Professional Documents

Culture Documents

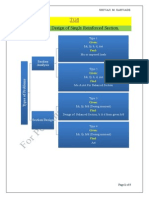

Comparison of Speed Control of DC Servo Motor Using Pi, PID, Fuzzy, SMC

Uploaded by

shubham kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparison of Speed Control of DC Servo Motor Using Pi, PID, Fuzzy, SMC

Uploaded by

shubham kumarCopyright:

Available Formats

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 3, Issue 11, November 2016

Comparison of Speed Control of Dc Servo Motor

using Pi, PID, Fuzzy, SMC

G. Vasudevarao1, V. Rangavalli2

PG Student of Control Systems (EEE), ANITS College, Visakhapatnam, Andhra Pradesh 1

Asst. Prof, ANITS College, Visakhapatnam, Andhra Pradesh2

Abstract: DC servo motor is widely used in many applications like Robotics, Conveyor Belts and Camera. In this

paper a dc servo motor using MATLAB has been designed whose speed may be investigated using the Proportional,

Integral, Derivative (KP, KI, KD) gain of the PID controller. The purpose of this paper is to design a Ziegler-Nichols

controller to improve the performance (speed) of the DC motor in order to control the speed of the motor. The results

are compared with controller tuned by PI, PID Ziegler- Nichols method. Since, classical controllers like P, PI and PID

are failing to control the drive when weight parameters are also changed. The PID controller has some disadvantages

like: high overshoot, sensitivity to controller gains and slow response. Fuzzy control and SMC is proposed in this

study. In this paper a comparison among PI, PID and fuzzy logic controller, sliding model controller, through

MATLAB/Simulink software have been presented the obtained results are promising and is likely to be utilized by the

industries.

Keywords: Control System, Proportional-Integral (P-I) controller, Fuzzy logic control, Sliding mode controller Speed

control, Modelling of System, D.C. Servo Motor, MATLAB / SIMULINK

1. INTRODUCTION 2. MODELING OF D.C SERVOMOTOR

Electric motors can be classified by their functions as A DC motor may be controlled by varying the input

servomotors, gear motors, and so forth, and by their voltage or by changing the input current. In this paper, the

electrical configurations as DC (direct current) and AC DC servo motor model is chosen due to its good electrical

(alternating current) motors. and mechanical performances compared to other DC

motor models. Consider armature controlled dc motor

The Automatic systems are common in our daily life, they circuit shown below

can be found in almost any electronic devices and

appliances we use daily, starting from air conditioning

systems automatic doors and automotive cruise control

+ a i( f i(

systems to more advanced technologies such as robotic

t) t) E

f

E

arms, production lines and thousands of industrial and

a

scientific applications.

(t)

The development of high performance motor drives is (t) Eb

very important in industrial as well as other purpose _ ωT

applications such as steel rolling mills, electric trains and (t)

robotics. m motor

Fig 1 DC servo

DC servomotors are one of the main components of Where

automatic systems; any automatic system should have an T or Tm =Torque developed by motor

actuator module that makes the system to actually perform B =equivalent viscous friction co-efficient of motor

its function. Generally, a high performance motor drive J= equivalent moment of inertia of motor

system must have good dynamic speed command tracking ωm =Motor angular velocity

and load regulating response to perform task. B=Viscous friction coefficient

Kb=Back e.m.f constant

DC drives, because of their simplicity, ease of application, KT=Torque constant

high reliabilities, flexibilities and favorable cost have long R or R a =armature resistance

been a backbone of industrial applications, robot L or La =armature inductance

manipulators and home appliances where speed and Eb =back emf of motor

position control of motor are required. The control of the Va or Ea =armature voltage

speed of a DC motor with high accuracy is required. Ia =armature current

Copyright to IARJSET DOI 10.17148/IARJSET.2016.31129 151

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 3, Issue 11, November 2016

The dynamics of a separately excited DC motor may be Transfer function of dc motor is given by

expressed as: 𝜔 (𝑠) 0.052

𝐸 (𝑠)

= (0.0002979 𝑠 2 +0.01012 𝑠+0.092 )

The air gap flux ∅ is proportional to the field current 𝑎

∅ =K f If (1)

3 .PROPORTIONAL PLUS INTEGRAL

Torque developed by motor is proportional to the field CONTROLLER DESCRIPTION

current and air gap flux

Tm =K f If K1 Ia (2) The PI controller is standard and proved solution for the

most industrial application. The main reason is its

In armature controlled dc motor field current is kept relatively simple structure, which can be easily understood

constant. and implemented in practice, and that many sophisticated

Tm =K T Ia (3) control strategies, such as model predictive control, are

based on it. An application with large speed capabilities

requires different PI gains than an application which

The motor back emf being proportional to speed

dω operates at a fixed speed. In addition, industrial equipment

Eb = K b dt (4) that are operating over wide range of speeds, requires

different gains at the lower and higher end of the speed

The differential equation of armature current is range in order to avoid overshoots and oscillations.

d Ia Generally, tuning the proportional and integral constants

L dt + Ia R a +Eb =Ea (5)

for a large speed control process is costly and time

consuming. The task is further complicated when incorrect

The torque equation is given by

2

d ω dω

PI constants are sometimes entered due the lack of

J dt2 +B dt =Tm =K T Ia (6) understanding of the process. The control action of a

proportional plus integral controller is defined as by

On taking Laplace transforms on both sides with zero following equation:

initial conditions we get u(t) = Kp + Ki (11)

Eb (s)= K b sω (s) (7)

(Ls+R) Ia (s)+ Eb (s) = Ea (s) (8) Where:

(Js2 +Bs)ω(s) =K T Ia (s) (9) u(t) is actuating signal.

e(t) is error signal.

The transfer function of the system is given by Kp is Proportional gain constant.

ω (s)

G(s) = E (s) Ki is Integral gain constant.

a

From eqn.(8) The Laplace transform of the actuating signal

(Ls+R) Ia (s)+ Eb (s) = Ea (s) incorporating in proportional plus integral control is

(Ls+R) Ia (s)+ K b sω(s) =Ea (s) u(s) = kp e(s) + ki e(s) (12)

𝐾𝑇

(𝐿𝑠 + 𝑅) 𝐼𝑎 (𝑠) + 𝐾𝑏 𝑠 ∗ ( ( 𝑠 2 +𝐵𝑠) ) 𝐼𝑎 (s) = 𝐸𝑎 (s)

𝐾 𝐾

𝑇

(𝐿𝑠 + 𝑅) + ( ( 𝐽𝑠𝑏 +𝐵)) 𝐼𝑎 (𝑠)= 𝐸𝑎 (s)

𝑤 (𝑠) 𝜔 (𝑠) 𝐼 (𝑠)

G(s) = 𝐸 𝑎(𝑠) =𝐼 * 𝐸𝑎 (𝑠)

𝑎 𝑎 (𝑠) 𝑎

Therefore the transfer function of motor is given by

𝐾𝑇

G(s) = (𝑠 𝐿𝑠+𝑅 𝐽𝑠 +𝐵 +𝐾 𝐾 ) 𝑏 𝑇 Fig 3 Block diagram of PI Controller

The armature circuit inductance is generally negligible i.e.

L=0

𝜔 (𝑠) 𝐾

𝐸 (𝑠)

=G(s)= (𝑠 𝑅 𝐽𝑠 +𝐵𝑇 +𝐾 𝐾 ) (10)

𝑎 𝑏 𝑇

Fig 4 Simulink Model of D.C. Servo Motor Using Pi

Fig 2 Block diagram of dc servo motor Controller

Copyright to IARJSET DOI 10.17148/IARJSET.2016.31129 152

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 3, Issue 11, November 2016

Then, Ki and Kd are set to zero and only Kp value is

increased until it creates a periodic oscillation at the output

response. This critical Kp value is attained to be “ultimate

gain”, Kc and the period where the oscillation occurs is

named as Pc “ultimate period”. As a result, the whole

process depends on two variables and the other control

parameters are calculated according to the table.

Type of 𝐾𝑝 𝑇𝑖 𝑇𝑑

controller

P 0.5𝐾𝑐𝑟 ∞ 0

Fig 5 Simulation output of pi controller PI 0.45K 𝑐𝑟 1 0

𝑃

1.2 𝑐𝑟

4. PROPORTIONAL-INTEGRAL-DERIVATIVE PID 0.6𝐾𝑐𝑟 0.5𝑃𝑐𝑟 0.125𝑃𝑐𝑟

(PID) CONTROLLER Fig 7 Estimation value for gain, reset and derivative

PID controllers are widely used in industrial control

applications due to their simple structures, comprehensible

control algorithms and low costs. Below figure shows the

schematic model of a control system with a PID.P-I-D

controller has the optimum control dynamics including

zero steady state error, fast response (short rise time), no

oscillations and higher stability. The necessity of using a

derivative gain component in addition to the PI controller Fig 8 Simulink Model of D.C. Servo Motor

is to eliminate the overshoot and the oscillations occurring using pid controller

in the output response of the system. One of the main

advantages of the P-I-D controller is that it can be used

with higher order processes including more than single

energy storage.

u(t) = Kp + Ki +kd (13)

4.1 ZIEGLER-NICHOLS METHOD

More than six decades ago, P-I controllers were more

widely used than P-I-D controllers. Despite the fact that P-

I-D controller is faster and has no oscillation, it tends to be

unstable in the condition of even small changes in the

input set point or any disturbances to the process than P-I Fig 9 simulation output of pid

controllers. Ziegler-Nichols Method is one of the most

effective methods that increase the usage of P-I-D 5. FUZZY LOGIC CONTROLLER DESCRIPTION

controllers

Fuzzy logic control is a control algorithm based on a

linguistic control strategy, which is derived from expert

knowledge into an automatic control strategy. Fuzzy logic

control doesn't need any difficult mathematical calculation

like the others control system. While the others control

system use difficult mathematical calculation to provide a

model of the controlled plant, it only uses simple

mathematical calculation to simulate the expert

knowledge. Although it doesn't need any difficult

mathematical calculation, but it can give good

performance in a control system Thus, it can be one of the

best available answers today for a broad class of

Fig 6 Ziegler-Nichols P-I-D controller tuning method challenging controls problems. A fuzzy logic control

usually consists of the following:

The logic comes from the neutral heuristic principle.

Firstly, it is checked that whether the desired proportional FUZZIFICATION

control gain is positive or negative. For this, step input is This process converts or transforms the measured inputs

manually increased a little, if the steady state output called crisp values, into the fuzzy linguistic values used by

increases as well it is positive, otherwise; it is negative. the fuzzy reasoning mechanism.

Copyright to IARJSET DOI 10.17148/IARJSET.2016.31129 153

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 3, Issue 11, November 2016

KNOWLEDGE BASE

A collection of the expert control rules (knowledge)

needed to achieve the control goal.

FUZZY REASONING MECHANISM

This process will perform fuzzy logic operations and result

the control action according to the fuzzy inputs.

DEFUZZIFICATION UNIT

This process converts the result of fuzzy reasoning

mechanism into the required crisp value.

FUZZY CONTROLLER DESIGN

The most important things in fuzzy logic control system Fig 14 Rule View of FLC

designs are the process design of membership functions

for inputs, outputs and the process design of fuzzy if-then

rule knowledge base. They are very important in fuzzy

logic control. The basic structure of Fuzzy Logic

Controller is given in the D.C drive, speed error (E) and

change in speed error (CE) are taken as the two inputs for

the fuzzy controller and one output control input (CI). For

this, a three-member as well as a seven-member rule base

is devised. The rule base for seven membership functions

is shown in Table

CE NL NM NS Z PS PM PL

NL NL NL NL NM NS NS Z

NM NL NL NM NS NS Z PS

NS NL NM NS NS Z PS PM

Z NM NM NS Z PS PM PM Fig 15 Surface View of FLC Block diagram

PS NM NS Z PS PS PM PL

PM NS Z PS PS PM PL PL

PL Z PS PS PM PL PL PL

Fig 10.Fuzzy rules table

Fig 16 Simulink Model of D.C. Servo Motor using fuzzy

logic controller

Fig 11 Error

Fig 12 Change in error

Fig.17 simulation output fuzzy logic controller

6. SLIDING MODE CONTROLLER

VSS (variable structure system) is well known as special

class of nonlinear systems for solving several specific

Fig 13 Change in input control tasks in second order linear and nonlinear systems.

Copyright to IARJSET DOI 10.17148/IARJSET.2016.31129 154

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 3, Issue 11, November 2016

However VSS did not receive wide acceptance among problem can be eliminated, by using an initial virtual state

engineering professionals until the first survey paper that that makes the initial sliding function equal to zero.

is IEEE Transactions on Automatic Control in 1977 was Therefore, it is possible to use the SMC technique with

published by Utkin. The most interesting fact is that various types of controller.

robustness has becomes a major requirement in modern A linear system can be described in the state space as

control application. follows

𝑥 = Ax+Bu (14)

The most distinguishing property of VSS is its ability to

result in very robust control systems. In other words, the Where 𝑥 ∈ 𝑅𝑛 , u ∈ R, A ∈ Rn*n, and B∈ Rn and B is full

system is completely insensitive to parametric uncertainty rank matrix. A and B are controllable matrixes. The

and external disturbances. Due to its excellent invariance functions of state variables are known as switching

and robustness properties, the VSS concepts have been function

developed into practical application mainly in the field of 𝜎=sx (15)

control of DC servo motors, robotic manipulators, PM

synchronous servomotors, induction motors, aircraft The main idea in sliding mode control is to

control, spacecraft control and flexible space structure Design the switching function so that 0 (sliding

control. These experiments confirm the theoretical results mode) provide the desired dynamic.

regarding robustness of VSS with sliding modes. Finding a controller ensuring sliding mode of the system

However, in some of these experimental results, it was occurs in finite time First of all, the system should be

found that the resulting control is discontinuous and the converted to its regular form

chattering phenomenon which can leads to low accuracy 𝑥 = Tx (16)

in control system.

T is the matrix that brings the system to its regular form

These problems can be solved by replacing a continuous 𝑥1 = 𝐴11 𝑥1 +𝐴12 𝑥2

control into the computation of the control input (a sign 𝑥2 =𝐴21 𝑥1 +𝐴22 𝑥2 + 𝐵2 (17)

function). As a result, the large error behaviour of a

system is identical to that with discontinuous control. It The switching function in regular form

can be assumed that, the behaviour of the system in small 𝜎 = 𝑠1 𝑥1 + 𝑠2 𝑥2 (18)

error region as a high gain system and this is similar to

that of system with discontinuous control. Hence, this high on the sliding mode manifold (𝜎 = 0)

gain effect of sliding mode control based on VSS, 0=𝑠1 𝑥1 + 𝑠2 𝑥2

suppressed the uncertainties due to parametric variations,

𝑥2 = -𝑠2 −1 𝑠1 𝑥1 (19)

external disturbances and variable payloads.

From (16) &(19)

Besides that the proper selection of the switching

𝑥1 =𝐴11 𝑥1 - 𝐴12 𝑠2 −1 𝑠1

functions will avoid chattering problem in the DC drive

𝑥1 = (𝐴11 -𝐴12 𝑠2 −1 𝑠1 )𝑥1 (20)

systems, hence result in high accuracy control. The choice

of switching functions to control the system states, such

One of matrixes in product: 𝑠2 −1 𝑠1 should be chosen

that current, speed or position has been discussed and

examined in detail in literature under this control strategy, arbitrary. Usually (21) is used to ensure that 𝑠2 is

the dynamic performance of the system can be shaped invertible

according to the system specification by an appropriate 𝑠2 = 𝐵2 −1 (21)

choice of switching function.

𝑠1 can be calculated by assigning the Eigen value of (20)

It is well known, that the sliding mode control is a popular by pole placement method. Hence, switching function will

robust control Method. However it has a reaching phase be obtained as follows

problem and an input chattering problem (as discussed S= [ 𝑠1 𝑠2 ] T (22)

above). These problems cause the sliding mode control

(SMC) is very conservative to be used with other The control rule is

controller design methods because the state trajectory of 𝑢 = 𝑢𝑐 +𝑢𝑑 (23)

the sliding mode control system is determined by sliding

mode dynamics, which cannot have the same order Where 𝑢𝑐 and 𝑢𝑑 are continuous and discrete parts,

dynamics of the original system. respectively and can be calculated as follows

𝑢𝑐 = - A21 x1 - A22 𝜎 (24)

This leads to the introduction of robust controller design

with novel sliding surface. To overcome the conservatism 𝑢𝑑 = -𝐾𝑠 sgn 𝜎 - 𝐾𝑝 (25)

of the SMC, the novel sliding surface has been used which

the same dynamics of the nominal original system has where sgn is sign function. 𝐾𝑠 , and 𝐾𝑝 are constants

controlled by a nominal controller. The reaching phase calculated regarding to lyapunov stability function.

Copyright to IARJSET DOI 10.17148/IARJSET.2016.31129 155

IARJSET ISSN (Online) 2393-8021

ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

ISO 3297:2007 Certified

Vol. 3, Issue 11, November 2016

6.2 MODELLING OF DC SERVO MOTOR

The state space model of DC motor is as follows

The modelling and state space model of dc motor is

already discussed

𝑏 𝑘𝑚

− 𝑥1 0

𝐽 𝐽

𝒙 =Ax+Bu = 𝑘 𝑅 𝑥2 + 𝑢

1 (26)

− 𝑒 − 𝐿

𝐿 𝐿

In this equation x is two dimensional vector

𝑥1

x= 𝑥

2 Fig 19 Simulink output of sliding mode controller

Where 7. D.C. SERVO MOTOR PARAMETER

𝑥1 = angular velocity of shaft.

𝑥2 = armature current. The motor used in this experiment is a 25V D.C. motor

u is the armature voltage. with no load speed of 4050 rpm

R= resistance of armature coil. R-resistance 1 Ω

L= inductance of the armature coil. L-inductance 29.79 mH

𝑘𝑒 = velocity constant.

𝑘𝑚 = torque constant. J-moment of inertia 0.01 kg.m2

Kt -torque constant 0.052 Nm/A

By using the Laplace transform of (26), the transfer Kb-electromotive force constant 0.1 V/rad/s

functions of system according to angular speed of shaft (𝜔 B-viscous friction coefficient 0.004 N.m/rad/s

(s) ) and armature voltage (U(s)) can be calculated

8. CONCLUSION

Take 𝜃 (s)= 𝜔 (s) and 𝐸𝑎 (𝑠)=U(s) from motor model we

have For the speed control of dcservo motor drives, it is

𝜔 (𝑠) 𝑘𝑚 observed that Sliding mode controller gives a better

= ( 𝐿𝑠+𝑅 𝐽𝑠 +𝐵 +𝑘 𝑘 ) response compared than other controllers.

𝑈(𝑠) 𝑒 𝑚

Therefore the state space model is REFERENCES

𝑥1 0 1 𝑥1 𝑘0

= + 𝑚 𝑢 (27) [1] “SIMULINK User's Guide”, The Math Works Inc. 1992.

𝑥2 𝐴1 𝐴2 𝑥2 𝐽𝐿

[2] E.H. Mamdani, “Application of Fuzzy Algorithm for Control of

Simple Dynamic Plant”, Proc. IEE121 (12), pp.1585-1588, 1974.

(𝑅𝑏 +𝑘 𝑒 𝑘 𝑚 ) [3] V M Venkateswara Rao , “Performance Analysis Of Speed Control

Where 𝐴1 = - 𝐽𝐿

(28) Of Dc Motor Using P, PI, PD And PID Controllers” International

Journal of Engineering Research & Technology (IJERT) Vol. 2

𝑏 𝑅 Issue 5, May - 2013 ISSN: 2278-0181.

𝐴2 = -( + ) (29) [4] Gopal K. Dubey, “Fundamental of electrical Drives”, Narosa

𝐽 𝐿

Publication 2009.

[5] Stephen, J.2005, "Electric Machinery Fundamentals", Hand Book,

The methodology to design switching function is Fourth Edition, McGraw Hill, Higher Education, Australia.

U=-𝑠2 [𝐴1 𝜔- 𝐴1 ( 𝜔-r) +𝑠2 (𝐴1 +𝐴2 𝜆 - 𝜆2 ) [6] Khuntia, K.B. Mohanty, S. Panda and C. Ardil, “A Comparative

(𝜔-r) + (𝐴2 - 𝜆) 𝜎 +𝑘𝑠 sgn(𝜎)+ 𝑘𝑝 𝜎] Study of P-I, I-P, Fuzzy and Neuro-Fuzzy Controllers for Speed

Control of DC Motor Drive”, International Journal of Electrical and

U=1/174.5((33.97 e(t))-(c-30.8)e(t)+k sign(s) Computer.

[7] I. H. Altas and A .M. Sharaf, “A Generalized Direct Approach for

Designing Fuzzy Logic Controllers in Matlab/ Simulink GUI

environment”, International Journal of Information Technology

and Intelligent Computing, Int.J. IT&IC no.4 vol.1, 2007.

Fig 18 Simulink Model of D.C. Servo Motor using sliding

mode controller

Copyright to IARJSET DOI 10.17148/IARJSET.2016.31129 156

You might also like

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- A PID Controlled Real Time Analysis of DC MotorDocument9 pagesA PID Controlled Real Time Analysis of DC MotorBharath PulavarthiNo ratings yet

- IISTE Journals Publication Nearest EditiDocument8 pagesIISTE Journals Publication Nearest EditiNguyễn Hải ĐăngNo ratings yet

- A Football Kicking High Speed Actuator For A Mobile Robotic ApplicationDocument7 pagesA Football Kicking High Speed Actuator For A Mobile Robotic ApplicationMuhammad FadhilNo ratings yet

- Voltage Vectors of Matrix Converters For Torque Ripple Reduction in Direct Torque Control of Induction MachinesDocument8 pagesVoltage Vectors of Matrix Converters For Torque Ripple Reduction in Direct Torque Control of Induction MachinesKatta VenkateshNo ratings yet

- Motor Speed Control Using FPGA: July 2014Document5 pagesMotor Speed Control Using FPGA: July 2014Jaime SaenzNo ratings yet

- EnhancDocument7 pagesEnhancsofNo ratings yet

- Servo Motor Driver Design For High Performance Applications: "' - (L L) I - L IDocument6 pagesServo Motor Driver Design For High Performance Applications: "' - (L L) I - L ISHADES 4 ALLNo ratings yet

- Performance Analysis of Direct Torque Control of 3-Phase Induction MotorDocument6 pagesPerformance Analysis of Direct Torque Control of 3-Phase Induction MotormaheswaranNo ratings yet

- Comparative Analysis of Speed Control Techniques of DC Motors With MatlabDocument4 pagesComparative Analysis of Speed Control Techniques of DC Motors With Matlabsrinureddy2014No ratings yet

- Artículo Base de DatosDocument6 pagesArtículo Base de DatosJuan Sebas Causil Causil RamirezNo ratings yet

- Speed Control of DC Motor Using PID Controller For Industrial ApplicationDocument4 pagesSpeed Control of DC Motor Using PID Controller For Industrial ApplicationEditor IJTSRDNo ratings yet

- Effect of harmonics on asynchronous machinesDocument7 pagesEffect of harmonics on asynchronous machinespayalNo ratings yet

- Comparison of DC Motor Speed Control Using Fuzzy Logic and MPCDocument5 pagesComparison of DC Motor Speed Control Using Fuzzy Logic and MPCraghav4life8724No ratings yet

- Speed Control of BLDC Motor Using PID Controller: I J A R E E I EDocument5 pagesSpeed Control of BLDC Motor Using PID Controller: I J A R E E I EAhmed ShoeebNo ratings yet

- PID Controller Design for DC-DC Converter CircuitsDocument6 pagesPID Controller Design for DC-DC Converter CircuitsannaNo ratings yet

- B4e2 PDFDocument13 pagesB4e2 PDFعلي كامل الاسديNo ratings yet

- Design of Rotation Monitor and Simulation Design To Record The Variation of Frequency Effect On ALFC LoopDocument8 pagesDesign of Rotation Monitor and Simulation Design To Record The Variation of Frequency Effect On ALFC LoopIJRASETPublicationsNo ratings yet

- Control of SRM Using 3-Level Neutral Point Diode Clamped Converter With PI and Fuzzy ControllerDocument7 pagesControl of SRM Using 3-Level Neutral Point Diode Clamped Converter With PI and Fuzzy ControllerHarsha VardhanNo ratings yet

- RT-Lab Based Real-Time Simulation of A Direct Field-Oriented Controller For An Induction MotorDocument6 pagesRT-Lab Based Real-Time Simulation of A Direct Field-Oriented Controller For An Induction MotorMagpie 2023No ratings yet

- 2015.11 - Speed Control of A Three Phase Induction Motor Using Field Oriented ControlDocument9 pages2015.11 - Speed Control of A Three Phase Induction Motor Using Field Oriented ControlamrrefkyNo ratings yet

- Research Paper On DC MachinesDocument5 pagesResearch Paper On DC Machinesfyr5efrr100% (1)

- Improving Power Factors by Using Landsman Converter in PMBLDC MotorDocument5 pagesImproving Power Factors by Using Landsman Converter in PMBLDC MotorVIVA-TECH IJRINo ratings yet

- Performance Comparison of Conventional Controller With Fuzzy Logic Controller Using Chopper Circuit and Fuzzy Tuned PID ControllerDocument12 pagesPerformance Comparison of Conventional Controller With Fuzzy Logic Controller Using Chopper Circuit and Fuzzy Tuned PID ControllerranaNo ratings yet

- Speed and Position Control of DC Motor Using LabVIEW-IJRASETDocument8 pagesSpeed and Position Control of DC Motor Using LabVIEW-IJRASETIJRASETPublicationsNo ratings yet

- Design and Implementation of Flux Vector PDFDocument15 pagesDesign and Implementation of Flux Vector PDFBelal AshrafNo ratings yet

- Field Oriented Control of Permanent Magnet PDFDocument8 pagesField Oriented Control of Permanent Magnet PDFLê Đức ThịnhNo ratings yet

- Irjet V4i8388Document12 pagesIrjet V4i8388Vijetha KNo ratings yet

- A KC Vector ControlDocument25 pagesA KC Vector ControljdiazcuNo ratings yet

- Comparative Study Between Pid and Fuzzy Pid Controller For Speed Control of BLDC Motor IJERTV7IS050098Document6 pagesComparative Study Between Pid and Fuzzy Pid Controller For Speed Control of BLDC Motor IJERTV7IS050098DIVYA PRASOONA CNo ratings yet

- Application of Fuzzy Logic To The Speed Control of DC MotorDocument6 pagesApplication of Fuzzy Logic To The Speed Control of DC MotorHemanth SaiNo ratings yet

- DC Motor Speed Control Using Fuzzy Logic Controller: Articles You May Be Interested inDocument7 pagesDC Motor Speed Control Using Fuzzy Logic Controller: Articles You May Be Interested inWai ChiNo ratings yet

- Small Signal Stability Analysis of Multi Machine Power Systems Interfaced With Micro Grid IJERTV3IS080275Document8 pagesSmall Signal Stability Analysis of Multi Machine Power Systems Interfaced With Micro Grid IJERTV3IS080275Emílio CamargoNo ratings yet

- Digital Signal Processing Based Speed Control of Induction Motor Drive SystemDocument5 pagesDigital Signal Processing Based Speed Control of Induction Motor Drive SystemramjiNo ratings yet

- Ecuaciones para Curva de Conductores y MotoresDocument6 pagesEcuaciones para Curva de Conductores y MotoresCarlos Lovera Rodriguez100% (1)

- Paris, FranceICSTEM (2019)Document6 pagesParis, FranceICSTEM (2019)Dr. D. V. KamathNo ratings yet

- Motor DC Control System Using PID ControllerDocument4 pagesMotor DC Control System Using PID ControllerenrikeNo ratings yet

- Induction Motor Protection Using PLCDocument5 pagesInduction Motor Protection Using PLCVIVA-TECH IJRINo ratings yet

- ANN-Based DTC Speed Control of Induction MotorDocument6 pagesANN-Based DTC Speed Control of Induction MotormazenNo ratings yet

- Solid State TransformerDocument5 pagesSolid State TransformerVIVA-TECH IJRINo ratings yet

- BLDC Driver PDFDocument10 pagesBLDC Driver PDFtarnaNo ratings yet

- Design and Implementation Speed Control System of PDFDocument8 pagesDesign and Implementation Speed Control System of PDFvince kafuaNo ratings yet

- Advanced Optimal GWO-PID Controller For DC MotorDocument14 pagesAdvanced Optimal GWO-PID Controller For DC MotorInternational Journal of Advances in Applied Sciences (IJAAS)No ratings yet

- Jsaer2014 01 02 55 63Document9 pagesJsaer2014 01 02 55 63jsaereditorNo ratings yet

- Integrated Motor DrivesDocument10 pagesIntegrated Motor DrivesRaiyan TarekNo ratings yet

- Induction Motor ControlDocument4 pagesInduction Motor ControlJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- 4 PBDocument8 pages4 PBs.mencouNo ratings yet

- Current-Source Converter and Cycloconverter Topologies For Industrial Medium-Voltage DrivesDocument12 pagesCurrent-Source Converter and Cycloconverter Topologies For Industrial Medium-Voltage DrivesAnonymous hzXy93FAENo ratings yet

- Design, Implementation and Test Results of A Robust Control Method For A Powered Ankle Foot Orthosis (AFO)Document6 pagesDesign, Implementation and Test Results of A Robust Control Method For A Powered Ankle Foot Orthosis (AFO)jose diazNo ratings yet

- IPACT178 PID4686151 Digital Applicationfor Grouning Grid Design Calculationsof SubstationDocument7 pagesIPACT178 PID4686151 Digital Applicationfor Grouning Grid Design Calculationsof SubstationJoule BarkNo ratings yet

- Back-EMF Sensorless Control Algorithm For High Dynamics Performances PMSMDocument9 pagesBack-EMF Sensorless Control Algorithm For High Dynamics Performances PMSMSaranji GuruNo ratings yet

- Ga Speed and DQ Currnets Control of PMSM WithDocument9 pagesGa Speed and DQ Currnets Control of PMSM Withhieuhuech1No ratings yet

- Improving wind power generation with fuzzy logicDocument5 pagesImproving wind power generation with fuzzy logicR.SRIKANTHNo ratings yet

- LAMDAMAP99030FUDocument9 pagesLAMDAMAP99030FUSujal jadhavNo ratings yet

- Experiment On Servo Positioning ControlDocument9 pagesExperiment On Servo Positioning ControlPinaki SankarNo ratings yet

- Design of Electric VehicleDocument13 pagesDesign of Electric VehicleIJAERS JOURNALNo ratings yet

- Simulation DC Motor Speed Control System by Using PID ControllerDocument6 pagesSimulation DC Motor Speed Control System by Using PID ControllerEditor IJTSRDNo ratings yet

- Thermal Analysis of Induction and Synchronous Reluctance MotorsDocument6 pagesThermal Analysis of Induction and Synchronous Reluctance MotorsShraddha kaleNo ratings yet

- Voltage Amplification, Trail Cable Length & Power ShovelsDocument9 pagesVoltage Amplification, Trail Cable Length & Power ShovelsMaikPortnoyNo ratings yet

- Excitation System of Alternator IJERTV2IS2515Document6 pagesExcitation System of Alternator IJERTV2IS2515MangeshRudrawar100% (1)

- Chapter 1 - Introduction To Differential EquationsDocument16 pagesChapter 1 - Introduction To Differential EquationsnawidwardakNo ratings yet

- Mapua Institute of Technology: Field Work 1 Pacing On Level GroundDocument7 pagesMapua Institute of Technology: Field Work 1 Pacing On Level GroundIan Ag-aDoctorNo ratings yet

- 1 s2.0 0304885395011137 MainDocument2 pages1 s2.0 0304885395011137 MainAyush VermaNo ratings yet

- Design Guide Handbook For EN 1996 Design of Masonry StructuresDocument46 pagesDesign Guide Handbook For EN 1996 Design of Masonry Structuresbusyspider100% (1)

- TFA 1 2 3 4 5 6 7 8 9 10 in Nozzles Sizes: OptionDocument1 pageTFA 1 2 3 4 5 6 7 8 9 10 in Nozzles Sizes: OptionrajkumarfNo ratings yet

- Ewald SphereDocument57 pagesEwald SphereMohammad Rameez0% (1)

- Inverse Time Characteristics RelaysDocument1 pageInverse Time Characteristics Relayssuperthambi100% (1)

- ASTM STP1385 Durability 2000 Accelerated and Outdoor Weathering TestingDocument186 pagesASTM STP1385 Durability 2000 Accelerated and Outdoor Weathering TestingKYAW SOENo ratings yet

- Measuring Planck's Constant with LEDsDocument7 pagesMeasuring Planck's Constant with LEDsAngy100% (1)

- CNC CONTOUR VALIDATION WITH LASER BALL BARDocument15 pagesCNC CONTOUR VALIDATION WITH LASER BALL BARNitin DaduNo ratings yet

- Ad 7746Document28 pagesAd 7746pskorovsNo ratings yet

- Biological Materials Structure and PropertiesDocument206 pagesBiological Materials Structure and PropertiesDulce Job BenitezNo ratings yet

- Assignment MetrologyDocument8 pagesAssignment MetrologyPratama sudibyo0% (1)

- Spectrophotometric Determination of The Equilibrium Constant of A ReactionDocument5 pagesSpectrophotometric Determination of The Equilibrium Constant of A Reactionnarras11100% (1)

- Chapter 2 1 - Linear EquationsDocument23 pagesChapter 2 1 - Linear Equationsapi-263209117No ratings yet

- The Weighted Histogram Analysis Method (WHAM) : Michael AndrecDocument14 pagesThe Weighted Histogram Analysis Method (WHAM) : Michael AndrecWilliam AgudeloNo ratings yet

- Atomic Structure and Fundamental ParticlesDocument32 pagesAtomic Structure and Fundamental ParticleshumayunbashaNo ratings yet

- Virtual Work 3rd Year Structural EngineeringDocument129 pagesVirtual Work 3rd Year Structural EngineeringStefano Martin PorciunculaNo ratings yet

- Lecture2 Semiconductor StatisticsDocument13 pagesLecture2 Semiconductor StatisticsRakib KhanNo ratings yet

- Metodo Epa 18Document40 pagesMetodo Epa 18Luis TrejoNo ratings yet

- How Does DCPIP WorkDocument3 pagesHow Does DCPIP WorkIsaac LeeNo ratings yet

- Extrusion Press PDFDocument2 pagesExtrusion Press PDFRobert25% (4)

- SOAL ElmesDocument16 pagesSOAL ElmesNurul HanifahNo ratings yet

- Human at Mars PDFDocument55 pagesHuman at Mars PDFVuningoma BoscoNo ratings yet

- Handbook5 PDFDocument257 pagesHandbook5 PDFZAKROUNNo ratings yet

- How To Design R.C. Flat Slabs Using Finite Element AnalysisDocument16 pagesHow To Design R.C. Flat Slabs Using Finite Element Analysisocenkt100% (10)

- Design and Analysis of G+8 Commercial Building Using Staad ProDocument8 pagesDesign and Analysis of G+8 Commercial Building Using Staad ProVikaskumar ReddyNo ratings yet

- 4th International Conference On Thermal Equipment, Renewable Energy and Rural Development PDFDocument500 pages4th International Conference On Thermal Equipment, Renewable Energy and Rural Development PDFMittapalli SaikiranNo ratings yet

- AAS 6300 Service ManualDocument76 pagesAAS 6300 Service Manualfuadye100% (1)

- Notes Singly RF BeamDocument5 pagesNotes Singly RF Beamshivaji_sarvadeNo ratings yet

- Generative AI: The Insights You Need from Harvard Business ReviewFrom EverandGenerative AI: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (2)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldFrom EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldRating: 4.5 out of 5 stars4.5/5 (54)

- Who's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesFrom EverandWho's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesRating: 4.5 out of 5 stars4.5/5 (12)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- AI Money Machine: Unlock the Secrets to Making Money Online with AIFrom EverandAI Money Machine: Unlock the Secrets to Making Money Online with AINo ratings yet

- Artificial Intelligence: A Guide for Thinking HumansFrom EverandArtificial Intelligence: A Guide for Thinking HumansRating: 4.5 out of 5 stars4.5/5 (30)

- How to Make Money Online Using ChatGPT Prompts: Secrets Revealed for Unlocking Hidden Opportunities. Earn Full-Time Income Using ChatGPT with the Untold Potential of Conversational AI.From EverandHow to Make Money Online Using ChatGPT Prompts: Secrets Revealed for Unlocking Hidden Opportunities. Earn Full-Time Income Using ChatGPT with the Untold Potential of Conversational AI.No ratings yet

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessFrom EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNo ratings yet

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldFrom EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldRating: 4.5 out of 5 stars4.5/5 (107)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewFrom EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (104)

- Power and Prediction: The Disruptive Economics of Artificial IntelligenceFrom EverandPower and Prediction: The Disruptive Economics of Artificial IntelligenceRating: 4.5 out of 5 stars4.5/5 (38)

- 2084: Artificial Intelligence and the Future of HumanityFrom Everand2084: Artificial Intelligence and the Future of HumanityRating: 4 out of 5 stars4/5 (81)

- The Emperor's New Mind: Concerning Computers, Minds, and the Laws of PhysicsFrom EverandThe Emperor's New Mind: Concerning Computers, Minds, and the Laws of PhysicsRating: 3.5 out of 5 stars3.5/5 (403)

- AI and Machine Learning for Coders: A Programmer's Guide to Artificial IntelligenceFrom EverandAI and Machine Learning for Coders: A Programmer's Guide to Artificial IntelligenceRating: 4 out of 5 stars4/5 (2)

- 100+ Amazing AI Image Prompts: Expertly Crafted Midjourney AI Art Generation ExamplesFrom Everand100+ Amazing AI Image Prompts: Expertly Crafted Midjourney AI Art Generation ExamplesNo ratings yet

- Mastering Large Language Models: Advanced techniques, applications, cutting-edge methods, and top LLMs (English Edition)From EverandMastering Large Language Models: Advanced techniques, applications, cutting-edge methods, and top LLMs (English Edition)No ratings yet

- The Digital Mindset: What It Really Takes to Thrive in the Age of Data, Algorithms, and AIFrom EverandThe Digital Mindset: What It Really Takes to Thrive in the Age of Data, Algorithms, and AIRating: 3.5 out of 5 stars3.5/5 (7)

- Killer ChatGPT Prompts: Harness the Power of AI for Success and ProfitFrom EverandKiller ChatGPT Prompts: Harness the Power of AI for Success and ProfitRating: 2 out of 5 stars2/5 (1)

- ChatGPT for Business the Best Artificial Intelligence Applications, Marketing and Tools to Boost Your IncomeFrom EverandChatGPT for Business the Best Artificial Intelligence Applications, Marketing and Tools to Boost Your IncomeNo ratings yet

- System Design Interview: 300 Questions And Answers: Prepare And PassFrom EverandSystem Design Interview: 300 Questions And Answers: Prepare And PassNo ratings yet