Professional Documents

Culture Documents

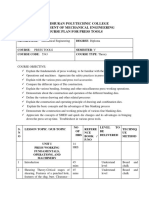

Lesson Plan for Spinning Technology-I Subject

Uploaded by

Santosh0 ratings0% found this document useful (0 votes)

103 views4 pagesOriginal Title

3.1SpinningTechnology-3rdSemTheory&Practical.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

103 views4 pagesLesson Plan for Spinning Technology-I Subject

Uploaded by

SantoshCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Lesson Plan

Name of Faculty : Puneet Garg

Discipline: Textile Technology

Semester: 3rd

Subject: SPINNING TECHNOLOGY-I

Lesson Plan Duration: 15 weeks (From JULY 2018 – NOV 2018)

Work Load (Lecture / Practical) per week (in hours): 4 / 6

Theory Practical

Week Lecture Topic Practical

day (including assignment / test) day Topic

1st Objects of ginning, ginning To sketch and study the working

percentage, of different parts of Single

description and working of Double Macarthy Gin and to operate it

2nd Knife

Roller Gin,

1st

1st Double Macarthy Gin and Saw

3rd Gin

Importance of mixing and blending,

mixing

4th and blending techniques in Blow

Room,

description and working of Auto Demonstration of Mixing and

5th Mixer and Blending

Multi Mixer techniques during with visit/Mill

Principle of opening and cleaning, training

opening Practically sketch and describe

6th by the action of nails, beaters and air the

2nd currents. 2nd passage of material through

Description and working of Condenser condenser.

7th

Study of following opening and

8th cleaning

machines: Blending Bale Opener,

Automatic Practically sketch and describe

9th Bale Plucker, Feeder the passage of material through

Feeder; Super Jet Cleaner, condenser. Practically sketch and

10th Mono Cylinder Cleaner, ERM Cleaner, describe the

CVT-3 cleaner. passage of material through

Objects of evener motion and its Blending

3rd 3rd Bale Opener, Hopper Feeder,

importance, construction and working Step

11th of Piano Type Feed Cleaner, Feed Unit, Porcupine

Regulating Motion, of Cone Drums Opener

Objects, construction and working of

12th Two

Bladed Beater and Krischner Beater

Objects of calendaring in Scutcher and Study of feed regulating motion.

13th passage of cotton sheet through them and cone Drums

4th Lap rejection and lap variation: their 4th - To sketch and understand the

14th

causes working

and remedies of Krischner Beater.

- Defects in laps and their removal - Practice of setting & guages of

Cleaning efficiency of Blow Room line the

and waste percentage openers & beaters in the Blow

15th - Work load distribution in Blow Room Room

Automatic lap doffing and its Line

Advantages - Study of exhaust system and

Necessity & working of Chute Feed Cages in

16 th System Scutcher

at Blow Room.

Main features and - Practice of drawing of gearing to

th

17 advantages of Modern Blow Room understand drive to various parts.

Line - Study of Lap Forming Unit.

Main features and - Calculate draft/Production of

18th advantages of Modern Blow Room Blow

Line Room & Maintenance schedule of

5th conversion from one to other 5th Blow Room

system and calculation of - Workload distribution at Blow

Room

19th equivalent count. & card machine.

- Practical study of Automatic Lap

doffing mechanism

Gearing diagram of Scutcher and

Calculation

20th of lap hank, lap weight

21th Sessional 1 Practically study of the Chute Feed

22 th lap length and System during mill visit/mill

Scutcher production per shift training. Gearing diagram of

Calculation of clearing efficiency of Scutcher and

rd blow Calculation of lap hank, lap weight,

6th 23 room line 6th lap

Calculation of calendar roll and shell roll length and Scutcher production per

speeds and tension draft between shift

24th calendar

roll and shell roll

Mixing and blending cost calculations Calculation of production constant

25th of blow room Scutcher.

Maintenance schedule of Blow Room Calculation of calendar roll and

26th line shell roll

Objects of carding, Passage of material speeds and tension draft between

through Revolving Flat Card and calendar roll and shell roll

7th 27th functions of 7th

various parts i.e.

licker-in, mote knives, back

plate, front plate, cylinder, flats, doffer

28th and

Under casing

Difference between carding action and

stripping action Study of various electronics

29th parts/motion

in Blow Room

Flexible and metallic card clothing,

30th

8th Advantages of metallic card clothing. 8th

th

31

Objects of stripping, procedure for

th

32 Plain

Roller stripping and Vacuum stripping

33rd Demonstrate the passage of

material

Objects of grinding and Types of through the machine and to

th

34 Grinding introduce

with different parts of Revolving

9th Web doffing by doffer comb, India Roll 9th Flat

35 th System Card

Web doffing Cross Roll Verga System

th

36

General settings and gauges for Semi Stripping of cylinder and doffer of

37th

High Speed Card Card.Grinding of Card with dead

10th 38th General settings and gauges for High 10th roll grinder

Speed Card and Traverse Roller Grinder

Objects principle of Auto

39th Levellers at card

working of Auto Levellers at card

40th

41th Sessional 2

Card wastes e.g. motes, fly Piecing of web and sliver on Card.

42th To Practice the setting and gauging

th Card wastes e.g. strips and sweeps between different parts of Card

11 43th 11th Machine

Salient features of High Production

44th Card.

Defects in card web and their removal

45th Calculate drafts between various

Defects in card web and their removal parts,

46th total draft, draft constant, tension

12th Calculation of waste percentage of a 12th draft

th

47 card. and tension draft constant

Cleaning efficiency of Card.

48th

Calculation of draft, draft constant

49th Calculate production and

Tension draft and tension draft production

th

50 constant constant of Card

13th Calculation of production and 13th

51th production

Constant

Calculation of production and

52th production

Constant

53th Calculation of time taken to exhaust a

lap Calculate the time taken to exhaust

Calculation of time taken to exhaust a a lap

54th lap on Card

14th 55 th Sessional 3 14th

Maintenance Schedule of Carding

th

56 Machine

Process control Parameter in mixing,

57th Study of various electronic

Process control Parameter in Blow Parts/Motion in carding

58th Room

Process control Parameter in Carding

15th 15th

59th

Process control Parameter in (yarn

th

60 realization, trash

Content etc)

You might also like

- TRI 1008 Quality CardingDocument17 pagesTRI 1008 Quality Cardingalcon1No ratings yet

- Reiter Manual of Spinning Vol 1-7 FullDocument578 pagesReiter Manual of Spinning Vol 1-7 FullSweta DuttaNo ratings yet

- LEGAL STATUs of A PersonDocument24 pagesLEGAL STATUs of A Personpravas naikNo ratings yet

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Car Loan ProposalDocument6 pagesCar Loan ProposalRolly Acuna100% (3)

- Checklist For HR Audit Policy and ProceduresDocument3 pagesChecklist For HR Audit Policy and ProcedureskrovvidiprasadaraoNo ratings yet

- Fibre to Fabric: Understanding Textile Production ProcessDocument41 pagesFibre to Fabric: Understanding Textile Production ProcessSantoshNo ratings yet

- Blow Room - Carding Manual - Reiter88 PagesDocument88 pagesBlow Room - Carding Manual - Reiter88 PagesKannan Krishnamurthy100% (2)

- Electrical Distribution in Papermills: Monographs on Paper and Board MakingFrom EverandElectrical Distribution in Papermills: Monographs on Paper and Board MakingRating: 2 out of 5 stars2/5 (1)

- Gases and Vacua: Handbook of Vacuum PhysicsFrom EverandGases and Vacua: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- Fibres To FabricDocument23 pagesFibres To FabricPallavi Luthra KapoorNo ratings yet

- OF Ministry Road Transport Highways (Road Safety Cell) : TH THDocument3 pagesOF Ministry Road Transport Highways (Road Safety Cell) : TH THAryann Gupta100% (1)

- The Rieter Manual of Spinning Vol. 4 1924-V3 83538 Original English 83538Document80 pagesThe Rieter Manual of Spinning Vol. 4 1924-V3 83538 Original English 83538Oscar Morales100% (3)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Vdoc - Pub Parrys Valuation and Investment TablesDocument551 pagesVdoc - Pub Parrys Valuation and Investment TablesWan Rosman100% (1)

- Jamaica's Unemployment Aims, Causes and SolutionsDocument23 pagesJamaica's Unemployment Aims, Causes and Solutionsnetzii300067% (3)

- Bluetooth Modules - Martyn Currey PDFDocument64 pagesBluetooth Modules - Martyn Currey PDFAng Tze Wern100% (1)

- Talking About Your Home, Furniture and Your Personal Belongings - Third TemDocument4 pagesTalking About Your Home, Furniture and Your Personal Belongings - Third TemTony Cañate100% (1)

- OPTIMIZE BLOW ROOM PROCESS PARAMETERSDocument7 pagesOPTIMIZE BLOW ROOM PROCESS PARAMETERSKhan Ali100% (2)

- The Rieter Manual of Spinning LL Textilestudycenter - Com LL v-3 (Spinning Preparation)Document80 pagesThe Rieter Manual of Spinning LL Textilestudycenter - Com LL v-3 (Spinning Preparation)Durjoy Roy100% (1)

- 1ci3pqr1q 814635Document5 pages1ci3pqr1q 814635Santosh50% (2)

- Production Planning in SpinningDocument15 pagesProduction Planning in SpinningSantoshNo ratings yet

- Production Planning in SpinningDocument15 pagesProduction Planning in SpinningSantoshNo ratings yet

- The Rieter Manual of SpinningDocument80 pagesThe Rieter Manual of SpinningAline Freire100% (1)

- People V Gona Phil 54 Phil 605Document1 pagePeople V Gona Phil 54 Phil 605Carly GraceNo ratings yet

- Maintenance Schedule of Stenter Machine: ObjectsDocument14 pagesMaintenance Schedule of Stenter Machine: ObjectsAbel TayeNo ratings yet

- The Rieter Manual of Spinning Vol. 1-Pages 40 PDFDocument80 pagesThe Rieter Manual of Spinning Vol. 1-Pages 40 PDFAbdul RafayNo ratings yet

- Draw FrameDocument4 pagesDraw Framemohsin soomroNo ratings yet

- Modern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantFrom EverandModern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantA. SherryRating: 4 out of 5 stars4/5 (5)

- The Rieter Manual of Spinning LL Textilestudycenter - Com LL v-5 (Rotor Spinning)Document112 pagesThe Rieter Manual of Spinning LL Textilestudycenter - Com LL v-5 (Rotor Spinning)Souro Banerjee50% (2)

- p2 PDFDocument10 pagesp2 PDFAkash SwamiNo ratings yet

- Textile Technology Syllabus GtuDocument3 pagesTextile Technology Syllabus GtuAbhilasha PathakNo ratings yet

- The Rieter Manual of Spinning Vol. 1 1921-V3 en Original 68489Document80 pagesThe Rieter Manual of Spinning Vol. 1 1921-V3 en Original 68489singhgirendra20001523No ratings yet

- Gujarat Technological University Textile Technology (29) : Yarn Manufacturing-I B.E. Semester IiiDocument3 pagesGujarat Technological University Textile Technology (29) : Yarn Manufacturing-I B.E. Semester IiiKagi mecNo ratings yet

- Machinery 40 - 14Document6 pagesMachinery 40 - 14Mohamed NaeimNo ratings yet

- Chendhuran Polytechnic College Department of Mechanical Engineering Course Plan For Press ToolsDocument6 pagesChendhuran Polytechnic College Department of Mechanical Engineering Course Plan For Press Toolsscholarship cptcNo ratings yet

- Informeeeeeeee11 (1) (Carlos Enrique Diaz Chavez)Document12 pagesInformeeeeeeee11 (1) (Carlos Enrique Diaz Chavez)Paola Caravedo ManzanaresNo ratings yet

- Manual TXP221Document50 pagesManual TXP221Vishabh YadavNo ratings yet

- Machine Shop 2 Course SpecificationsDocument3 pagesMachine Shop 2 Course SpecificationsMark Niño Javier100% (1)

- Internal Combustion EnginesDocument203 pagesInternal Combustion EnginesJhon WilliamsNo ratings yet

- KINEMATICS LABDocument9 pagesKINEMATICS LABmNo ratings yet

- 3322902WT IDocument5 pages3322902WT ISinaiDasNo ratings yet

- Machine Building For Profit and The Hartness Flat Turret Lathe 1909 PDFDocument262 pagesMachine Building For Profit and The Hartness Flat Turret Lathe 1909 PDFjohn silverNo ratings yet

- Fluid Mechanics Lab ManualDocument89 pagesFluid Mechanics Lab ManualJVC MaliackalNo ratings yet

- The Rieter Manual of SpinningDocument80 pagesThe Rieter Manual of SpinningHashinclude Iostream Int MainNo ratings yet

- Wa0094Document3 pagesWa0094VIGNESH RAJNo ratings yet

- TX450 Spinning Calculation: Schedule Website Instructor ContactDocument3 pagesTX450 Spinning Calculation: Schedule Website Instructor Contactsandeep225No ratings yet

- Chendhuran Polytechnic College Department of Mechanical Engineering Course Plan For R &ac PracticalDocument4 pagesChendhuran Polytechnic College Department of Mechanical Engineering Course Plan For R &ac Practicalscholarship cptcNo ratings yet

- Study On Maintenance Tools & Equipment's of Knitting Machines.Document14 pagesStudy On Maintenance Tools & Equipment's of Knitting Machines.Naimul HasanNo ratings yet

- Machinery: FluidDocument315 pagesMachinery: FluidPrajyot SatkarNo ratings yet

- Guideline For Writing A Lab Report: Title PageDocument66 pagesGuideline For Writing A Lab Report: Title PageAshiqur RahmanNo ratings yet

- DeekshaDocument55 pagesDeekshadikshaNo ratings yet

- Mom SyllabusDocument4 pagesMom SyllabussarojNo ratings yet

- Yarn Manufacture - Set of 2 VolsDocument2 pagesYarn Manufacture - Set of 2 VolsAnonymous Pt7NHkat9No ratings yet

- Fluid Machinery Lecture PlanDocument2 pagesFluid Machinery Lecture Planविन्तु अधिकारीNo ratings yet

- Power Plant and Calculations - 40 Important Question & Answers On Belt Conveyor For Power Plant Engineers & OperatorsDocument9 pagesPower Plant and Calculations - 40 Important Question & Answers On Belt Conveyor For Power Plant Engineers & OperatorsRajeshNo ratings yet

- Nmu at ExaminerDocument6 pagesNmu at Examinernavneetkpatil8409No ratings yet

- 4th Semester: Ptx4I102 Yarn Manufacture - IiDocument2 pages4th Semester: Ptx4I102 Yarn Manufacture - Iilalit kashyapNo ratings yet

- Production Planning Course Code 3352904Document6 pagesProduction Planning Course Code 3352904Sher Hai HamNo ratings yet

- Lab Manual PMFM - 2024Document79 pagesLab Manual PMFM - 2024Vishnu Vardhan Reddy PeddireddyNo ratings yet

- Uk BL Ethos 511975Document284 pagesUk BL Ethos 511975oromia pressNo ratings yet

- CALCULATION OF PRODUCTIVITY FOR DRILLING MACHINESDocument8 pagesCALCULATION OF PRODUCTIVITY FOR DRILLING MACHINESsamratNo ratings yet

- Auto Coner Machine OperatorDocument15 pagesAuto Coner Machine Operatorzeeshan_2200% (1)

- Training ReportDocument34 pagesTraining ReportRoyalAryansNo ratings yet

- Rotor Dynamics in Design of A High Speed Cryogenic Pump For Geo Stationary Launch Vehicles PDFDocument8 pagesRotor Dynamics in Design of A High Speed Cryogenic Pump For Geo Stationary Launch Vehicles PDFMounicaRasagyaPallaNo ratings yet

- Laboratory Manual MEC229: Theory of Machines LaboratoryDocument51 pagesLaboratory Manual MEC229: Theory of Machines Laboratoryhemanth singhNo ratings yet

- INDUSTRIAL ROBOTICS SYSTEM COMPONENTSDocument11 pagesINDUSTRIAL ROBOTICS SYSTEM COMPONENTSRahul RoyNo ratings yet

- ME 206 Fluid Machinery PDFDocument3 pagesME 206 Fluid Machinery PDFnandan144No ratings yet

- Marine NotesDocument10 pagesMarine NotesPradeep Msc ShippingNo ratings yet

- Design and Fabrication of Paultry Litter PulverizerDocument4 pagesDesign and Fabrication of Paultry Litter PulverizerAnonymous izrFWiQ0% (1)

- Milling operations and EDM processDocument2 pagesMilling operations and EDM processsegarvijay vijayNo ratings yet

- Manufacturing Processes 4-5-1592953812. PrintDocument238 pagesManufacturing Processes 4-5-1592953812. PrintVo Van Duy BaoNo ratings yet

- Barc Develops Gamma Scanner: NewsletterDocument24 pagesBarc Develops Gamma Scanner: NewsletterPradeep GsNo ratings yet

- Stirling Cycle Engines: Inner Workings and DesignFrom EverandStirling Cycle Engines: Inner Workings and DesignRating: 3 out of 5 stars3/5 (1)

- Study On The Effect of Air Suction Pressure On The Quality of Compact Yarn by Changing The Frequency of InverterDocument7 pagesStudy On The Effect of Air Suction Pressure On The Quality of Compact Yarn by Changing The Frequency of InverterSantoshNo ratings yet

- Get PDFDocument10 pagesGet PDFSantoshNo ratings yet

- Card Setting A Factor For Controlling Sliver Quality and Yarn 2165 8064 1000246Document3 pagesCard Setting A Factor For Controlling Sliver Quality and Yarn 2165 8064 1000246aniruddhaNo ratings yet

- Card Setting A Factor For Controlling Sliver Quality and Yarn 2165 8064 1000246Document3 pagesCard Setting A Factor For Controlling Sliver Quality and Yarn 2165 8064 1000246aniruddhaNo ratings yet

- SE-640 Description of The Features 1Document24 pagesSE-640 Description of The Features 1SantoshNo ratings yet

- European Patent Specification: To Make Elastic Shirting Fabric Comprising Spandex and Hard YarnDocument22 pagesEuropean Patent Specification: To Make Elastic Shirting Fabric Comprising Spandex and Hard YarnSantoshNo ratings yet

- Yarn Manufacturing I Blow RoomDocument39 pagesYarn Manufacturing I Blow RoomSantoshNo ratings yet

- Yarn Manufacturing - I Carding ProcessDocument31 pagesYarn Manufacturing - I Carding ProcessSantoshNo ratings yet

- Cardingmachine 140324082245 Phpapp01Document33 pagesCardingmachine 140324082245 Phpapp01SantoshNo ratings yet

- Yarn PDFDocument8 pagesYarn PDFSantoshNo ratings yet

- COVID-19 Vaccination Certificate 1st DoseDocument1 pageCOVID-19 Vaccination Certificate 1st DoseSantoshNo ratings yet

- COVID-19 Vaccination Certificate 1st DoseDocument1 pageCOVID-19 Vaccination Certificate 1st DoseSantoshNo ratings yet

- Plan Vouchers 17 July 2020Document11 pagesPlan Vouchers 17 July 2020Rajat SooodNo ratings yet

- IPL 2021 Schedule Fixture and Time TableDocument2 pagesIPL 2021 Schedule Fixture and Time Tableprasanna220274No ratings yet

- Chemical Processing IIDocument2 pagesChemical Processing IISantoshNo ratings yet

- Textile Engineering AND Fibre ScienceDocument9 pagesTextile Engineering AND Fibre ScienceSantosh0% (1)

- GATE 2011 TF PaperDocument12 pagesGATE 2011 TF PaperRakeahkumarDabkeyaNo ratings yet

- V10I3 (2) U. HussainDocument8 pagesV10I3 (2) U. HussainSantoshNo ratings yet

- Q: What Is Technical Textiles?Document7 pagesQ: What Is Technical Textiles?SantoshNo ratings yet

- True or False: Assignment 04Document3 pagesTrue or False: Assignment 04SantoshNo ratings yet

- Q.No. Type Section Key MarksDocument3 pagesQ.No. Type Section Key MarksSantoshNo ratings yet

- Model Apt Test PaperMADocument6 pagesModel Apt Test PaperMASantoshNo ratings yet

- Food Processing & ClassificationDocument3 pagesFood Processing & ClassificationAzrielle JaydeNo ratings yet

- 2006 - Bykovskii - JPP22 (6) Continuous Spin DetonationsDocument13 pages2006 - Bykovskii - JPP22 (6) Continuous Spin DetonationsLiwei zhangNo ratings yet

- Remnan TIIDocument68 pagesRemnan TIIJOSE MIGUEL SARABIANo ratings yet

- Lecture1 SEODocument24 pagesLecture1 SEOUsman AnwarNo ratings yet

- Global Finance - Introduction ADocument268 pagesGlobal Finance - Introduction AfirebirdshockwaveNo ratings yet

- HDFC Bank's Organizational Profile and BackgroundDocument72 pagesHDFC Bank's Organizational Profile and Backgroundrohitkh28No ratings yet

- Unit 3 Test A Test (Z Widoczną Punktacją)Document4 pagesUnit 3 Test A Test (Z Widoczną Punktacją)Kinga WojtasNo ratings yet

- Global GovernanceDocument20 pagesGlobal GovernanceSed LenNo ratings yet

- 5.3.2 Generation of Dislocations: Dislocations in The First Place!Document2 pages5.3.2 Generation of Dislocations: Dislocations in The First Place!Shakira ParveenNo ratings yet

- All Over AgainDocument583 pagesAll Over AgainJamie Kris MendozaNo ratings yet

- Data Report Northside19Document3 pagesData Report Northside19api-456796301No ratings yet

- Court Rules on Debt Collection Case and Abuse of Rights ClaimDocument3 pagesCourt Rules on Debt Collection Case and Abuse of Rights ClaimCesar CoNo ratings yet

- Revised Answer Keys for Scientist/Engineer Recruitment ExamDocument5 pagesRevised Answer Keys for Scientist/Engineer Recruitment ExamDigantNo ratings yet

- Apexocardiograma Precizari PracticeDocument12 pagesApexocardiograma Precizari PracticeDaniel VelciuNo ratings yet

- GST Project ReportDocument29 pagesGST Project ReportHENA KHANNo ratings yet

- Something About UsDocument18 pagesSomething About UsFercho CarrascoNo ratings yet

- SOG 5 Topics With SOPDocument2 pagesSOG 5 Topics With SOPMae Ann VillasNo ratings yet

- A Story Behind..: Dimas Budi Satria Wibisana Mario Alexander Industrial Engineering 5Document24 pagesA Story Behind..: Dimas Budi Satria Wibisana Mario Alexander Industrial Engineering 5Owais AwanNo ratings yet

- Modern Dental Assisting 11Th Edition Bird Test Bank Full Chapter PDFDocument37 pagesModern Dental Assisting 11Th Edition Bird Test Bank Full Chapter PDFRichardThompsonpcbd100% (9)

- Chapter 2 Review of Related Lit - 1Document83 pagesChapter 2 Review of Related Lit - 1CathyNo ratings yet

- Residential Water Piping Installation GuideDocument28 pagesResidential Water Piping Installation GuideMunir RasheedNo ratings yet