Professional Documents

Culture Documents

Ap 5 Bitumen Disposal Pits

Uploaded by

nischal_babuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ap 5 Bitumen Disposal Pits

Uploaded by

nischal_babuCopyright:

Available Formats

Karnataka State Highways Improvement Project - II Detailed Project Report

Consultancy Services for Preparation of DPR, Bid Documents Volume IV – Part 1: EMP Report

and Associated Safeguard Instruments – EPC Packages Funded by World Bank

Appendix – 5

BITUMINOUS PAVEMENT RECYCLING

Introduction:

The bituminous pavement rehabilitation alternatives are mainly overlaying, recycling and

construction. In the recycling process the material from deteriorated pavement, known as reclaimed

asphalt pavement (RAP), is partially or fully reused in fresh construction. Some of the advantages

associated with pavement recycling are

(i) Less user delay

(ii) Conservation of energy

(iii) Preservation of environment

(iv) Reduced cost of construction

(v) Conservation of aggregate and binder

(vi) Preservation of existing pavement geometrics, etc.

It is also reported that recycled mix has higher resistance to shearing and scuffing, which in turn

increase the rutting resistance. Chances of reflective cracking are found to be less with recycled mix.

The RAP is a deteriorated bituminous mix that contains aged bitumen and aggregates. Hence, its

performance is poorer when compared to the fresh mix. The purpose of the bituminous recycling is to

regain the properties of the RAP, such that it tends to perform as good as fresh mix. Thus, the process

of bituminous recycling involves mixing of the RAP, fresh bitumen, rejuvenators and new aggregates

in suitable proportions. Rejuvenators are low viscosity oily substance, which helps to bring down the

high viscosity of aged bitumen. The present article intends to discuss briefly the various possible

methods of bituminous pavement recycling.

RECYCLING METHODS:

I. Based on the process adopted in recycling the bituminous mix, it can be broadly classified

as central plant recycling and in-situ recycling. If the RAP is modified at a plant, away

from construction site then the process is known as central plant recycling. In-situ

recycling process the RAP modified in place, where from it is available. Further, the

RAP could be heated to condition it. If heat is applied then the process is known as hot

mix recycling. In case of cold mix recycling, old materials are conditioned using

recycling agent (like, low viscosity emulsion) without application of heat.

II. Another way of classification could be based on the depth of the old pavement removed.

If the top layers of pavement fail, then the upper layers are removed and laid again. This

process is known as surface recycling. However, if base failure occurs then the pavement

layers up to base layer is removed and constructed again. This process is known as full

depth reclamation.

III. The following paragraphs elaborate further the various recycling processes.

HOT IN-PLACE RECYCLING:

Initially the pavement intended to be recycled is heated to a higher temperature using suitable

heating arrangement. This facilitates easier removal of materials. After heating, the pavement

surface is scarified to the required depth. Further, depending on the requirement fresh aggregate

and binder are added. The material is mixed well and compacted to the required thickness. As this

process consumes less time, least disruption to traffic is caused. Also the transportation cost is

less, as materials need not be taken away. Machinery required for this purpose being bulky in

Appendix 5: Bitumen Disposal Pits 1 Scott Wilson

Karnataka State Highways Improvement Project - II Detailed Project Report

Consultancy Services for Preparation of DPR, Bid Documents Volume IV – Part 1: EMP Report

and Associated Safeguard Instruments – EPC Packages Funded by World Bank

nature, sufficient right-of-way is required. This becomes an important consideration for in-place

recycling within the city areas.

COLD IN PLACE RECYCLING:

In cold in-place recycling process, first, the pavement is scarified with a scarifier. The scarified

material is crushed to the required gradation. Then the required amount of fresh aggregates and

binder in cold form (emulsion or cutback) is added. It is compacted and left for aeration. During

this process additives like, cement, quick lime, fly ash may be used. The cold mix recycling takes

care of local geometric correction, correction of pavement distresses like surface cracks. Being an

in-situ process the hauling cost is considerably low. The air quality related problems during

construction is almost negligible as compared to hot mix process. Similar to hot in place recycling

process the machinery required being bulky, sufficient maneuvering space should be available for

operating the equipment. Also, the lane needs to be closed for certain time so that sufficient time

is available for curing of freshly laid course. Moisture content (when bitumen emulsion is used)

needs to be given importance as it influences gradation control, mixing and workability of

recycled mix to a large extent.

HOT CENTRAL PLANT RECYCLING:

In this process, RAP is combined with required quantity of bituminous binder, and fresh

aggregates in a hot mix plant. The resultant mix is heated to an elevated temperature and mixed

thoroughly. The hot mix is transported to paving site, placed, and compacted to the required

compaction level. The main advantage of this process is that the mix properties and performance

is comparable to that of virgin mix. It is noted that the quality control in this process is better

when compared to hot in-place recycling. As RAP is susceptible to moisture, care needs to be

taken while storing it. Less workspace is required for laying the recycled mix, hence this is

suitable for the roads where the right-of-way is somewhat restricted. The RAP should not be

exposed to extremely high temperature as it causes pollution due to smoke emission.

COLD CENTRAL PLANT RECYCLING:

This is the similar process as is the hot central plant mixing, except it does not involve any

heating and therefore emulsion bitumen is used binder in most of the cases. Precise control on the

mixing time is important, over-mixing may cause premature breaking of emulsified bitumen,

under-mixing results in insufficient coating of aggregates.

Details of scarified bitumen generated from the proposed road project and the number of Bitumen

Disposal Pits (of volume 547 Cu m) required for the disposal are given in the following table.

Quantity of Scarified No of Bitumen

Link ID

Bitumen generated (Cu M) Disposal Pits

67A 7369 13

Appendix 5: Bitumen Disposal Pits 2 Scott Wilson

Karnataka State Highways Improvement Project - II Consultancy Services for Detailed Project Report

Preparation of DPR, Bid Documents and Associated Safeguard Instruments Volume IV – Part 1: EMP Report

plus Implementation Support for upgrading of 3,411km of state roads - STAGE 1

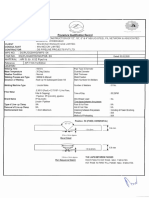

FIGUR

E:

TYPICAL DRAWING OF BITUMEN DISPOSAL PIT

Appendix 5: Bitumen Disposal Pits 3 Scott Wilson

You might also like

- Management of Ash Disposal: Naresh, D.NDocument8 pagesManagement of Ash Disposal: Naresh, D.NUjjaval MistryNo ratings yet

- Geotechnical AssessmentDocument421 pagesGeotechnical AssessmentLea A ManaloNo ratings yet

- EEMUA 159 Corrigendum Imprint 04 2015 PDFDocument22 pagesEEMUA 159 Corrigendum Imprint 04 2015 PDFAlfian Ibnu Pratama100% (1)

- Cold in Place Recycling A Relevant Process For Road PDFDocument13 pagesCold in Place Recycling A Relevant Process For Road PDFMatei PopaNo ratings yet

- Ronnel AC Design Solution 2Document36 pagesRonnel AC Design Solution 2Xype LanderNo ratings yet

- Gear Box-Flender Rro3710421Document23 pagesGear Box-Flender Rro3710421Shihab JamaanNo ratings yet

- Questioned: Document ExaminationDocument4 pagesQuestioned: Document ExaminationApple AsneNo ratings yet

- Aac Block PDDDocument84 pagesAac Block PDDsurendarNo ratings yet

- Final Year ProjectDocument50 pagesFinal Year ProjectDanish KaiserNo ratings yet

- Kandhal Keynote 1 - Paving Bitumen For Bituminous Road Construction in IndiaDocument49 pagesKandhal Keynote 1 - Paving Bitumen For Bituminous Road Construction in IndiaProf. Prithvi Singh Kandhal50% (4)

- Ten Rules Energy Efficient Brick FiringDocument6 pagesTen Rules Energy Efficient Brick FiringBhavna TanvaniNo ratings yet

- Working Instruction of Cement Lining Procedure PDFDocument4 pagesWorking Instruction of Cement Lining Procedure PDFtoni blaireNo ratings yet

- Condensate Stabilization Unit 1Document23 pagesCondensate Stabilization Unit 1Vraja KisoriNo ratings yet

- Recycling of Asphalt Pavements: An OverviewDocument12 pagesRecycling of Asphalt Pavements: An OverviewProf. Prithvi Singh Kandhal100% (1)

- Triboelectric NanogeneratorsDocument537 pagesTriboelectric NanogeneratorsAviraj Limaye100% (1)

- Fundamentals of Pipeline Design, Hydraulics & PumpsDocument75 pagesFundamentals of Pipeline Design, Hydraulics & PumpsMIRACLE26No ratings yet

- Wye BranchesDocument8 pagesWye BranchesbarukomkssNo ratings yet

- Bituminous Pavement RecyclingDocument4 pagesBituminous Pavement RecyclingMatei PopaNo ratings yet

- Dewatering and Briquetting ProcessDocument24 pagesDewatering and Briquetting ProcessJayaraj VNo ratings yet

- Bituminous Pavement Recycling - Effective Utilization of Depleting Non-Renewable ResourcesDocument9 pagesBituminous Pavement Recycling - Effective Utilization of Depleting Non-Renewable ResourcestheijesNo ratings yet

- 2021-ALANEME-Mechanical Properties Optimization of Soil-Cement Kiln Dust Mixture Using Extreme Vertex DesignDocument32 pages2021-ALANEME-Mechanical Properties Optimization of Soil-Cement Kiln Dust Mixture Using Extreme Vertex DesignHugoNo ratings yet

- Cold In-Place Recycling Using Foamed Bitumen - Step Towards Sustainable Road ConstructionDocument14 pagesCold In-Place Recycling Using Foamed Bitumen - Step Towards Sustainable Road ConstructionBijay Krishna DasNo ratings yet

- CH 052Document10 pagesCH 052MapeixNo ratings yet

- 28-00024 PMS1 - MAT PRO - PRG-004 (1st December 2023) - R00Document20 pages28-00024 PMS1 - MAT PRO - PRG-004 (1st December 2023) - R00Khalid JunaidNo ratings yet

- Fukuoka Paper Saravanan 30-08-2015 4 Pages 1Document5 pagesFukuoka Paper Saravanan 30-08-2015 4 Pages 1sih190016No ratings yet

- Design and Construction For Asphalt Pavement PDFDocument20 pagesDesign and Construction For Asphalt Pavement PDFM TaufikNo ratings yet

- Bitumen-Stabilised Materials For Sustainable Road InfrastructureDocument16 pagesBitumen-Stabilised Materials For Sustainable Road InfrastructureNM2104TE06 PRATHURI SUMANTHNo ratings yet

- Effect of Laterite Soil Using Corncob AshDocument4 pagesEffect of Laterite Soil Using Corncob AshHarsha VardhanNo ratings yet

- In-Situ Recycling of A Cement Treated Base Course UsingDocument14 pagesIn-Situ Recycling of A Cement Treated Base Course UsingHery BudiantoNo ratings yet

- 155 Iwanski PDFDocument8 pages155 Iwanski PDFJose Manuel Muñoz BlancoNo ratings yet

- Whitetopping - A Cost-Effective Rehabilitation PDFDocument18 pagesWhitetopping - A Cost-Effective Rehabilitation PDFAnupam SinghNo ratings yet

- CECR RecyclingofPavemets PDFDocument6 pagesCECR RecyclingofPavemets PDFMILENKA YSABEL UCEDA PUICONNo ratings yet

- CECR RecyclingofPavemetsDocument6 pagesCECR RecyclingofPavemetsMILENKA YSABEL UCEDA PUICONNo ratings yet

- Construction of Plastic Roads: An Effective Way To Utilize WastesDocument3 pagesConstruction of Plastic Roads: An Effective Way To Utilize WastesGanesh BhisteNo ratings yet

- Minnesota Heat-Transfer Method For Recycling Bituminous PavementDocument9 pagesMinnesota Heat-Transfer Method For Recycling Bituminous PavementsefrifamilyNo ratings yet

- Compacted Soil LinersDocument42 pagesCompacted Soil Linersumer farooqNo ratings yet

- A Study On M-Sand Bentonite Mixture For Landfill LinersDocument6 pagesA Study On M-Sand Bentonite Mixture For Landfill LinersGRENZE Scientific Society100% (2)

- Specifications For Flexible Airfield Pavements: Section - 1Document47 pagesSpecifications For Flexible Airfield Pavements: Section - 1Chandel PrakashNo ratings yet

- DOCS AND FILES-6151426-v1-Environment - Resource Use - Recycled Materials For Road Pavements Section 2011 - WDocument2 pagesDOCS AND FILES-6151426-v1-Environment - Resource Use - Recycled Materials For Road Pavements Section 2011 - WJEAN DE DIEU MUVARANo ratings yet

- Coimbatore Municipal Solid Waste MGMT Project PDFDocument18 pagesCoimbatore Municipal Solid Waste MGMT Project PDFAbhipsa MallickNo ratings yet

- BFC 31802 Chapter 6 ADocument34 pagesBFC 31802 Chapter 6 AfathullahaizatNo ratings yet

- Use of Recycled and Waste Materials in Concrete A Serbian PerspectiveDocument8 pagesUse of Recycled and Waste Materials in Concrete A Serbian PerspectiveMhel LaurelNo ratings yet

- Bitumen Grading System - From Penetration GradingDocument12 pagesBitumen Grading System - From Penetration GradingrajibchattarajNo ratings yet

- MS - 33 Rev 0 - Reinstatement of KNO.06 Lateral Line AsphaltDocument6 pagesMS - 33 Rev 0 - Reinstatement of KNO.06 Lateral Line AsphaltSyed Umair HashmiNo ratings yet

- Foamed Bitumen 4Document4 pagesFoamed Bitumen 4AnantNo ratings yet

- Cold in Place RecyclingDocument10 pagesCold in Place RecyclingRajesh ChoudharyNo ratings yet

- Investigationof Performanceof AsphaltDocument6 pagesInvestigationof Performanceof AsphaltJonathan GaniNo ratings yet

- Pipeline Installation Using Horizontal DirectionalDocument9 pagesPipeline Installation Using Horizontal DirectionalmuhammedpmubarakNo ratings yet

- Foamed Bitumen Stabilisation PDFDocument17 pagesFoamed Bitumen Stabilisation PDFjuanmelendezNo ratings yet

- Properties of Foam TECH REPORTDocument21 pagesProperties of Foam TECH REPORTharika gannavarapuNo ratings yet

- Practical Aspects in The Design of A Compacted Concrete Mixture (RCC) For Construction PurposesDocument21 pagesPractical Aspects in The Design of A Compacted Concrete Mixture (RCC) For Construction PurposesLuis Eloy FeoNo ratings yet

- Effect and Behaviour of Light Weight Concrete Using Fly Ash AggregateDocument5 pagesEffect and Behaviour of Light Weight Concrete Using Fly Ash AggregateMustafaMahdiNo ratings yet

- 5.1 General: Basic RatesDocument5 pages5.1 General: Basic Ratesdinesh chaudhariNo ratings yet

- An Ambitious Project Taken Up by Kerala PWD (National Highways) - Cold in Place Recycling of Bituminous PavementDocument4 pagesAn Ambitious Project Taken Up by Kerala PWD (National Highways) - Cold in Place Recycling of Bituminous Pavementdivyadeenu9390No ratings yet

- Recycling of Asphalt Pavement (RAP) - SUDDHASHIL PURKAIT - MTech. Geo Tech Civil - 2022-24Document17 pagesRecycling of Asphalt Pavement (RAP) - SUDDHASHIL PURKAIT - MTech. Geo Tech Civil - 2022-24suddhashil purkaitNo ratings yet

- A Case Study On Design of Ring Footing For Oil Storage Steel TankDocument7 pagesA Case Study On Design of Ring Footing For Oil Storage Steel TankMudit VermaNo ratings yet

- Rapid Flexural Toughness Development Dry-Mix Shotcrete For Mining ApplicationsDocument12 pagesRapid Flexural Toughness Development Dry-Mix Shotcrete For Mining ApplicationsAhmedNo ratings yet

- An Advanced Concrete Recycling Technology and Its Applicability Assessment Through Input-Output AnalysisDocument15 pagesAn Advanced Concrete Recycling Technology and Its Applicability Assessment Through Input-Output AnalysisAymanAlMahfuzNo ratings yet

- 2.carbonaceous Cementing MaterialDocument14 pages2.carbonaceous Cementing MaterialakurilNo ratings yet

- 1 - 316 - SR284 Bituminous Bases and Surfacings HitchDocument46 pages1 - 316 - SR284 Bituminous Bases and Surfacings HitchpvrsrpvarmaNo ratings yet

- Experimental Investigation On Mineral Content of Fly Bottom Ash and Strength Characteristics of Fly Bottom Ash Bricks - A ReviewDocument8 pagesExperimental Investigation On Mineral Content of Fly Bottom Ash and Strength Characteristics of Fly Bottom Ash Bricks - A ReviewEditor IJTSRDNo ratings yet

- Crushed Returned Concrete As Aggregates For New Concrete: Final ReportDocument51 pagesCrushed Returned Concrete As Aggregates For New Concrete: Final ReportMadalina DucaNo ratings yet

- Method Statement For RCC R0 09.03.2017Document6 pagesMethod Statement For RCC R0 09.03.2017Susil Kumar SahooNo ratings yet

- WRAP-A120 Stansted To Braintree Bypass Case HistoryDocument7 pagesWRAP-A120 Stansted To Braintree Bypass Case HistorysandycastleNo ratings yet

- PDFDocument7 pagesPDFRaka AdityaNo ratings yet

- Estudio Laterita - 17TH Riad Congreso - Ingles - Jose Antonio OrtizDocument15 pagesEstudio Laterita - 17TH Riad Congreso - Ingles - Jose Antonio OrtizJOSE ANTONIO ORTIZ OLIVANo ratings yet

- Irc 091-1985Document13 pagesIrc 091-1985kruttika_apNo ratings yet

- Slide Soft Soil Treatment For Package C13a ReportDocument36 pagesSlide Soft Soil Treatment For Package C13a ReportWanna PhyoNo ratings yet

- Advances in Materials Science for Environmental and Energy Technologies VIFrom EverandAdvances in Materials Science for Environmental and Energy Technologies VITatsuki OhjiNo ratings yet

- PMM PDFDocument17 pagesPMM PDFrajuwithualwaysNo ratings yet

- Pressure Conversion: Inhg MMHGDocument3 pagesPressure Conversion: Inhg MMHGnischal_babuNo ratings yet

- 01 - Test Certificate - Multipurpose - Cem IV 32.5n - Specification LimitsDocument1 page01 - Test Certificate - Multipurpose - Cem IV 32.5n - Specification Limitsnischal_babuNo ratings yet

- Earth Work CalculationDocument11 pagesEarth Work Calculationnischal_babuNo ratings yet

- ASC - GSHAP Seismic Hazard Map For Andhra Pradesh, IndiaDocument1 pageASC - GSHAP Seismic Hazard Map For Andhra Pradesh, Indianischal_babuNo ratings yet

- Construction ChecklistDocument2 pagesConstruction Checklistnischal_babuNo ratings yet

- Black Cotton Soil in Construction IndustryDocument3 pagesBlack Cotton Soil in Construction Industrynischal_babuNo ratings yet

- BIT 50-70 ResultsDocument1 pageBIT 50-70 Resultsnischal_babuNo ratings yet

- KT 15Document6 pagesKT 15nischal_babuNo ratings yet

- KT 39Document6 pagesKT 39nischal_babuNo ratings yet

- QC of CutbackDocument7 pagesQC of Cutbacknischal_babuNo ratings yet

- C 2004 24 0 1Document25 pagesC 2004 24 0 1nischal_babuNo ratings yet

- 01 - Test Certificate - Multipurpose - Cem IV 32.5n - Specification LimitsDocument1 page01 - Test Certificate - Multipurpose - Cem IV 32.5n - Specification Limitsnischal_babuNo ratings yet

- 20-30 Penetration Grade Bitumen Specification CONSILIARI PARTNERSDocument4 pages20-30 Penetration Grade Bitumen Specification CONSILIARI PARTNERSnischal_babuNo ratings yet

- File, 16939, enDocument35 pagesFile, 16939, ennischal_babuNo ratings yet

- TDS - Rheobuild 850Document2 pagesTDS - Rheobuild 850nischal_babuNo ratings yet

- TDS - Rheobuild 850Document2 pagesTDS - Rheobuild 850nischal_babuNo ratings yet

- 4770.1 Pumping SLC-The Team ApproachDocument2 pages4770.1 Pumping SLC-The Team Approachnischal_babuNo ratings yet

- Basic Requirements For PilesDocument1 pageBasic Requirements For Pilesnischal_babuNo ratings yet

- Hamburg Wheel Tracking TestDocument24 pagesHamburg Wheel Tracking Testnischal_babuNo ratings yet

- Series 0800Document25 pagesSeries 0800nischal_babu100% (1)

- Rheobuild 850Document2 pagesRheobuild 850Haresh BhavnaniNo ratings yet

- QC of Continuous Flight Auger PilesDocument1 pageQC of Continuous Flight Auger Pilesnischal_babuNo ratings yet

- Engineering Surveying,-5th Ed - Construction MaterialsDocument20 pagesEngineering Surveying,-5th Ed - Construction Materialsnischal_babuNo ratings yet

- Kpic - Material Submittal GRP LadderDocument81 pagesKpic - Material Submittal GRP LadderPranoy JosephNo ratings yet

- Caltrans Seismic Design Criteria SDC Version 1.7 PDFDocument180 pagesCaltrans Seismic Design Criteria SDC Version 1.7 PDFMaitrabarun KarjeeNo ratings yet

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Loctite 401™: Technical Data SheetDocument3 pagesLoctite 401™: Technical Data Sheetehsan100% (1)

- Problem of Low Nox Pfister Pre Hoper Stirring Device "Agitator"Document8 pagesProblem of Low Nox Pfister Pre Hoper Stirring Device "Agitator"Mohammed El rajyNo ratings yet

- Objective Type Questions With AnswersDocument29 pagesObjective Type Questions With AnswersNikka LopezNo ratings yet

- Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Month& Year Code For CastingDocument2 pagesMonth Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Month& Year Code For CastingJatin SharmaNo ratings yet

- Development of A Model Code For Direct Displacement Based Seismic Design Calvi 2009Document31 pagesDevelopment of A Model Code For Direct Displacement Based Seismic Design Calvi 2009pouyamhNo ratings yet

- PQR 3Document2 pagesPQR 3Mecon HyderabadNo ratings yet

- Optimization and Analysis of NF3 in Situ Chamber Cleaning Plasmas 2004Document12 pagesOptimization and Analysis of NF3 in Situ Chamber Cleaning Plasmas 2004Регина ШаяхметоваNo ratings yet

- Plastics Carbon FootprintDocument14 pagesPlastics Carbon FootprintBegenkzNo ratings yet

- Asme Codes: Section IDocument2 pagesAsme Codes: Section IChamboo ChapsNo ratings yet

- 06 Melting PointDocument21 pages06 Melting PointFranchiezca AoananNo ratings yet

- 2nd Summative Test Earth and LifeDocument3 pages2nd Summative Test Earth and LifeJarven SaguinNo ratings yet

- Crystals in Supramolecular Chemistry: Transactions of The American Crystallographic AssociationDocument76 pagesCrystals in Supramolecular Chemistry: Transactions of The American Crystallographic Associationfitri wahyuniNo ratings yet

- Análisis de Ciclo de VidaDocument12 pagesAnálisis de Ciclo de VidaOscar VicenteNo ratings yet

- Heat Tracing Catalog DataDocument160 pagesHeat Tracing Catalog Datalam266No ratings yet

- Terluran or Novodur HI-10Document2 pagesTerluran or Novodur HI-10bobNo ratings yet

- Dot 36734 DS2 PDFDocument122 pagesDot 36734 DS2 PDFArab WeldersNo ratings yet

- Structure of WaterDocument5 pagesStructure of Waterapi-233981890No ratings yet

- KTG UpdatedDocument5 pagesKTG Updateddeejam123No ratings yet