Professional Documents

Culture Documents

A 240

Uploaded by

Mario Diaz Lopez100%(1)100% found this document useful (1 vote)

2K views89 pagesTrouble-shooting, teardown - assembly, removal and installation is fully covered. This transmission is currently found in the Toyota Corolla models.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTrouble-shooting, teardown - assembly, removal and installation is fully covered. This transmission is currently found in the Toyota Corolla models.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

2K views89 pagesA 240

Uploaded by

Mario Diaz LopezTrouble-shooting, teardown - assembly, removal and installation is fully covered. This transmission is currently found in the Toyota Corolla models.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 89

Technical Service Information

INTRODUCTION

TOYOTA A240

The A-240 transaxle is a 4 speed front wheel drive fully automatic

transmission with a converter clutch. Trouble-shooting, teardown -

assembly, removal and installation is fully covered.

This transmission is currently found in the Toyota Corolla models.

We thank the Toyota Corporation

for the illustrations and information

that have made this booklet possible.

ROBERT D. CHERRNAY DALE ENGLAND

TECHNICAL DIRECTOR FIELD SERVICE CONSULTANT

FRANK MIETUS WAYNE COLONNA

HOTLINE TECHNICIAN HOTLINE TECHNICIAN

ED KRUSE

LAY OUT

AUTOMATIC TRANSMISSION SERVICE GROUP

9200 SOUTH DADELAND BLVD.

SUITE 720

MIAMI, FLORIDA 33156

(305) 661-4161

INDEX

TROUBLE~SHOOTING

ELECTRIC CONTROL ....

REMOVAL OF TRANSAXLE

‘TEARDOWN

COUNTERSHAFT

VALVE BODY

ASSEMBLY ....

OIFFERENTIAL

ATSG Technical Service Information

TROUBLESHOOTING

Problem Ponsible cause Remedy

Fad dacolored or] Fond contaminated Replace uid

smells burnt Torque converter faulty Replace torque converter

Transmission faulty Disassemble and inspect

transmission

Vehicle dots not move | T/M contrl eable out of adjustment ‘Adjust control cable

in any forward range ‘Valve body or primary regulator faulty Inspect valve body

OF reverse: ‘Transmission faulty Disassemble and inspect

[Vericie does not move | Park lock paw faulty Inspect park paw

in any range Valve body or primary regulator faulty | Inspect valve body

Torque converter faulty Replace torque converter

Converter drive plate broken | Replace torque converter

O11 Pump intake strainer Blocked Clean strainer

| Transmission faulty Disassemble and inspect

| transmission

Shik lever pouiton TIM control cable ut of adjustment | Agjust contro able

incorrect, Manual vale and lever faulty Inspect valve body

Transmision faulty Disassembie and inspect

transmission

Harsh engagement Throttle cable out of adjustment ‘Adjust throttle cable |

into any dive range | Valve body or primary regulator faulty | Inspect vave body

Accumulator pistons faulty Inspect accumulator pistons

Transmission faulty Disassemble and inspect

transmission

Delayed 1-2, 23 or Throttle cable out of adjustment ‘Adjust throttle cable

3-00 upsshitt, or down | Governor faulty | tnsnect oavernoe

TROUBLESHOOTING (Cont'd)

Technical Service Information

Problem Possible cause Remedy

Down-shift occurs too | Throttle cable out of adjustment ‘Adjust throwtle cable 1

ek — tate while | Governor faulty Inspect governor |

Valve body faulty Inspect valve body

Transmission faulty Disatsemble and inspect

No O03, 320r24 Throttle cable out of adjustment ‘Adjust throttle cable

kick-down

Governor faulty Inspect governor

L Valve body faulty Inspect valve body

No engine braking Valve body faulty Tnapect valve body

Transmission faulty Disassemble and inspect,

transmission

Vehicle does not TIM control cable out of adjustment ‘Adjust control cable

pein Parking lock pawl and rod Inspect lock pawl and rod

GENERAL NOTES

1, Troubles occuring with the automatic transmission can be caused by either the engine or the transmis:

sion itself. These two areas should be distinctly isolated before proceeding with troubleshooting.

2. Troubleshooting should begin with the simpliest operation, working up in order of difficulty, but first

determine whether the trouble lies within the engine or transmission.

3. Proceed with the inspection as follows.

(1) Preminary Check

Basic check

{a) Check oil level.

(b} Check throttle cable mark.

(c) Check shift cable.

(a) Check neutral start switch.

(e) Check idle speed.

(f) Check tire inflation pressure (See page

| FA-3). Repair as necessary.

‘Check engine and torque converter. (2) Stall Test

T Repair as necessary.

creck ae (3) Time Lag Test

Cheek each clutch, brake and gear for wear

i

Confirm by road test and repair as necessary.

‘Measure line pressure and make basic check of (4) Hydraulic Test

ftuid cireuit, Confirm shift point and extent of shock by

foad test. Repair as necessary.

‘Check ATM by road test. tb iced hese

I Confirm if trouble lies within ATM.

If noisy or vibrating, the possible cause could

Overhaul transmission be with the compressor, engine, drive shaft,

tires, etc.

COn-vehicle repair

YZ

7 Ads it hot

Technical Service Information

Ok it hot

\M

Rubber Boot

Cabie Stopper

Adjusting Nut

Swivel nut

ATF INSPECTION

1. CHECK FLUID LEVEL

2. CHECK FLUID CONDITION

If the ATF smelles burnt or is black, replace it.

3. REPLACE ATF

ADJUSTMENTS

ADJUSTMENT OF THROTTLE CABLE

1. DEPRESS ACCELERATOR PEDAL ALL THE WAY

AND CHECK THAT THROTTLE VALVE OPENS

FULLY

If the throttle valve does not open fully, adjust the accele-

rator link.

2, FULLY DEPRESS ACCELERATOR

3. LOOSEN ADJUSTMENT NUTS

4, ADJUST THROTTLE CABLE

(a) Adjust the cable housing so that the distance between

‘the end of the boot and the stopper on the cable is

correct.

Distance: 0-1 mm (0 — 0.04 in.)

(b) Tighten the adjusting nuts.

{c)_ Recheck the adjustments.

ADJUSTMENT OF TRANSMISSION CONTROL

CABLE

(a) Loosen the swivel nut on the lever.

{b) Push the manual lever fully toward the right side of

the vehicle.

(c)_ Return the lever two notches to the NEUTRAL posi-

tion,

(d) Set the shift lever in “N” range.

{e) While holding the lever lightly toward the “R” range

side, tighten the swivel nut.

ADJUSTMENT OF NEUTRAL START SWITCH

If the engine will start with the shift selector in any range

other than “N’ or “P” range, adjustment is required.

1. LOOSEN NEUTRAL START SWITCH BOLTS AND SET

SHIFT SELECTOR IN “N” RANGE

2, ADJUST NEUTRAL START SWITCH

{a) Disconnect the neutral start switch connector.

{b) Connect an ohmmeter between the terminals.

{c) Adjust the switch to the point where there is con-

tinuity between terminals.

{d) Connect the neutral start switch connector.

3. TORQUE NEUTRAL START SWITCH BOLTS

Torque: 55 kg-cm (48 in.-Ib, 5.4 N-m)

7

Technical Service Information

ON-VEHICLE REPAIR

REMOVAL OF GOVERNOR VALVE

REMOVE GOVERNOR COVER AND O-RING

‘A240L REMOVE GOVERNOR BODY WITH THRUST

WASHER

REMOVE GOVERNOR BODY ADAPTOR

INSTALLATION OF GOVERNOR VALVE

INSTALL GOVERNOR BODY ADAPTER

Technical Service Information

INSTALLATION OF THROTTLE CABLE

a

INSTALL CABLE IN TRANSMISSION CASE

(a) Be sure to push it in all the way.

(b) Install the retaining plate and bolt.

INSTALL VALVE BODY

IF THROTTLE CABLE IS NEW, STAKE STOPPER ON

INNER CABLE

NOTE: New cable do not have a cable stopper staked.

(a) Bend the cable about 200 mm (7.87 in.) in radius.

(b) Pull the inner cable lightly until a slight resistance is

felt, and hold it.

{c)_ Stake the stopper as shown, 0.8 — 1.5 mm (0,031 —

0.059 in.) in width.

CONNECT THROTTLE CABLE

Connect the cable to the throttle linkage.

ADJUST THROTTLE CABLE

INSTALL NEUTRAL START SWITCH

{a) Install the neutral start switch.

(b) Install the manual shift lever.

(c)_ Adjust the neutral start switch.

(See page AT-4)

(d) Connect the transmission control cable.

TEST DRIVE VEHICLE

9

A2@00

Technical Service Information

REMOVAL OF VALVE BODY

CLEAN TRANSMISSION EXTERIOR

To help prevent contamination, clean the exterior of the

transmission.

DRAIN TRANSMISSION FLUID

Using SST, remove the drain plug and drain the

fluid into suitable container, (A130L, A131L)

SST 09043-38100

REMOVE OIL PAN AND GASKET

CAUTION: Some fluid will remain in the oil pan.

Remove all pan bolts, and carefully remove the pan

assembly, Discard the gasket.

REMOVE OIL STRAINER

Remove the three bolts, and the oil strainer.

CAUTION: Be careful as some oil will come out with the

strainer.

REMOVE OIL TUBES

Pry up both tube ends with a large screwdriver and re

move the tubes.

REMOVE MANUAL DETENT SPRING

10

Technical Service Information

REMOVE VALVE BODY

(a) Remove the fourteen bolts.

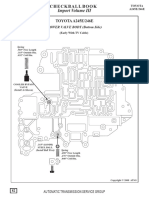

‘A240

{b) Disconnect the throttle cable.

(c) Disconnect the manual valve connecting rod.

(A240L)

(d) Remove the valve body.

REMOVE GOVERNOR APPLY GASKET

SX

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

INSTALLATION OF VALVE BODY

ROL 22530 INSTALL FOURTEEN BOLTS IN VALVE BODY

fash NOTE: Each bolt length (mm) is indicated in the figure.

will Pgs Finger tighten the all bolts first. Then tighten them with a

xl ~VReL— 20 torque wrench.

Torque: 100 kg-cm (7 ft-lb, 10 N-m)

3020 2020 onoos

“A2A0L. INSTALL OIL TUBES

a i i

° Tap the tubes with a plastic hammer to install them into

the positions indicated in the figure,

CAUTION: Be careful not to bend or damage the tubes.

INSTALL DETENT SPRING

NOTE: Each bolt length (mm) is indicated in the figure.

(a) Finger tighten the all bolts first. Then tighten them

with a torque wrench,

Torque: 100 kg-cm (7 ftlb, 10 N-m)

(b) Check that the manual vaive lever is in contact with

the center of the roller at the tip of the detent spring.

INSTALL OIL STRAINER

Each bolt length (mm) is indicated in the figure.

AUTOMATIC TRANSMISSION SERVICE GROUP

12

Technical Service Information

ELECTRIC CONTROL (A240L)

CIRCUIT

Gauge

Fuse

® ov oFF

Indieator

+ie

FAVEET T

[le >

® ODOFF indicator @_ OD Solenoid

(Wire side)

{SMW side)

(i

[5] Fae

Indicator

lumination

© 00 Main saw

(SAW sided

© water Thremo S/W

(S/W side)

13

TSG

Technical

Service Information

REMOVAL OF TRANSAXLE

ik

2.

3.

10.

n,

12,

REMOVE NEGATIVE BATTERY TERMINAL

REMOVE AIR CLEANER

DISCONNECT NEUTRAL START SWITCH

CONNECTOR

DISCONNECT SOLENOID VALVE CONNECTOR

(A240L)

DISCONNECT SPEEDOMETER CABLE

REMOVE THROTTLE CABLE

REMOVE CONTROL CABLE

(a) Remove the clip.

(b) Remove the retainer.

(c) Remove the contro! cable bracket.

DISCONNECT OIL COOLER HOSE

REMOVE WATER INLET (4A-C engine)

RAISE VEHICLE AND DRAIN TRANSAXLE

REMOVE ENGINE UNDER COVER

REMOVE FRONT AND REAR MOUNTING

(a)

(b)

te)

Remove the two dust covers from the member.

Remove the four bolts.

Remove the front and rear mounting.

14

Technical Service Information

13, REMOVE ENGINE MOUNTING CENTER MEMBER

(a) Remove the four bolts.

(b) Remove the center member.

14. REMOVE DRIVE SHAFT

15, REMOVE STEERING KNUCKLE

16. REMOVE STARTER MOTOR

17, REMOVE ENGINE REAR END PLATE

(4A engine

18. REMOVE REAR END PLATE HOLE PLUG

(1C engine)

19, REMOVE SIX TORQUE CONVERTER MOUNTING

BOLTS

(a) Turn the crankshaft to gain access to each bolt.

{b) Hold the crankshaft pulley nut with a wrench.

{c) Remove the six bolts.

20. REMOVE LH ENGINE MOUNTING

(a) Hold the engine and transaxle with two jacks, or a

chain block and jack.

(b) Remove the mounting set bolts.

21, REMOVE TRANSAXLE MOUNTING BOLTS

22. INSTALL GUIDE PIN IN TORQUE CONVERTER

Install the guide pin in one of the torque converter bolt

holes.

If necessary, a guide pin can be made by cutting off the

head of a bolt.

23. PRY ON END OF GUIDE PIN TO BEGIN MOVING

TRANSMISSION WITH CONVERTER

‘The guide pin helps keep the converter with the transmis

sion.

24, REMOVE TRANSAXLE ASSEMBLY FROM ENGINE

25. REMOVE TORQUE CONVERTER FROM

TRANSMISSION

15

Technical Service Information

DISASSEMBLY OF TRANSMISSION (A240L)

COMPONENTS

Governor Driven Gear ‘Throttle Cable

Oil Fitler Tube

Gasket | Thrust Washer

Governor Body

}@ O-Ring

Cover Bracket —@y

Governor Cover

oe

Transaxle Housing

Manual

‘Shift Lever

Manual Valve

‘Spring

(Pq — Oi Gallery Cover

0 sv kserew

eso

By Accumulator Piston

Snap Ring |@0-Ring

Second Coast: ET

Brake Piston ft we

Cover

‘Accumulator Piston

@Gasker

Cover Tightening torque

lo © Nowreusable part

3k: Precoated part age

4 ATSG Technical Service Information

COMPONENTS (Cont'd)

Technical Service Information

COMPONENTS (Cont'd)

Lock Paw! Shaft

| Parking Lock Paw!

Pawl Shaft Clamp |

ob

ot

8

Guide Sleeve

cam Guide

Parking Lock

‘Sleeve

Stopper Plate

Parking Manual Valve

toacttes | Sut

WSoacer | washer © Oi Seat

Manual Retaining Soring

Vatve Lever

Differential Drive Pinion

‘and Output Flange Snap Ring

Outer Race

Outer Race

Inner Race

Lock Nut Bearing

; 5 ‘ Md | A are

vo a . * f 0}

Counter Driven Gear

Besring

Oil Seat Ring Needle Bearing

ikgcem (eI, Nema] : Tightening torque

©: Noneuabe par sy

Snap Ring Return Spring

18

Technical Service Information

SEPARATE BASIC SUBASSEMBLY

1. REMOVE TWO OIL COOLER PIPES

2. REMOVE OIL FILLER GAUGE AND TUBE

3. REMOVE MANUAL SHIFT LEVER

4. REMOVE NEUTRAL START SWITCH

REMOVE THROTTLE CABLE RETAINING PLATE

6. REMOVE SOLENOID WIRE RETAINING PLATE

7. REMOVE GOVERNOR BODY

(a) Remove the two bolts and cover brackets.

(b) Remove the governor cover and O-ring.

{c) Remove the governor body with thrust washer.

{d) Remove the three bolts and governor body adaptor.

(e) Remove the gasket.

19

Technical Service Information

8 REMOVE PAN AND GASKET

{a) Remove the eighteen bolts.

(b) Remove the pan by lifting the transmission case,

CAUTION: Do not turn the transmission over as it will

contaminate the valve body with the foreign materi

the bottom of the pan.

(c) Place the transmission on wooden blocks to prevent

damage to the pipe.

9, EXAMINE PARTICLES IN PAN

My Remove the magnet and use it to collect any steel chips.

Look carefully at the chips and particles in the pan and on

A the magnet to anticipate what type of wear you will find

in the transmission

Steel (magnetic)... . bearing, gear and clutch plate

wear

Brass (non-magnetic) . .. bushing wear

10. TURN TRANSMISSION OVER AND REMOVE

OIL STRAINER

11, REMOVE FIVE OIL TUBES

Pry up both tube ends with a large screwdriver and remove

the five tubes.

12, REMOVE MANUAL DETENT SPRING

20

Technical Service Information

13, DISCONNECT SOLENOID

14, REMOVE VALVE BODY

(a) Remove the solenoid set bolt.

{b) Remove teh thirteen bolts and wire retail

(c) Disconnect the throttle cable from the cam.

(d) Disconnect manual valve connecting rod from the

manual valve lever and remove the valve body.

15, REMOVE THROTTLE CABLE FROM CASE

16. REMOVE SOLENOID WIRE

21

Technical Service Information

17. REMOVE GOVERNOR APPLY GASKET

18, REMOVE C, ACCUMULATOR PISTON AND SPRING

Using low pressure compressed air (1 kg/em?, 14 psi or

98 kPa) pop out the piston into a rag. Force air into the

hole shown and remove the piston and spring.

19. REMOVE ACCUMULATOR PISTON AND SPRINGS

(a) Loosen the six bolts one turn at a time until the

spring tension is released.

(b) Remove the cover and the gasket.

(c)_ Remove the piston and spring for C1.

(d) Using low-pressure compressed air (1 kg/em?, 14 psi

or 98 98 kPa) pop out piston Bs and Ca it

Force air into the hole shown and remove the piston,

and springs.

20. TURN TRANSMISSION OVER AND MEASURE

PISTON STROKE OF SECOND COAST BRAKE

(2) Remove the snap ring,

{b) Remove the cover.

{c)_ Remove the piston and the outer spring.

{d) Install the piston without the outer spring,

(e) Install the snap ring.

(f)_ Firmly push the brake apply rod into the case. At this

time, measure the distance between the outside of the

snap ring and the tip of the piston rod as shown.

Distance: 14.0 — 15.5 mm (0.551 — 0.610 in.)

[Actual piston stroke is 1.5 — 3.0 mm (0.059 —0.118in.)}

(a) Remove the snap ring and piston,

22

Technical Service Information

21, REMOVE SIX BOLTS HOLDING OIL PUMP TO

TRANSMISSION CASE

22, PULL OIL PUMP FREE FROM TRANSMISSION

CASE WITH SST

SST 09350-32011

23, REMOVE OIL PUMP

24. WATCH FOR RACE AND BEARING BEHIND OIL

PUMP

2. REMOVE DIRECT CLUTCH

26. REMOVE FORWARD CLUTCH

27. WATCH FOR RACE

ara 23

28.

29.

30.

31,

32.

Technical Service Information

REMOVE SECOND COAST BRAKE BAND

{a) Push the pin with a small screwdriver and remove it

from the bolt hole of the oil pump mounting.

(b) Remove the brake band.

REMOVE FRONT PLANETRARY RING GEAR

WITH BEARING AND RACE

WATCH FOR RACE AND BEARING ON RING GEAR

REMOVE FRONT PLANETARY GEAR WITH RACE

WATCH FOR RACES AND BEARING ON FRONT

PLANETARY GEAR

24

You might also like

- Overhaul A240eDocument140 pagesOverhaul A240eSamuel83% (6)

- Overhaul A240e PDFDocument140 pagesOverhaul A240e PDFMuslihnofal50% (2)

- Re4ro1a PDFDocument106 pagesRe4ro1a PDFженя евчин100% (1)

- U-340 Valve BodyDocument19 pagesU-340 Valve BodyAle100% (4)

- Dokumen - Tips - Technical Service Information Atsg Toyotalexus U150u250 Preliminary Information PDFDocument5 pagesDokumen - Tips - Technical Service Information Atsg Toyotalexus U150u250 Preliminary Information PDFAleksandr Kuznichenko0% (1)

- Auto Trans U241e PDFDocument396 pagesAuto Trans U241e PDFmasakp94% (16)

- Honda Accord, Acura RSX, TSX, CR-V Transmission SpecsDocument8 pagesHonda Accord, Acura RSX, TSX, CR-V Transmission Specshidraulic100% (5)

- Toyota U151ef U250eDocument1 pageToyota U151ef U250eMauricio Exequiel Chavez100% (1)

- A340 VB ID PDFDocument5 pagesA340 VB ID PDFleeroy381No ratings yet

- A760EDocument47 pagesA760ENeqcer Martínez100% (3)

- U340 441E DescriptionDocument25 pagesU340 441E Descriptionruslan1580No ratings yet

- Toyota A340FDocument1 pageToyota A340FReydeEspa171% (7)

- A340E and A343E automatic transmission specifications and operationDocument8 pagesA340E and A343E automatic transmission specifications and operationcalixtoruas75% (4)

- Valve Body A246e PDFDocument1 pageValve Body A246e PDFLuis Velazquez63% (8)

- Automatic A245E, A246EDocument17 pagesAutomatic A245E, A246EAntonio Carlos Santos77% (13)

- Specification and function of U340E and U441E automatic transaxlesDocument25 pagesSpecification and function of U340E and U441E automatic transaxlesOliverFrancoCruzAranibar100% (2)

- Shop Manual U-341FDocument115 pagesShop Manual U-341FDavid100% (3)

- Automatic Transaxle Repair Manual Section TermsDocument132 pagesAutomatic Transaxle Repair Manual Section TermsRoman Filatov83% (6)

- JR405EDocument8 pagesJR405ELalo Barajas Garcia100% (2)

- Location Valve Body U151EDocument5 pagesLocation Valve Body U151EgabotoyoNo ratings yet

- JF016E-JF017E Vacuum Manual Valve BodyDocument4 pagesJF016E-JF017E Vacuum Manual Valve Bodyak_adamNo ratings yet

- A245 ToyotaDocument56 pagesA245 ToyotaEderson BJJ100% (5)

- U140e U241e Zip PDFDocument8 pagesU140e U241e Zip PDFossoski100% (1)

- F4ael PDFDocument120 pagesF4ael PDFPablo Cansas100% (2)

- Import Checkball Vol III 82-92 PDFDocument11 pagesImport Checkball Vol III 82-92 PDFJulio Chalbaud100% (1)

- U151E ComponentsDocument203 pagesU151E ComponentsAndres Chavez Barrios100% (3)

- Toyota U660E FWD 6-speed transmission rebuild kit guideDocument4 pagesToyota U660E FWD 6-speed transmission rebuild kit guidemickabd2002100% (1)

- A40Document15 pagesA40Ale100% (3)

- U760e Zip inDocument11 pagesU760e Zip inJorge Hernandez Villeda100% (5)

- A-240L-A241E-A243 ManualDocument278 pagesA-240L-A241E-A243 Manualilloatayde100% (3)

- A750Document2 pagesA750ReydeEspa1100% (2)

- Automatic Transaxle Components and OperationDocument140 pagesAutomatic Transaxle Components and OperationRadu Xnx100% (6)

- Toyota A245eDocument18 pagesToyota A245etambache6969% (16)

- Toyota U151E-U250E Zip Kit: Electronic CautionsDocument8 pagesToyota U151E-U250E Zip Kit: Electronic CautionsMajdy Alsobhi100% (2)

- Daihatsu Type A4q A4r Series Automatic Transmission Electrically Controlled Service Manual No9738Document48 pagesDaihatsu Type A4q A4r Series Automatic Transmission Electrically Controlled Service Manual No9738Guillermo Rosas GonzalezNo ratings yet

- F4A4x at Manual PDFDocument135 pagesF4A4x at Manual PDFDener Rogerio Dos SantosNo ratings yet

- U440e PDFDocument2 pagesU440e PDFMaxisys Autel75% (4)

- U341e PDFDocument18 pagesU341e PDFmaq8048100% (2)

- U151e PDFDocument155 pagesU151e PDFAlejandro Roldan Valle88% (8)

- Transmission Valve Body ReplacementDocument5 pagesTransmission Valve Body ReplacementPablo MontesNo ratings yet

- Toyota k310 CVT Transmission Repair ManualDocument2 pagesToyota k310 CVT Transmission Repair ManualMessanh Koutoukloui29% (7)

- Toyota A44d PDFDocument50 pagesToyota A44d PDFAdal Vera100% (3)

- Re 4 Fo 4 ADocument116 pagesRe 4 Fo 4 AWissem RatelNo ratings yet

- A750 TransmissionDocument30 pagesA750 Transmissionjohnatan chui100% (2)

- Re4f03a PDFDocument112 pagesRe4f03a PDFCarlos Treviño80% (5)

- A4CF2Document65 pagesA4CF2Alex Maceira Graterol100% (2)

- TRANSMISSION VALVE BODY ASSY REMOVALDocument1 pageTRANSMISSION VALVE BODY ASSY REMOVALLuis Velazquez75% (4)

- U140eand U241Document25 pagesU140eand U241yosergey80% (5)

- A245e PDFDocument21 pagesA245e PDFluizjunior501100% (2)

- 1995 Ford Escort 1Document11 pages1995 Ford Escort 1Francisco SanchezNo ratings yet

- 25F-PRCServ PDFDocument38 pages25F-PRCServ PDFsindelu60No ratings yet

- Manual MitsubishiDocument219 pagesManual Mitsubishimiguel100% (1)

- Overhaul A140eDocument84 pagesOverhaul A140eDang Tien PhucNo ratings yet

- 1G FUEL SYSTEM (DOHC) - Service Adjustment ProceduresDocument40 pages1G FUEL SYSTEM (DOHC) - Service Adjustment ProceduresAgus Prasetyanto100% (1)

- A440FDocument49 pagesA440FRobert Moreau100% (6)

- Eclipse Electrical 1g PDFDocument320 pagesEclipse Electrical 1g PDFKrzysztof BanasikNo ratings yet

- 90 91electricalDocument320 pages90 91electricalradariderNo ratings yet

- Number: Group: Date:: Transmission (Sales Code DG6)Document6 pagesNumber: Group: Date:: Transmission (Sales Code DG6)Mohamed AhmedNo ratings yet

- 2GR-FE Engine MechanicalDocument156 pages2GR-FE Engine MechanicalLuks Fernandez100% (7)