Professional Documents

Culture Documents

Aquaculture: Producing Aqua Feed Pellets

Uploaded by

International Aquafeed magazineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aquaculture: Producing Aqua Feed Pellets

Uploaded by

International Aquafeed magazineCopyright:

Available Formats

March | April 2011

Feature title: Aquaculture - Producing aqua feed pellets

International Aquafeed is published five times a year by Perendale Publishers Ltd of the United Kingdom.

All data is published in good faith, based on information received, and while every care is taken to prevent inaccuracies,

the publishers accept no liability for any errors or omissions or for the consequences of action taken on the basis of

information published.

©Copyright 2009 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form

or by any means without prior permission of the copyright owner. Printed by Perendale Publishers Ltd. ISSN: 1464-0058

The International magazine for the aquaculture feed industry

F: Feed pellets F: Feed pellets Extruder_90x270_Kopie von 90 X 270 10.02.2011 16:18 Seite 1

endless screw or oil expeller that presses blood and bones,

it and squeezes out most of the remaining etc which are

water and oils. often difficult to

Pressed fish coming out of the press commercialize.

(press cakes) then cut into smaller portions Nowadays,

and placed into a dryer on a steam heated however, these by-

surface. During the drying period, the mash products constitute

is in constant motion and subject to an the basic raw mate-

air jet that removes all the steam emitted. rial of the bone and

The dried mash obtained is now called 'fish blood meals widely

meal' and contains from 8 to 10 percent used in industry for

of water. animal feeding.

However, if the moisture level is more Considerable

Aquaculture:

than 11 -12 percent, there is a risk of the amounts of blood Find us on

fish meal developing moulds. Generally, are produced by

antioxidants are added when fish meal is abattoirs, and this

booth no. G 061

Producing aqua feed pellets

introduced and taken out of the dryer, and product is usu-

by so doing ensuring the stability of the oils ally transported

remaining within the fish meal. to drying ovens

and converted

Soy protein into blood meal.

Not all fish species have easy digestibility Blood from differ-

by R V Malik, CEO, Malik Engineers, Mumbai, India of soy protein, primarily due to increased ent origins such

carbohydrate content fraction. It is usually as, sheep, goat, and

A

used as supportive additive with other eas- poultry are usually

s more of world’s natural proteins which is strongly demanded by then cooked in a continuous heating oven ily digestible protein like fish meal which is stored and proc-

fisheries are depleted and the animal feeds industry. This is due to its at 90-95 percent, which in-turn coagulates rich in fish proteins. essed separately.

demand of fish continues balanced amino acid content, which makes proteins and lose their water-holding capac- Bean processing consists essentially of However, so as to

to rise, aquaculture will it an ideal feed for many domestic animals. ity. The hot mash is then transported to an extracting the oil so as to concentrate comply with basic

continue to grow, thus raising demand Moreover, its use to adjust the proteins. This process provides a very sanitary measures,

for healthy, commercially prepared (improve) the amino acid con- important by-product, namely soya oil, it is generally com-

fish tent of other dietary protein which is widely used as a raw material pulsory to store Laboratory Extruder

sources also contributes to and oil for human consumption. This proc- blood within cool-

Mostly, aquaculture relies upon extrusion increase demand for fishmeal. ess also contributes to the elimination of ing chambers and for Food and Feed

cooking to produce feeds that are good mix As its name points out, fishmeal certain anti-nutritional factors present in to ensure that the

and nutritionally available, but also in a form is derived from captured fish, the raw bean. level of bacteria is

that is capable of moving through water including whole fish, fish scraps The first step in processing involves kept within pre-

column very slowly (floating) to be ingested. from fillets, and preserves of the removal of the shell (cellulose) from scribed maximum

Thus, the big dependency in aquaculture is industries. the grain. The ‘bare’ beans are then limits.

selecting ingredients that when extruded Most of the main capture heated, on the one hand to reduce the

will possess just right buoyancy, not migrate fishery producers devote the activity of certain enzymes, and on the The

nutrients into water, with high palatability main part of this activity to fish other to break the cellulose strands and manufacture

for specific fish species. meal production. The raw mate- facilitate the following steps. The heated of

Fishfeed pellets are prepared either rials used in fish meal manufac- beans are then mashed to form thin bloodmeal

by pressed cut sheets or by Extrusion ture come almost entirely from paste-like slices, which further facilitates Fresh blood

methods. This article will discuss about species which are not often used the destruction of the cellulose structure is kept cool at

Ingredients and Extrusion process for pro- for human consumption (either and oil extraction. the factory, and

ducing the pellets. due their size, or because they The product, now termed ‘whole soya sizeable particles

Main ingredients include: are very abundant). cake’, still contains its oil and has around 40 filtered and the

1) Fish & Bone Meal The fishmeal processing percent protein, and as such is sold directly blood mass stirred Quality control and testing of

2) Soy protein (though it is not preferred system consists of preserving for animal feeding. so as to separate raw materials

by farmers being not easily digestible initial fish proteins by means of Next, the oil can be extracted from the the fibrillar phase

by many fish species) a controlled dehydration, which whole cake by means of a solvent (such from the liquid Product development and

3) Wheat extracts around 80 percent of as hexane). After total evaporation of the mass. The fibrin is recipe optimization

4) Starch the water and oils contained solvent, there remains the solvent extracted then heated up to

5) Blood Meal when fresh from fish. soya cake, which in turn is widely used for coagulation and the Small-scale production

Other ingredients like Vitamins, Minerals This leads to the produc- animal feeding, and contains 45 - 50 percent coagulated mass Quick change of test conditions

and Lipids (Fat Oil) are also added in tion of a dry product, easy to protein. divided and dried

producing pellets. preserve and easier to transport through a hot air

than the initial product. Bloodmeal stream (that is by

Fishmeal Fresh fish entering the manu- Abattoirs or slaughterhouses produce spray drying). This Brabender® GmbH & Co. KG

Fishmeal is a well-known source of facturing plant is first ground and many important by-products, such as method is particu- E-Mail: food-sales@brabender.com • www.brabender.com

10 | InternatIonal AquAFeed | March-april 2011 March-april 2011 | InternatIonal AquAFeed | 11

F: Feed pellets F: Feed pellets

larly gentle (spraying a product in a hot air- Lipids Formulation of fishfeed force, position as ‘expanded feed’, is also marketed by

stream) and does not denature the proteins Fish oils are co-products of the fish- As we have seen, feed formulators can themselves form- some manufacturers.

because the water evaporation cools down meal industry. Their nutritional charac- resort to a wide assortment of raw materi- ing a star on The main difference between a pressed

the hot air very quickly, thereby preventing teristics regarding fatty acids make them als to make up a food mixture so as to the rotor and and an extruded feed is the cooking of the

overheating. indispensable for fish feed manufacture, meet the nutritional requirements of the split the incom- feedstuff in the case of extrusion, with the

and in particular their characteristic fish for energy, amino acids, fatty acids, ing feedstuff added mechanical and biological advantages

Wheat flour high content of n-3 unsaturated fatty carbohydrates, vitamins and minerals. apar t, which previously described, especially with regard

Wheat is one of the most important acids (first double bond linkage in posi- These raw materials are generally used is then forced to starch gelatinization

cereals worldwide, and is used for making tion 3), which are essential for a well in flour or liquid form, and will have to by depression

bread and for many other produces. It is balanced food formula for carnivorous undergo binding by means of a technologi- through a metal Extruded Feeds:

also an essential raw material for livestock fish species. cal process to obtain a food mixture in the grid composed The Extruder can be described as a

feeding, including fish. A large amount of fish oil arising from form of dry pellets, which are easy to use of appropriately Bio-Reactor with (mostly) a single, multiple-

fish meal manufactures is re-processed in and preserve. sized meshes. flighted screw (rotor) rotating at high speed

Wheat in fish feeding specialized facilities for diverse purposes; As a guide, salt water marine aquaculture inside a stationery hollow tube (stator).

Starch products, especially wheat, are fre- part of it being hydrogenated and mixed is dependant upon high levels of proteins - Mixing The raw materials fall from top at

quently used as binders for the manufacture of with other lipids, and transformed into mar- with high digestibility. The fresh water aqua- The ground one end on the rotating screw which has

pellets; the gelatinizing property of starch when garine, mayonnaise and bakery compounds, culture relies upon more carbohydrates, ingredients must multiple flights and varying pitches along

water-heated being useful for this purpose as and the other part used directly by the feed that is high levels of grains coupled with be mixed accord- its length. The barrel (tube) is externally

the starch absorbs water and forms a gel. industry. modest to high quality proteins, minerals, ing to the desired heated/cooled by steam and cold water

vitamins with little or no fiber. proportions to externally around. Due to this arrangement,

The first factor to be considered for obtain a homoge- a high pressure of around 40-70 bars

feed formulation is the total energy and wide variety of ingredients that can have neous mixture. If the grinding process (Kg/cm2) is developed on the ingredients,

protein/energy ratio of the final product. varying particle sizes. It is desirable, but not is correctly developed, the particles are temperature of ingredients varies from 110

After this, the protein content must be cal- necessary that all ingredients be of uniform homogeneous in size and the mixture C to 160 C, which ensures cooking of ingre-

culated according to the amino acid balance particle sizes, to prevent segregation during produces pellets which statistically have the dients into plastic mass which is extruded

desired, and the lipids included to satisfy mixing and transport prior to extrusion. same formulation. out of multiple die openings/orifices and

the best fatty acid profile for the species Uniform particle size of ingredients pro- Generally, the dry ingredients (flours) cut to produce porous pellets for fish feed.

concerned and the energy level desired. All motes better mixing and uniform moisture are first mixed, followed by the liquid Pre-Extrusion: Dry ingredients after

this must be considered taking into account uptake by all particles during the precondi- components. Continuous mixers are having been mixed & ground thoroughly in

the vitamin and mineral requirements of the tioning step. designed so that the feedstuff moves desired proportions, are usually transport-

cultured species. If the particle size of raw ingredients along the mixer as it mixes. There are ed to the Single screw Extruder (Cooker)

This formulation is not easily reached is too large, the final product may contain many different types of mixers, including provided with a Pre-conditioner at top.

Moreover, when starch is gelatinized its Minerals and so computerised linear programming particles which are improperly cooked, horizontal band-mixers, vertical mixers, The Feed Delivery System: It consists of

digestibility improves considerably. Various Minerals are measured as ash in the techniques must be used. Furthermore, which degrade product appearance and conical screw-mixers, and turbine mixers, a “Live Hopper” or Bin with a horizontal

starch types (wheat, barley, rice, maize or recipe. Though they serve no functionality it is also necessary, after covering all the palatability. etc. conveying screw to convey dry ingredients

potatoes) can gelatinize but each one will in extrusion (on the contrary their abrasive nutritional requirements of the species Also, if particle size is larger than die During this mixing process, the vitamin to the Preconditioner from above. The Bin

have its own characteristics. nature will accelerate wear and tear of within the formula to also produce a range orifice used at extruder discharge, it may ‘premix’, the binding agents and other is provided with device which avoids bridg-

In addition, all three starch types gener- working parts in extruder), these are usu- of tasty feeds of different pellet sizes for the cause plugging of some orifices affecting additives are added; they must in turn con- ing of material (since raw ingredients have

ally have the capacity to form a stable ally added in proportions < 5 percent. They different age classes. capacity and appearance. As rule of thumb, tribute to one or other particular desired low bulk density and poor flow through a

structure when subjected from high to low include phosphorous, calcium (from calcium it is necessary to maintain size of raw quality of the pellets during the pelleting normal Hopper) and ensures continuous

pressure during the extrusion process. carbonate or ground lime stone), sodium Manufacturing stages ingredients one third of the die opening die. process. flow of materials to the Preconditioner

It is this property that is used for chloride (salt), magnesium, potassium, etc. Hence the need of size reduction equip- below, hence the name “live” bottom bin.

feeds that must have a high lipid content, - Storage ment and sifting. - Pelleting It should hold adequate volume to support

during the extrusion process the starch Vitamins: The raw materials coming into the feed In hammer-mills, the grinding chamber Two different types of pellets are gener- the extruder operation for minimum 5-8

forms a cell structure with alveoli that They can be water soluble or soil solu- manufacturing plant are generally stored in consists of a series of mobile hammers ally prepared for aquafeeds, namely pressed minutes, as a buffer time for the operator

can then be filled with oil instead of air ble. Vitamin B and C are water soluble, A, D, silos with an ideal height calculated so as to on a rotor. The hammers, by centrifugal and extruded pellets. A third type, designed and auto control network to respond

and/or steam. E, and K are fat soluble. They are added in allow the raw material flow to be conveyed

For carnivorous fish feeding purposes proportions < 0.5-0.6 percent in diet, but downwards, during the manufacturing proc-

the starch must be considered as a sup- due to harsh processing conditions inside ess, until the final product is produced. This COMPLETE PLANTS AND MACHINES FOR THE FISH FEED INDUSTRY

porting structure that gives the pellets the extruder, these get destroyed, hence is in order to avoid having to pull the prod-

their texture and together with the other they are added well in excess of minimum ucts up by vertical conveyors that usually

dietary ingredients allows the formation of requirements. cause breaks and dust in the final product.

a binded diet. Apart from above, the feed may

However, since the natural feeding habits contain, flavors/aromas, antioxidant - Grinding

and foods of seabass and/or seabream (preservative) and antimicrobials, dyes Grinding raw materials reduces particle Fabric Belt

usually contain very small proportions of & pigments (for human appeal and dis- size and increases ingredient surface area, Driers/Coolers

carbohydrates (ca. three percent glyco- tinction, rather than for fish itself), etc. thus facilitating mixing, pelleting and digest- AMANDUS KAHL GmbH & Co. KG

gen, animal starch - glucose polymer). If It is important to use certified ingredi- ibility. The most commonly used grinders Dieselstrasse 5-9, D-21465 Reinbek / Germany

Phone: +49 40 727 71 0, Fax: +49 40 727 71 100

excessive quantities of digestible starch are ents that does not affect health of fish. are hammer-mills, for fish feed manufacture, info@amandus-kahl-group.de

provided in the feed this may result in the Pigments are usually added as a coating as plate-grinders do not generally produce www.akahl.de

accumulation of excess liver glycogen, which step, to minimize losses during harsh fine enough ground materials.

MIXING CONDITIONING PELLETING EXTRUSION COATING COOLING

in turn may trigger a liver dysfunction. extrusion processing conditions. The Extrusion cooking process utilizes

12 | InternatIonal AquAFeed | March-april 2011 March-april 2011 | InternatIonal AquAFeed | 13

F: Feed pellets

"As more of world’s natural fisheries are

depleted and demand of fish continues

to rise, aquaculture will continue to

grow, thus raising demand for healthy,

commercially prepared fish"

and allow recharging the bin from top. “Wet Extruder” since feed materials con-

The screw is provided with variable speed - Extrusion tain around 25 to 30 percent moisture

motor to properly adjust the flow as per Usually single screw Extruders with sin- (water). Both screw and the barrel are

production capacity of the Extruder. gle barrel and screw is used for cooking the made up as separate segments so that

Preconditioning: This step ensures the preconditioned ingredients, but twin screw individual components could be replaced

dry ingredients are constantly added with extruders are also used. The latter have when worn. Multiple flighted, varying pitch

moisture (water) in desired proportions limited use because of high initial capital screw elements are usually employed to

(25-30%) and steam is also added, at 5-6 bar, costs compared to single screw extruder. provide cooking and forward convey-

for pre-cooking the wet ing of feed materials.

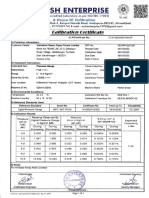

ingredients. As the ingre- Table 1: The Volumetric capacity

dients move forward of screw is highest at

FEED A FEED B Difference

towards the Extruder Feed zone to account

feed opening, they are of low bulk density of

held at temperature of (1) Growth 1 1.1 10% ingredients. However, it

approximately 100 C reduces (lower pitch)

2) Conversion rate 2 2 0%

and atmospheric pres- towards the die, which

(3) Feed price / kg 5 6 +20%

sure. Preconditioning causes compression and

makes the ingredients (4) Selling price of fish 50 50 0% cooking of feed mate-

soft by precooking and it (5) Feed expenditure for 1 kg of fish rial. The final discharge

10 12 +20%

reduces energy require- produced (2) X (3) end of screw is usu-

ment in the Extruder. If (6) Profit from fish sales (1) X (4) 50 55 +l 0% ally Conical to generate

Lipids are to be added, high pressure and attain

(7) Gross margin for feed item (6) - (5) 40 43 +7.5%

their proportion is lim- maximum expansion of

ited from 5-7 percent in pellet when emerging

this stage. The action of the Extruder allows the from die opening. The barrel heads are

Conventional Preconditioners had only free flowing ingredients to bond to each provided with Steam Heating and water

one tank and single agitator, but modern other and remain in pellet form after exiting cooling Jackets around, for heating or

preconditioners have special oval tanks with from shaping (pelleting) die. It does this cooling, as per process demand. The proc-

two agitating shafts with adjustable beaters by the action of rotating screw or spiral ess temperature is held from 110 C to

to control residence time inside the tank. inside a stationery barrel by generating high 160 C gradient from Feeding Zone to

Two agitators result in the better mixing of mechanical shear and raised temperature Final Cooking Zone. Maximum convey-

dry and liquid ingredients. Longer retention on feed materials. ance & mechanical shear of material is

time approximately 2-2 ½ minutes are Extruders for Fish Feed production have ensured by action of multiple flighted

desirable before feeding into the Extruder. Mechanical Energy Input levels between screw elements and spirally grooved bar-

Usually lipids are added not more than 20-40 Kw-hr/ton of produce. Their screws rel segments. Water present inside the

5-7 percent by weight here, since it leads run between 400-1000 RPM depending on mixture is held as steam at high tem-

to excessive slippages inside the Extruder sizes. Output capacities range between 1 t perature and pressure. However, as soon

and poor mixing & expansion/texture of to 20 t per hour. as the cooked mass emerges out of die

final pellets. The Extruder usually employed is openings pressure drops to atmospheric

14 | InternatIonal AquAFeed | March-april 2011 March-april 2011 | InternatIonal AquAFeed | 15

F: Feed pellets

and the product expands or “puffs”, being time of products should be carefully applied through bed of pellets to lower the

cut continuously by Rotating Die Knives adjusted to attain properly dried product temperature.

working against the die Face, giving the that can absorb maximum fats and coat- Cooling is important, since if packed in Improvement

pellet the specific rounded shape for ings in the Coating step. hot state, moisture will condense in the

by nature

extruded pellets.

Retention time inside Extruder is from - Sifting

packing, wetting the outer surface of the

pellets, allowing mold growth. It is desir-

Natural ingredients for aqua feed

100-180 seconds, which ensures 70-85 per- The mechanical manufacturing processes able to cool down within 10 C of ambient

cent starch gelatinization and production of inevitably results in shocks and scorching air tempt. So that problem of condensation Whether you’re looking for a natural EU and USDA approved pellet binder for your

good shape and density. that partially crumble the pellets at their in packing doesn’t occur. production of stable pellets or nature’s best alternatives for fish meal, you can contact Sonac.

The above Extruder produces Floating surface and cause various breaks and dust Sonac produces valuable and essential ingredients for the production of aqua feed.

Pellets with low bulk density, e.g 350-450g/l that must be eliminated. This is achieved by - Bagging

that are classified as “Floating” and sink very sifting, a process that is generally applied Bagging usually produces different

• Pro-Bind Plus a nutritional, gelatin based pellet binder, especially for pelleted (shrimp) feed.

slowly into water column. Most Extruders at least twice before the final condition- types of feed presentations within the

have an arrangement, whereby the water ing (sifting after drying and after coating/ same factory, namely either small bags • Hydrolyzed feather protein a fish meal alternative, especially for carnivorous fish species.

vapour present in the mix is released by a cooling). (20 or 25 kg) on pallets covered with • Muco-Pro® high contents of natural proteins, amino acids and peptides.

vent opening on the barrel so that high den- a plastic film, or big-bags (500 or 1000 • Blood meal and Hemoglobin Powder high protein content and good digestibility, for better

sity pellets or sinking pellets are produced - Coating kg) in bulk.

feed conversion.

for certain species of fish. The pellets emerging from the pel-

The following parameters will con- leting presses or extruders do not Viability of Extrusion

trol the final pellet density: 1. Initial generally contain more than 7 to 10 process

moisture content (usually 25-30 percent percent lipid. To achieve higher dietary It follows from the higher tempera-

on wet basis). 2. Process temperature. lipid levels (20-27%), coating is neces- tures and pressures used during extrusion

3. Extruder back pressure. 4. Extruder sary with the appropriate oils, generally processing that investment and energy

RPM (residence time). 4. Drying condi- using heat. In the same manner, certain costs will be higher than those of conven-

tions and temperature. 5. Quantity of heat sensitive vitamins and/or drugs tional pressed feeds. Despite this however,

Fats, vitamins & minerals applied post that would not normally withstand the the use of extruded feeds may be more

extrusion. harsh extrusion processes (thermo profitable.

labile products) can also be added Following Table (illustration) summa-

Visit us at: Stand B069, Victam International

- Drying later during the coating process. These rizes the theoretical results obtained with

When added to Extruder, the ingre- ingredients are usually added through fish fed a pressed (A) or extruded (B) feed.

dients contain around 25-30 percent spray nozzles fed through dosing pumps Table showing Justification for Extrusion SON0296_AD_AquaFeed_180X118_W2.indd 1 16/02/2011 14:35

moisture (wet basis). Extrusion process which accurately control the weights Over Press Feed production method for

evaporates approx. 4-7 percent moisture deposited. They can be vacuum assisted Fish Feed.

thus still retaining considerable moisture for still more good results. It is clear from the example given DP

inside the pellets. After the pelleting The Expansion that occurs as a result that despite the fact that the price of the

LS LS

M

4

LS

process, the pellets usually have a high of extrusion processing makes the product extruded feed is 20 percent higher, the

moisture content (17 to 22%) that must porous with low bulk density and air feed which provides 10 percent additional LS

be quickly reduced to avoid spoilage. pockets, so that more oil is absorbed during growth provides a 7.5 percent additional

This is usually achieved by using a hot-air the spray coating process. Fats could be gross margin.

LS

drier, which lowers the moisture level added in the form of Animal fats, Fish Oil or

to between 8 and 10 percent depending Vegetable Oil.

M M

6 6 6

L

LS

upon the manufacturing process. DP

- Cooling Note:

MCC 2

Continuous Belt Dryers are com- LS

L 10

MCC 1

monly employed that provide heated air On completion of the coating process

The author is CEO Malik Engineers,

LS

to remove excess moisture from wet (generally undertaken with heated mate- Mumbai, which manufactures a wide range

product, as it travels on multiple decks rial) the pellets are then cooled and sieved of extruders for food processing and aqua/

of perforated steel belting. Since the before the final conditioning; cooling occur- animal feed. He can be reached on info@

Drying process is critical and determines ring in a cool-air flow generated by a malikengg.com Tel: +919821676012, +91 22

the quality of pellets, it needs to be cooling-machine. Again, this machine usually 28830751, +91 250 2390839

carefully monitored and controlled. The provides continuous flow of product on

Air Temperature, Humidity and Residence perforated steel belts, while cooling air is

ARCHIVE

Every feature that appears in International Aquafeed magazine, will also appear in our

online archive. Please visit:

http://www.aquafeed.co.uk/archive.php

16 | InternatIonal AquAFeed | March-april 2011

LINKS

This digital re-print is part of the March | April 2011 edition of International Aquafeed magazine.

Content from the magazine is available to view free-of-charge, both as a full online magazine on our

website, and as an archive of individual features on the docstoc website.

Please click here to view our other publications on www.docstoc.com.

Vo l u m e 1 4 I s s u e 2 2 0 1 1

• See the full issue

Aquaculture:

• Visit the International Aquafeed website

Producing aquafeed pellets

Krill:

Feed makers need to look at krill

Feed Management:

• Contact the International Aquafeed Team

An assessment of aquaculture production with

special reference to Asia and Europe

Pigmentation

Effects of Corn Gluten Meal on Flesh

Pigmentation of Rainbow Trout

• Subscribe to International Aquafeed

the international magazine for the aquaculture feed industry

To purchase a paper copy of the magazine, or to subscribe to the paper edition please contact

our Circulation and Subscriptions Manager on the link above.

INFORMATION FOR ADVERTISERS - CLICK HERE

www.aquafeed.co.uk

You might also like

- 8.4.4 Instron Tensile Tester SOPDocument1 page8.4.4 Instron Tensile Tester SOPDarby BrownNo ratings yet

- Alovebali: SOP HTST MachineDocument7 pagesAlovebali: SOP HTST MachinePt Putra W SNo ratings yet

- SOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesDocument10 pagesSOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesAli RizviNo ratings yet

- TDS - Shell Gadus S3 V460 1 - EN PDFDocument2 pagesTDS - Shell Gadus S3 V460 1 - EN PDFdtcuongNo ratings yet

- In-process inspection reportDocument8 pagesIn-process inspection reportMohan KumarNo ratings yet

- PAM Company ProfileDocument53 pagesPAM Company ProfilefathoniNo ratings yet

- Luperox Organic Peroxides Better Performance in Suspension PolystyreneDocument4 pagesLuperox Organic Peroxides Better Performance in Suspension PolystyreneCamelia MoiseNo ratings yet

- ISO Yeast and Mould Enumeration MethodDocument3 pagesISO Yeast and Mould Enumeration MethodAL-NOOR labNo ratings yet

- Technical Data Sheet Brown Flax Seeds 1Document5 pagesTechnical Data Sheet Brown Flax Seeds 1JESSICA GONZALEZ MENDEZNo ratings yet

- PriDocument8 pagesPritubNo ratings yet

- Pressure Gauge Calibration CertificateDocument1 pagePressure Gauge Calibration CertificateCustomer Support100% (1)

- Powder Coating Procedure Guide for Oven Temperature Control, Degreasing, and Part PreparationDocument1 pagePowder Coating Procedure Guide for Oven Temperature Control, Degreasing, and Part Preparationnastyn-1No ratings yet

- SNI 0727 Certification - PT BridonDocument1 pageSNI 0727 Certification - PT BridonRahmat RiskiNo ratings yet

- ISO 9000 2015 (En) Quality Management Systems - Fundamentals and VocabularyDocument23 pagesISO 9000 2015 (En) Quality Management Systems - Fundamentals and VocabularyPaulino MutomboNo ratings yet

- Astm F1089-02 - Standard Test Method For Corrosion of Surgical InstrumentsDocument3 pagesAstm F1089-02 - Standard Test Method For Corrosion of Surgical InstrumentsmurleyjNo ratings yet

- AE-QA-02 - First Piece Inspection ReportDocument1 pageAE-QA-02 - First Piece Inspection ReportKarthi ThiyagarajanNo ratings yet

- DBMS Lab Manual AmendmentsDocument1 pageDBMS Lab Manual AmendmentsThaddeus MooreNo ratings yet

- Calibrating Mobile Force Measurement SystemsDocument16 pagesCalibrating Mobile Force Measurement Systemsprasadjoshi781429No ratings yet

- Bunching Machine Working InstructionDocument2 pagesBunching Machine Working InstructionWendimagen Meshesha Fanta100% (1)

- 02-Calibration & Control of Measuring & Monitoring DevicesDocument1 page02-Calibration & Control of Measuring & Monitoring DeviceskitekNo ratings yet

- Instruction Manual Water Chiller Model PRR 50 (N)Document18 pagesInstruction Manual Water Chiller Model PRR 50 (N)kasper kasperNo ratings yet

- Instruction Manual for Semi-Automatic Dough Divider RoundersDocument20 pagesInstruction Manual for Semi-Automatic Dough Divider Roundershugo_1990No ratings yet

- Dosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceDocument5 pagesDosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceMahin patelNo ratings yet

- Trend Analysis Sheet OOSDocument11 pagesTrend Analysis Sheet OOSHaroon RasheedNo ratings yet

- Centrifuge CalibrationDocument5 pagesCentrifuge CalibrationVeronika Violeta ProjustitianiNo ratings yet

- Codex Standard For RiceDocument8 pagesCodex Standard For RiceDedhieajaNo ratings yet

- Vendor Rejection and Debit PolicyDocument6 pagesVendor Rejection and Debit PolicysharanNo ratings yet

- Oiml R111 PDFDocument2 pagesOiml R111 PDFRameshNo ratings yet

- Form 18 NABL 163Document2 pagesForm 18 NABL 163asr labNo ratings yet

- Platinium Marine Products SDN BHD Hazard Analysis and Critical Control Point (Haccp) Manual Title Section: Process Flow ChartDocument7 pagesPlatinium Marine Products SDN BHD Hazard Analysis and Critical Control Point (Haccp) Manual Title Section: Process Flow ChartHas platiniumNo ratings yet

- NIST Procedure For Method Validation 20180101Document7 pagesNIST Procedure For Method Validation 20180101Tonio DimaculanganNo ratings yet

- Coating Report FinalDocument19 pagesCoating Report FinalMayson BaliNo ratings yet

- Removing Steryl Glucosides in Palm Oil-Based BiodieselDocument7 pagesRemoving Steryl Glucosides in Palm Oil-Based BiodieselNestor Armando Marin Solano100% (1)

- Standard Operating Procedure For Ghee ProcessingDocument4 pagesStandard Operating Procedure For Ghee ProcessingUmesh Poudel JoJo100% (1)

- Manufacturing Process of Piston IN Shriram Pistons & Rings LTDDocument11 pagesManufacturing Process of Piston IN Shriram Pistons & Rings LTDVipul SinghalNo ratings yet

- Restroom Inspection Checklist Restroom Inspection Checklist: Restroom: Date: Restroom: DateDocument15 pagesRestroom Inspection Checklist Restroom Inspection Checklist: Restroom: Date: Restroom: DateCheli Yanda RositaNo ratings yet

- Standard Operating Procedure (SOP) Blister MachineDocument1 pageStandard Operating Procedure (SOP) Blister MachineSahil RathoreNo ratings yet

- Mustard Oil TestingDocument6 pagesMustard Oil TestingMYUTILITY100% (1)

- Sidhi International Metalloys Pvt. LTD.: Customer Property RecordsDocument2 pagesSidhi International Metalloys Pvt. LTD.: Customer Property Recordspulkit gargNo ratings yet

- Quality Control For Aluminium Alloy IngotsDocument1 pageQuality Control For Aluminium Alloy Ingotsankit kumarNo ratings yet

- 5S Organization ChartDocument1 page5S Organization Chartrishi gautam100% (1)

- SOP of MachinesDocument2 pagesSOP of MachinesSangram Kandekar100% (1)

- LGT - WHD - QP03-Material Handling and Storage Control ProcedureDocument7 pagesLGT - WHD - QP03-Material Handling and Storage Control ProcedureGregorNo ratings yet

- GLIER QSP ManagementrequirementsDocument72 pagesGLIER QSP ManagementrequirementsMurugan RajaNo ratings yet

- (PRPS) ListDocument9 pages(PRPS) ListDeepak MoreNo ratings yet

- Standard Operating Procedures for Stack SamplerDocument6 pagesStandard Operating Procedures for Stack SamplerSangam SharmaNo ratings yet

- API Q1 Supplier Audit Check List - PurchaseDocument8 pagesAPI Q1 Supplier Audit Check List - PurchaseSandra SandersNo ratings yet

- RBD Palm Olein Technical Data SheetDocument1 pageRBD Palm Olein Technical Data SheetThao BichNo ratings yet

- Calb 4Document1 pageCalb 4ranjt53No ratings yet

- Standard Procedure List for Quality DocumentsDocument1 pageStandard Procedure List for Quality DocumentsRaja RehaNo ratings yet

- NASA RP-1364: Metrology - Measurement Assurance Program GuidelinesDocument108 pagesNASA RP-1364: Metrology - Measurement Assurance Program GuidelinesPaulNo ratings yet

- Customer Enquiry and Contract Review Procedure: PDF Created With Fineprint Pdffactory Trial VersionDocument7 pagesCustomer Enquiry and Contract Review Procedure: PDF Created With Fineprint Pdffactory Trial VersionGib ArNo ratings yet

- Supplier Qualification and Monitoring ProcedureDocument3 pagesSupplier Qualification and Monitoring ProcedureLinda Setya WatiNo ratings yet

- MARATHAN MOTOR SOP Recruitment ProcedureDocument4 pagesMARATHAN MOTOR SOP Recruitment Procedurerishi gautamNo ratings yet

- MaterialShelfLife PDFDocument1 pageMaterialShelfLife PDFSunil VermaNo ratings yet

- IPC-TM-650 Test Methods ManualDocument4 pagesIPC-TM-650 Test Methods ManualSSmyLoginNo ratings yet

- Cutting Procedure GuideDocument3 pagesCutting Procedure Guiderial100% (1)

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- The Continuing Demand For Sustainable Fishmeal and Fish Oil in Aquaculture DietsDocument5 pagesThe Continuing Demand For Sustainable Fishmeal and Fish Oil in Aquaculture DietsInternational Aquafeed magazineNo ratings yet

- Fish Oils: Production and PropertiesDocument6 pagesFish Oils: Production and PropertiesGaluhNo ratings yet

- International Aquafeed - May - June 2016 FULL EDITIONDocument80 pagesInternational Aquafeed - May - June 2016 FULL EDITIONInternational Aquafeed magazineNo ratings yet

- FISH FARMING TECHNOLOGY: The Use of Feed in Recirculating Aquaculture Systems (RAS)Document4 pagesFISH FARMING TECHNOLOGY: The Use of Feed in Recirculating Aquaculture Systems (RAS)International Aquafeed magazineNo ratings yet

- FISH FARMING TECHNOLOGY: The Faivre Equipped Trout Farms of AbbevilleDocument4 pagesFISH FARMING TECHNOLOGY: The Faivre Equipped Trout Farms of AbbevilleInternational Aquafeed magazine100% (1)

- International Aquafeed - March - April 2016 FULL EDITIONDocument72 pagesInternational Aquafeed - March - April 2016 FULL EDITIONInternational Aquafeed magazineNo ratings yet

- EXPERT TOPIC: Common CarpDocument6 pagesEXPERT TOPIC: Common CarpInternational Aquafeed magazineNo ratings yet

- EXPERT TOPIC: SalmonidsDocument8 pagesEXPERT TOPIC: SalmonidsInternational Aquafeed magazineNo ratings yet

- A Technological Innovation For Crustacean Aquaculture - AQUAVI® Met-MetDocument2 pagesA Technological Innovation For Crustacean Aquaculture - AQUAVI® Met-MetInternational Aquafeed magazineNo ratings yet

- Potential For European Lobster MaricultureDocument4 pagesPotential For European Lobster MaricultureInternational Aquafeed magazineNo ratings yet

- Innovation Nation - How New Developments in Aquaculture Are Boosting The Scottish EconomyDocument4 pagesInnovation Nation - How New Developments in Aquaculture Are Boosting The Scottish EconomyInternational Aquafeed magazineNo ratings yet

- Larval Culture of Pangasius in Puerto RicoDocument4 pagesLarval Culture of Pangasius in Puerto RicoInternational Aquafeed magazineNo ratings yet

- Mud Carab Farming in IndiaDocument4 pagesMud Carab Farming in IndiaInternational Aquafeed magazine67% (3)

- FISH FARMING TECHNOLOGY: A Breath of Fresh Air in Fish FarmingDocument4 pagesFISH FARMING TECHNOLOGY: A Breath of Fresh Air in Fish FarmingInternational Aquafeed magazineNo ratings yet

- Brewers' Yeast ProductsDocument4 pagesBrewers' Yeast ProductsInternational Aquafeed magazine100% (1)

- Parasite Control in European Farmed FinfishDocument4 pagesParasite Control in European Farmed FinfishInternational Aquafeed magazineNo ratings yet

- FISH FARMING TECHNOLOGY: Cage Culture in Indian Reservoirs: Present Status and ProspectsDocument4 pagesFISH FARMING TECHNOLOGY: Cage Culture in Indian Reservoirs: Present Status and ProspectsInternational Aquafeed magazineNo ratings yet

- Infectious Diseases and Control Strategies in ShrimpDocument7 pagesInfectious Diseases and Control Strategies in ShrimpInternational Aquafeed magazineNo ratings yet

- Potential Abounds in MexicoDocument4 pagesPotential Abounds in MexicoInternational Aquafeed magazineNo ratings yet

- Dinnissen Celebrates 25 Years of The Pegasus® Vacuum CoaterDocument2 pagesDinnissen Celebrates 25 Years of The Pegasus® Vacuum CoaterInternational Aquafeed magazineNo ratings yet

- Carbohydrates in Fish NutritionDocument4 pagesCarbohydrates in Fish NutritionInternational Aquafeed magazine100% (1)

- International Aquafeed Jan - Feb 2016 - FULL EDITIONDocument72 pagesInternational Aquafeed Jan - Feb 2016 - FULL EDITIONInternational Aquafeed magazine100% (1)

- KRILL OIL: Phospholipids That Make A Difference To Filet Quality and QuantityDocument2 pagesKRILL OIL: Phospholipids That Make A Difference To Filet Quality and QuantityInternational Aquafeed magazineNo ratings yet

- FISH FARMING TECHNOLOGY - Efficient and Reliable Feed System For Fish Farming Operations - AKVA Group Feed BargesDocument3 pagesFISH FARMING TECHNOLOGY - Efficient and Reliable Feed System For Fish Farming Operations - AKVA Group Feed BargesInternational Aquafeed magazineNo ratings yet

- Economics of Drying AquafeedDocument4 pagesEconomics of Drying AquafeedInternational Aquafeed magazineNo ratings yet

- FISH FARMING TECHNOLOGY - Light Emitting Diode (LED) Lighting Systems For Early Stage AquacultureDocument3 pagesFISH FARMING TECHNOLOGY - Light Emitting Diode (LED) Lighting Systems For Early Stage AquacultureInternational Aquafeed magazineNo ratings yet

- Gut Health in 4 (Easy) StepsDocument2 pagesGut Health in 4 (Easy) StepsInternational Aquafeed magazineNo ratings yet

- EXPERT TOPIC: Channel CatfishDocument5 pagesEXPERT TOPIC: Channel CatfishInternational Aquafeed magazineNo ratings yet

- The Future of Fish Meal Replacement: Cotton ProteinDocument4 pagesThe Future of Fish Meal Replacement: Cotton ProteinInternational Aquafeed magazineNo ratings yet

- Field-Tested Health Protection For Shrimp FeedDocument2 pagesField-Tested Health Protection For Shrimp FeedInternational Aquafeed magazineNo ratings yet

- International Aquafeed - November - December 2015 - FULL EDITIONDocument68 pagesInternational Aquafeed - November - December 2015 - FULL EDITIONInternational Aquafeed magazineNo ratings yet

- Eth 165071Document16 pagesEth 165071Ina SurcNo ratings yet

- Rhubarb 1Document1 pageRhubarb 1voraciouscommentsNo ratings yet

- Apple Cider VinDocument10 pagesApple Cider VinBradley GabrielNo ratings yet

- The Botanical Science and Cultural Value of CocaLeaf in South AmericaDocument19 pagesThe Botanical Science and Cultural Value of CocaLeaf in South Americarafael bortolozoNo ratings yet

- Reading 2 GuideDocument6 pagesReading 2 GuideSIMPLEJGNo ratings yet

- Beef and Dairy CattleDocument28 pagesBeef and Dairy Cattlejennifer bajoNo ratings yet

- South NegrosDocument1 pageSouth NegrosGrignionNo ratings yet

- PDF Snack Attack Card PackDocument7 pagesPDF Snack Attack Card PackShannon HopkinsNo ratings yet

- Tarlac Farming Mechanization Survey InsightsDocument7 pagesTarlac Farming Mechanization Survey InsightsKeneth Brayle LorenzoNo ratings yet

- Formulation of LPP ProblemsDocument7 pagesFormulation of LPP ProblemsBhavesh KundnaniNo ratings yet

- Military Ambush and Aftermath Captured on VideoDocument109 pagesMilitary Ambush and Aftermath Captured on VideoJessiLorenskyNo ratings yet

- The Science of Sociology BeginDocument10 pagesThe Science of Sociology BeginSadaf Bint E JalilNo ratings yet

- Fumigation Practices For Quarantine PurposesDocument4 pagesFumigation Practices For Quarantine PurposesNor Hisham BadriNo ratings yet

- Balanced Diet ChartDocument2 pagesBalanced Diet ChartjosephNo ratings yet

- Ai 410 e 00Document27 pagesAi 410 e 00Lukman PitonoNo ratings yet

- AbraDocument16 pagesAbraJefferson BeraldeNo ratings yet

- Swadro 700 - 800 - 900 770 000Document90 pagesSwadro 700 - 800 - 900 770 000zoran_itnNo ratings yet

- Rural InsuranceDocument38 pagesRural InsuranceFrancis SimethyNo ratings yet

- Agricultural Leaflet: CREATED BY: MGS, TEFL Laura Gisella Romero CoronelDocument24 pagesAgricultural Leaflet: CREATED BY: MGS, TEFL Laura Gisella Romero CoronelsunilbholNo ratings yet

- Management Guide For Laying Hens in Deep Litter, Perchery and Free-Range SystemsDocument16 pagesManagement Guide For Laying Hens in Deep Litter, Perchery and Free-Range SystemsVali Marius0% (1)

- Strategic Management Analysis of Engro FoodsDocument38 pagesStrategic Management Analysis of Engro FoodsbilalNo ratings yet

- LED WorksheetDocument24 pagesLED WorksheetJologs Jr LogenioNo ratings yet

- Earth Science Gr. 11 Module 2Document4 pagesEarth Science Gr. 11 Module 2Shmaira Ghulam RejanoNo ratings yet

- East Walton "Our Village - Our History"Document32 pagesEast Walton "Our Village - Our History"Anonymous SKP0jiK9100% (1)

- Uganda: Livestock Production Systems SpotlightDocument12 pagesUganda: Livestock Production Systems SpotlightKalpesh RathodNo ratings yet

- Domestic agriculture support cutsDocument21 pagesDomestic agriculture support cutsAnwesha Tripathy100% (1)

- English Assignment 6Document2 pagesEnglish Assignment 6Pelangi Maharani SetiadiNo ratings yet

- Koebel, 1909 - Madeira-Old and NewDocument392 pagesKoebel, 1909 - Madeira-Old and NewAntónio Aguiar100% (1)

- FOCARS ReadingMaterialDocument578 pagesFOCARS ReadingMaterialkuldeepdeepikaNo ratings yet

- House of Flameballah Wedo: Orisha Offerings and PetitionsDocument3 pagesHouse of Flameballah Wedo: Orisha Offerings and PetitionsFelipe ArandaNo ratings yet