Professional Documents

Culture Documents

9 IJAEST Vol No.4 Issue No.1 Effect of Fibre Volume Fraction On The Tensile Strength of Banana Fibre Reinforced Vinyl Ester Resin Composites.089 091

Uploaded by

iserpOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9 IJAEST Vol No.4 Issue No.1 Effect of Fibre Volume Fraction On The Tensile Strength of Banana Fibre Reinforced Vinyl Ester Resin Composites.089 091

Uploaded by

iserpCopyright:

Available Formats

Rajesh Ghosh et al.

/ (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES

Vol No. 4, Issue No. 1, 089 - 091

Effect of fibre volume fraction on the tensile strength

of Banana fibre reinforced vinyl ester resin

composites

Rajesh Ghosh* G. Reena

Assistant Professor, System Analyst, Onsite ETL Coordinator,

Department of Mechanical Engineering Mahindra Satyam, Singapore.

Gitam University,Visakhapatnam, India g.reena0001@gmail.com

rajesh_ghosh@yahoo.com

Bh.Lakshmipathi Raju

Dr. A. Rama Krishna Assistant Professor,

Professor, Department of Mechanical Engineering,

T

Department of Mechanical Engineering, Gitam University, India.

Andhra University, India. bhlpr19@rediffmail.com

ramakrishna_a@yahoo.com

Abstract—Natural fibre reinforced polymer composites are being Thermoset resin commonly used in engineering

ES

worked upon for various engineering applications. Various

natural fibres such as jute, sisal, palm, coir and banana are used

as reinforcements. In this paper, banana fibres have been used as

reinforcement in Vinyl ester resin matrix. The influence of

applications is epoxy. Epoxy has better mechanical properties

but it is costly. The thermoplastics offer recycling possibilities

whereas the thermosets achieve improved mechanical

properties [6]. Polyester resins are low cost materials, but have

different volume fraction of the fibres in the composite is studied. inferior mechanical properties. Vinyl ester resins make a

It is seen that with the increase in the fibre fraction, the tensile compromise between the above two limits. They have

strength have increased after an initial dip. At 35% of fibre properties comparable with epoxy, but are available at low

volume fraction, an increase of 38.6% in tensile strength is noted.

cost. Plant fiber polymer composites are used in interior parts

The specific tensile strength increased by 65%. With increase in

mechanical properties it can be deduced that banana fibre can be

of automobiles [7, 8].

reliably reinforced with vinyl ester resin which may be used in Researchers have reported that the mechanical properties

engineering utilities. can be improved by appropriate surface treatments [9, 10].

With the increase in surface area, the cellulose micro fibrils get

A

Keywords- fibre volume; banana; vinyl ester; composites; exposed, which in turn improves the wettability and

mechanical properties; impregnation [11].

In the present work, the fibres were treated with NaOH to

I. INTRODUCTION increase the wettability. Banana fibres are used as

Much work is done in the application of natural fibre as reinforcement in vinyl ester resin and the effect of fibre volume

reinforcement in polymer composites. In India, banana is fraction in the composite is studied.

IJ

abundantly cultivated. Banana fiber can be obtained easily

from the plants which are rendered as waste after the fruits II. MATERIALS AND METHODS

have ripened. So banana fiber can be explored as a potential

reinforcement. Jute fiber composite have better strength than A. Chemical treatment of fibers

wood composites as reported by Gowda et al [1]. Laly et al [2]

Banana fibers as shown in fig1, were procured from

have reported the optimum content in banana fiber in polyester

TamilNadu – India. The fibers were then treated with 5%

composite to be 40%. Sreekumar et al [3] have investigated

NaOH solution for 4

effect of fiber content in polyester composites and have

hours. The fibers are then

reported 40% volume fraction to show maximum tensile

washed thoroughly with

strength. Henequen, palm and sisal fibre all have nearly the

distilled water. Fibers are

same kind of tensile, chemical and physical properties as

then put in a oven for 24

reported by Belmares et al [4]. Pothan et al [5] researched on

hours at 80 oC to remove

reinforced polyester composites with short banana fiber. It is

any traces of moisture.

shown that 30 mm fiber length gave maximum tensile strength

and 40mm fiber length shows maximum impact strength.

Fig1. Untreated banana fiber.

ISSN: 2230-7818 @ 2011 http://www.ijaest.iserp.org. All rights Reserved. Page 89

Rajesh Ghosh et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES

Vol No. 4, Issue No. 1, 089 - 091

B. Matrix composite plotted against percentage fiber volume fraction.

Vinyl ester resin is obtained from Ecmas India pvt ltd The graph shows a near linear increase in the tensile

under the trade name of Ecmalon 9911. It appears as a clear

yellow color liquid with viscosity of 400 cps and specific 6

gravity of 1.05. The cast resin has a tensile strength of 70 MPa 5

Tensile modulus (GPa)

and tensile modulus of 3200 MPa.

4

C. Preparation of the composite

The composites are made by hand lay-up technique. As 3

shown in fig2. The mould used for the composite is made of 2

mild steel with plywood sheet placed in the inner surface. A

debonding agent is applied on the plywood sheet and the 1

composite specimen is casted in the mould. The inner cavity

dimension of the mould is 200 mm x 200 mm x 10 mm. The

0

0 10 20 30 40 50

upper plate is bolted to the % fiber volume fraction

mould and the setup is left

to cure for 24 hours at Fig.4 Effect of fibre volume fraction on tensile modulus

room temperature. The

composite plate so formed

T

is then oven cured for 24 modulus with 65% increase at 35% fiber volume fraction. The

hours at 80 oC. Specimens graphs of specific tensile strength (fig.5) and specific tensile

are cut for testing as per modulus (fig.6) plotted against fiber volume fraction show an

ASTM standards. increasing trend in accordance with the tensile strength and

Fig2. The mould. tensile modulus.

D. Tensile test

Tensile test is done according to ASTM D638 with a

gauge length of 50 mm. Tests are carried out in Hounsfield

tensometer model –H20 KW. The cross head speed is 1

mm/min.

ES Specific tensile strength

(MN-m/kg)

0.16

0.14

0.12

0.1

III. RESULTS AND DISCUSSION 0.08

There is a decrease in the density of the composite with the 0.06

increase in the fiber volume fraction. This can be attributed to 0.04

the fact that the density of fiber is lower than the resin. Fig3 0.02

shows the variation of mean tensile strength with the increase

in percentage of fiber volume fraction. There is a dip in the 0

A

mean tensile strength during the initial stages of fiber loading. 0 10 20 30 40 50

This shows that the load is not properly transmitted to the % fiber volume fraction

fibers. The sole purpose of reinforcement is not properly served

at lower volume fractions. But as the fiber volume percentage Fig.5 Effect of fibre volume fraction on specific tensile

increases from 10%, the mean tensile strength also increases. strength.

At 35 % of fiber volume, the tensile strength is increased by

38.6%. This should be because of the increased bonding

IJ

between the fiber and the matrix. The load sharing is easily

transmitted to the fibers. Fig4 shows the tensile modulus of the 0.007

140 0.006

Specific tensile modulus

120 0.005

(GN-m/kg)

Tensile strength (MPa)

100 0.004

80 0.003

60 0.002

40

0.001

20

0

0 10 20 30 40 50

0

0 10 20 30 40 50 % fiber volume fraction

% fiber volume fraction

Fig.6: Effect of fibre volume fraction on specific tensile

Fig.3 Effect of fibre volume fraction on tensile strength modulus

ISSN: 2230-7818 @ 2011 http://www.ijaest.iserp.org. All rights Reserved. Page 90

Rajesh Ghosh et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES

Vol No. 4, Issue No. 1, 089 - 091

IV. CONCLUSION banana fiber reinforced polyester composites fabricated by RTM. J.

App. Poly. Sci, 109, (2008) pp.1547-1555.

There is an improvement in the tensile properties of the [4] H.Belmares, A.Barrera and M.Monjaras, New composite materials from

banana fiber – vinyl ester resin composites. natural hard fibers. Part 2: Fatigue studies and a novel fatigue

At 35% of fiber volume fraction, the tensile strength is degradation model. Ind Eng Chem Prod Res Dev, 22(1983) pp.643–52.

increased by 38.6% and 65% increases in tensile modulus. [5] L.A.Pothan, T.Sabu, and Neelakantan, Short Banana Fiber Reinforced

Polyester Composites: Mechanical, Failure and Aging Characteristics, J.

At lower volume fractions of banana fiber, the strength of Reinforced Plastics and Composites, 16(8)(1997) pp.744–765.

the composite specimen is reduced when compared with the [6] S.Padma Priya and S.K.Rai, Mechanical Performance of Biofiber/Glass-

virgin resin. reinforced Epoxy Hybrid Composites. Journal of Industrial Textiles

Banana fiber having high specific strength makes a 35(3) (2006) pp.217-226.

lightweight composite material and can be used to make light [7] S.Panthapulakkal, M.M.Sain, Injection molded short hemp fiber/glass

weight automobile interior parts. fiber reinforced polypropylene hybrid composites – mechanical, water

absorption and thermal properties. Journal of applied polymer science,

103(2007) pp. 2432-2441

[8] B.Reck, J.Turk, Thermally curable aqueous acrylic resins – a new class

of duroplastic binders for wood and natural fibers. Die Angewandte

REFERENCES Makromolekulare Chemie, 272(1999) pp.5-10.

[9] S.H.Aziz, M P.Ansell, The effect of alkanization and fiber alignment on

[1] T.M.Gowda, A.C.B.Naidu and R.Chhaya, Some Mechanical Properties the mechanical and thermal properties of kenaf and hemp bast fiber

of Untreated Jute Fabric-Reinforced Polyester Composites, J. composites: part 1 – polyester resin matrix. Composites science and

Composites Part A: Applied Science and Manufacturing, 30(3)(1999), technology,64(2004) pp.1219 – 1230

pp.277–284.

T

[10] A.Bessadok, S.Marais, S.Roudesli, C.Lixon, M.Metayer, Influence of

[2] A.Laly Pothan, Zachariah Oommenb and Sabu Thomas, Dynamic chemical modifications on water sorption and mechanical properties of

Mechanical Analysis of Banana Fiber Reinforced Polyester Composites, Agave fibers. Composites: Part A, 39(2008) pp.29-45.

Composites Science and Technology, 63(2)(2003), pp.283–293. [11] F.Zbidi, S.Sghaier, M.B.Nejma and M.Zidi, Influence of alkaline and

[3] P.A.Sreekumar, Pradeesh Albert, G.Unnikrishnan, Kuruvilla Joseph and enzymatic treatments on the properties of Doum Palm Fibers and

Sabu Thomas, Mechanical and water sorption studies of ecofriendly Composite, Journal of Applied Sciences,2009 pp.366-371.

ES

A

IJ

ISSN: 2230-7818 @ 2011 http://www.ijaest.iserp.org. All rights Reserved. Page 91

You might also like

- Mechanical, Thermal and Fatigue Behaviour of Surface-Treated Novel Caryota Urens Fibre-Reinforced Epoxy Composite.Document11 pagesMechanical, Thermal and Fatigue Behaviour of Surface-Treated Novel Caryota Urens Fibre-Reinforced Epoxy Composite.Santosh PatelNo ratings yet

- 7 Ijmperdaug20187Document6 pages7 Ijmperdaug20187TJPRC PublicationsNo ratings yet

- Processing and Characterization of Natural Fiber-Lycra Composite Reinforced With Epoxy ResinDocument5 pagesProcessing and Characterization of Natural Fiber-Lycra Composite Reinforced With Epoxy ResinsivaNo ratings yet

- 3 PDFDocument3 pages3 PDFsriyajambukarNo ratings yet

- NotesDocument36 pagesNotesULTRA College of Engineering & Technology for WomenNo ratings yet

- Jute Coir Fiber With UPDocument9 pagesJute Coir Fiber With UPbiniyamNo ratings yet

- Effect of Graphene Powder On Banyan Aerial Root Fibers Reinforced Epoxy CompositesDocument9 pagesEffect of Graphene Powder On Banyan Aerial Root Fibers Reinforced Epoxy Compositeskibrom adisuNo ratings yet

- 52 Fiber Volume FractionDocument7 pages52 Fiber Volume FractionsuganthNo ratings yet

- Mechanical Characterization of Natural and Synthetic Fibre Based Penta Layered Hybrid PolymerDocument9 pagesMechanical Characterization of Natural and Synthetic Fibre Based Penta Layered Hybrid PolymerVinyas MaheshNo ratings yet

- International Journal of Adhesion and AdhesivesDocument11 pagesInternational Journal of Adhesion and Adhesivesilham essaketNo ratings yet

- Hybrid Knaf GlasDocument6 pagesHybrid Knaf Glasagus MujiantoNo ratings yet

- Fevi ColDocument10 pagesFevi Coldharmadas bairagiNo ratings yet

- Evaluation of Mechanical Properties Ofabacaglassbanana Fiber Reinforced HybridcompositesDocument9 pagesEvaluation of Mechanical Properties Ofabacaglassbanana Fiber Reinforced HybridcompositesJulie VenzonNo ratings yet

- Dynamic Mechanical Properties of Sisal Fiber Reinforced Polyester CompositesDocument8 pagesDynamic Mechanical Properties of Sisal Fiber Reinforced Polyester CompositesMuthamizhan TamilNo ratings yet

- Mechanical Characterization of NanocelluloseJute Fiber Based CompositesDocument4 pagesMechanical Characterization of NanocelluloseJute Fiber Based CompositesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Experimental and Characteristic Study of Abaca Fiber ConcreteDocument10 pagesAn Experimental and Characteristic Study of Abaca Fiber ConcreteAika LorenNo ratings yet

- Hari Ij9Document14 pagesHari Ij9T Hari PrasadNo ratings yet

- Composites Part B: D.K.K. Cavalcanti, M.D. Banea, J.S.S. Neto, R.A.A. Lima, L.F.M. Da Silva, R.J.C. CarbasDocument8 pagesComposites Part B: D.K.K. Cavalcanti, M.D. Banea, J.S.S. Neto, R.A.A. Lima, L.F.M. Da Silva, R.J.C. Carbasmohd asrofi muslim0% (1)

- Experimental Analysis of Hybrid (Roselle, Aloe Vera and Glass) Natural Fiber-Reinforced Composite MaterialDocument12 pagesExperimental Analysis of Hybrid (Roselle, Aloe Vera and Glass) Natural Fiber-Reinforced Composite MaterialTJPRC PublicationsNo ratings yet

- Mechanical Properties of Sisal/Banana Hybrid Composite Reinforced Polyester CompositesDocument11 pagesMechanical Properties of Sisal/Banana Hybrid Composite Reinforced Polyester CompositesedmealemNo ratings yet

- JRPC GK - Sathishkumar Article 2017Document15 pagesJRPC GK - Sathishkumar Article 2017Sajailslhuti JilluNo ratings yet

- Experimental Investigation of Mechanical Behavior of Jute-Flax Based Glass Fiber Reinforced CompositeDocument12 pagesExperimental Investigation of Mechanical Behavior of Jute-Flax Based Glass Fiber Reinforced Compositerahul reddyNo ratings yet

- Comparing Impact Behavior of Natural Fiber With Termite Mound and Egg Shell Filler Added Reinforced CompositeDocument8 pagesComparing Impact Behavior of Natural Fiber With Termite Mound and Egg Shell Filler Added Reinforced CompositeTJPRC PublicationsNo ratings yet

- Hybrid Composite Materials: November 2010Document6 pagesHybrid Composite Materials: November 2010Suman Kumar NarigeNo ratings yet

- Construction and Building Materials: M.A.A. Ahmad, M.S. Abdul Majid, M.J.M. Ridzuan, M.N. Mazlee, A.G. GibsonDocument12 pagesConstruction and Building Materials: M.A.A. Ahmad, M.S. Abdul Majid, M.J.M. Ridzuan, M.N. Mazlee, A.G. GibsonPaulo UtargNo ratings yet

- Hybrid Composite Materials: November 2010Document6 pagesHybrid Composite Materials: November 2010berhaneNo ratings yet

- Mechanical Properties of Silanized Jute-Polypropylene CompositesDocument6 pagesMechanical Properties of Silanized Jute-Polypropylene CompositesJuan Camilo Pedraza OrtizNo ratings yet

- Ent 152154Document4 pagesEnt 152154anowartexNo ratings yet

- Mechanical Properties of Sisal and Banana Fiber Hybrid Epoxy CompositesDocument5 pagesMechanical Properties of Sisal and Banana Fiber Hybrid Epoxy CompositesbiniyamNo ratings yet

- Experimental Investigation of Mechanical and Morphological Properties of Flax-Glass Fiber Reinforced Hybrid Composite Using Finite Element AnalysisDocument11 pagesExperimental Investigation of Mechanical and Morphological Properties of Flax-Glass Fiber Reinforced Hybrid Composite Using Finite Element AnalysissriyajambukarNo ratings yet

- Investigation of Mechanical and Thermal Behavior of Sis 2023 Materials TodayDocument6 pagesInvestigation of Mechanical and Thermal Behavior of Sis 2023 Materials Todaydeepali boradeNo ratings yet

- 1 s2.0 S2214785323027499 MainDocument5 pages1 s2.0 S2214785323027499 MaindvktrichyNo ratings yet

- Jurnal Internasional Komposit 2Document6 pagesJurnal Internasional Komposit 2Andi Indar Wangii 311201No ratings yet

- Pemanfaatan Serat Alam Kulit Terap Sebagai Bahan Kombinasi Pembuatan Winglet Sepeda MotorDocument7 pagesPemanfaatan Serat Alam Kulit Terap Sebagai Bahan Kombinasi Pembuatan Winglet Sepeda MotorSuhendraNo ratings yet

- A Study On Mechanical Properties of Bamboo Fiber Rei - 2020 - Materials Today PDocument7 pagesA Study On Mechanical Properties of Bamboo Fiber Rei - 2020 - Materials Today PClaudia UngureanuNo ratings yet

- Study On The Dynamic Characteristic of Coconut Fibre Reinforced CompositesDocument18 pagesStudy On The Dynamic Characteristic of Coconut Fibre Reinforced CompositesAngelineAlinsodNo ratings yet

- Study of Mechanical and Acoustic Properties of Flax - Kenaf-Tamarind Seed Fiber Reinforced Hybrid Composites: Effect of Flax Fiber HybridizationDocument36 pagesStudy of Mechanical and Acoustic Properties of Flax - Kenaf-Tamarind Seed Fiber Reinforced Hybrid Composites: Effect of Flax Fiber HybridizationREMIGIUS MARIOENo ratings yet

- 16 Influence of Weave Pattern and Composite Thickness On MechanicalDocument13 pages16 Influence of Weave Pattern and Composite Thickness On MechanicalEngr Md. Nayemul IslamNo ratings yet

- Mechanical Property of Tailor Made Flax/Glass Fiber Reinforced Hybrid Polyester CompositeDocument4 pagesMechanical Property of Tailor Made Flax/Glass Fiber Reinforced Hybrid Polyester CompositesriyajambukarNo ratings yet

- Kenaf Fiber ApperDocument6 pagesKenaf Fiber ApperDr. R. Sathish KumarNo ratings yet

- Comparative Study of Areca Fiber Reinforced Polyester Composites and PlywoodDocument15 pagesComparative Study of Areca Fiber Reinforced Polyester Composites and PlywoodMasudur RahmanNo ratings yet

- Mazumder 2018 IOP Conf. Ser. Mater. Sci. Eng. 438 012007Document9 pagesMazumder 2018 IOP Conf. Ser. Mater. Sci. Eng. 438 012007asif mahmudNo ratings yet

- Prasad 2018 IOP Conf. Ser. Mater. Sci. Eng. 402 012103 PDFDocument7 pagesPrasad 2018 IOP Conf. Ser. Mater. Sci. Eng. 402 012103 PDFlekNo ratings yet

- 10.1515 - Secm 2015 0441Document8 pages10.1515 - Secm 2015 0441Simon Rei EstacioNo ratings yet

- 105-Article Text-669-3-10-20190901Document10 pages105-Article Text-669-3-10-20190901Naga KiranNo ratings yet

- Mechanical behavior of disposed fiberglass filled bamboo mat compositesDocument8 pagesMechanical behavior of disposed fiberglass filled bamboo mat compositesYerco muñozNo ratings yet

- Effectiveness of Rattan Fiber As A Reinforcing Material in Polymer Matrix Composites: An Experimental StudyDocument11 pagesEffectiveness of Rattan Fiber As A Reinforcing Material in Polymer Matrix Composites: An Experimental Studysabenid984No ratings yet

- EvaluationofTensileBehaviorofSeaShell JuteFabric PDFDocument7 pagesEvaluationofTensileBehaviorofSeaShell JuteFabric PDFPrince Ghosh EponNo ratings yet

- Materials Today: Proceedings: Chethan Kumar G, Sagar M. Baligidad, A.C. Maharudresh, Nishchay Dayanand, T.N. ChetanDocument6 pagesMaterials Today: Proceedings: Chethan Kumar G, Sagar M. Baligidad, A.C. Maharudresh, Nishchay Dayanand, T.N. ChetanNISHCHAY DAYANANDNo ratings yet

- Comparative Evaluation On Properties of Hybrid Glass Fiber-Sisal/Jute Reinforced Epoxy CompositesDocument6 pagesComparative Evaluation On Properties of Hybrid Glass Fiber-Sisal/Jute Reinforced Epoxy CompositesUMA MAHESHNo ratings yet

- Report Proj Composite Materials Based On Coconut FiberDocument30 pagesReport Proj Composite Materials Based On Coconut Fibermujeeb100% (1)

- Nallusamy 2017 IOP Conf. Ser. Mater. Sci. Eng. 225 012283 PDFDocument10 pagesNallusamy 2017 IOP Conf. Ser. Mater. Sci. Eng. 225 012283 PDFSayan RakshitNo ratings yet

- Effect of Chemical Treatments On Tensile Strength of Areca Fiber Reinforced Natural Rubber CompositesDocument10 pagesEffect of Chemical Treatments On Tensile Strength of Areca Fiber Reinforced Natural Rubber CompositesIOSRjournalNo ratings yet

- J1Document12 pagesJ1gp rajeshNo ratings yet

- The Effect of Hybridization On Mechanical Behaviour of Kevlar and Natural Fiber Reinforced CompositeDocument10 pagesThe Effect of Hybridization On Mechanical Behaviour of Kevlar and Natural Fiber Reinforced CompositeTJPRC PublicationsNo ratings yet

- Mechanical Properties of Natural Cellulose Fibers Reinforced PolymerDocument8 pagesMechanical Properties of Natural Cellulose Fibers Reinforced Polymernurshiyama89No ratings yet

- Muthalagu 2021Document9 pagesMuthalagu 2021Mechanical Engg. Alagappa Poly College,KaraikudiNo ratings yet

- Pembuatan Dan Karakterisasi Komposit SerDocument5 pagesPembuatan Dan Karakterisasi Komposit Serhadi sufyanNo ratings yet

- Analysis of Mechanical Properties of Natural Waste Particle Reinforced Polymer CompositesDocument10 pagesAnalysis of Mechanical Properties of Natural Waste Particle Reinforced Polymer CompositesGODWIN GNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- 22.IJAEST Vol No 6 Issue No 1 Variable Frequency Scheme For Low Power Digital Circuits 141 143Document3 pages22.IJAEST Vol No 6 Issue No 1 Variable Frequency Scheme For Low Power Digital Circuits 141 143iserpNo ratings yet

- 21.ijaest Vol No 6 Issue No 1 Improvement of PSRR in Common Source Amplifiers 133 140Document8 pages21.ijaest Vol No 6 Issue No 1 Improvement of PSRR in Common Source Amplifiers 133 140iserpNo ratings yet

- 20.IJAEST Vol No 6 Issue No 1 A Novel Dangerous Vehicle Detection Protocol For Safety Application 124 32Document9 pages20.IJAEST Vol No 6 Issue No 1 A Novel Dangerous Vehicle Detection Protocol For Safety Application 124 32iserpNo ratings yet

- 12.IJAEST Vol No 6 Issue No 1 Implementation of Partial Reconfigurable FIR Filters Using Dynamic Partial Re Configuration 065 069Document5 pages12.IJAEST Vol No 6 Issue No 1 Implementation of Partial Reconfigurable FIR Filters Using Dynamic Partial Re Configuration 065 069iserpNo ratings yet

- 8.IJAEST Vol No 6 Issue No 1 Adaptive Beam Forming Using DMI and CMA Algorithms 035 040Document6 pages8.IJAEST Vol No 6 Issue No 1 Adaptive Beam Forming Using DMI and CMA Algorithms 035 040helpdesk9532No ratings yet

- 19.IJAEST Vol No 6 Issue No 1 Comparative Study On Steel Fiber Reinforced Cum Control Concrete 116 120Document5 pages19.IJAEST Vol No 6 Issue No 1 Comparative Study On Steel Fiber Reinforced Cum Control Concrete 116 120iserpNo ratings yet

- 18.IJAEST Vol No 6 Issue No 1 An Area Efficient and Low Power Design For Decimation Filter Using CSD Representation 111 115Document5 pages18.IJAEST Vol No 6 Issue No 1 An Area Efficient and Low Power Design For Decimation Filter Using CSD Representation 111 115iserpNo ratings yet

- 14.IJAEST Vol No 6 Issue No 1 Automatic Detection of Glaucoma Disease in Eye 077 080Document4 pages14.IJAEST Vol No 6 Issue No 1 Automatic Detection of Glaucoma Disease in Eye 077 080iserpNo ratings yet

- 1.IJAEST Vol No 5 Issue No 2 Assessment and Improvement of The Accuracy of The Odemark Transformation Method 105 110Document6 pages1.IJAEST Vol No 5 Issue No 2 Assessment and Improvement of The Accuracy of The Odemark Transformation Method 105 110iserpNo ratings yet

- 16.IJAEST Vol No 6 Issue No 1 Tensile and Hardness Tests On Natural Fiber Reinforced Polymer Composite Material 097 104Document8 pages16.IJAEST Vol No 6 Issue No 1 Tensile and Hardness Tests On Natural Fiber Reinforced Polymer Composite Material 097 104iserpNo ratings yet

- Ijaest: Cluster Based Web Search Using Support Vector MachineDocument16 pagesIjaest: Cluster Based Web Search Using Support Vector MachineiserpNo ratings yet

- 10.IJAEST Vol No 6 Issue No 1 Information Systems Strategic Planning at The Siliwangi University Tasikmalaya 053 059Document7 pages10.IJAEST Vol No 6 Issue No 1 Information Systems Strategic Planning at The Siliwangi University Tasikmalaya 053 059iserpNo ratings yet

- 2.IJAEST Vol No 6 Issue No 1 Breast Cancer Detection and Classification Using Neural Network 004 009Document6 pages2.IJAEST Vol No 6 Issue No 1 Breast Cancer Detection and Classification Using Neural Network 004 009iserpNo ratings yet

- 6.IJAEST Vol No 6 Issue No 1 Investigation of Performance and Emissions of 2 Stroke Single Cylinder SI Engine Operating on Alcohol Gasoline Fuel Blends Using 4 Spark Plugs a New Kind of Ignition 027 030Document4 pages6.IJAEST Vol No 6 Issue No 1 Investigation of Performance and Emissions of 2 Stroke Single Cylinder SI Engine Operating on Alcohol Gasoline Fuel Blends Using 4 Spark Plugs a New Kind of Ignition 027 030iserpNo ratings yet

- 9.ijaest Vol No 6 Issue No 1 Effect of Wedm Conditions On Surface Roughness A Prapmetric Ion Using Taguchi Method 041 048Document8 pages9.ijaest Vol No 6 Issue No 1 Effect of Wedm Conditions On Surface Roughness A Prapmetric Ion Using Taguchi Method 041 048iserpNo ratings yet

- 30.IJAEST Vol No 5 Issue No 2 An Efficient Protocol For Intelligent Transportation in Vehicular Adhoc Networks 301 309Document9 pages30.IJAEST Vol No 5 Issue No 2 An Efficient Protocol For Intelligent Transportation in Vehicular Adhoc Networks 301 309tribal338No ratings yet

- 7.IJAEST Vol No 6 Issue No 1 A Design Approach For Vehicle Black Box System Using FPGA Basd LIN Controller 031 034Document4 pages7.IJAEST Vol No 6 Issue No 1 A Design Approach For Vehicle Black Box System Using FPGA Basd LIN Controller 031 034iserpNo ratings yet

- 5.IJAEST Vol No 6 Issue No 1 VLSI Implementation of AES Crypto Processor For High Throughput 022 026Document5 pages5.IJAEST Vol No 6 Issue No 1 VLSI Implementation of AES Crypto Processor For High Throughput 022 026iserpNo ratings yet

- 32.IJAEST Vol No 5 Issue No 2 Performance Analysis of Optical OFDM On Fading Channel With Adaptive Interleaving 315 318Document4 pages32.IJAEST Vol No 5 Issue No 2 Performance Analysis of Optical OFDM On Fading Channel With Adaptive Interleaving 315 318iserpNo ratings yet

- 3.IJAEST Vol No 6 Issue No 1 A Novel Approach For Indian License Plate Recognition System 010 014Document5 pages3.IJAEST Vol No 6 Issue No 1 A Novel Approach For Indian License Plate Recognition System 010 014iserpNo ratings yet

- 1.IJAEST Vol No 6 Issue No 1 Alternative Measures For Modeling Risk and Expected Utility Theory 001 003Document3 pages1.IJAEST Vol No 6 Issue No 1 Alternative Measures For Modeling Risk and Expected Utility Theory 001 003iserpNo ratings yet

- 4.IJAEST Vol No 6 Issue No 1 On Chip Implementation of Z Source Inverter Fed Induction Motor Drive 015 021Document7 pages4.IJAEST Vol No 6 Issue No 1 On Chip Implementation of Z Source Inverter Fed Induction Motor Drive 015 021iserpNo ratings yet

- 34.IJAEST Vol No 5 Issue No 2 A Correlation Method Between Erosion and The Acoustic Properties of Bladed Turbo Machinery 333 338Document6 pages34.IJAEST Vol No 5 Issue No 2 A Correlation Method Between Erosion and The Acoustic Properties of Bladed Turbo Machinery 333 338iserpNo ratings yet

- 31.IJAEST Vol No 5 Issue No 2 VLSI Architecture and ASIC Implementation of ICE Encryption Algorithm 310 314Document5 pages31.IJAEST Vol No 5 Issue No 2 VLSI Architecture and ASIC Implementation of ICE Encryption Algorithm 310 314iserpNo ratings yet

- 35.IJAEST Vol No 5 Issue No 2 Design Analysis of FFT Blocks For Pulsed OFDM UWB Systems Using FPGA 339 342Document4 pages35.IJAEST Vol No 5 Issue No 2 Design Analysis of FFT Blocks For Pulsed OFDM UWB Systems Using FPGA 339 342iserpNo ratings yet

- 28.IJAEST Vol No 5 Issue No 2 Raod Extraction Using K Means Clustering and Morphological Operations 290 295Document6 pages28.IJAEST Vol No 5 Issue No 2 Raod Extraction Using K Means Clustering and Morphological Operations 290 295iserpNo ratings yet

- 33.IJAEST Vol No 5 Issue No 2 Energy Efficient Domino VLSI Circuits and Their Performance With PVT Variations in DSM Technology 319 331Document19 pages33.IJAEST Vol No 5 Issue No 2 Energy Efficient Domino VLSI Circuits and Their Performance With PVT Variations in DSM Technology 319 331iserpNo ratings yet

- 7 IJAEBM Vol No.1 Issue No.2 Continuous Modeling of Foreign Exchange Rate of USD Versus TRY 102 106Document5 pages7 IJAEBM Vol No.1 Issue No.2 Continuous Modeling of Foreign Exchange Rate of USD Versus TRY 102 106iserpNo ratings yet

- 29.IJAEST Vol No 5 Issue No 2 The Estimation of Forging Load For Closed Die Forging of Axi Symmetric Job Using Computer 296 300Document5 pages29.IJAEST Vol No 5 Issue No 2 The Estimation of Forging Load For Closed Die Forging of Axi Symmetric Job Using Computer 296 300iserpNo ratings yet

- 6 IJAEBM Volume No 1 Issue No 2 From Discrete To Continuous 98 101Document4 pages6 IJAEBM Volume No 1 Issue No 2 From Discrete To Continuous 98 101iserpNo ratings yet

- Forticlient Ems v1.2.0 Quickstart GuideDocument27 pagesForticlient Ems v1.2.0 Quickstart GuideIndra PramonoNo ratings yet

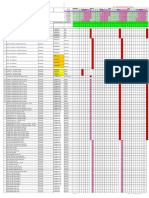

- 52 Week PPM Planner Template-15 Jul 14Document26 pages52 Week PPM Planner Template-15 Jul 14safetydellNo ratings yet

- Print Lesson PlanDocument6 pagesPrint Lesson Planapi-297789042100% (1)

- S4hana C4C Erp Integration Hci1702Document32 pagesS4hana C4C Erp Integration Hci1702prasadgvkNo ratings yet

- ARM Cortex-A7 Allwinner A20 Dual Core Development Kit, ViewDocument4 pagesARM Cortex-A7 Allwinner A20 Dual Core Development Kit, ViewederelkNo ratings yet

- Isolator Design ConsiderationsDocument5 pagesIsolator Design ConsiderationsJinho JungNo ratings yet

- Registry Explorer User Guide in Under 40Document86 pagesRegistry Explorer User Guide in Under 40AnyNo ratings yet

- Tuff Tile CalculationDocument12 pagesTuff Tile CalculationFareena FatimaNo ratings yet

- Salesforce Platform Workshop, Winter '17: @salesforcedocsDocument141 pagesSalesforce Platform Workshop, Winter '17: @salesforcedocsMahesh GoparajuNo ratings yet

- QTP11 00Document25 pagesQTP11 00Anand DhanaNo ratings yet

- Ficha Tecnica Luminaria Led Vt3 Vt2Document1 pageFicha Tecnica Luminaria Led Vt3 Vt2neymarronNo ratings yet

- XenServer Administrator's GuideDocument133 pagesXenServer Administrator's Guidemlmcbride33No ratings yet

- Literature Case Study: Affordable HousingDocument15 pagesLiterature Case Study: Affordable HousingPayal Subbaiah100% (2)

- Influence of Le Corbusier in Modern ArchitectureDocument56 pagesInfluence of Le Corbusier in Modern ArchitectureMurtaza NooruddinNo ratings yet

- Wp-Oracle-jdbc Thin SSL 2007Document22 pagesWp-Oracle-jdbc Thin SSL 2007Rolando CanalesNo ratings yet

- Timber-To-Timber Spacer Screw: Double Thread, DifferentiatedDocument2 pagesTimber-To-Timber Spacer Screw: Double Thread, DifferentiatedAnonymous KRS4mebjxYNo ratings yet

- Harvard ArchitectureDocument11 pagesHarvard Architecturepratham gunjNo ratings yet

- Inspection of Storage TankDocument19 pagesInspection of Storage TanknovazhaiNo ratings yet

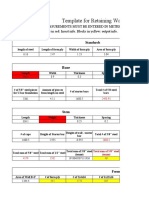

- Retaining Wall Template BreakdownDocument15 pagesRetaining Wall Template BreakdownKofi DanielNo ratings yet

- Drawing Templates - FreeCAD DocumentationDocument17 pagesDrawing Templates - FreeCAD Documentationwdany100% (1)

- Syllabus For B.Arch - 2014 15 Onwards IX To X Sem PDFDocument18 pagesSyllabus For B.Arch - 2014 15 Onwards IX To X Sem PDFManish Singh RathorNo ratings yet

- FirewallDocument3 pagesFirewallWawan Naning A'imNo ratings yet

- The Ultimate PC Building Handbook Volume 2Document180 pagesThe Ultimate PC Building Handbook Volume 2Bao Vinh100% (5)

- CSG EN XX ALL Optiplex 3020 Spec Sheet PDFDocument3 pagesCSG EN XX ALL Optiplex 3020 Spec Sheet PDFFareez TaherNo ratings yet

- SAP Technical TOOLSDocument6 pagesSAP Technical TOOLSKumarReddyNo ratings yet

- First Floor Beam & Slab Details PDFDocument1 pageFirst Floor Beam & Slab Details PDFRaghul ShangarthiyanNo ratings yet

- (Toa) Ornament and Crime PDFDocument14 pages(Toa) Ornament and Crime PDFMuskaan RajputNo ratings yet

- Lightweight ArchDocument28 pagesLightweight ArchHritika GurungNo ratings yet

- Bosch ASD DesignDocument2 pagesBosch ASD DesignChowKC03No ratings yet

- Drughelp - Care 6.22 PDFDocument52 pagesDrughelp - Care 6.22 PDFJoko RifaiNo ratings yet