Professional Documents

Culture Documents

Device Selection and Basic Concepts

Uploaded by

mehfuzansari1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Device Selection and Basic Concepts

Uploaded by

mehfuzansari1Copyright:

Available Formats

Device Selection and Basic Concepts

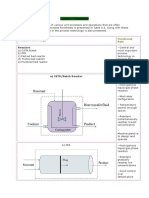

Background:

Key steps involved in Tower Design – An Overview

1. Define the key separations: Yield & Purity of the pdt being produced

2. Obtain the appropriate VLE and Enthalpy data method: Use of inappropriate data method will

lead to off-spec products or inoperable design.

3. Calc. the theoretical trays reqd. at diff. reflux rates: by changing no of plate and reflux rates, the

shapes of theo tray vs. reflux ratio curve can be determined. This will assist in determining

economical tower height and diameter combination.

4. Estimate Tray efficiency:

5. Define the max and min feed rates that the tower must handle: In general, a turndown ratio of

2/1 is adequate for most services.

6. Selecting the best tower internal: For most trayed columns, sieve or valve trays will be the first

choice whereas for packed towers a dumped packing of the 2 in. (50 mm) size will normally

sufficient.

7. Tower Sizing and tray hydraulic calculations:

8. Process Control:

Types of contacting devices available:

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- TSMP3003 - SmartPlant 3D Cableway Reference Data LabsDocument61 pagesTSMP3003 - SmartPlant 3D Cableway Reference Data LabsGopi BNo ratings yet

- Electrical Basis of Design Standards GuidelinesDocument19 pagesElectrical Basis of Design Standards Guidelinesessk100% (1)

- Boiler House PFDDocument1 pageBoiler House PFDmehfuzansari1No ratings yet

- Modern Component Families and Circuit Block DesignFrom EverandModern Component Families and Circuit Block DesignRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Material and Energy BalanceDocument23 pagesMaterial and Energy BalanceSaurabh KumarNo ratings yet

- The Maplin Electronic Circuits HandbookFrom EverandThe Maplin Electronic Circuits HandbookRating: 4.5 out of 5 stars4.5/5 (6)

- Design Guidelines Pro II Rev inDocument8 pagesDesign Guidelines Pro II Rev inNareshNo ratings yet

- D Cem1000 1001 Ops ADocument76 pagesD Cem1000 1001 Ops Aawiverma789No ratings yet

- Norsok P 002 Ac 2017 PDFDocument4 pagesNorsok P 002 Ac 2017 PDFmehfuzansari1No ratings yet

- 4.SIL Studies ExternalDocument12 pages4.SIL Studies ExternalHarivanan ShanmugamNo ratings yet

- Mechanical Engineering Design GuidelinesDocument23 pagesMechanical Engineering Design GuidelinesTep PiNo ratings yet

- OGS HVAC Design Guide SummaryDocument25 pagesOGS HVAC Design Guide Summarysolarstuff100% (1)

- STN HiAv V2.0Document88 pagesSTN HiAv V2.0Sagar JadhavNo ratings yet

- Design and Sizing of Screw FeedersDocument8 pagesDesign and Sizing of Screw FeedersPooja PillaiNo ratings yet

- Trafo Spec PDFDocument56 pagesTrafo Spec PDFMohammad Fadhil KoesputraNo ratings yet

- National Grid Design Handbook dh01Document26 pagesNational Grid Design Handbook dh01akmezim100% (2)

- VlsiDocument13 pagesVlsiRajaganapathi RajappanNo ratings yet

- Bechtel Limited: Engineering Guide Instruction 3DG-E23E-00100 D.C. Supply Units (Batteries & Battery Chargers)Document11 pagesBechtel Limited: Engineering Guide Instruction 3DG-E23E-00100 D.C. Supply Units (Batteries & Battery Chargers)mohammadkassarNo ratings yet

- FLARENETDocument19 pagesFLARENETrohmanNo ratings yet

- Pump Sizing Calculation SpreadsheetDocument3 pagesPump Sizing Calculation Spreadsheetmehfuzansari1No ratings yet

- Pro II Tutorial - Rev 9Document15 pagesPro II Tutorial - Rev 9Manikandan SubramanianNo ratings yet

- KRT Planing Information-DataDocument110 pagesKRT Planing Information-DataNicolas Alvarez GomezNo ratings yet

- Material and Energy Balance Q&ADocument10 pagesMaterial and Energy Balance Q&AEmyboy AgboNo ratings yet

- AutoPIPE Modelling ApproachesDocument110 pagesAutoPIPE Modelling Approachessjois_hs100% (1)

- Interview Que & AnswDocument33 pagesInterview Que & AnswRadheshyam RaiNo ratings yet

- Iec-61439 Se6461Document32 pagesIec-61439 Se6461carlosmandopintoNo ratings yet

- Brian Windsor Troubleshooting1Document35 pagesBrian Windsor Troubleshooting1brandlabBDNo ratings yet

- Information Sheet 1.2-4 Installation of Wire Ways and Cable TraysDocument4 pagesInformation Sheet 1.2-4 Installation of Wire Ways and Cable TraysMarc GelacioNo ratings yet

- ProtocolsDocument9 pagesProtocolsSantanu RoutNo ratings yet

- Complex Engineering ProblemDocument13 pagesComplex Engineering ProblemMuhammad AbubakarNo ratings yet

- 2020-MC-274 System 2Document17 pages2020-MC-274 System 2David JamesNo ratings yet

- COEN212_LAB_MANUAL (2)Document77 pagesCOEN212_LAB_MANUAL (2)yacine.ray.gasNo ratings yet

- Intro Mechatronics Systems ChaptersDocument5 pagesIntro Mechatronics Systems ChaptershaldoisNo ratings yet

- M4 U4 Bracket FabricationDocument26 pagesM4 U4 Bracket FabricationKaliya PerumalNo ratings yet

- Fundamentals of Polymer Engineering Lab ManualDocument45 pagesFundamentals of Polymer Engineering Lab ManualFARANNo ratings yet

- Robot For Boiler Header Inspection "LS-01": Procedia Engineering December 2012Document8 pagesRobot For Boiler Header Inspection "LS-01": Procedia Engineering December 2012Jason RichardsonNo ratings yet

- Texas AM PDFDocument43 pagesTexas AM PDFJorgito AriasNo ratings yet

- H250 M40 H250 M40 H250 M40 H250 M40: Variable Area FlowmeterDocument48 pagesH250 M40 H250 M40 H250 M40 H250 M40: Variable Area FlowmeterAbel VegaNo ratings yet

- Capitulo 2Document176 pagesCapitulo 2Jorge Ivan MorenoNo ratings yet

- Distillation Column Design 2014Document4 pagesDistillation Column Design 2014John PortlandNo ratings yet

- lab report for computer networkDocument22 pageslab report for computer networkchaudharyaaryan420No ratings yet

- Innovus Study Notes-CSDN BlogDocument6 pagesInnovus Study Notes-CSDN BlogAgnathavasiNo ratings yet

- Exp 3 Case Study General InstructionsDocument4 pagesExp 3 Case Study General InstructionsOmkar BhabalNo ratings yet

- 2020 IC Design Contest: Full-Custom CategoryDocument6 pages2020 IC Design Contest: Full-Custom CategoryE94086018陳寧文No ratings yet

- Simulation of Standard Telecontrol Protocol IEC 60870-5-101: Mudathir Mohammed Abdalla SharifDocument92 pagesSimulation of Standard Telecontrol Protocol IEC 60870-5-101: Mudathir Mohammed Abdalla SharifOUSSAMA MOUSSAOUINo ratings yet

- 6 - Completions EquipmentDocument42 pages6 - Completions EquipmentNew Auto TVNo ratings yet

- Module 12 Environ Racks and Cabinets oVxCNPCBDocument28 pagesModule 12 Environ Racks and Cabinets oVxCNPCBioanovNo ratings yet

- EPDE process design principles and flow diagramsDocument8 pagesEPDE process design principles and flow diagramsZaidNo ratings yet

- ASHRAE-NEBB Online Ala Carte Course Copy Order Form For Web - UPDATED - 7.26.18 - Fillable FormDocument8 pagesASHRAE-NEBB Online Ala Carte Course Copy Order Form For Web - UPDATED - 7.26.18 - Fillable Formamr elzeinyNo ratings yet

- 1 HeatTracePanel PDSGDocument14 pages1 HeatTracePanel PDSGDott PalmitoNo ratings yet

- UsingDocument16 pagesUsingTATATAHERNo ratings yet

- SOWDocument7 pagesSOWAnonymous rey6aU3ZNo ratings yet

- Specifications of DATA Revovery Centre (DRC) NIA, HyderabadDocument38 pagesSpecifications of DATA Revovery Centre (DRC) NIA, HyderabadankitNo ratings yet

- (TP0A013) Liquid Measurement Station DesignDocument5 pages(TP0A013) Liquid Measurement Station DesignRoberto Carlos TeixeiraNo ratings yet

- 4.1 Microprocessors and Applications: RationaleDocument16 pages4.1 Microprocessors and Applications: Rationalevaishak123No ratings yet

- Low Head Pico Hydro Turbine Selection Using A Multi-Criteria AnalysisDocument8 pagesLow Head Pico Hydro Turbine Selection Using A Multi-Criteria AnalysisZehab ud DinNo ratings yet

- Cost_Model_for_Planning_Development_and_Operation_Document37 pagesCost_Model_for_Planning_Development_and_Operation_Manolis FounargiotakisNo ratings yet

- Jeo Uoc 10-Manage System Modification ActivitiesDocument41 pagesJeo Uoc 10-Manage System Modification ActivitiesTarmizi KembaliNo ratings yet

- Logging InnovationDocument8 pagesLogging InnovationAnkit ChourasiaNo ratings yet

- Mec e 463Document329 pagesMec e 463Dule NilkNo ratings yet

- Samson: Control Valve Design Aspects For Critical Applications in Petrochemical PlantsDocument20 pagesSamson: Control Valve Design Aspects For Critical Applications in Petrochemical PlantsdharmendrabholeNo ratings yet

- Embedded LAB MANUAL(1)Document217 pagesEmbedded LAB MANUAL(1)Pinak RoyNo ratings yet

- Caesar-II User GuideDocument313 pagesCaesar-II User GuideSDNo ratings yet

- JR - Officer Production (On Contract - Third Party Payroll)Document2 pagesJR - Officer Production (On Contract - Third Party Payroll)mehfuzansari1No ratings yet

- Trip PlanningDocument2 pagesTrip Planningmehfuzansari1No ratings yet

- Read MeDocument1 pageRead Memehfuzansari1No ratings yet

- Claim On Death of Depositors in BanksDocument2 pagesClaim On Death of Depositors in Bankssatur123No ratings yet

- Edible Oil Chemistry, Properties, and Health EffectsDocument34 pagesEdible Oil Chemistry, Properties, and Health Effectsmehfuzansari1No ratings yet

- Mod 01 - Introduction Lect 02 OrientationDocument4 pagesMod 01 - Introduction Lect 02 Orientationmehfuzansari1No ratings yet

- Steam Consu MayDocument36 pagesSteam Consu Maymehfuzansari1No ratings yet

- WWW Tech-Tools MEDocument1 pageWWW Tech-Tools MEmehfuzansari1No ratings yet

- Aspen Capital Cost EstimatorDocument3 pagesAspen Capital Cost Estimatormehfuzansari1No ratings yet

- Plant EconomicsDocument16 pagesPlant Economicsmehfuzansari1No ratings yet

- Cooling Tower Flow Measurement: Flow Inlet Temp Out Temp Flow Inlet TempDocument2 pagesCooling Tower Flow Measurement: Flow Inlet Temp Out Temp Flow Inlet Tempmehfuzansari1No ratings yet

- Elements of Pinch AnalysisDocument11 pagesElements of Pinch Analysismehfuzansari1No ratings yet

- Glycerin PurificationDocument6 pagesGlycerin Purificationmehfuzansari1No ratings yet

- CalculationDocument4 pagesCalculationmehfuzansari1No ratings yet

- WELCOME To Cost & Evaluation Workbook by Peters, Timmerhaus and West. Accompanying Plant Design and Economics For Chemical Engineers, 5th EditionDocument15 pagesWELCOME To Cost & Evaluation Workbook by Peters, Timmerhaus and West. Accompanying Plant Design and Economics For Chemical Engineers, 5th Editionxhche7No ratings yet

- MSDS of Sulphur TrioxideDocument5 pagesMSDS of Sulphur Trioxidemehfuzansari1No ratings yet

- IncomeTaxCalculator 2013/14Document7 pagesIncomeTaxCalculator 2013/14mehfuzansari1No ratings yet

- Tesserect Techno SolutionsDocument8 pagesTesserect Techno Solutionsmehfuzansari1No ratings yet

- Natural Gas Conversion Pocketbook PDFDocument40 pagesNatural Gas Conversion Pocketbook PDFNusirwan MzNo ratings yet

- All Plan Comparison PrepaidDocument1 pageAll Plan Comparison Prepaidmehfuzansari1No ratings yet

- Vacuum Distillation ColumnsDocument2 pagesVacuum Distillation Columnsmehfuzansari1100% (1)

- FFODocument8 pagesFFOmehfuzansari1No ratings yet