Professional Documents

Culture Documents

Kasha Guitar Plan

Uploaded by

Andrey BalalinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kasha Guitar Plan

Uploaded by

Andrey BalalinCopyright:

Available Formats

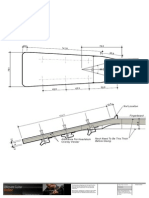

Optional Independent Side Braces - Refer To Latteral

Section For More Info. Spread Evenly Around The

Sides Of The Guitar. Refer To Section For The Exact

Profile. Usually Between 6 and 8 Are Used. These

Are Shaped Similar To A Brace Out Of The Same

Material As The Top Braces. Put In Place Just Prior

To Glueing The Back Plate To The Sides.

Certain Luthiers Tune The Top By Making The Top

Progressively Thinner As It Reaches The Guitar Edge

And Remain Full Thickness At The Top. If You Do

This Do Not Reduce The Edges Below 2.2mm And

Make The Center Slightly Thicker.

Center Bridge Brace On

660mm Line For Scale

Length.

K

C

Tone Brace

S Note: Arch This Transverse Brace Over Brace Key Numbers. Refer To

R 5.5 The Tone Brace So The Tone Brace Brace Diagram Plan For

5.8 21.7 7/32" Bracing Layouts

7/32" 27/32" 128.6

20.8 X A Runs Through. See Detail On Top

5 1/16" 4.8 Brace Plan L

13/16" 3/16" 660.0

25 31/32"

R 36.8 Scale Length

29.1 1 7/16" Dashed Line Indicates Rossette

85.7 12.7 1.1 Reinforcement Extends Beyond

1 5/32" 3 3/8" 1/2" 1/32" Rossette Approx. 5mm.

Depth Of Holes For Rollers Can 330.0 U

13" V

Vary With Tuning Machine Mfr.

Re-Constituted Ivory Or Excellent Quality

Dashed Lines Indicate Outline Of M

Neck Block Where It Meets The

Bone For the Nut. Top. D 15.2

5/16"

19/32"

7.9

1 3/32"

15.9

27.9

5/8"

43.5 N

11 3/32"

1 25/32"

2 21/32"

E

2 9/16"

2 3/32"

3 3/32"

1 23/32"

9 1/16"

14 1/2"

1.77°

2 7/8"

2 3/8"

2 1/2"

1 1/2"

1 1/2"

230.1

368.5

73.0

65.1

45.2

53.2

60.0

63.5

50.8

38.0

50.8

38.0

67.3

78.5

290

R 60.9

2"

2"

R 42.1 2 13/32"

1.77°

1 21/32"

Rossette - Usually

Prefabricated. But You Can

15.9

5/8"

Make Them Yourself.

F O

3

1 3.9

7.9

5/16"

Transverse Brace

11

/3

String Ramps 2"

74.2

2 29/32" G P

21.8 20.8 4.8

34.9 34.9 3/16" Back Block or Butt Block. Vertical Grain

37.0 1 3/8" 27/32" 13/16"

1 15/32" 1 3/8" R 643.5 Cedar Or Spruce Minimum 20 Grains/

Butt Rossette Reinforcing Into 25 11/32" In. Some Luthiers Shave This Block or

Side Of Brace. H Q

7 1 8.8

"

/32

Angle It Away From The Top As This

128.6

17

Block Often Gives A Guitar A "Hump"

5 1/16" Tone Brace 52 In The Top And Can Cause Cracking.

2 1 .2

Cut Slots Into Headstock After Drilling Holes For

Machine Head Rollers. Make A Template To

Fret Wire Detail /16

"

B S

Locate Holes And Drile Precisely With A Drill

J R W

Press. Cut String Ramps In With A Round Rasp

and Final Shape With Sandpaper Wrapped Around

A Dowel.

43.

Note: Be Sure To Check The Actual Roller Spacing 1 237

For Your Tuning Machines Before Making The /3 2"

Template and Layout. They Vary Slightly From Mfr. Optional Independent Side Braces - Refer To Latteral T

Guitar Plan View

To Mfr. Section For More Info. Spread Evenly Around The

Sides Of The Guitar. Refer To Section For The Exact

Profile. Usually Between 6 and 8 Are Used. These

Are Shaped Similar To A Brace Out Of The Same

Material As The Top Braces. Put In Place Just Prior

To Glueing The Back Plate To The Sides. Kerfed Lining Made From Either Basswood Or Cedar.

Many Spanish Classicals Use Solid Kerfing For The

Back Plate Attachment. If You Choose To Do That

Make Sure The Kerfing Is Pre-Bent Prior To Gluing. Do Note: Bracing Shown Here Is The

Not Introduce Stress Into The Guitar Actual Placement Of The Bracing

On The Interior Side Of The Top

Plate. This Bracing Is Not Shown

In Xray Mode.

494.4

19 15/32"

Materials: Tips and Techniques: Methods: Methods - Continued: Methods - Continued:

Assemble the proper materials before you begin your project. If you don't have your tone wood Always make sure your tools are razor sharp and not dull. Buy good sharpening stones or Start by sanding your top plate, back plate and sides to rough thickness (within 1mm of final Now you should assemble the guitar neck. I recommed Cuban Cedar because it is light and strong. Now fit the top to the sides. Trim the top to fit exactly inside the inside form. Drop the sides on top

already, there are several great suppliers including LMI (Luthier's Merchantile) which has a wide sharpening grinders such as the Tormek sharpener. It is also important to knock off the burr on your thickness). Carefully glue the center joints of the back and sides together. When gluing the back, Cut the Head scarf joint with a band saw first. Prepare this joint so it is perfectly tight. Next, cut the and glue the sides to the top with individual blocks. These should be about 1/2 to 3/4" long

range of top and back and side wood available. If this is your first guitar, you may want to try wood chisels and other hand tools. you will want to insert your decorative center strip at the same time. This should be pre-assembled blank to size and capture any blocks you can to glue to the heel/foot assembly. Now cut the neck depending of the contour they encounter and should be only set into place by hand and not

that is a bit less expensive for your first try, such as mahogany for backs and sides or walnut, which if you have multiple colors. blank right down the center and flip the grain so it is opposed and working against each other. Slip a clamped as this adds undue stress to the guitar top plate. The line from the neck to the tip should

is about 50 to 33% of the cost of the Rosewoods etc. If you want an easy build guitar for your first If you use stationary tools, make sure the blades on your bandsaw, tablesaw, jointer etc. are also 6mm strip of Ebony between the halves and prepare all pieces in a similar manner to the plate be perfectly level and even or you will be in trouble. Check, double check and triple check that the

try, go with the Honduros Mahogany. It works easily, sands nicely, and finishes quite easily too. You very sharp and you do not have to force wood through the machines. If given a choice, always use To prepare the joints, sand carefully with sandpaper glued to a perfectly straight edge. I like to use joints - or if you have a stationary drum sander, just run all the pieces through that. Prepare the neck centerline aligns with the top centerline before gluing. Get everything perfect at this point.

don't have to deal with exotic resins in the wood like you do with Rosewood, Cocobolo oand some carbide-tipped blades. Some of these hardwoods are tough to cut without a good carbide blade. adhesive backed sandpaper in rolls and stick it to the side of a 24" metal level. Trim the sandpaper other half of the scarf joint so you will have a good joint for the headstock trim.

of the the other exotic woods. Setup of power tools is extremely important too - follow included direction or obtain good books on carefully. Use 120 grit paper and do not use a lot of force. The plates are joined most easily with a Now you can glue the back plate to the sides by using 3/4" elastic upholstery tape, rubber bands or

proper setup of bandsaws, table saws etc. You can't believe what a difference this will make. cam-action jig while using a piece of wood on the top to keep things in alignment. Of course use Glue the heel/foot block on the neck - all the while checking with your neck template. Once the neck spindle clamps. Get even pressure, but DO NOT FORCE anything - no stress here either.

When you order wood make sure you order wood that is at least 1" oversized in each direction so waxed paper wherever you risk having your wood stuck to the jig - or coat the jig with wax. has dryed, do a final sanding on a stationary belt sander for the headstock and double-check the

you can eliminate splits etc. 2" is even better and quite often accomodated with tone wood. Make You can never have enough jigs, templates etc. in guitar-making. If you plan to continue beyond this thickness of the head. Now glue the headstock trim and purfling and set aside to dry. Next is the time to trim the plates, rout purfling groove around the edge of the guitar and fit the

sure the tops and backs are bookmatched for grain pattern. guitar and make several others, templates and jigs are a must more making your work a lot easier. Once glued (If you use Rosewood, or one of the other exotic woods mentioned here, be sure to get purfling. With groove cleaned out, nice tight fit and everything cut to length, glue on the purfling.

all of the resin out of the wood with acetone before you glue anything. Trace your top and back on Next rough-cut the heel and foot/endblock shape of the neck on the bandsaw, keeping things true

Neck blanks can be Cuban Cedar. This is a very lightweight but very strong wood. Fretboards If you are starting from scratch, building guitars, make sure you make excellent quality forms for the wood - use a white pencil for dark wood. Then run the top and back through a wide stationary and plumb. Remember to always cut a bit outside the lines to allow for slight error. Now rough cut Rough sand the sides, back and top plates and round the edge of the purfling.

should be clear Ebony, solid and you will have to buy 2 of them to allow you to add the Ebony your guitar. Both inside and outside forms for the body assembly. Look at LMI's side bending belt sander - or use scrapers and hand sanding methods. Be careful with the use of acetone also. the head after tracing with your headstock template. Sand the sides to final shape and size and drill

reinforcing to the center of the neck. machine. It works great and you can pump out a lot of bent sides in a short time. Use rubber gloves and a resperator. You may also need to use a resperator for exotic wood dust as you machinehead roller holes of each side of the head. You can now drill your holes for the string Next sand the fingerboard to thickness, cut to correct width and final sand the edges on a stationary

many people have allergic reactions to the sanding dust (including myself). slots - being careful not to get any drill runout or tearout. Now cut the remainer of the slot out with belt sander. Cut the fret grooves and locate the fretboard on the neck. Lightly clamp it and drill 2

Most suppliers will have brace wood available, which is split from to log so there isn't any runout in Put together the templates we have shown here at a bare minimum. You should have a template to either a router or a jigsaw. Cut outside the line and finish the slots with sanding stick. small holes down through the fret groove at the body and nut ends of the fretboard. Place small

the wood - look for this in the literature. trace your basic guitar boddy shape, your top and back brace locations, Your neck and foot profile When I started out making guitars, I couldn't afford all the expensive stationary sanders etc,, locator nails in the holes and double check the fingerboard location before gluing. Double check all

and the headstock layout, showning all the drilling locations for the tuning machine rollers and string that makes the work so simple now. I used to get one side of the plate completely flat, then I Cut your string ramps in the string grooves with a round rasp and finish with sandpaper wrapped the latteral and vertical locations with a precise straight edge. Glue the fret board in place.

You will also need additional wood to make up the purfling around he edges and you will need slots. Also it comes in handy to have back brace curvature templates, brace scalloping patterns, fret would chuck up a small bit in the drill press and set it to stop at the desired thickness of my aroung a dowel. This can be a dowel section about 8" long with a slot cut in the end, right down the

maple or some other type of white wood if you want white stripping accents at your purflings. For slot location templates and bridge templates. plate. I would then drill dimples over the entire surface of the unfinished side and simply center of the dowel for about 1/2 the dowel length. Insert the sandpaper in the slot and wrap around Final shape the neck to the fretboard size, shape the heel and finish sand. Place a heel trim on the

the dark wood use Rosewood veneer. sand until all of the dents were gone - pretty slick! the dowel. bottom of the heel. Dry-fit the tuning machine and make any adjustments so there is no binding or

There are a lot of great little tools and gadgets available for Guitar Lutherie - Here are a few: forcing in place. Fit the nut and bridge. Check the action, bridge location and after verifying glue the

We did not get into the details of how purfling is put on this guitar as that is more of a construction After you have your thickness completed on the top plates. trace the guitar contour and carefully cut Next rough-shape the neck with a 4-way rasp, using the rough cut blade. Get the neck to within bridge in place.

Thumb Planes - Available from Luthier supply houses - they are primarilary used for violins.

issue and not a guitar play issue. Any number of guitar construction books will guide you in the the outline out. Make the cut line at least 1/8" outside the line to give you some give. about 1/16" of final thickness and width. Now cut in the guitar side slots in the sides of the neck. Do

Spindle Sander - This is a tabletop stationary tool.

proper techniques of installing purfling, where it should be and how to laminate it and bend it. this very carefully and make sure you have good joints. I like to use dovetail saws for this operation Give all wood surfaces a final sanding with 220 grit sandpaper, install the frets and prepare to install

Dremel Router with roller bearing bushings - or other small hand-held mini-routher.

Get your sides bent, either with a bending jig or on a bending iron. You can also boil the sides and and g--o s--l--o--w. Thick the fitting often with your guitar sides clamped in the inside form. the finish.

Buy good fret stock with at least 18% silver content. Steward MacDonald has a good assortment of Note Stewmac has a lot of adapters available for the Dremel such as purfling routers, bits

clamp them to an outside form for a few days to a week. Be sure to overbend a bit to allow for

fretwire as does LMI. etc. Once the neck fits in the sides precisely, trim the butt joint of the sides and glue the butt block on

springback. There are many different opionions on finish material from french polish to varnish to lacquers and

Fret cutting jig - this is available from Stewmac also. Give you precise control over fret sawing. the bottom of the sides. Make sure to carefully fit the butt block the ot contour of the sides and urethanes. Do your research and decide on what suite you best.

Rossettes are best purchased already made unless you are determined to complete that difficult Make a jig to glue your bracing. This consists of 2 plywood plates with dowel supports at each make sure the block is vertical grain. Once the butt block is in place, final fit and glue the neck. It is

While the sides are curing, rout the channel for the rossette and insert and glue that. I use a dremel

operation. Many of the supply housed carry a great assortment of prefabricated rossettes. corner. The braces are glued using bent dowels that span between the two plates. essential that the side channels in the neck and the sides are trimed to match each other exactly.

router with a steel stud sticking up through the center of the soundhold (the sound hole is not cut Finishing is a whole different operation in and of itself is too lengthy to discuse in this format. I

out at this point. Once the rossette is installed, rout out the soundhole with the router too. sugguest you get a good book on instrument finishing from one of the suppliers.

Buy good tuning machines. Make sure they have good plating on them and the metal is a heavy Make sure your shop is held an a very constant humidity level all year long. Never vary more than Check the latteral and vertical positioning of the neck as this is extremely important at this time.

gauge. Buttons can be pearl, pearloid or ebony on many good quality machine heads. 5% between 45 and 55%. This will minimize cracking, shrinkage and give overall durability to Now is the time to install all of your bracing on the top and back. As I mentioned I use a dowel jig. I The foot and top of the block may need some additional trimming when the back and top are fit. You This was a quick overview of guitar construction and I have not had the room to go into any great

guitars you plan to sell or gift. plan on detailing these jigs in an upcoming book on guitar construction, but do not have plans on also want to make sure that the sides are perfectly plumb in the form by using stretcher clamps. detail on anything. At Ultimate Guitar OnLine, we plan on publishing an ebook on guitar

Interior blocking for the butt blocks can be either Spruce or Cedar or even Mahogany or Cuban the jig at this point. It works fast and really secures the bracing evenly and uniform. construction in the near future, so watch for that.

Cedar. Just make sure it is free from knots and is striaght grained. Optain this at specialty lumber Some of the other great little tools I love are: With the sides rough-cut to contour, glue in the lining to receive the back plate. This lining can be

yards or instrument supply shops. Japanese Saws that cut both ways Now is the time to install all of your bracing on the top and back. As I mentioned I use a dowel jig. I either kerfed lining or solid pre-bent lining. Glue with wooden clothespins with rubber bands Good Luck and most of all HAVE FUN!

Lots of the German Cam Clamps - both 6" and 8" plan on detailing these jigs in an upcoming book on guitar construction, but do not have plans on wrapped on them to strengthen their tension or use mini spring clamps. Make sure you have even

1" Spring Clamps - A whole 2# coffee can full of these the jig at this point. It works fast and really secures the bracing evenly and uniform. It also gives you glue squeeze out and clean it up as you did on the braces. I like to elevate the lining slightly above Check Us Out At:

A great set of instrument maker's chisels in 1mm 2mm 4mm and 6mm sizes a lot of fingerspace to allow gluing all of the braces in a single operation without a lot of clamps to the sides while gluing (about 1/16" inch). This will allow you to easily sand down the lining only to

Fret file, dovetail saws, fret end dressing tool, fret rocker etc. see my fret repair series for work around. completely level the top. www.ultimate-guitar-online.com

detail on these and a lot more tools http://ultimate-guitar-building.com

Typically the braces are only roughed-out for their final shaping is done after they are glued. After Now fit the back to the sides and neck with the side following the contour of the inside form. Since david@ultimate-guitar-online.com

Look at www.ultimate-guitar-online.com/woodworking-hand-tools.html for hand tools required and: the glue is mostly dry, remove the plate and get all of the glue squeeze out off the bracing and plate the braces for the back are slightly arched (about 1/8 to 1/4" ) carefully mark the trim marks for the

www.ultimate-guitar-online.com/woodworking-power-tools.html for stationary tools recommended. with a sharp small chisel. The glue should be dry enough to not be liquid but not fully adhered to the sides. This will vary with every aspect of the guitar beause the inherent nature of it's shape. Do Our sites have a LOT of tips on such things as fret installation, neck adjustments and

wood. NOT glue the back on at this time. The top must be secured to the sides first. recommendations etc. Check out the articles and come back often as we are adding content all the

Above all else make sure everything fits together perfectly before gluing. Do not force anything as time.

stress is a guitar ruins the tone. When in doubt take a few extra hours of sanding trimming and pre- Once the braces have had at least a couple of hours to dry, shape them and round them with small

assembly to get everything as perfect as you can. planes, finger planes, chisels and sanding sticks. Final shape and sand them with 220 sandpaper

until satin smooth.

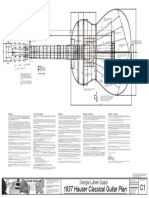

Date: Feb. 2010 Sheet Number

Ultimate Guitar OnLine's

This Drawing or Drawings Are To Used For One

Use Only And Not Reproduced For Any Other

Purpose Than Construction Of This Particular Revisions:

C1

Instrument, and a One Time Reproduction Only is

Classical Guitar Plan #2

Allowed

Unless Noted Otherwise,

Reproduction, Distribution or Sales For Any Other These Plans Are Drawing

Use Is Strictly Prohibitied And Falls Under U.S Full Scale. They Are

Copyright Laws For Ultimate Guitar OnLine 2010 Labeled in mm and

Fractional Inches

You might also like

- The Art and Craft of Making Classical GuitarsFrom EverandThe Art and Craft of Making Classical GuitarsRating: 2 out of 5 stars2/5 (1)

- Classic 3 PlanDocument1 pageClassic 3 PlanMichele PacilliNo ratings yet

- Guitar Assembly Work Board - Top View 1937 Hauser Classical Guitar ShapeDocument1 pageGuitar Assembly Work Board - Top View 1937 Hauser Classical Guitar ShapeDaniel Garfo100% (1)

- Guitar Inside Mold - Side View 1937 Hauser Classical Guitar ShapeDocument1 pageGuitar Inside Mold - Side View 1937 Hauser Classical Guitar ShapeDaniel GarfoNo ratings yet

- Classic3plan 2Document1 pageClassic3plan 2Michele Pacilli100% (1)

- Classic3plan 3Document1 pageClassic3plan 3Michele PacilliNo ratings yet

- Guitar Inside Mold - Top View 1937 Hauser Classical Guitar ShapeDocument1 pageGuitar Inside Mold - Top View 1937 Hauser Classical Guitar ShapeDaniel Garfo100% (3)

- Top Plate Brace Layouts: Classical Guitar Plan #3Document1 pageTop Plate Brace Layouts: Classical Guitar Plan #3Michele PacilliNo ratings yet

- Classic 2 TemplatesDocument1 pageClassic 2 TemplatesDaniel Garfo100% (3)

- Master Class Guitar MakingDocument50 pagesMaster Class Guitar MakingCharles Alfaro83% (18)

- Guitar Fe18 Antonio de TorresDocument1 pageGuitar Fe18 Antonio de Torresandua40100% (7)

- Progetto TorresDocument1 pageProgetto TorresMichele Pacilli50% (2)

- Martin V Joint NeckDocument1 pageMartin V Joint Neckandua40100% (2)

- Bolt On Acoustic Guitar NeckDocument1 pageBolt On Acoustic Guitar NeckJayMorgan50% (2)

- Construction Notes For A Steel String Guitar - SampleDocument32 pagesConstruction Notes For A Steel String Guitar - SampleDennistoun75% (4)

- Soundboards DF PDFDocument17 pagesSoundboards DF PDFalberto reyes100% (2)

- (Luthieria) Acoustic Guitar MakingDocument63 pages(Luthieria) Acoustic Guitar MakingKa LuthieriaNo ratings yet

- Instructions Neck AngleDocument21 pagesInstructions Neck Angleandua40100% (2)

- Guitar Guru: What'S The Difference Between Handmade and Handcrafted?Document2 pagesGuitar Guru: What'S The Difference Between Handmade and Handcrafted?Jared WilliamsNo ratings yet

- Tonewood Technical DataDocument24 pagesTonewood Technical DataCaps Lock100% (4)

- Bending Iron For Guitar MakingDocument1 pageBending Iron For Guitar Makingpeter100% (1)

- Ukelele Tenor PlanosDocument1 pageUkelele Tenor PlanosBROSHER100% (2)

- 11 Free Guitar Plans, 20 Guitar Building Jigs and 35 More Resources For Newbie Luthiers - PDFDocument22 pages11 Free Guitar Plans, 20 Guitar Building Jigs and 35 More Resources For Newbie Luthiers - PDFBatik Kambangsri100% (4)

- Classic3plan 2 PDFDocument1 pageClassic3plan 2 PDFarantxa16No ratings yet

- Making A Classical GuitarDocument45 pagesMaking A Classical GuitarRalie Ralev100% (5)

- Make Your Own Spanish Guitar (1957)Document40 pagesMake Your Own Spanish Guitar (1957)Erdem Kapan100% (2)

- Luthieria - Selmer Maccaferri NeckDocument9 pagesLuthieria - Selmer Maccaferri Neckmandolinero67% (9)

- ManZer GuitarsDocument18 pagesManZer Guitarsdedalus777100% (5)

- United States Patent: (12) (10) Patent N0.: US 6,894,209 B2Document14 pagesUnited States Patent: (12) (10) Patent N0.: US 6,894,209 B2Arnab BhattacharyaNo ratings yet

- Livro Antonio de Torres Guitar Maker His Life and Work J. L - RomanillosDocument377 pagesLivro Antonio de Torres Guitar Maker His Life and Work J. L - RomanillosCassio Ribeiro Silva67% (15)

- Archtop Guitar ManualDocument123 pagesArchtop Guitar ManualCarlo351100% (13)

- French PolishingDocument34 pagesFrench Polishingaboutsoundcraft89% (9)

- Rosettes PDFDocument7 pagesRosettes PDFjuvemoraisNo ratings yet

- Archtop Guitar PlansDocument1 pageArchtop Guitar PlansBart Stratton83% (6)

- Bracing Styles For Classical Guitars - This Is Classical GuitarDocument9 pagesBracing Styles For Classical Guitars - This Is Classical Guitarmenique100% (1)

- Acoustic Guitar MakingDocument1,000 pagesAcoustic Guitar MakingRicardo Luis Martin Sant'Anna100% (9)

- Acoustic Guitar Building InstructionsDocument40 pagesAcoustic Guitar Building InstructionsLeeUnder100% (2)

- HHHDocument3 pagesHHHAsemNo ratings yet

- 16 Archtop Guitar BuildDocument123 pages16 Archtop Guitar Buildluis7oliveira_2100% (4)

- Curso Luthier by Johnny GuitarDocument95 pagesCurso Luthier by Johnny GuitaradmlewisNo ratings yet

- Fret Position Calculator - Stewmac 1Document3 pagesFret Position Calculator - Stewmac 1Josué S. De Jesus - Jorge100% (1)

- ItishDocument140 pagesItishGabriel Cano100% (6)

- Guitar DimensionsDocument4 pagesGuitar DimensionsWalied SamiNo ratings yet

- (Luthier) Making A Ukulele, Plans 1915Document5 pages(Luthier) Making A Ukulele, Plans 1915Esteban HNo ratings yet

- Introduction to Kit Acoustic Guitars (or) Life is Short...Build a GuitarFrom EverandIntroduction to Kit Acoustic Guitars (or) Life is Short...Build a GuitarRating: 1 out of 5 stars1/5 (1)

- The Uke Book Illustrated: Design and Build the World's Coolest UkuleleFrom EverandThe Uke Book Illustrated: Design and Build the World's Coolest UkuleleRating: 5 out of 5 stars5/5 (1)

- Classic3plan PDFDocument1 pageClassic3plan PDFarantxa16No ratings yet

- 900 Spanish VerbsDocument10 pages900 Spanish VerbsMarlene VotawNo ratings yet

- Fitzpatrick DermatologyDocument2,576 pagesFitzpatrick DermatologyRiris Sutrisno100% (2)

- Fitzpatrick Dermatology in General Medicine WWW - Emchnet.com - Pdffitzpatrick PDFDocument2,576 pagesFitzpatrick Dermatology in General Medicine WWW - Emchnet.com - Pdffitzpatrick PDFToby MarshallNo ratings yet

- Current Calcasieu Parish School Board Election DistrictsDocument1 pageCurrent Calcasieu Parish School Board Election DistrictsKPLC 7 News0% (1)

- This Page Intentionally Left BlankDocument99 pagesThis Page Intentionally Left BlankRakesh GandhiNo ratings yet

- EL ENAMORADO - Saxofón Soprano - MusxDocument1 pageEL ENAMORADO - Saxofón Soprano - MusxErasto AriasNo ratings yet

- Osp 401 Boat Deck 0.3Document1 pageOsp 401 Boat Deck 0.3erikacheuqueman80No ratings yet

- Request To ReDocument1 pageRequest To ReJoloPadayaoNo ratings yet

- Les Écoles Modernes: AppendixDocument1 pageLes Écoles Modernes: AppendixFlorin CrisanNo ratings yet

- A Graça Eterna de JesusDocument4 pagesA Graça Eterna de JesusDanielNo ratings yet

- JAN FEAT Erotic 1... Middle EastDocument5 pagesJAN FEAT Erotic 1... Middle EastАгент Гусь67% (3)

- Clase 4Document42 pagesClase 4Carlos ValenciaNo ratings yet

- Savarez Cantiga PremiumDocument2 pagesSavarez Cantiga PremiumAndrey BalalinNo ratings yet

- 1937 Hauser PlanDocument1 page1937 Hauser PlanDaniel Garfo100% (1)

- Australian LutherieDocument7 pagesAustralian LutherieAndrey BalalinNo ratings yet

- прайс 2015 PDFDocument1 pageпрайс 2015 PDFAndrey BalalinNo ratings yet

- 1937 Hauser PlanDocument1 page1937 Hauser PlanDaniel Garfo100% (1)

- Sinier de Ridder - Lacote A Paris GB PDFDocument9 pagesSinier de Ridder - Lacote A Paris GB PDFAndrey BalalinNo ratings yet

- Ramirez прайс 2015Document1 pageRamirez прайс 2015Andrey BalalinNo ratings yet

- Ramirez Modelo SencilloDocument2 pagesRamirez Modelo SencilloAndrey BalalinNo ratings yet

- Yamashita ProgrammDocument4 pagesYamashita ProgrammAndrey Balalin100% (1)

- 12STEM3 Group5 FINALCHAPTER3Document7 pages12STEM3 Group5 FINALCHAPTER3Josh RoqueNo ratings yet

- Kemper Profiler Basics EN-DE 2.0 PDFDocument136 pagesKemper Profiler Basics EN-DE 2.0 PDFAlexandre NovaisNo ratings yet

- VANDA-Science Olympiad-Grade-7Document14 pagesVANDA-Science Olympiad-Grade-7datam mirhoseiniNo ratings yet

- Denver, John - Take Me Home, Country Roads Chords Heartwood Guitar PDFDocument1 pageDenver, John - Take Me Home, Country Roads Chords Heartwood Guitar PDFlepaulzNo ratings yet

- 2021 Jackson Custom Select Options Menu Us MSRP 1.5.21Document2 pages2021 Jackson Custom Select Options Menu Us MSRP 1.5.21carlos gottardiNo ratings yet

- Beginner Fingerstyle Guitar PatternsDocument1 pageBeginner Fingerstyle Guitar PatternsJean-Claude Bruce Lee100% (1)

- Major Keys Root Notes For Bass Guitar PDFDocument1 pageMajor Keys Root Notes For Bass Guitar PDFJerry WisarNo ratings yet

- Matt Warnock Guitar: Your Online Guide To Playing Better Jazz GuitarDocument66 pagesMatt Warnock Guitar: Your Online Guide To Playing Better Jazz GuitarAnonymous uuV9d4r3No ratings yet

- Peru Book Denotter ch2Document47 pagesPeru Book Denotter ch2Helene EgbertsNo ratings yet

- Real Guitar ManualDocument23 pagesReal Guitar ManualFivos Kororos100% (1)

- Catalog Yamaha GuitarDocument6 pagesCatalog Yamaha GuitarRanjan SahooNo ratings yet

- ProductGuide EURO AcousticsDocument28 pagesProductGuide EURO AcousticsFredNo ratings yet

- AdvancedFingerpicking FiddleTunes PDFDocument19 pagesAdvancedFingerpicking FiddleTunes PDFPoss Hum100% (1)

- Power ChordsDocument4 pagesPower ChordsBingoTrendNo ratings yet

- Guitar Forum 2 (2004)Document112 pagesGuitar Forum 2 (2004)Tamara Sims100% (5)

- Brand Manual GibsonDocument25 pagesBrand Manual GibsonThomas VeugenNo ratings yet

- Andrea Gonzalez Caballero: Serenata EspañolaDocument15 pagesAndrea Gonzalez Caballero: Serenata EspañolaCarlos Eduardo Raboch100% (4)

- G6 PatchMemoryList v1.1 E2Document27 pagesG6 PatchMemoryList v1.1 E2nick rentNo ratings yet

- Descriptive EssayDocument3 pagesDescriptive Essaysawkiew79No ratings yet

- Ajeeb Dasta On GuitarDocument5 pagesAjeeb Dasta On GuitarSurendra SinghNo ratings yet

- Guitar HarmonicsDocument3 pagesGuitar HarmonicsgernNo ratings yet

- Concert Report Music History IDocument4 pagesConcert Report Music History IDevin MatthewsNo ratings yet

- Linc Brew Plexi HX Stomp Patch 2 - 1 ReadMeDocument5 pagesLinc Brew Plexi HX Stomp Patch 2 - 1 ReadMeDavid SérgioNo ratings yet

- Opus 2 Pupil TextbookDocument64 pagesOpus 2 Pupil TextbookPaul CecchettiNo ratings yet

- 2008 Fender FrontlineInStore PricelistDocument156 pages2008 Fender FrontlineInStore Pricelistglue2No ratings yet

- Guitar Lessons PDFDocument223 pagesGuitar Lessons PDFpeterlouisanthony785980% (5)

- 2013 Lowden Guitars UK Retail Price ListDocument4 pages2013 Lowden Guitars UK Retail Price ListGeorge Lowden GuitarsNo ratings yet

- The Principles of Musical InstrumentsDocument3 pagesThe Principles of Musical InstrumentsMathew CorderoyNo ratings yet

- Alternate Open-G Guitar Tuning For Disabled PlayersDocument5 pagesAlternate Open-G Guitar Tuning For Disabled PlayersVince MiglioreNo ratings yet

- Classical 1 21Document19 pagesClassical 1 21George Karidis100% (2)