Professional Documents

Culture Documents

APS Vertical Mill

Uploaded by

chp_pradeep4989Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APS Vertical Mill

Uploaded by

chp_pradeep4989Copyright:

Available Formats

Advanced Photon Source

Mill Study Guide P.1

Vertical Milling Machine

This study guide will cover the major working parts, functions, and machining techniques that can be found/used on most vertical milling machines. This study guide has been designed to directly represent the questions that will be found on the open book written assessment and as an aid for the hands-on usability assessment. Both assessments will also include questions related to standard machine shop safety and APS internal user safety guidelines. Answering the questions found at the end of the study guide will enable the user to successfully pass the hands-on usability and open book written assessments. Study guide practice test and answers can be found at the end of the guide.

The Milling Machine uses a rotating milling cutter to produce machined surfaces by progressively removing material from a work piece. The vertical milling machine also can function like a drill press because the spindle is perpendicular to the table and can be lowered into the work piece.

JG 2005

Advanced Photon Source

Mill Study Guide P. 2

THE CONTROLS START/STOP The green button starts the spindle motor and the red button shuts the motor off.

Variable Motor Drive used on some Milling Machines FORWARD/REVERSE This switch changes the rotation direction of the spindle. When the milling machine is in high range this switch is in the forward position for cutting but in low range the switch is in the reverse position. Putting the switch in the opposite position while remaining in the same range reverses the rotation of the spindle. HAND BRAKE Also known as the spindle brake, it is used to bring the spindle rotation to a stop after the power is turned off and to aid in removing collets and chucks. The spindle can be locked by pressing or pulling the brake and then pushing it up. SPINDLE SPEED This wheel is used to change the speed of the spindle for both high range and low range. The milling machine must be running when changing the speed. POWER FEED The power feed uses a motor to control the motion of the longitudinal feed in either direction at various speeds. Not all of the milling machines in the shop have this option. CROSS-FEED HANDWHEEL This hand-wheel moves the table in and out.

JG 2005

Advanced Photon Source

Mill Study Guide P. 3

VERTICAL FEED HANDCRANK This is used to raise and lower the table. LONGITUDINAL HANDWHEEL This hand-wheel moves the table left and right. On some machines the handles are spring activated to keep them from rotating when the power feed is used. HIG-LOW SPEED CONTROL The high-low speed switch changes the range from high to low and vise-versa. The spindle may need to be turned by hand while engaging the gears.

Quill Feed Selector

Quill Lock

QUILL FEED HANDLE You can raise and lower the quill (spindle) with this handle. QUILL LOCK Pushing this lever down will lock the quill, pulling it back up releases the lock. The quill must be locked when milling.

JG 2005

Advanced Photon Source

Mill Study Guide P. 4

QUILL STOP The quill stop can be adjusted by hand to set a limit on the quill travel is also used to disengage the quill feed. This is useful when multiple holes have to be drilled to the same depth. QUILL FEED LEVER AND SELECTOR These are used to activate the power feed for the quill. The selector will adjust the speed of the power feed and the lever activates the drive. The quill can be Feed down into the part or up. DIGITAL READOUT Digital readouts (DRO) are added to the milling machines to aid in the accuracy of cuts and increase productivity. The lateral movement of the table can be measured to 2/10,000th of an inch with the readouts. Other operations the readout can perform include dividing any dimension by two, running with absolute or relative measurements, and displaying in inches or millimeters.

LONGITUDINAL/CROSS-FEED AXIS The digital readout will display the distance traversed in both the X and Y-axis. ZERO BUTTONS These two buttons will set their respective displays to zero. This is used after the machinist finds the edge of their part and wants to reference all of the other measurements off that axis. INCHES/METRIC BUTTON The readout can give all measurements in inches or millimeters, by pressing this button it will switch from one system of measurement to the other. KEYPAD Dimensions can be entered into the readout using the keypad. This can be helpful when a reference point is needed other than zero.

JG 2005

Advanced Photon Source

Mill Study Guide P. 5

Peripheral and Face Milling Techniques

Peripheral milling uses teeth on the outer edge of the cutter body. The surface produced corresponds to the contour of the milling cutter, which can range from a flat surface to a formed shape. There are two different methods of peripheral milling, Conventional or Up Milling (Fig. 1) and Climb or Down Milling (Fig. 2). The figures on the left show the rotation of the cutting tool with respect to the direction of the part on the table. In conventional milling the work is fed against the cutter, which compensates for backlash in the table. Each tooth of the cutting tool starts its cut in clean metal, prying the material off the work. Fig. 1 Down milling will give a better quality of work and is better suited for thin pieces of material since the cutting action forces the work into the table. This method should not be used on hard materials and the machine has to be rigid so backlash cannot occur. The cutting tool will also last longer using Down milling as long as good tool pressure is maintained. The machines in the shop are suitable for both types of milling. If you are unsure of which method you should use ask somebody in the shop for assistance. Face milling uses the bottom of the mill to machine the work instead of the sides. The cutting comes from the combined action of cutting edges located on the face (or end) of the cutting tool as well as the edges on the periphery. The direction of the feed with relation to the rotation is not important when using this method.

Fig. 2

JG 2005

Advanced Photon Source

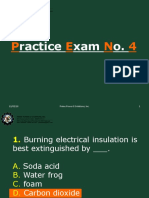

Mill Study Guide P. 6 Practice Test

The following questions have been designed to directly represent the questions that will be found on the written assessment and as an aid for the hands-on usability assessment. 1. Always stop the machine before making measurements or cleaning out chips. True False Counter-boring is done to prepare a drilled hole to receive a fillister or socket-head screw. True 3. 4. True False False Machine shields should be in place before actual machining takes place. The inclined angle of the standard countersink used for countersinking for flat head machine screws is: A. 82 B. 60 C. 90 D. 41 5. 6. Always use vises or clamps to hold work pieces. True False Face milling cutters are intended for machining large flat surfaces parallel to the face of the cutter. True 7. 8. True False False Never activate the rapid traverse while the cutter is making a cut. Be thoroughly familiar with the placement of the machines stop switch or lever. True 9. False Climb milling should never be performed on machines __________. A. with play in the table B. that are not in top condition C. not fitted with an anti-backlash device D. All of the above E. None of the above

2.

JG 2005

Advanced Photon Source

Mill Study Guide P. 7

10.

Stop the milling machine before ________________. A. Attempting to make adjustments or measurements. B. Trying to remove accumulated chips. C. Before opening or removing guards and covers D. All of the above.

11. The milling machine is a very versatile machine tool. It can be used to ____________ . A. drill, bore, and cut gears B. machine flat surfaces C. machine irregularly shaped surfaces D. All of the above E. None of the above 12. It is permissible to leave the chuck key in the chuck while drilling a hole. True False 13. Machine safety guards are not required to be in place most during machining operations. True True True False False False 14. Always keep hands at a safe distance from moving machine parts. 15. In conventional milling the work is fed against the cutter.

A

16. Which of the pictures portrays Conventional cutting method? ______________

JG 2005

Advanced Photon Source

Mill Study Guide P. 8

Identify the parts of a Vertical Milling Machine.

17. _________ Start/Stop Button 18. _________ Digital Readout 19. _________ Longitudinal Hand Wheel 20. _________ Power Feed 21. _________ Forward/Reverse Switch 22. _________ Spindle 23. _________ Table 24. _________ Hand Brake 25. _________ Cross-Feed Hand Wheel 26. _________ Spindle Speed 27. _________ Vertical Feed Hand-crank

A K

B C D

E F J G

JG 2005

Advanced Photon Source

Mill Study Guide P. 9

28. Never wear jewelry or loose clothing while operating machine True False

29. Machine safety guards are not required to be in place during machining operations. True False

Identify the parts of a Vertical Milling Machine Head

30. _____ Quill Feed Lever 31. _____ Quill Stop 32. _____ High/Low Speed Control 33. _____ Quill Feed Handle 34. _____ Quill Lock 35. _____ Quill Feed Selector

B F

E D

JG 2005

Advanced Photon Source

Vertical Milling Machine

Study Guide Answer Sheet

1. True 2. True 3. True 4. A 5. True 6. True 7. True 8. True 9. D 10. D 11. D 12. False 13. False 14. True 15. True 16. B 17. K 18. D

19. J 20. 21. 22. G A E

23. F 24. B 25. H 26. C 27. I 28. True 29. False 30. E 31. D 32. A 33. B 34. C 35. F

JG 2005

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2014 Metabo Katalog GB LRDocument291 pages2014 Metabo Katalog GB LRTh Nattapong100% (1)

- Blasting For Construction PDFDocument9 pagesBlasting For Construction PDFHugo FernandezNo ratings yet

- Simulator TutorialsDocument29 pagesSimulator TutorialstmadamolekunNo ratings yet

- Auction of Machine Shop Tools and EquipmentDocument4 pagesAuction of Machine Shop Tools and Equipmentbelchior alvaroNo ratings yet

- A Small Bench Lathe Made of PipeDocument2 pagesA Small Bench Lathe Made of PipeCicero Milan100% (3)

- Ac 193Document46 pagesAc 193Tiago Castelani100% (1)

- Shell Air Tool S2 A 100: Performance, Features & BenefitsDocument2 pagesShell Air Tool S2 A 100: Performance, Features & BenefitsRaden ArdyNo ratings yet

- Investigation of The Effect of Drill Bit Rotation Speed On Sustainable DrillingDocument5 pagesInvestigation of The Effect of Drill Bit Rotation Speed On Sustainable DrillingMohamed Anis BoumazaNo ratings yet

- Engineering Vol 72 1901-11-29Document31 pagesEngineering Vol 72 1901-11-29ian_newNo ratings yet

- Catalog BredentDocument520 pagesCatalog Bredentee100% (1)

- Practice Exam No. 4 2018 PDFDocument43 pagesPractice Exam No. 4 2018 PDFJevan CalaqueNo ratings yet

- Catalogo AlimakDocument42 pagesCatalogo AlimakJulio MoleroNo ratings yet

- MIS Catalogue 2013Document178 pagesMIS Catalogue 2013Bojana StefanovikNo ratings yet

- Vermeer Falcon f2Document2 pagesVermeer Falcon f2Movison AustinNo ratings yet

- CNC Drilling and Dowel Inserting Machine DRILLTEQ C 100 NBS033Document8 pagesCNC Drilling and Dowel Inserting Machine DRILLTEQ C 100 NBS033sufea saadNo ratings yet

- Micro DrillingDocument17 pagesMicro DrillingzerogravityNo ratings yet

- Layout and Line BalancingDocument72 pagesLayout and Line BalancingJolly JyotiNo ratings yet

- Top Drive Tesco 250 Hmis 475Document2 pagesTop Drive Tesco 250 Hmis 475Draghiceanu VasileNo ratings yet

- Leaf Drill Jig Design and Analysis in CAD/CAMDocument52 pagesLeaf Drill Jig Design and Analysis in CAD/CAMKarthi KeyanNo ratings yet

- Rezimi Obrade TitexDocument396 pagesRezimi Obrade TitexTomislav TropcicNo ratings yet

- WoodsDocument35 pagesWoodsGlen Michael WongNo ratings yet

- DF457D CORDLESS DRIVER DRILL PARTS DIAGRAM AND LIST FOR INDIADocument3 pagesDF457D CORDLESS DRIVER DRILL PARTS DIAGRAM AND LIST FOR INDIAMihai MogaNo ratings yet

- Introduction To Machine Tool, Machine Tool ClassificationsDocument33 pagesIntroduction To Machine Tool, Machine Tool ClassificationsDeepan Raj100% (1)

- Hotel OS&E ListDocument29 pagesHotel OS&E Listamyraeuhj83% (6)

- Pedal-Powered Washing Machine DIY InstructionsDocument5 pagesPedal-Powered Washing Machine DIY InstructionsAnonymous GEHeEQlajbNo ratings yet

- Principles of Jigs DesignDocument12 pagesPrinciples of Jigs DesignAkeju AyodeleNo ratings yet

- Ruko Twist DrillsDocument80 pagesRuko Twist DrillsPeter NomikosNo ratings yet

- Universal 3 Motor Drilling MachineDocument6 pagesUniversal 3 Motor Drilling MachineMectrosoft Creative technologyNo ratings yet

- Raiseboringheads Brochure EnglishDocument56 pagesRaiseboringheads Brochure EnglishAlain TremblayNo ratings yet

- TRIP OUT OF HOLE TOP DRIVE PROCEDURESDocument164 pagesTRIP OUT OF HOLE TOP DRIVE PROCEDURESMohsen Yavari100% (1)