Professional Documents

Culture Documents

ASCO Solenoid Valves Serie SCB316

Uploaded by

katja kafkaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASCO Solenoid Valves Serie SCB316

Uploaded by

katja kafkaCopyright:

Available Formats

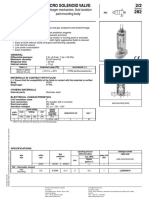

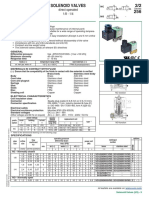

SOLENOID VALVES NC

A

3/2

Series

pilot operated, high flow

floating diaphragms

E P

316

3/8 to 1 NO

FEATURES

• Brass bodied high flow valves with two floating diaphragms for larger single ac-

tuators

• The solenoid valves vent to 0 bar

• Direct lift pilot operators have a resilient soft seating to control the floating

diaphragms and to ensure absolute tight shut-off

• The solenoid valves satisfy all relevant EU Directives

GENERAL

Differential pressure See «SPECIFICATIONS» [1 bar =100 kPa]

Maximum viscosity 65 cSt (mm2/s)

Response time 40 - 120 ms

fluids () temperature range (TS) seal materials ()

air, inert gas, water - 20°C to + 80°C NBR (nitrile)

MATERIALS IN CONTACT WITH FLUID

() Ensure that the compatibility of the fluids in contact with the materials is verified

Body Brass

Core tube Stainless steel

Core and plugnut Stainless steel

Core spring Stainless steel

Seat Brass

Seat insert POM

Seals & discs NBR

Diaphragms NBR

Disc holder

Shading coil

ELECTRICAL CHARACTERISTICS

POM

Copper E

Coil insulation class F NC function

Connector Spade plug (cable Ø 6-10 mm)

Connector specification ISO 4400 / EN 175301-803, form A

Electrical safety IEC 335

Electrical enclosure protection Moulded IP65 (EN 60529)

Standard voltages DC (=) : 24V - 48V

(Other voltages and 60 Hz on request) AC (~) : 24V - 48V - 115V - 230V / 50 Hz

power ratings operator

ambient replacement coil

prefix inrush holding hot/cold temperature type (1)

option ~ ~ = range (TS) ~ =

(VA) (VA) (W) (W) (C°) 230 V/50 Hz 24 V DC

34 15,6 6 7 / 9,7 -20 to + 75 400325-117 400325-142 01

SC 78 35 16,7 - -20 to + 50 400425-217 - 02 NO function

- - - 12/16,8 -20 to + 75 - 400625-142 03

Refer to the dimensional drawings on the following page.

(1)

SPECIFICATIONS

Availability, design and specifications are subject to change without notice. All rights reserved.

operating pressure options

flow differential (bar) catalogue

pipe orifice power coil

coefficient number

size size (W)

man. operator

max. (PS)

Kv

maintained

EPDM

min. air () water ()

PTFE

FPM

CR

NPT (mm) (m3/h) (l/min) ~ = ~ = ~ = ~/=

NC - Normally closed

8,5 8,5 8,5 8,5 - - 6 9,7 SCB316A054 MO V E - -

3/8 16 2 33,3 0,7

17 17 17 17 - - 16,7 16,8 SCB316D014 MO V E - -

8,5 8,5 8,5 8,5 - - 6 9,7 SCB316A064 MO V E J -

1/2 16 2,8 46,6 0,7

17 17 17 17 - - 16,7 16,8 SCB316D024 MO V E - -

8,5 8,5 8,5 8,5 - - 6 9,7 SCB316B074 MO V E - -

3/4 18 4,2 70 0,7

17 17 17 17 - - 16,7 16,8 SCB316E044 MO V E J -

1 25 11,3 188,3 0,7 8,5 8,5 8,5 8,5 - - 6 9,7 SCB316E034 MO V E - -

NO - Normally open

8,5 8,5 8,5 8,5 - - 6 9,7 SCB316A056 MO V E - -

3/8 16 2 33,3 0,7

17 17 17 17 - - 16,7 16,8 SCB316D016 MO V E - -

8,5 8,5 8,5 8,5 - - 6 9,7 SCB316A066 MO V E - -

1/2 16 2,8 46,6 0,7

17 17 17 17 - - 16,7 16,8 SCB316D026 MO V E - -

00081GB-2016/R01

8,5 8,5 8,5 8,5 - - 6 9,7 SCB316B076 MO V E - -

3/4 18 4,2 70 0,7

17 17 17 17 - - 16,7 16,8 SCB316E046 MO V E - -

1 25 11,3 188,3 0,7 8,5 8,5 8,5 8,5 - - 6 9,7 SCB316E036 MO V E - -

All leaflets are available on: www.asco.com

V620-1

SOLENOID VALVES SERIES 316

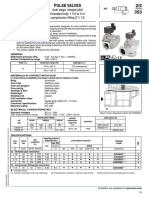

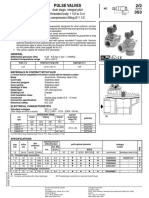

OPTIONS

• Valves can also be supplied with FPM (fluoroelastomer), EPDM (ethylene-propylene), CR (chloroprene) and PTFE seals and

discs. Use the appropriate optional suffix letter for identification

• Waterproof enclosure with embedded screw terminal coil according to protection class IP67, CEE-10

• Explosionproof enclosures for use in zones 1/21-2/22, categories 2-3 to ATEX Directive 2014/34/EU (see “Explosionproof solenoids” section)

• Electrical enclosures according to “NEMA” standards are available

• Compliance with “UL”, “CSA” and other local approvals available on request

• Mounting brackets for brass body valves, suffix MB

• Other pipe connections are available on request

• Plug with visual indication and peak voltage suppression or with cable length of 2 m (see Solenoids, Coils & Accessories section)

INSTALLATION

• The solenoid valves can be mounted in any position without affecting operation

• Pipe connection identifier is B = NPT (ANSI 1.20.3)

• Installation/maintenance instructions are included with each valve

SPARE PARTS KIT & ACCESSORIES ORDERING EXAMPLES:

spare parts kit no. mounting SC B 316 A 064 230V / 50 Hz

catalogue number

~ = bracket no. SC B 316 A 064 MO 115V / 50 Hz

SCB316A054/A064/B074 C314491 C314540 038713-000 SC B 316 D 016 V 24V / DC

SCB316D014/D024/E044 C314495 C314550 038713-000 SC B 316 E 046 230V / 50 Hz

SCB316E034 C302661 C302681 - prefix

SCB316E036 C302671 C302691 - pipe thread voltage

SCB316A056/A066/B076 C314492 C314494 038713-000 basic number suffix

SCB316D016/D026/E046 C314496 C314551 038713-000

(1)

Standard prefixes/suffixes are also applicable to kits. ORDERING EXAMPLES KITS:

- Not available

C314491(1)

C314540 V

C314492 E

basic number suffix

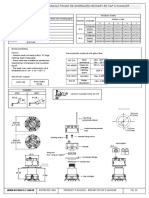

DIMENSIONS (mm), WEIGHT (kg)

TYPE 01-02-03 TYPE 01

Prefix “SC” Solenoid Prefix “SC” Solenoid

Epoxy moulded Epoxy moulded

IEC 335 / ISO 4400 IEC 335 / ISO 4400

IP65 IP65

TYPE 01: B316A054/A064/A056/A066 TYPE 01: B316B074/B076 SCB316E034/E036

TYPE 02/03: B316D014/D024/D016/D026 TYPE 02/03: B316E044/E046

A F A F

A F

B B

C B

C

C

360˚

360˚

360˚

J J

L J

L

K

Availability, design and specifications are subject to change without notice. All rights reserved.

K

KL

M

E M A

M

A P

E

D G D P D G

G

E H E H E H

73 17,5 51,5

97

17,5

21

Ø 7,1

42

42

66

21

Ø 7,1

42

123

prefix catalogue weight

type A B C D E F G H J K L M

option number (2)

SCB316A054/A056/B064/B066 75 45 27 69.5 110 39 35 70 100 130 140 85 1,6

01 SC SCB316B074/B076 75 45 27 48 84 39 31 86 110 152 169 107 4,4

SCB316E034/E036 75 45 27 90 136 39 41 113 116 168 185 123 3,4

00081GB-2016/R01

SCB316D014/D016/D024/D026 (~) 80 50 30 69.5 110 45 35 70 104 134 144 85 2,7

02 SC

SCB316E044/E046 (~) 80 50 30 48 84 45 31 86 114 156 173 107 4,4

SCB316D014/D016/D024/D026 (=) 86 56 33 69.5 110 50 35 70 111 141 151 84 2;6

03 SC

SCB316E044/E046 (=) 86 56 33 48 84 50 31 86 121 163 163 106 4,4

Incl. coil(s) and connector(s).

(2)

All leaflets are available on: www.asco.com

620-2

You might also like

- Solenoid Valves Pilot Operated 2/2 Series NCDocument2 pagesSolenoid Valves Pilot Operated 2/2 Series NCKhyle Laurenz DuroNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFDocument2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFKhyle Laurenz DuroNo ratings yet

- B 81417 EfaDocument2 pagesB 81417 EfaIshak EnginerNo ratings yet

- European Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Document2 pagesEuropean Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Farhan HirsanNo ratings yet

- SCG238 Series PDFDocument2 pagesSCG238 Series PDFrika monikaNo ratings yet

- Solenoid Valves-2 - 2-Stainless Steel body-238-CAT-01017GBDocument2 pagesSolenoid Valves-2 - 2-Stainless Steel body-238-CAT-01017GBtreborNo ratings yet

- Direct Operated 2/2 NC Solenoid Valve FeaturesDocument2 pagesDirect Operated 2/2 NC Solenoid Valve Featuresvineeth8624No ratings yet

- Solenoid valves control hot and cold waterDocument2 pagesSolenoid valves control hot and cold waterMehrzadNo ratings yet

- European Catalog Solenoid Valves Aluminum Body Series 215 Asco en 4902058Document4 pagesEuropean Catalog Solenoid Valves Aluminum Body Series 215 Asco en 4902058Roger Gustavo Gutierrez HuanquiriNo ratings yet

- Proportional Solenoid Valve Posiflow 2/2 203: Pilot Operated 3/8 - 1/2Document2 pagesProportional Solenoid Valve Posiflow 2/2 203: Pilot Operated 3/8 - 1/2Priya KaleNo ratings yet

- Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesPressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2влад камрNo ratings yet

- Catalog Series 210 Hung Diaphragm Asco Emea Ap en 5084892Document3 pagesCatalog Series 210 Hung Diaphragm Asco Emea Ap en 5084892raobenNo ratings yet

- 222LT Cryogenic Solenoid ValvesDocument2 pages222LT Cryogenic Solenoid ValvesRachiahi TarikNo ratings yet

- Series E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Document4 pagesSeries E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Carlos Enrique De Gumucio VargasNo ratings yet

- Asco E398a005Document2 pagesAsco E398a005ersanjeeb_456No ratings yet

- Solenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2Document4 pagesSolenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2AlexanderNo ratings yet

- Solenoid Valves 2/2 272: Direct Operated 1/4Document2 pagesSolenoid Valves 2/2 272: Direct Operated 1/4Rafael GustavoNo ratings yet

- Solenoid Valve SCE272ADocument2 pagesSolenoid Valve SCE272AVictor Ruiz FuentesNo ratings yet

- Válvulas Neumáticas-Asco NumaticsDocument4 pagesVálvulas Neumáticas-Asco NumaticsSamuel PlasenciaNo ratings yet

- ASCO Solenoid ValvesDocument2 pagesASCO Solenoid Valvesjmathew_984887No ratings yet

- Motorised control valve digital flow regulationDocument2 pagesMotorised control valve digital flow regulationBuddhikaNo ratings yet

- Valvula Solenoide Serie 121 AscoDocument2 pagesValvula Solenoide Serie 121 AscoBase SistemasNo ratings yet

- Solenoid Valves 2 - 2 Stainless Steel Body 262 CAT 00032GBDocument2 pagesSolenoid Valves 2 - 2 Stainless Steel Body 262 CAT 00032GBmohsenNo ratings yet

- ASCO Series 290 390 - ASCO Pressure Operated Solenoid Pilot Valves G1-8 1Document2 pagesASCO Series 290 390 - ASCO Pressure Operated Solenoid Pilot Valves G1-8 1Lassané KINDONo ratings yet

- Diaphragm Mechanism, Fluid Isolation Pad-Mounting BodyDocument2 pagesDiaphragm Mechanism, Fluid Isolation Pad-Mounting BodyErick SantosNo ratings yet

- Solenoid pilot valves optimize pneumatic controlDocument2 pagesSolenoid pilot valves optimize pneumatic controlBalotileNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated, Hung Diaphragm For Vacuum Service 3/8 To 3/4Document2 pagesSolenoid Valves 2/2 210: Pilot Operated, Hung Diaphragm For Vacuum Service 3/8 To 3/4Evgeny DedashkoNo ratings yet

- European Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Document2 pagesEuropean Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Julio César Herrera MontoyaNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated Hung Diaphragm 3/8 To 1 1/2Document2 pagesSolenoid Valves 2/2 210: Pilot Operated Hung Diaphragm 3/8 To 1 1/2Samuel ZabalaNo ratings yet

- Solenoid Valves-Dust Collector-353-CAT-60059GBDocument2 pagesSolenoid Valves-Dust Collector-353-CAT-60059GBangelosNo ratings yet

- Features: NC FunctionDocument4 pagesFeatures: NC FunctionSachin MoreNo ratings yet

- Valvula Asiento Inclinado Serie E290 AscoDocument3 pagesValvula Asiento Inclinado Serie E290 AscoBase SistemasNo ratings yet

- ASCO Series 353-2-2 Pulse Valves Single Stage 4Document2 pagesASCO Series 353-2-2 Pulse Valves Single Stage 4Peter UhuleNo ratings yet

- Pilot Operated Hung Diaphragm 3/8 To 1 1/2Document2 pagesPilot Operated Hung Diaphragm 3/8 To 1 1/2Yasir MehmoodNo ratings yet

- Solenoid valves NC series pilot operated hung diaphragmDocument2 pagesSolenoid valves NC series pilot operated hung diaphragmmadesh mNo ratings yet

- Solenoid Valves for High Pressure FluidsDocument10 pagesSolenoid Valves for High Pressure FluidssrushtiNo ratings yet

- Series S290 - ASCO Pressure Operated Clamp or Butt WeldingDocument4 pagesSeries S290 - ASCO Pressure Operated Clamp or Butt WeldingKevin Mero ConstantinoNo ratings yet

- Covna Valvulas Solenoides Corto PDFDocument28 pagesCovna Valvulas Solenoides Corto PDFECOSUPPLY S.A.No ratings yet

- Oseco Elfab BioPharmaceuticalDocument3 pagesOseco Elfab BioPharmaceuticalAdverNo ratings yet

- AFS DDocument1 pageAFS DGonzalo AlvarezNo ratings yet

- ASCO Series 353 2-2 Pules Valves Dual StageDocument2 pagesASCO Series 353 2-2 Pules Valves Dual StageAdnan AliNo ratings yet

- FM638 & FM639: Fully Lugged Butterfly Valve PN25Document1 pageFM638 & FM639: Fully Lugged Butterfly Valve PN25RonaldNo ratings yet

- Power Pulse Valves PDFDocument12 pagesPower Pulse Valves PDFUrip S. SetyadjiNo ratings yet

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Document16 pagesIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Kishor JadhavNo ratings yet

- Power Pulse Valves S353A720+730+Document2 pagesPower Pulse Valves S353A720+730+Victor Ruiz FuentesNo ratings yet

- DBB Series: Double-Block-and-Bleed Diaphragm ValvesDocument10 pagesDBB Series: Double-Block-and-Bleed Diaphragm ValvesThai VoNo ratings yet

- European Catalog Single Stage Pulse Valves Series 353 Asco en 7028704Document2 pagesEuropean Catalog Single Stage Pulse Valves Series 353 Asco en 7028704AirteamNo ratings yet

- Series 320Document6 pagesSeries 320Prathamesh GangalNo ratings yet

- Asc0 327Document6 pagesAsc0 327rizky efrinaldoNo ratings yet

- Page 9 V-2307197-K2 JHR01 DC 33kVDocument1 pagePage 9 V-2307197-K2 JHR01 DC 33kVHanitha (Digital & Technology)No ratings yet

- GEMS bilge water level switches provide reliable operation in contaminated liquidsDocument1 pageGEMS bilge water level switches provide reliable operation in contaminated liquidsAhmed EmamNo ratings yet

- DS2000 Threaded EU EN 21 PDFDocument11 pagesDS2000 Threaded EU EN 21 PDFDucSyHoNo ratings yet

- Asco 314Document2 pagesAsco 314Aziz SaputraNo ratings yet

- 2000 Threaded Port Angle-Seat Valve Technical SpecificationsDocument9 pages2000 Threaded Port Angle-Seat Valve Technical SpecificationsKuni KazeNo ratings yet

- 01 - Single Phase - Bil 200 KV - Polyamide Cap - l63,5 - enDocument1 page01 - Single Phase - Bil 200 KV - Polyamide Cap - l63,5 - enoreinoso2009No ratings yet

- Total View Industrial Flowmeters: View Flow Rate From 360°, Water or Air RangesDocument1 pageTotal View Industrial Flowmeters: View Flow Rate From 360°, Water or Air Rangespk cfctkNo ratings yet

- Asco Valves Series T298Document2 pagesAsco Valves Series T298OceanexNo ratings yet

- Pneumatic Rotary Actuators GuideDocument2 pagesPneumatic Rotary Actuators Guidejonobel567No ratings yet

- CB40Document1 pageCB40René Antonio Gonzalez TorresNo ratings yet

- Cat ST pcs7 11-2007 enDocument344 pagesCat ST pcs7 11-2007 enShashi ShekarNo ratings yet

- en SITRANS LVL200E Pressure Range 1... 64 BarDocument16 pagesen SITRANS LVL200E Pressure Range 1... 64 Barkatja kafkaNo ratings yet

- EhDocument130 pagesEhkatja kafkaNo ratings yet

- Hopf Elektronik GMBH - GPS and DCF77 Based Industrial Radio Controlled ClockDocument10 pagesHopf Elektronik GMBH - GPS and DCF77 Based Industrial Radio Controlled Clockkatja kafkaNo ratings yet

- Hopf 6870 - 1101Document58 pagesHopf 6870 - 1101macakafkaNo ratings yet

- Sic Her He Its Hand BuchDocument66 pagesSic Her He Its Hand Buchkatja kafkaNo ratings yet

- 3500 22m Transient Data Interface Manual 161580-01 PDFDocument82 pages3500 22m Transient Data Interface Manual 161580-01 PDFkatja kafka100% (1)

- Case Expansion Transducer 24765 PDFDocument6 pagesCase Expansion Transducer 24765 PDFkatja kafkaNo ratings yet

- Boiler Termoelectric AristonDocument36 pagesBoiler Termoelectric AristonRadu TaşcăNo ratings yet

- RiSEA SubSea Pte LTD A Member of RiSEA Propulsion GroupDocument20 pagesRiSEA SubSea Pte LTD A Member of RiSEA Propulsion GroupMol MolNo ratings yet

- CV - Mohd Nadim - 01-06-2017Document6 pagesCV - Mohd Nadim - 01-06-2017Mohammad NadimNo ratings yet

- 031 08Document2 pages031 08Ckaal74No ratings yet

- 3538-200 Qasr Project Pre-Commissioning Procedure For Qasr Rev 1Document146 pages3538-200 Qasr Project Pre-Commissioning Procedure For Qasr Rev 1HashemAliHashemNo ratings yet

- Hpwinch 31 1Document16 pagesHpwinch 31 1Eng-Mohammed SalemNo ratings yet

- Rheem 310 Series Heat Pump Hot WaterDocument68 pagesRheem 310 Series Heat Pump Hot WaterDavid HarpleyNo ratings yet

- Troubleshooting DNFT LedDocument4 pagesTroubleshooting DNFT LedDAVIS VELASQUEZNo ratings yet

- Piper Aircraft Corporation: Haven, Pennsylvania, U.S.ADocument2 pagesPiper Aircraft Corporation: Haven, Pennsylvania, U.S.AmaximeNo ratings yet

- Camco TRM Camco TRM Camco TRM Camco TRM - 4E SCSSV 4E SCSSV 4E SCSSV 4E SCSSVDocument4 pagesCamco TRM Camco TRM Camco TRM Camco TRM - 4E SCSSV 4E SCSSV 4E SCSSV 4E SCSSVAli AliNo ratings yet

- FMA Steam Boiler and UPV 1970 MalaysiaDocument59 pagesFMA Steam Boiler and UPV 1970 MalaysiaarifhonNo ratings yet

- 6400-6600 Series Catalog (394C) PDFDocument8 pages6400-6600 Series Catalog (394C) PDF20106285No ratings yet

- Aperval 1Document12 pagesAperval 1vitoNo ratings yet

- Installation and operating instructions for Weishaupt gas burners WG10 and WG20 LN versionsDocument27 pagesInstallation and operating instructions for Weishaupt gas burners WG10 and WG20 LN versionstrpac100% (4)

- Ignition StartingDocument42 pagesIgnition StartingTarik Benzineb100% (5)

- VCTDS 03384 enDocument8 pagesVCTDS 03384 enKrishnamoorthyNo ratings yet

- PC450-7 Shop Manual PDFDocument881 pagesPC450-7 Shop Manual PDFQuy Le Thanh85% (26)

- Maintenance Schedule Sauer Compressor WP33LDocument18 pagesMaintenance Schedule Sauer Compressor WP33LWee WeeNo ratings yet

- Well Head, ValvesDocument58 pagesWell Head, ValvesAhmed Ousama100% (1)

- Integral Blowdown Valve: DescriptionDocument1 pageIntegral Blowdown Valve: DescriptionIlham Rahmat KurniaNo ratings yet

- SSOP GMP Employee Hygiene PoliciesDocument22 pagesSSOP GMP Employee Hygiene PoliciesBilly Johanes SaderachNo ratings yet

- Hydraulic JD Valve - Lubes - Equip - CatalogDocument15 pagesHydraulic JD Valve - Lubes - Equip - CatalogErcan YilmazNo ratings yet

- Manual de Densitometro InglesDocument91 pagesManual de Densitometro Inglesprincipito12No ratings yet

- Mecanismos de Control - EN - WEBDocument12 pagesMecanismos de Control - EN - WEBJERRY LIUNo ratings yet

- Operating Manual - HEF and G - 86 °C FreezersDocument72 pagesOperating Manual - HEF and G - 86 °C Freezersfrank luNo ratings yet

- Lock Up Valve IL02-OM00011Document16 pagesLock Up Valve IL02-OM00011Chanh ThiNo ratings yet

- Pneumatic KnockerDocument1 pagePneumatic KnockerramaNo ratings yet

- A&F Machine Products CatalogDocument24 pagesA&F Machine Products CatalogreinpolyNo ratings yet

- MS TANK Transport TrailerDocument2 pagesMS TANK Transport TrailerAdrián Gómez LeónNo ratings yet

- 05 - YculDocument208 pages05 - Yculingrith_ortizsNo ratings yet