Professional Documents

Culture Documents

Cooling Towers: Design of Tall Structures Me Structural Engineering Drspdalal

Uploaded by

Megha Lakhani0 ratings0% found this document useful (0 votes)

89 views21 pagesCooling towers reject waste heat from a water stream to the atmosphere. There are different types based on build (package or field erected), heat transfer method (wet, dry, fluid cooler), air draft mechanism (atmospheric, natural draft, mechanical draft), and air/water flow pattern (cross flow, counter flow). The key components are the cold water basin, framework, water distribution system, fan deck, fan cylinders, fill material, and drift eliminators. Different materials are used for different components depending on their purpose and structural requirements.

Original Description:

Cooling Tower

Original Title

Cooling Tower

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCooling towers reject waste heat from a water stream to the atmosphere. There are different types based on build (package or field erected), heat transfer method (wet, dry, fluid cooler), air draft mechanism (atmospheric, natural draft, mechanical draft), and air/water flow pattern (cross flow, counter flow). The key components are the cold water basin, framework, water distribution system, fan deck, fan cylinders, fill material, and drift eliminators. Different materials are used for different components depending on their purpose and structural requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

89 views21 pagesCooling Towers: Design of Tall Structures Me Structural Engineering Drspdalal

Uploaded by

Megha LakhaniCooling towers reject waste heat from a water stream to the atmosphere. There are different types based on build (package or field erected), heat transfer method (wet, dry, fluid cooler), air draft mechanism (atmospheric, natural draft, mechanical draft), and air/water flow pattern (cross flow, counter flow). The key components are the cold water basin, framework, water distribution system, fan deck, fan cylinders, fill material, and drift eliminators. Different materials are used for different components depending on their purpose and structural requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 21

Cooling Towers

Design of Tall Structures

ME Structural Engineering

Dr S P Dalal

Cooling Tower - Definition

A cooling tower is a heat rejection device which rejects waste heat to

the atmosphere through the cooling of a water stream to a lower

temperature. Cooling towers may either use the evaporation of water

to remove process heat and cool the working fluid to near the wet-

bulb air temperature or, in the case of closed circuit dry cooling

towers, rely solely on air to cool the working fluid to near the dry-bulb

air temperature.

Types of Cooling Towers

Classification by Build

[1] Package Type

A. This type of cooling towers is preassembled and can be simply

transported on trucks as they are compact machines.

B. The capacity of package type towers are limited and for that

reason, they are usually preferred by facilities with low heat

rejection requirements such as food processing plants, textile

plants, buildings like hospitals, hotels, malls, chemical

processing plants, automotive factories etc.

C. Due to the intensive use in domestic areas, sound level control

is a relatively more important issue for package type cooling

towers.

Classification by Build

[2] Field erected type

A. Field erected type cooling towers are usually preferred for

power plants, steel processing plants, petroleum refineries, and

petrochemical plants.

B. These towers are larger in size compared to the package type

cooling towers.

Classification based on heat transfer

[1] Wet Cooling Tower

A. This type of cooling tower operates based on evaporation principle.

B. The working fluid and the evaporated fluid (usually water) are one

and the same.

C. In a wet cooling tower, the warm water can be cooled to a temperature

lower than the ambient air dry-bulb temperature, if the air is relatively

dry.

[2] Dry Cooling Tower

A. This tower operates by heat transfer through a surface that separates

the working fluid from ambient air, such as in a tube to air heat

exchanger, utilizing convective heat transfer.

B. Dry cooling tower does not use evaporation.

Classification based on heat transfer

[3] Fluid Cooler

This tower passes the working fluid through a tube bundle, upon which

clean water is sprayed and a fan-induced draft applied.

The resulting heat transfer performance is much closer to that of a wet

cooling tower, with the advantage provided by a dry cooler of protecting

the working fluid from environmental exposure and contamination.

Classification based on air draft

[1] Atmospheric Tower

A. An atmospheric tower consist of a big rectangular

chamber with two opposite louvered walls.

B. The tower is packed with a suitable tower fill.

C. Atmospheric air enters the tower through the louvers

driven by its own velocity.

D. An atmospheric tower is cheap but inefficient.

E. Its performance largely depends upon the direction

and velocity of wind.

Classification based on air draft

[2] Natural Draft Tower

A. The natural draft or hyperbolic cooling tower makes use of the difference in temperature between

the ambient air and the hotter air inside the tower.

B. As hot air moves upwards through the tower (because hot air rises), fresh cool air is drawn into the

tower through an air inlet at the bottom.

C. A natural draft tower is so called because natural flow of air occurs through the tower.

D. Due to the layout of the tower, no fan is required and there is almost no circulation of hot air that

could affect the performance.

E. But in some cases, a few fans are installed at the bottom to enhance the air flow rate.

F. This type of tower is called ‘fan-assisted’ natural draft tower.

G. Two factors are responsible for creating the natural draft:

- a rise in temperature and humidity of air in the column reduces its density, and

- the wind velocity at the tower bottom.

Classification based on air draft

Natural Draft Tower (continued .. )

Why a hyperbola?

more packing can be fitted in the bigger area at the bottom of the shell;

the entering air gets smoothly directed towards the center because of the shape of the wall,

producing a strong upward draft;

greater structural strength and stability of the shell is provided by this shape.

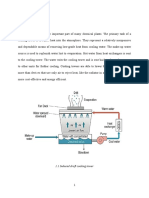

Figure : Cross Flow and Counter flow natural draft cooling tower

Classification based on air draft

[3] Mechanical Draft Tower

A. Because of their huge shape, construction difficulties and cost, natural draft towers

have been replaced by mechanical draft towers in many installations.

B. Mechanical draft towers have large fans to force or draw air through circulated

water.

C. The water falls downwards over fill surfaces, which helps increase the contact time

between the water and the air.

D. Cooling rates of mechanical draft towers depend upon various parameters; such as

fan diameter and speed of operation, fills for system resistance, etc.

E. There are two different classes of mechanical draft cooling towers:

(a) Forced Draft

(b) Induced Draft

Classification based on air draft

[3] Mechanical Draft Tower ( continued..)

Forced Draft

It has one or more fans located at the tower bottom to push air into the tower.

During operation, the fan forces air at a low velocity horizontally through the

packing and then vertically against the downward flow of the water that occurs on

either side of the fan.

The drift eliminators located at the top of the tower remove water entrained in the

air.

Vibration and noise are minimal since the rotating equipment is built on a solid

foundation.

The fans handle mostly dry air, greatly reducing erosion and water condensation

problems.

Classification based on air draft

[3] Mechanical Draft Tower ( continued..)

Induced Draft

A mechanical draft tower with a fan at the

discharge which pulls air through tower.

The fan induces hot moist air out the discharge.

This produces low entering and high exiting air

velocities, reducing the possibility of recirculation

in which discharged air flows back into the air

intake.

Classification based on air flow pattern

[1] Cross Flow

Crossflow is a design in which the air flow is directed perpendicular to the water flow.

Air flow enters one or more vertical faces of the cooling tower to meet the fill material.

Water flows (perpendicular to the air) through the fill by gravity.

The air continues through the fill and thus past the water flow into an open plenum area.

A distribution or hot water basin consisting of a deep pan with holes or nozzles in the bottom is utilized in a

crossflow tower.

Gravity distributes the water through the nozzles uniformly across the fill material.

Classification based on air flow pattern

[2] Counter Flow

In a counter flow design, the air flow is directly opposite to the water flow (see diagram below).

Air flow first enters an open area beneath the fill media and is then drawn up vertically.

The water is sprayed through pressurized nozzles and flows downward through the fill, opposite to the

air flow.

Structural Components of a Cooling Tower

Most cooling systems are very vulnerable to corrosion.

They contain a wide variety of metals and circulate warm water at relatively high linear velocities. Both of these

factors accelerate the corrosion process. Deposits in the system caused by silt, dirt, debris, scale and bacteria,

along with various gases, solids and other matter dissolved in the water all serve to compound the problem.

Even a slight change in the cooling water pH level can cause a rapid increase in corrosion.

Open recirculating systems are particularly corrosive because of their oxygen-enriched environment.

The components of cooling tower are

1. cold water basin

2. Framework

3. water distribution system

4. fan deck

5. fan cylinders

6. mechanical equipment supports

7. Fill

8. drift eliminators

9. Casing

10. louvers.

Structural Components of a Cooling Tower

[1] Cold water basin

The cold water basin has two fundamentally important functions: collecting the cold water following

its transit of the tower, and acting as the tower’s primary foundation.

[2] Tower framework

The most commonly used materials for the framework of field-erected towers are fiberglass, wood,

and concrete, with steel utilized infrequently to conform to a local building code, or to satisfy a

specific preference.

[3] Water distribution system

Lines might be buried to minimize problem of thrust loading, thermal expansion and freezing; or

elevated to minimize cost of installation and repair. In either case, the risers to the tower inlet must

be externally supported, independent of the tower structure and piping.

[4] Fan deck

The fan deck is considered a part of the tower structure, acting as a diaphragm for transmitting dead

and live loads to the tower framing. It also provides a platform for the support of the fan cylinders,

as well as an accessway to the mechanical equipment and water distribution system. Fan deck

materials are customarily compatible with the tower framework.

Structural Components of a Cooling Tower

[5] Fan cylinder

Fan cylinder directly affects the proper flow of air through the tower. Its efficiencies can be severely

reduced by a poorly designed fan cylinder, or significantly enhanced by a well-designed one.

[6] Mechanical equipment supports

Customary material for the unitized supports is carbon steel, hot-dip galvanized after fabrication,

with stainless steel construction available at significant additional cost.

[7] Fill (heat transfer surface)

Fill (heat transfer surface) is able to promote both the maximum contact surface and the maximum

contact time between air and water determines the efficiency of the tower. The two basic fill

classifications are splash type and film type.

Splash type fill breaks up the water, and interrupts its vertical progress, by causing it to cascade

through successive offset levels of parallel splash bars. It is characterized by reduced air pressure

losses, and is not conducive to logging. However, it is very sensitive to inadequate support.

Film type fill causes the water to spread into a thin film, flowing over large vertical areas, to promote

maximum exposure to the air flow. It has capability to provide more effective cooling capacity

within the same amount of space, but is extremely sensitive to poor water distribution.

Structural Components of a Cooling Tower

[8] Drift eliminator

Drift eliminators remove entrained water from the discharge air by causing it to

make sudden changes in direction.

The resulting centrifugal force separates the drops of water from air, depositing

them on the eliminator surface, from which they flow back into the tower.

Eliminator are normally classified by the number of directional changes or

“passes”, with an increase in the number of passes usually accompanied by an

increase in pressure drop.

[9] Casing

A cooling tower casing acts to contain water within the tower, provide an air

plenum for the fan, and transmit wind loads to the tower framework.

It must have diaphragm strength, be watertight and corrosion resistant, have fire

retardant qualities, and also resist weathering.

Structural Components of a Cooling Tower

[10] Louvers

Every well-designed cross flow tower is equipped with inlet

louvers, whereas counter flow towers are only occasionally

required to have louvers.

Their purpose is to retain circulating water within the

confines of the tower, as well as to equalize air flow into the

fill.

Reinforcement

You might also like

- Chapter 3.7 Cooling TowerDocument17 pagesChapter 3.7 Cooling TowerDeep DasNo ratings yet

- Cooling Tower PDFDocument3 pagesCooling Tower PDFmaimslapNo ratings yet

- Central Air Conditioning Systems ReviewDocument23 pagesCentral Air Conditioning Systems ReviewlalaNo ratings yet

- 16tj - Lj-Training - Book-2 CARRIER ABSORBDocument178 pages16tj - Lj-Training - Book-2 CARRIER ABSORBlist16947100% (1)

- Refrigeration Dryer 250 M3/mminDocument2 pagesRefrigeration Dryer 250 M3/mminAriep Rachman100% (1)

- Chilled beams: An efficient HVAC convection systemDocument1 pageChilled beams: An efficient HVAC convection systemrkibNo ratings yet

- G Temperature Glide MF EN PDFDocument14 pagesG Temperature Glide MF EN PDFKanaga RajNo ratings yet

- Cooling TowerDocument12 pagesCooling TowerLillianLinNo ratings yet

- Refrigeration and Air Conditioning Systems ExplainedDocument113 pagesRefrigeration and Air Conditioning Systems ExplainedHosnii QamarNo ratings yet

- BSE 3712 HVAC System Design for Commercial BuildingDocument19 pagesBSE 3712 HVAC System Design for Commercial BuildingChan Tsz HimNo ratings yet

- Catalogue CF For CTI 2.00 15dec2015Document104 pagesCatalogue CF For CTI 2.00 15dec2015X-flies0% (1)

- Bell-Coleman Refrigeration Cycle ProblemsDocument10 pagesBell-Coleman Refrigeration Cycle ProblemsBalvinderNo ratings yet

- Psych Rome TricsDocument46 pagesPsych Rome TricsDenitta D'RoseNo ratings yet

- Cooling Tower Makeup Water EstimationDocument3 pagesCooling Tower Makeup Water EstimationMuhammad NaeemNo ratings yet

- Energy Recovery Wheel Technical GuideDocument36 pagesEnergy Recovery Wheel Technical GuideDeepakkumarNo ratings yet

- Kigali Amendment HFC Phase Down ScheduleDocument2 pagesKigali Amendment HFC Phase Down SchedulePaulin PahNo ratings yet

- Chilled Water System Introduction, MyanmarDocument20 pagesChilled Water System Introduction, MyanmaracmvorgNo ratings yet

- Twi CrossflowDocument8 pagesTwi CrossflowDota NgNo ratings yet

- Building HVAC Requirements: 4.1 OverviewDocument55 pagesBuilding HVAC Requirements: 4.1 OverviewHaroon GhaniNo ratings yet

- District Cooling Systems ExplainedDocument7 pagesDistrict Cooling Systems ExplainedMarzook50% (2)

- Dryness FractionDocument3 pagesDryness Fractionmurali_228No ratings yet

- Refrigeration COP CalculationDocument17 pagesRefrigeration COP CalculationibrahimNo ratings yet

- Cooling Tower IntroductionDocument27 pagesCooling Tower Introductiondinesh babuNo ratings yet

- Basic Data SheetDocument15 pagesBasic Data Sheeterkamlakar2234No ratings yet

- Cooling Tower - BaltimoreDocument7 pagesCooling Tower - BaltimoreОсама А.ШоукиNo ratings yet

- L6 Cooling Tower PDFDocument58 pagesL6 Cooling Tower PDFharris100% (1)

- Oxycom IntrCool Brochure (2019) enDocument20 pagesOxycom IntrCool Brochure (2019) enAnkit JainNo ratings yet

- Heat Pump Report Final PDFDocument66 pagesHeat Pump Report Final PDFIna Rodica PricăNo ratings yet

- Free Cooling Types and ControlsDocument2 pagesFree Cooling Types and ControlsHnin PwintNo ratings yet

- Cooling TowerDocument18 pagesCooling TowerSalehAfadlehNo ratings yet

- Central Cooling and Heating Plants: Design Considerations and AdvantagesDocument21 pagesCentral Cooling and Heating Plants: Design Considerations and AdvantagesRolando Valdez GutierrezNo ratings yet

- Cooling Tower DefinitionsDocument68 pagesCooling Tower Definitionszubi13No ratings yet

- 25-01-10 Networking Event EMS FinalDocument41 pages25-01-10 Networking Event EMS FinalajeeshsivanNo ratings yet

- 3000 Brochure PDFDocument24 pages3000 Brochure PDFFarooque ShaikhNo ratings yet

- Cooling Tower Report PDFDocument49 pagesCooling Tower Report PDFSyed Waqas HussainNo ratings yet

- Dr. Fixit Newcoat 105 1 PDFDocument3 pagesDr. Fixit Newcoat 105 1 PDFmohdrashidNo ratings yet

- District Cooling Guide Second Edition - Unlocked-2Document2 pagesDistrict Cooling Guide Second Edition - Unlocked-2Ahmed LabibNo ratings yet

- Kathabar Liquid Desiccant Product Guide DigitalDocument9 pagesKathabar Liquid Desiccant Product Guide Digitalnathanielek1989No ratings yet

- TR-036 Trane Chiller Rehab Ilia Ti OnDocument3 pagesTR-036 Trane Chiller Rehab Ilia Ti OnJoel Maximo Javines MangaoangNo ratings yet

- Course Content: Fundamentals of HVAC ControlsDocument39 pagesCourse Content: Fundamentals of HVAC ControlsMuhammad AfzalNo ratings yet

- Taj Kitchen Case StudyDocument4 pagesTaj Kitchen Case StudySandeep GargNo ratings yet

- Machinery Room Ventilation Analysis ToolDocument48 pagesMachinery Room Ventilation Analysis ToolDon Quijote de la ManchaNo ratings yet

- Technical Data Sheet R32 ENGLISHDocument6 pagesTechnical Data Sheet R32 ENGLISHreddy PrasadNo ratings yet

- Lacos Sweeping Basin SystemDocument18 pagesLacos Sweeping Basin SystemSanto ENo ratings yet

- EKC316 - Humidification Process Design and Psychrometric AnalysisDocument95 pagesEKC316 - Humidification Process Design and Psychrometric AnalysisSathiswaran SelvamNo ratings yet

- Hz15 Atex/Iecex Scroll Compressor DatasheetDocument2 pagesHz15 Atex/Iecex Scroll Compressor DatasheettareqNo ratings yet

- Control chilled water system for energy efficient cleanroomsDocument6 pagesControl chilled water system for energy efficient cleanroomsSing Yew LamNo ratings yet

- Week 3 - Basic Components of Ahu and Fcu, Fan and Duct System 2020-2021 - 2tDocument112 pagesWeek 3 - Basic Components of Ahu and Fcu, Fan and Duct System 2020-2021 - 2tMei LamfaoNo ratings yet

- B7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallDocument30 pagesB7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallSMBEAUTYNo ratings yet

- Design For A Cold Storage and Ice Plant 1907 PDFDocument30 pagesDesign For A Cold Storage and Ice Plant 1907 PDFMark PamularNo ratings yet

- Chapter 11 - Refrigeration CyclesDocument25 pagesChapter 11 - Refrigeration CyclesPaul RodgersNo ratings yet

- By: Meet Shah & Arpit ThumarDocument27 pagesBy: Meet Shah & Arpit ThumarArpit ThumarNo ratings yet

- Cooling Tower ProjectDocument50 pagesCooling Tower ProjectRahul Wavdekar100% (1)

- Introduction Cooling TowerDocument12 pagesIntroduction Cooling TowerErnie Mark Patosa MaratasNo ratings yet

- Cooling Tower: Refrigeration and Air Conditioning LabDocument40 pagesCooling Tower: Refrigeration and Air Conditioning LabEngr Saad Bin SarfrazNo ratings yet

- Cooling Towers: Operation and MaintenanceDocument26 pagesCooling Towers: Operation and MaintenanceMandeep MalikNo ratings yet

- Cooling Tower REPORTDocument25 pagesCooling Tower REPORTSaroj KumarNo ratings yet

- Cooling tower functionsDocument16 pagesCooling tower functionsPrasanna kumar subudhi100% (1)

- ابراج التبريدDocument17 pagesابراج التبريدmuhammed atallaNo ratings yet

- Chapter 3.7 Cooling TowerDocument16 pagesChapter 3.7 Cooling TowerRaj Kumar ChakrabortyNo ratings yet

- Sub SeaDocument2 pagesSub SeaMegha LakhaniNo ratings yet

- Client Calculation of Pipe Rack Structur PDFDocument179 pagesClient Calculation of Pipe Rack Structur PDFMegha Lakhani100% (1)

- Cooling TowerDocument6 pagesCooling TowerMegha LakhaniNo ratings yet

- Load and Resistance Factor DesignDocument9 pagesLoad and Resistance Factor DesignYan Naung Ko100% (2)

- Freshwater Generator Aqua BrochureDocument6 pagesFreshwater Generator Aqua BrochureTapas ChaudhuriNo ratings yet

- Welding Safety QuizDocument4 pagesWelding Safety QuizNicolae MarinNo ratings yet

- Loctite Aa V5004-EnDocument4 pagesLoctite Aa V5004-EnDan AyalaNo ratings yet

- P H100Document3 pagesP H100nixneusNo ratings yet

- Ordering Information:: Back To Piping StudyDocument3 pagesOrdering Information:: Back To Piping StudyShankar JhaNo ratings yet

- Class 10 Science Chapter 4 Revision NotesDocument27 pagesClass 10 Science Chapter 4 Revision NotesShree Narsingh Universal SchoolNo ratings yet

- CHP 4, SolutionsDocument4 pagesCHP 4, SolutionsJacko CrestNo ratings yet

- PharmaDocument147 pagesPharmaDrChauhanNo ratings yet

- Bbet+tre-2018-C-Xi (Paper-2) PCMDocument22 pagesBbet+tre-2018-C-Xi (Paper-2) PCMPankaj DhankerNo ratings yet

- Microbiological Quality of Different Brands of Talcum Powder in IndiaDocument6 pagesMicrobiological Quality of Different Brands of Talcum Powder in IndiaJohan SukweenadhiNo ratings yet

- Dual Core YarnDocument55 pagesDual Core YarnTuan Nguyen MinhNo ratings yet

- Evaporated MilkDocument2 pagesEvaporated Milkswaggerbox100% (1)

- Beetroot ProductivityDocument7 pagesBeetroot Productivitytarekegn belaynehNo ratings yet

- Pipes and Tubes (VB)Document92 pagesPipes and Tubes (VB)Phúc nguyễnNo ratings yet

- Faster Class II Cabinet UltraSafeDocument2 pagesFaster Class II Cabinet UltraSafeahamad1No ratings yet

- SPEC Tamanu OilDocument1 pageSPEC Tamanu OilSuci Desriana RSNo ratings yet

- Alcohols and Halogenoalkanes HLDocument11 pagesAlcohols and Halogenoalkanes HLMary KalamakiNo ratings yet

- 15 & 16 Equipment ListDocument29 pages15 & 16 Equipment Listhekayat71No ratings yet

- Explosive Detection SystemsDocument8 pagesExplosive Detection SystemsSyed FazluNo ratings yet

- 8.1-8.6 Redox ReactionsDocument65 pages8.1-8.6 Redox ReactionsberonelleNo ratings yet

- BambuDocument115 pagesBambuDaniel Pinheiro100% (1)

- Environment Economics AssignmentDocument11 pagesEnvironment Economics AssignmentMuhammad Nouman YasinNo ratings yet

- Websitecompanies NewDocument33 pagesWebsitecompanies NewRajiv JulakantiNo ratings yet

- Fresh ConcreteDocument15 pagesFresh ConcreteAlwyne ReyesNo ratings yet

- Astm A185 A185m-07Document6 pagesAstm A185 A185m-07HelisNo ratings yet

- Bureau Circular 5 S 1997Document39 pagesBureau Circular 5 S 1997mrk_rlndNo ratings yet

- Conbextra EP150: Constructive SolutionsDocument4 pagesConbextra EP150: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- B705 Acpt1003Document3 pagesB705 Acpt1003taya1401No ratings yet

- Consumer Chemistry: Quarter 3 - Module 3: Chemicals Found in Dyes and Insect RepellantsDocument32 pagesConsumer Chemistry: Quarter 3 - Module 3: Chemicals Found in Dyes and Insect Repellantstrishia matas100% (4)

- Sikaflex 2c NS EZ Mix - (A-B) - EDocument10 pagesSikaflex 2c NS EZ Mix - (A-B) - EJHAN PIERDNo ratings yet