Professional Documents

Culture Documents

Type of Catalyst Deactivations

Uploaded by

LydiaRHCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Type of Catalyst Deactivations

Uploaded by

LydiaRHCopyright:

Available Formats

Lydia | UiTM SA | CPE666 EH2207G

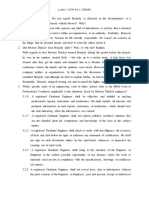

Type of

Catalyst Sintering/Thermal Degradation Poisoning Fouling/Coking

Deactivations

Type Thermal Chemical Mechanical or Chemical

Dependency Independent of fluid phase composition. Dependent on concentration of reactant/ product/impurities.

- Gradual change in structure due to

- In reversible poisoning, the strength

high temperature. - Caused by physical deposition of

of adsorption bond is not great and

- Loss of catalytic activity due to loss of substance on the active sites of

activity is regained when the poison is

active surface area (due to high gas- catalysts (carbonaceous

removed from the feed.

phase temp) deposition/coke).

- In Irreversible poisoning, the

- 2 types - It is common to reactions involving

adsorbed material is tightly held on

o Crystal agglomeration & hydrocarbons.

the active sites and poisoning is

Mechanism growth of the metals - Carbon covers the active site of the

permanent. In this case, it is called

deposited on the support catalysts and may also partially plug

irreversible chemisorption.

o Loss of activity by the pore entrance.

- Reduces the number of sites

narrowing/closing of the pores - Partially reversible and regeneration

available for the main reaction

inside the catalyst pellet can be done by burning in air.

- Due to impurities such as sulphur,

- Sintering is usually negligible at - Fouled catalyst is called spent

lead, and other components that are

temperatures below 40% of the catalyst.

costly to remove.

melting temperature of the solid.

You might also like

- Graph of Percentage of Insects Affected Vs Log (Dose)Document3 pagesGraph of Percentage of Insects Affected Vs Log (Dose)LydiaRHNo ratings yet

- Corrosion: Lydia - Uitm SaDocument9 pagesCorrosion: Lydia - Uitm SaLydiaRH100% (1)

- PolymersDocument4 pagesPolymersLydiaRHNo ratings yet

- Air PollutionDocument8 pagesAir PollutionLydiaRHNo ratings yet

- Thermoplastic Thermosets: Lydia - Uitm SaDocument1 pageThermoplastic Thermosets: Lydia - Uitm SaLydiaRHNo ratings yet

- Bar Screen and Grit Chamber DesignDocument8 pagesBar Screen and Grit Chamber DesignLydiaRHNo ratings yet

- Biological TreatmentDocument3 pagesBiological TreatmentLydiaRHNo ratings yet

- Solid Waste ManagementDocument7 pagesSolid Waste ManagementLydiaRHNo ratings yet

- Roger Boisjoly and The Challenger DisasterDocument3 pagesRoger Boisjoly and The Challenger DisasterLydiaRHNo ratings yet

- Petrochemicals, An IntroductionDocument2 pagesPetrochemicals, An IntroductionLydiaRHNo ratings yet

- Phthalic Anhydride SafetyDocument11 pagesPhthalic Anhydride SafetyLydiaRHNo ratings yet

- Hazardous Waste Management & CompostingDocument14 pagesHazardous Waste Management & CompostingLydiaRHNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Telescope: A Brief History of The TelescopeDocument3 pagesTelescope: A Brief History of The TelescopeHazraphine LinsoNo ratings yet

- Circulation Rates in Thermosiphon ReboilerDocument7 pagesCirculation Rates in Thermosiphon ReboilersNo ratings yet

- Phosphate Rock Processing and Fertilizers Production at Al-Qaim Fertilizers Complex, IraqDocument12 pagesPhosphate Rock Processing and Fertilizers Production at Al-Qaim Fertilizers Complex, IraqEndah SaraswatiNo ratings yet

- The Role of Thickeners in Optimizing Coatings PerformanceDocument13 pagesThe Role of Thickeners in Optimizing Coatings PerformanceArturo Antonio Matencio Arroyo100% (1)

- Pogil Photosynthesis and Respiration-SDocument6 pagesPogil Photosynthesis and Respiration-Sapi-2623786400% (1)

- Capillary Flow Technology Solves Difficult GC Problems and Enables New CapabilitiesDocument28 pagesCapillary Flow Technology Solves Difficult GC Problems and Enables New CapabilitiesTho AnhNo ratings yet

- Francis Drilling Fluids, Ltd. Material Safety Data Sheet: I. Product IdentificationDocument4 pagesFrancis Drilling Fluids, Ltd. Material Safety Data Sheet: I. Product IdentificationPartha MukherjeeNo ratings yet

- Integral Kalkulus Dan Integral TheoremsDocument24 pagesIntegral Kalkulus Dan Integral TheoremsRifa NabillaNo ratings yet

- REVIEWER FOR ChE COMPRE 07082018Document352 pagesREVIEWER FOR ChE COMPRE 07082018Ahe BeongNo ratings yet

- Batch ReactorDocument4 pagesBatch ReactorHarini BugattiveyronNo ratings yet

- Isotech Journal OF Thermometry: Published by Isothermal Technology LTDDocument57 pagesIsotech Journal OF Thermometry: Published by Isothermal Technology LTDlizarazojavierNo ratings yet

- Total Internal Reflection at a Single Curved SurfaceDocument30 pagesTotal Internal Reflection at a Single Curved SurfaceIlakkiyaa KPNo ratings yet

- S82B1B eDocument36 pagesS82B1B eMoscavo3No ratings yet

- Colorimetry 1Document23 pagesColorimetry 1Denise CssNo ratings yet

- Starting With Zero: Create Your Own Topographic Map ProjectDocument4 pagesStarting With Zero: Create Your Own Topographic Map ProjectVinujah SukumaranNo ratings yet

- Vapor Phase Soldering TechniqueDocument5 pagesVapor Phase Soldering TechniquealisakeerpkNo ratings yet

- Nuclear Engineering and TechnologyDocument8 pagesNuclear Engineering and TechnologyBharat MahajanNo ratings yet

- 40 International Chemistry Olympiad: Preparatory ProblemsDocument104 pages40 International Chemistry Olympiad: Preparatory ProblemsLê Hoàng MinhNo ratings yet

- CHE202.2 SPRING 2023 Course OutlineDocument11 pagesCHE202.2 SPRING 2023 Course OutlineZahra NasreenNo ratings yet

- 10biology Practical - StomataDocument2 pages10biology Practical - StomataHridaan SherawatNo ratings yet

- Bioprinting 101: Design, Fabrication, and Evaluation of Cell-Laden 3D Bioprinted ScaffoldsDocument21 pagesBioprinting 101: Design, Fabrication, and Evaluation of Cell-Laden 3D Bioprinted ScaffoldsAlejandra CastillaNo ratings yet

- Iyr Phy em 2marksDocument6 pagesIyr Phy em 2marksBYREDDY 4567No ratings yet

- LG200-FRF Integrated Temperature TransmitterDocument12 pagesLG200-FRF Integrated Temperature TransmitterYounes El GhandouriNo ratings yet

- Carbon Dioxide: Pressure - Enthalpy Diagram: R 90 0 Sity 7 00 KG/MDocument1 pageCarbon Dioxide: Pressure - Enthalpy Diagram: R 90 0 Sity 7 00 KG/MJackNo ratings yet

- Scince (Assement-1)Document4 pagesScince (Assement-1)ARAF ABDULLAHNo ratings yet

- 2.0 Electric FieldsDocument4 pages2.0 Electric FieldsEdAnNo ratings yet

- 01 StudyGuide (2021) ChemDocument157 pages01 StudyGuide (2021) ChemYzakRVNo ratings yet

- Ionic EquilibriumDocument91 pagesIonic EquilibriumGabrielNo ratings yet

- Water Purification Experiment Dissolved OxygenDocument2 pagesWater Purification Experiment Dissolved OxygenJunNo ratings yet

- TRANSIENT HEAT TRANSFER CALCULATIONSDocument3 pagesTRANSIENT HEAT TRANSFER CALCULATIONSSanith RenjalNo ratings yet