstechnical@hotmail.com

P & S Technical Consultant and Serviced Co.,Ltd.

8. Welding with Tig process with low current to avoid burn through the pipe inner surface and bottom

casing.

9. Penetrant testing on site welding joint.

P & S Technical Consultant and Serviced Co.,Ltd

129/113 Moo2 T.Tubma A.Muangrayong Rayong Province 21000

Tel/Fax : (038) 034097 E-mail : pstechnical@hotmail.com

P & S Technical Consultant and Serviced Co.,Ltd.

10. Touch-up paint as per Vogt specification.

11. Put ceramic fiber 128 kg/m3 insulation inside between upper and lower outboard flanges.

12. Wrap with fabric cloth and sewing with high temp PTFE thread.

13. Wrap external layer with fabric belt and splicing two pieces together by heat seal iron.

14. Clamp down the whole expansion bellow to both upper and lower flange by stainless steel clamp.

15. Reinstall lagging cover sheet and sealing at seam.

P & S Technical Consultant and Serviced Co.,Ltd

129/113 Moo2 T.Tubma A.Muangrayong Rayong Province 21000

Tel/Fax : (038) 034097 E-mail : pstechnical@hotmail.com

P & S Technical Consultant and Serviced Co.,Ltd.

16. Final inspection.

17. Area cleaning

C. Material data sheets

1. Fabric belt

2. Fiberglass cloth

3. Fiber blanket

P & S Technical Consultant and Serviced Co.,Ltd

129/113 Moo2 T.Tubma A.Muangrayong Rayong Province 21000

Tel/Fax : (038) 034097 E-mail : pstechnical@hotmail.com

PRODUCT DATA SHEET

AFS PRODUCT CODE : FL-05-TFG

APPLICATIONS : Saturated or intermittant Wet Flue or Exhuast Gas Ducting

Expansion Joints from -60 o to 600 o (to 2000 oF with insulation).

Designed for severs corrosive service exposure on one side.

TYPICAL PROPERTIES

REINFORCEMENT : High Strength Woven Fiberglass

MATRIX : Fluoroplastic

CHEMICAL BARRIER : Fluoroplastic Film

o o

CONTINUOUS TEMPERATURE RATING : - 60 to 600 F

o

EXCURSION TEMPERATURE RATING : 700 F for 48 cumulative hours

PRESSURE RATING : 5 psig.

WEIGHT : 60 Oz./ Yd2

THICKNESS : .047 inches, nominal

TENSILE STRENGTH : 1200 lbs/in2. x 1200 lbs/in2. (warp x fill)

SPLICE METHOD : Heat Seal

CHEMICAL RESISTANCE : Excellent for high and low pH wet media.

THE FUNCTION OF FABRIC EXPANSION JOINT COMPONENTS

FABRIC EXPANSION JOINT COMPOSITE BELT DETAILS

PRODUCT NAME : Woven Glass Fiber Cloth

PHYSICAL PROPERTIES :

Weight : 24 Oz / Square Yard for basic fabric

30 Oz / Square Yard with aluminized film.

Construction : 10 x 8

Thickness : .0625"

Continuous Temperature : Continuous temperature to 1100 oF

(593 oC) for the base fabric.

Service temperature 500 oF (260 oC )

for the aluminized film. Can reflect 90 percent

of radiant heat up to 3000 oF.

Breaking strength (minimum) : Warp - 278 lbs.

Fill - 221 lbs.

Abrasion Resistance, Taber : Cycles to failure using CS 10 wheel with 1000 grams

weight resistance at 50 percent vacuum level - 2000

aluminized film side and 700 + fabric side.

K Factor (Heat Conductivity) :0.3399

Chemical Resistance : Resists most acids, alkalies and solvents, with the exception of

hydrofluoric acid and corrosive environments at elevated temperature

THE FUNCTION OF FABRIC EXPANSION JOINT COMPONENTS

FABRIC EXPANSION JOINT COMPOSITE BELT DETAILS

PRODUCT NAME : Ceramic Fiber Blanket

Max Service Temp ( o C ) : 1400

Density : 128 kg/m3

Fiber Diameter (um) : <3

Melting Point ( o C ) : 1760

Specific Gravity : 2.6 ~ 2.7

Specific Heat at 1000 o C (kcal/kg o C) : 0.23

Tensile Strength (kgf/cm2) : 2.5 x 104

Chemical Analysis (%) :

*Al2 O3 (%) 47

*SiO2 (%) 52

Others (%) 1

Ceramic fibres, as with other textile fibres, should be processed in such

a way that the amount of dust produced is kept to an absolute minimum.

If the concentration is too high, the wearing of a mask is recommended.

The precautionary measure is particularly advisable when processing free fibres.

Because of their structure, fineshed textile productd produce little dust.

Low thermal conductivity

Excellent resistance to chemical products, with the exception of hydrofluoric

acid, phosphoric acid and concentrated bases.

Good resistance to oxidizing and reducing agents

No ignition loss as ceramic fibres do not contain any crystallization water.

Neither the thermal nor the physical properties are affected by watr or steam.

You might also like

- Upgraded Thermal Insulation for Minimizing Heat Losses in Cement PlantsDocument39 pagesUpgraded Thermal Insulation for Minimizing Heat Losses in Cement PlantsBalson VijaishNo ratings yet

- Xlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundDocument3 pagesXlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundLe MinhNo ratings yet

- Thermobreak SolarblockDocument4 pagesThermobreak SolarblockChristian Dominic Dela CruzNo ratings yet

- Superlon 16 Pages CatalogDocument16 pagesSuperlon 16 Pages CatalogDevan SanmugamNo ratings yet

- TB Coroflake 23 PDFDocument2 pagesTB Coroflake 23 PDFHatem JafouraNo ratings yet

- Chemically Resistant FibersDocument60 pagesChemically Resistant FibersMuddaserNo ratings yet

- Thermal Ceramics - KaowoolDocument2 pagesThermal Ceramics - Kaowooljandresb23No ratings yet

- Thermobreak Solarblock Brochure - Email - 18012021Document4 pagesThermobreak Solarblock Brochure - Email - 18012021Trương Tấn KhoaNo ratings yet

- Polyken 1600 High TempDocument2 pagesPolyken 1600 High TempKyaw Kyaw AungNo ratings yet

- Cold-Applied Tape Coating - Rev 3-17Document19 pagesCold-Applied Tape Coating - Rev 3-17AhmedNo ratings yet

- Rubber Mastic and Sealant Tapes PDFDocument18 pagesRubber Mastic and Sealant Tapes PDFNikhil MathewNo ratings yet

- 3 LayerDocument4 pages3 LayerArya Raditya100% (1)

- Product Data: Hexply 200Document4 pagesProduct Data: Hexply 200MirceaNo ratings yet

- PAL Polyurethane Panel Spec 31102008Document4 pagesPAL Polyurethane Panel Spec 31102008Mohd Fahmie Bin MustapaNo ratings yet

- MISE en OEUVRE Composites Thermoplastiques 2023 COURS 1 2 3Document45 pagesMISE en OEUVRE Composites Thermoplastiques 2023 COURS 1 2 3El gharbaoui AnasNo ratings yet

- Ceramic Fiber BlanketDocument2 pagesCeramic Fiber BlanketYYo YudiNo ratings yet

- Scotch Super 88 Vinyl Electrical Tape: Data SheetDocument2 pagesScotch Super 88 Vinyl Electrical Tape: Data Sheetsaururja saururjaNo ratings yet

- 3M Scotch 50 51 Data SheetDocument4 pages3M Scotch 50 51 Data SheetPedro Francisco Hernandez MendozaNo ratings yet

- PDS Terostat PCFRi enDocument2 pagesPDS Terostat PCFRi enDherbecourtNo ratings yet

- PolyflameDocument2 pagesPolyflameumn_mlkNo ratings yet

- JZ-20220423 Siliocne Composite Tape Bochure-ENDocument12 pagesJZ-20220423 Siliocne Composite Tape Bochure-ENLongsun KejiNo ratings yet

- Tech Specs 1Document22 pagesTech Specs 1headqcNo ratings yet

- Synroof Pics PDFDocument3 pagesSynroof Pics PDFNATHASHANo ratings yet

- Technical Specifications For 33 KV Xlpe Insulated Underground Cables 1. ScopeDocument22 pagesTechnical Specifications For 33 KV Xlpe Insulated Underground Cables 1. Scopethumula.rameshNo ratings yet

- Scotch Super 33+ Vinyl Electrical Tape: Data SheetDocument2 pagesScotch Super 33+ Vinyl Electrical Tape: Data SheetArmenta EdwinNo ratings yet

- VORTEX Powder Coating For Conductor Insulation of Transformer WindingsDocument4 pagesVORTEX Powder Coating For Conductor Insulation of Transformer WindingsYogesh ChadawatNo ratings yet

- Cable Repairs From NETDocument8 pagesCable Repairs From NETsonotiumNo ratings yet

- BC Petro Tape (S-Type)Document2 pagesBC Petro Tape (S-Type)DianWidodoNo ratings yet

- Ceramic Coating Product Data SheetDocument3 pagesCeramic Coating Product Data SheetANIBALLOPEZVEGANo ratings yet

- Soudafoam 1KDocument2 pagesSoudafoam 1KCHERIF YAHIANo ratings yet

- Polytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingDocument2 pagesPolytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingVaittianathan MahavapillaiNo ratings yet

- peekDocument23 pagespeekwamikshahidrizviNo ratings yet

- ROTH EN Fabric Expansion Joints CatalogueDocument15 pagesROTH EN Fabric Expansion Joints CatalogueRoberta PugnettiNo ratings yet

- Li14YC14Y Data PDFDocument1 pageLi14YC14Y Data PDFRafael LinarezNo ratings yet

- You Chang CatalougDocument25 pagesYou Chang Catalougscribd4uallNo ratings yet

- TechnicalDocument7 pagesTechnicalDaniel RomanNo ratings yet

- 751 Epoxy Zinc Primer TDS enDocument2 pages751 Epoxy Zinc Primer TDS enAgoritsaNo ratings yet

- Dynaflow Lecture Presentation Gaskets 7-10-2010Document125 pagesDynaflow Lecture Presentation Gaskets 7-10-2010Jan SmitNo ratings yet

- Afico Pipe Insulation PDFDocument4 pagesAfico Pipe Insulation PDFHusni HayathNo ratings yet

- Belzona 1311 Original Specification SheetDocument2 pagesBelzona 1311 Original Specification SheetSaad IqbalNo ratings yet

- Coal Tar Tape & Synthetic Prmer-15337Document2 pagesCoal Tar Tape & Synthetic Prmer-15337nirdoshkumar100% (2)

- Flexible Duct Insulated & Non InsulatedDocument4 pagesFlexible Duct Insulated & Non Insulatedali faragallahNo ratings yet

- 3LPE Coating System for PipesDocument7 pages3LPE Coating System for PipesnareshvartakNo ratings yet

- Technical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 ScopeDocument22 pagesTechnical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 Scopethomas chinNo ratings yet

- 3m Electrical Tape PDFDocument2 pages3m Electrical Tape PDFefmartin21No ratings yet

- 3000m3 Double Membranes Biogas Holder Quotation Mingshuo 2020.10.13Document4 pages3000m3 Double Membranes Biogas Holder Quotation Mingshuo 2020.10.13Jesciel Generalao NugasNo ratings yet

- Product Data: Refratherm - AceDocument7 pagesProduct Data: Refratherm - AceMuntandwe georgeNo ratings yet

- Primer EP61 Datenblatt Renitherm enDocument2 pagesPrimer EP61 Datenblatt Renitherm enMuhammad ArslanNo ratings yet

- Glass Wool BoardsDocument5 pagesGlass Wool BoardsGerman Tonino LópezNo ratings yet

- Asset Doc LocDocument32 pagesAsset Doc LocAshiqur Rahman ZituNo ratings yet

- 3lpe & 3lpeDocument7 pages3lpe & 3lpenareshvartakNo ratings yet

- Faced Duct Wrap Insulation Technical Data SheetDocument4 pagesFaced Duct Wrap Insulation Technical Data Sheethello1230No ratings yet

- Sikacor Eg PhosphatplusDocument4 pagesSikacor Eg PhosphatplusCatalina ChescuNo ratings yet

- Special Specification 4604 Stay CablesDocument15 pagesSpecial Specification 4604 Stay CablesAbok Cai NginumNo ratings yet

- DESMOFLEX TOP COΑΤ v2 ENDocument3 pagesDESMOFLEX TOP COΑΤ v2 ENprestigebuild888No ratings yet

- Poly FlameDocument2 pagesPoly Flamemk779900mkNo ratings yet

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Document5 pagesSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530No ratings yet

- Butyl Tapes, Mastic Tapes, Adhesives & SealantsDocument35 pagesButyl Tapes, Mastic Tapes, Adhesives & SealantsNikhil MathewNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Tubular TYK Fabrication and Inspection: It Is Important To Plan Ahead For These Complex WeldsDocument5 pagesTubular TYK Fabrication and Inspection: It Is Important To Plan Ahead For These Complex Weldsluz82No ratings yet

- Two Way Diverter Technical Specification PDF FreeDocument94 pagesTwo Way Diverter Technical Specification PDF FreeprasongNo ratings yet

- Pip Pic001Document79 pagesPip Pic001Dhanny Miharja100% (6)

- Pipe Material SpecificationDocument12 pagesPipe Material SpecificationprasongNo ratings yet

- Intergranular Embrittlement of SS 321 Alloy Due To High Temperature CarburizationDocument16 pagesIntergranular Embrittlement of SS 321 Alloy Due To High Temperature CarburizationprasongNo ratings yet

- Toyota PDFDocument54 pagesToyota PDFprasong100% (2)

- Receiving Materials Equipment Inspect 26Document1 pageReceiving Materials Equipment Inspect 26prasongNo ratings yet

- 870116a Com Invoice Bar Po 100404Document2 pages870116a Com Invoice Bar Po 100404prasongNo ratings yet

- Dressup Beams DEX-0 Gas-Gas Heat Exchanger I BDocument1 pageDressup Beams DEX-0 Gas-Gas Heat Exchanger I BprasongNo ratings yet

- GAS Flow: Section Z1-Z1Document1 pageGAS Flow: Section Z1-Z1prasongNo ratings yet

- M112 Engine PDFDocument89 pagesM112 Engine PDFprasong75% (4)

- P&S 27-5-2019 Box1B Unit1 Rev.1Document12 pagesP&S 27-5-2019 Box1B Unit1 Rev.1prasongNo ratings yet

- 2494 P Eng Usa LTR PDFDocument4 pages2494 P Eng Usa LTR PDFDuc NguyenNo ratings yet

- Plate Material SpecificationDocument24 pagesPlate Material SpecificationprasongNo ratings yet

- Such ArtDocument1 pageSuch ArtprasongNo ratings yet

- Sara WutDocument1 pageSara WutprasongNo ratings yet

- 9053-16-1000 - 01 Stack Threaded BarDocument4 pages9053-16-1000 - 01 Stack Threaded BarprasongNo ratings yet

- Liner Plate For HRSG Inlet Exp Joint at GT SideDocument1 pageLiner Plate For HRSG Inlet Exp Joint at GT SideprasongNo ratings yet

- Bms.0100 r1 Bms Manual - Context Scope ResponsibilitiesDocument1 pageBms.0100 r1 Bms Manual - Context Scope ResponsibilitiesprasongNo ratings yet

- Work Instruction Template PDFDocument2 pagesWork Instruction Template PDFdrg. Bobet Evih Hedi I.R., MMRNo ratings yet

- Job Experience ListDocument1 pageJob Experience ListprasongNo ratings yet

- JSA Installation of GearboxDocument2 pagesJSA Installation of Gearboxprasong100% (1)

- Job Safety Scaffolding AnalysisDocument1 pageJob Safety Scaffolding AnalysisAbdullah KamilNo ratings yet

- Pra SongDocument1 pagePra SongprasongNo ratings yet

- bms.0100 r1 Bms Manual - Context Scope Responsibilities PDFDocument11 pagesbms.0100 r1 Bms Manual - Context Scope Responsibilities PDFwaleedNo ratings yet

- Jsa Removal and Install Expansion JointDocument1 pageJsa Removal and Install Expansion JointprasongNo ratings yet

- Mr. Prasong SingthomDocument2 pagesMr. Prasong SingthomprasongNo ratings yet

- Bank VerificationDocument1 pageBank VerificationprasongNo ratings yet

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- Main Kart Complete Sheet 03 ModelDocument1 pageMain Kart Complete Sheet 03 ModelprasongNo ratings yet

- Shaft AnalysisDocument28 pagesShaft Analysissaravan2015No ratings yet

- What Are Engineering Materials Their Types and Selection Notes With PDFDocument8 pagesWhat Are Engineering Materials Their Types and Selection Notes With PDFcharanNo ratings yet

- Influence of Operating Pressure On Water Absorption of A Polymeric Composite Applied in Oil PipelinesDocument3 pagesInfluence of Operating Pressure On Water Absorption of A Polymeric Composite Applied in Oil PipelinesFIRDAUSIL JANNAHNo ratings yet

- Fractography, Fluidity, and Tensile Properties of Aluminum/Hematite Particulate CompositesDocument6 pagesFractography, Fluidity, and Tensile Properties of Aluminum/Hematite Particulate CompositesAugusto OliveiraNo ratings yet

- RT Duroid 5870 5880 Data SheetDocument2 pagesRT Duroid 5870 5880 Data SheetKingslayer RennesNo ratings yet

- OILFIELD - Inside AdvantageDocument174 pagesOILFIELD - Inside AdvantageGLIM100% (1)

- Three Point Bending Test Research of Carbon FibreDocument3 pagesThree Point Bending Test Research of Carbon FibrekishoreNo ratings yet

- GFRP NCODE Designlife DigimatDocument11 pagesGFRP NCODE Designlife DigimatKruthika K CNo ratings yet

- Fixfast DF12 HT DatasheetDocument6 pagesFixfast DF12 HT DatasheetJonathan DouglasNo ratings yet

- Bulk Fill Resin Composites in DentistryDocument184 pagesBulk Fill Resin Composites in DentistryRochaManuelNo ratings yet

- Laser Welding and Laser Cladding of High Performance Materials - CRACKSDocument8 pagesLaser Welding and Laser Cladding of High Performance Materials - CRACKSVitor JardimNo ratings yet

- F1 CARS ChassisDocument27 pagesF1 CARS ChassisNikhil Goyal100% (1)

- Design and Analysis of Composite Drive ShaftDocument8 pagesDesign and Analysis of Composite Drive ShaftInternational Journal of Research in Engineering and TechnologyNo ratings yet

- ICMIEE ScheduleDocument14 pagesICMIEE ScheduleSajidNo ratings yet

- Chapter 18 - Aluminium Doors and Windows, Composite Cladding, Louvers and GlassDocument19 pagesChapter 18 - Aluminium Doors and Windows, Composite Cladding, Louvers and GlassbuddhikaNo ratings yet

- CSE577 Advanced Structural DesignDocument3 pagesCSE577 Advanced Structural DesignPrashantNo ratings yet

- PH.D Scholars UGCDocument25 pagesPH.D Scholars UGCUsha MurthyNo ratings yet

- 2002, B.S. Kim, Numerical Analysis of The Dimensional Stability of Thermoplastic Composites Using A Thermoviscoelastic ApproachDocument15 pages2002, B.S. Kim, Numerical Analysis of The Dimensional Stability of Thermoplastic Composites Using A Thermoviscoelastic Approachhalil yıldırımNo ratings yet

- MTS Masina Universala ElectromecanicaDocument20 pagesMTS Masina Universala ElectromecanicaMarius IanaNo ratings yet

- FEA Guide For Aerospace SDocument47 pagesFEA Guide For Aerospace SManoj KumarNo ratings yet

- Arkema PDFDocument38 pagesArkema PDFDo Hyung KimNo ratings yet

- Chemistry SPMDocument20 pagesChemistry SPMJacob ChowNo ratings yet

- 2017 - Fantilli - The Use of Wool As Fiber - Reinforcement in Cement - Based MortarDocument8 pages2017 - Fantilli - The Use of Wool As Fiber - Reinforcement in Cement - Based Mortarmeyli80No ratings yet

- Investigation On Tensile Properties of Epoxy/graphene Nano-Platelets/ Carboxylated Nitrile Butadiene Rubber Ternary Nanocomposites Using Response Surface MethodologyDocument12 pagesInvestigation On Tensile Properties of Epoxy/graphene Nano-Platelets/ Carboxylated Nitrile Butadiene Rubber Ternary Nanocomposites Using Response Surface MethodologyAbdalla Mohamed AbdallaNo ratings yet

- C393C393M 24798 PDFDocument8 pagesC393C393M 24798 PDFMohamed Belmokaddem100% (1)

- Steel Structures 3 - Composite Structures - Lecture Notes Chapter 10.7Document29 pagesSteel Structures 3 - Composite Structures - Lecture Notes Chapter 10.7iSoK11No ratings yet

- Investigation On A Multispar Composite WingDocument9 pagesInvestigation On A Multispar Composite Wingjcdt94No ratings yet

- Metal Matrix Composites ReportDocument11 pagesMetal Matrix Composites ReportSameh AhmedNo ratings yet

- CH 03Document44 pagesCH 03RODRIGO JAVIER BRIZUELA PADILLANo ratings yet

- OML753 UNIT 1 Classification Metal and AlloysDocument36 pagesOML753 UNIT 1 Classification Metal and AlloysSiva RamNo ratings yet