Professional Documents

Culture Documents

Fundamentals of Building Piping Systems

Uploaded by

KhaleelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fundamentals of Building Piping Systems

Uploaded by

KhaleelCopyright:

Available Formats

NI BC O WOR L D

I NC . H EAD QU ART E RS

1516 MIDDLEBURY STREET ELKHART, IN USA 46516-4740

TECHNICAL SERVICES PHONE: FAX: 888.446.4226

888.336.4226

Technical Bulletin

Fundamentals of Building Piping Systems

HVAC By Chuck Baumgarten

The most important factor in understanding how an HVAC system works, is to realize that "cold" does not exist. Cold is merely the absence of heat. Heat is either removed from or added to air in order to "condition" the space in a building. The primary functions of a buildings HVAC system are to: 1. Add or remove heat from the air in the building 2. Control humidity 3. Filter the air in the building 4. Bring fresh air into the building.

Cooling

There are two primary refrigeration methods used in air-conditioning. The first is DX or direct expansion. This is the type of air conditioning system used in residential and light commercial construction. It does not utilize piping and therefore it will not be discussed here. The other is chilled water which is the type of system we see in heavy commercial and institutional construction. The process of removing the heat from a building usually incorporates the use of a refrigerant, such as R-22 (Freon was outlawed in 1995). Due to the laws of physics all liquids absorb heat when vaporized and throw off heat when condensed or compressed. Refrigerants are simply chemicals that dramatically expand and contract when compressed or vaporized. This gives them the ability to carry relatively large amounts of heat into or out of a piece of equipment. In the case of a "chilled water system", which is where NIBCO sells a great number of its products, this process is aided by the use of a piping system, which uses cooled water to carry the heat out of a building (Dia.1). There are many different piping configurations in

NTB-1004-01

TrainingWarrantyTechnical Services

NI BC O WOR L D

I NC . H EAD QU ART E RS

1516 MIDDLEBURY STREET ELKHART, IN USA 46516-4740

TECHNICAL SERVICES PHONE: FAX: 888.446.4226

888.336.4226

chilled water systems, but for illustration purposes traditional chilled and condenser water systems will be discussed.

The Chilled Water System Water is pumped in a "closed loop" system and is never mixed with the condenser water or exposed to the atmosphere. Heat is absorbed and passed off at three primary points in the chilled water system The first point at which heat is moved out of the building is at a fan coil unit. These units are located throughout the building inside the occupied spaces and work much like a car radiator, only in reverse. The difference is that the cars radiator dissipates heat from the cars engine, via water, and the fan coil absorbs heat into the water within it. Because the coils are cool, heat is absorbed when a fan forces warm air inside the building, over the coils in the fan coil unit. Although the amount of temperature change that occurs in the chilled water is relatively small (+10) this is still a very efficient way of cooling a building. The heated chilled water is then circulated back to the chiller which is the next point where the heat is transferred. The chiller has both chilled and condenser water running through it but the two are never mixed. The chiller uses a refrigerant to cool the chilled water and acts as a heat exchanger to move the heat into the condenser water.

NTB-1004-01

TrainingWarrantyTechnical Services

NI BC O WOR L D

I NC . H EAD QU ART E RS

1516 MIDDLEBURY STREET ELKHART, IN USA 46516-4740

TECHNICAL SERVICES PHONE: FAX: 888.446.4226

888.336.4226

The Condenser Water System The heat, which is originally taken out of the occupied space to be cooled, is passed to the chilled water and is now in the condenser water. The condenser water system is usually an "open loop" system. This means that the water is exposed to the atmosphere at the cooling tower. It is at the cooling tower that the final transfer of the heat will occur. The heat is moved out of the condenser water into the atmosphere by the cooling tower.

The condenser water pumps push the heated condenser water out of the chiller to the cooling tower. A cooling tower is a large open structure which has two basic components; several large fans and some type of framework that the condenser water is allowed to fall or drain across. The framework is usually ceramic, fiberglass or plastic and is often built like a giant honeycomb. The water in the cooling tower is pumped to the top where it is allowed to fall through the framework. The fans, which are normally located at the top of the cooling tower force air up and through the framework. The heat is dissipated out of the condenser water into the atmosphere at this point, primarily through evaporation. Again, due to certain laws of physics, evaporation is a natural cooling process. When the condenser water comes into contact with the outside air, inside the cooling tower, evaporation occurs thus cooling the condenser water. This evaporation can be seen as mist coming out of the top of most cooling towers. Because some of the condenser water is continually being evaporated, there is a make-up water line which constantly adds fresh water to the system as it is required.

Heating Systems

The HVAC system must also be capable of adding heat to the occupied space in the building. A buildings heating system usually utilizes one of three primary types of heat sources; electricity, steam or hot water. Electrically generated heat is the simplest but least cost effective. It does not require piping and simply incorporates strips of metal to which electricity is applied much like an electric toaster. Air is then forced across the strips to heat the occupied space. Due to its high

NTB-1004-01

TrainingWarrantyTechnical Services

NI BC O WOR L D

I NC . H EAD QU ART E RS

1516 MIDDLEBURY STREET ELKHART, IN USA 46516-4740

TECHNICAL SERVICES PHONE: FAX: 888.446.4226

888.336.4226

operating cost it is generally used in warmer climates were there are fewer days in the year that the building is heated. The Steam System In a steam system a boiler, which is usually fired by natural gas or fuel oil, is used to produce steam. When water is boiled it expands and therefore builds pressure within the boiler. This pressure is used to force the steam through the piping system to a heat exchanger. A heat exchanger works much like a chiller only in reverse. At that point the steam is allowed to give off its heat thus condensing back into a liquid. Inside the heat exchanger the heat from the steam is transferred into a hot water system and is carried to the occupied space. After the steam has given off its heat and allowed to condense back to a liquid state, a steam trap is used to collect the condensate.

Condensate pumps are then used to pump the condensed water back to the boiler to be processed again. The Hot Water System The hot water system is probably the simplest piping system of the HVAC processes. It too is a closed loop system. The source of heat is normally a heat exchanger as outlined above. The hot water is pumped to the spaces within the building which are to be heated. Again, the hot water passes through coils in the fan coil unit where its heat is given off the air in the building. The water is then piped back to the heat exchanger to start the process over again.

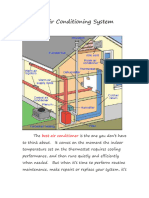

Warm Air Out To Atmosphere Cool Air Out To Building

Diagram 1

Fan Coil Unit

Cool Air In From Atmosphere

Cooling Tower

Warm Air In From Building

NTB-1004-01

Condenser TrainingWarrantyTechnical Services Water Pump

Chiller

Chilled Water Pump

NI BC O WOR L D

I NC . H EAD QU ART E RS

1516 MIDDLEBURY STREET ELKHART, IN USA 46516-4740

TECHNICAL SERVICES PHONE: FAX: 888.446.4226

888.336.4226

For additional questions regarding this or any other technical issue involving NIBCO products, please contact : NIBCO Technical Services at 1-888-446-4226 02/11/05

NTB-1004-01

TrainingWarrantyTechnical Services

You might also like

- Cooling Tower 1Document69 pagesCooling Tower 1Hemchand MoreNo ratings yet

- Dean Paul Cueto 2 0 0 6 - 1 8 3 0 8: Me 188: Powerplant EngineeringDocument40 pagesDean Paul Cueto 2 0 0 6 - 1 8 3 0 8: Me 188: Powerplant EngineeringDean Paul100% (1)

- Cooling Towers Improve HVAC EfficiencyDocument18 pagesCooling Towers Improve HVAC EfficiencyHarjo Wiyono100% (1)

- Computer-linked bench top cooling towerDocument9 pagesComputer-linked bench top cooling towerMuhammad Suleman AttariNo ratings yet

- Cooling TowersDocument60 pagesCooling TowersaffashNo ratings yet

- Cooling TowersDocument60 pagesCooling TowersMudassar NoreNo ratings yet

- Cooling Towers PDFDocument60 pagesCooling Towers PDFRamakrishnaNo ratings yet

- INTRODUCTIONDocument16 pagesINTRODUCTIONsethi nagendrasundarNo ratings yet

- Cooling Towers GuideDocument60 pagesCooling Towers GuideAndhreNo ratings yet

- Cooling Tower1Document66 pagesCooling Tower1Er Bali Pandhare100% (1)

- ENERGY AUDIT AND CONSERVATION: 11 WAYS TO CREATE ENERGY EFFICIENT HOMESDocument39 pagesENERGY AUDIT AND CONSERVATION: 11 WAYS TO CREATE ENERGY EFFICIENT HOMESNmg KumarNo ratings yet

- AgikDocument7 pagesAgikRejg MendozaNo ratings yet

- EssayWritting AircondDocument6 pagesEssayWritting Aircondnurschaaa55No ratings yet

- Powerplant - Cooling Sytem Cooling Tower Feedwater Heater Condenser EvaporatorDocument32 pagesPowerplant - Cooling Sytem Cooling Tower Feedwater Heater Condenser EvaporatorYehosuah RanoaNo ratings yet

- Cooling Tower DefinitionsDocument68 pagesCooling Tower Definitionszubi13No ratings yet

- Central Air Conditioning System-converted_2Document24 pagesCentral Air Conditioning System-converted_2gmusama1No ratings yet

- 1.1 Background of StudyDocument12 pages1.1 Background of StudyazlanNo ratings yet

- Cooling Tower Basics PDFDocument71 pagesCooling Tower Basics PDFMohamed TallyNo ratings yet

- Lecture 7Document16 pagesLecture 7shreshtha0095No ratings yet

- Cooling TowerDocument60 pagesCooling Towerkumar sandeep100% (1)

- Cooling Tower Efficiency ManualDocument26 pagesCooling Tower Efficiency ManualSyed Alwi AlattasNo ratings yet

- Air Conditioning Plant (BSME 5B)Document128 pagesAir Conditioning Plant (BSME 5B)Marvin ArnaizNo ratings yet

- CED Engineering-Cooling-Tower PDFDocument69 pagesCED Engineering-Cooling-Tower PDFSyed Shoeb100% (1)

- Chilled Water Air-conditioning System ComponentsDocument30 pagesChilled Water Air-conditioning System ComponentsMalik MussaNo ratings yet

- Air Conditioning Thesis StatementDocument7 pagesAir Conditioning Thesis Statementewdgbnief100% (2)

- Cooling Tower: Induced Draft Cooling TowersDocument5 pagesCooling Tower: Induced Draft Cooling TowerssuhailfarhaanNo ratings yet

- Cooling Tower AssignmentDocument11 pagesCooling Tower AssignmentSaad khan100% (2)

- Cooling TowerDocument20 pagesCooling TowerMazlia MazlanNo ratings yet

- Analysis and Design of Cooling Towers Etabs StadDocument33 pagesAnalysis and Design of Cooling Towers Etabs StadMohammed MurtuzaNo ratings yet

- Fundamentals of HVAC ControlsDocument68 pagesFundamentals of HVAC Controlsbenson100% (2)

- Mapua Institute of Technolog1Document15 pagesMapua Institute of Technolog1Ian KasaiNo ratings yet

- Cooling Systems ExplainedDocument6 pagesCooling Systems ExplainedYehosuah RanoaNo ratings yet

- Refrigeration System Saves Heat EnergyDocument47 pagesRefrigeration System Saves Heat EnergyAbhishek KumarNo ratings yet

- Table of Content:: Induced Draft Cooling TowerDocument34 pagesTable of Content:: Induced Draft Cooling TowerKiran PatilNo ratings yet

- ChE 153Document19 pagesChE 153Joyce EdrozoNo ratings yet

- What Is A (Wet, Atmospheric) Cooling Tower?Document20 pagesWhat Is A (Wet, Atmospheric) Cooling Tower?shruthi SundaramNo ratings yet

- Chapter 1. INTRODUCTIONDocument25 pagesChapter 1. INTRODUCTIONLakshmipathy JakkeriNo ratings yet

- Air Conditioning System: Comfort ConditionsDocument55 pagesAir Conditioning System: Comfort ConditionsTunaNo ratings yet

- How Do Chillers Work by Nathan SchumacherDocument5 pagesHow Do Chillers Work by Nathan SchumacherNathan SchumacherNo ratings yet

- The Key Differences Between Closed And Open Circuit Cooling Tower SystemsDocument5 pagesThe Key Differences Between Closed And Open Circuit Cooling Tower SystemskutecoolNo ratings yet

- Script:-.Air Condition ScriptDocument11 pagesScript:-.Air Condition Scriptaimri_cochinNo ratings yet

- Hot Water SupplyDocument56 pagesHot Water SupplyVismithaNo ratings yet

- Introduction To Hvac SystemDocument16 pagesIntroduction To Hvac SystemJohn ApeladoNo ratings yet

- Cooling Towers ExplainedDocument18 pagesCooling Towers ExplainedDrex Dela TorreNo ratings yet

- Shopmillingmsme: Steam Jet Refrigeration SystemDocument7 pagesShopmillingmsme: Steam Jet Refrigeration SystembbaytlNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- 100 Things Every Homeowner Must KnowFrom Everand100 Things Every Homeowner Must KnowFamily HandymanNo ratings yet

- The Home Owner's Guide to HVAC: The Envelope and Green TechnologiesFrom EverandThe Home Owner's Guide to HVAC: The Envelope and Green TechnologiesNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- How it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useFrom EverandHow it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useNo ratings yet

- Central Heating: A Design and Installation ManualFrom EverandCentral Heating: A Design and Installation ManualRating: 2 out of 5 stars2/5 (1)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AFrom EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ARating: 5 out of 5 stars5/5 (1)

- High-Piled Storage Classification GuideDocument19 pagesHigh-Piled Storage Classification GuideMohamed AbdallahNo ratings yet

- Pressure Reducing ValvesDocument4 pagesPressure Reducing ValvesAhrian BenaNo ratings yet

- Valve DefinitionsDocument28 pagesValve Definitionsprotech280% (1)

- Fire Flow Requirements For Buildings Using ISO MethodDocument3 pagesFire Flow Requirements For Buildings Using ISO MethodKhaleelNo ratings yet

- Combination Standpipe Sprinkler Systems GuideDocument10 pagesCombination Standpipe Sprinkler Systems Guideodemircioglu2No ratings yet

- HM Products Catalog e 2013-11-01Document14 pagesHM Products Catalog e 2013-11-01KhaleelNo ratings yet

- Fire PumpsDocument2 pagesFire PumpsKhaleelNo ratings yet

- High-Piled Storage Classification GuideDocument19 pagesHigh-Piled Storage Classification GuideMohamed AbdallahNo ratings yet

- Backflow Prevention For The Fire Protection IndustryDocument3 pagesBackflow Prevention For The Fire Protection IndustryhanloveNo ratings yet

- Press Dependent and Press Independent ControlsDocument4 pagesPress Dependent and Press Independent Controlsrogel_ganaNo ratings yet

- Inside This IssueDocument52 pagesInside This IssueJuan MartinezNo ratings yet

- Emergency Contact InfoDocument1 pageEmergency Contact InfoKhaleelNo ratings yet

- Emergency Contact InfoDocument1 pageEmergency Contact InfoKhaleelNo ratings yet

- FM Global Fire Water Storage TankDocument56 pagesFM Global Fire Water Storage TankSameer Selvi100% (1)

- Loud Speaking AvoidingDocument15 pagesLoud Speaking AvoidingKhaleelNo ratings yet

- Piping Material DistributorDocument16 pagesPiping Material DistributorKhaleelNo ratings yet

- Engineering Data: Iso 9001 Certified CompanyDocument32 pagesEngineering Data: Iso 9001 Certified CompanyKhaleelNo ratings yet

- Austin Hughes and Bill Drury (Auth.) Electric Motors and Drives. Fundamentals, Types and Applications 2013Document123 pagesAustin Hughes and Bill Drury (Auth.) Electric Motors and Drives. Fundamentals, Types and Applications 2013megamaster2010No ratings yet

- Balancing ValvesDocument7 pagesBalancing ValvesKhaleelNo ratings yet

- Fet - 2012 NotificationDocument1 pageFet - 2012 NotificationKhaleelNo ratings yet

- LEED FAQsDocument6 pagesLEED FAQsKhaleelNo ratings yet

- Best Practice Manual-Fluid PipingDocument43 pagesBest Practice Manual-Fluid Pipingapi-3869476100% (1)

- List of Accepted Makes of MaterialsDocument5 pagesList of Accepted Makes of MaterialsKhaleelNo ratings yet

- RJD Engages Faculty on Contract BasisDocument18 pagesRJD Engages Faculty on Contract BasisKhaleelNo ratings yet

- VRV Outdoor Unit Daikin - BrochureDocument2 pagesVRV Outdoor Unit Daikin - Brochurekunal_singhaiNo ratings yet

- FET 2012 BrochureDocument6 pagesFET 2012 BrochureKhaleelNo ratings yet

- Engineering ToolboxDocument7 pagesEngineering Toolboxasgart02No ratings yet

- Plama Mall Area Details by FloorDocument1 pagePlama Mall Area Details by FloorKhaleelNo ratings yet

- Block-C 95.0 LVLDocument1 pageBlock-C 95.0 LVLKhaleelNo ratings yet

- Unit 3Document16 pagesUnit 3Himanshu SinghNo ratings yet

- Pttchem-Sp-M-801 Equipment InstallationDocument14 pagesPttchem-Sp-M-801 Equipment InstallationCivil Friend80% (5)

- Joshua Custodio Bsme 5B 1Document4 pagesJoshua Custodio Bsme 5B 1Datu JonathanNo ratings yet

- Trane Heating and Cooling Coils PDFDocument8 pagesTrane Heating and Cooling Coils PDFChad Griffin100% (1)

- Acid Cleaning ProcedureDocument6 pagesAcid Cleaning ProcedureMadhan RajNo ratings yet

- HRSG Chemical Cleaning Procedure - KrakatauDayaDocument7 pagesHRSG Chemical Cleaning Procedure - KrakatauDayaSamuelTrinandoNo ratings yet

- NR13 Brazilian Pressure Vessel Code in EnglishDocument16 pagesNR13 Brazilian Pressure Vessel Code in Englishmcoswald83No ratings yet

- Vapor and Combined Power Cycles: Wan Rosli Wan SulaimanDocument13 pagesVapor and Combined Power Cycles: Wan Rosli Wan SulaimanJihan GorayahNo ratings yet

- BoilersDocument3 pagesBoilersatikulNo ratings yet

- Process Description and ASPEN Computer Modelling oDocument31 pagesProcess Description and ASPEN Computer Modelling oSachiel NightroadNo ratings yet

- Flash TanksDocument3 pagesFlash TanksnincitoNo ratings yet

- ME 331 Thermo II Steam Cycle 2Document81 pagesME 331 Thermo II Steam Cycle 2Mimo Ammar90% (10)

- Edreis 2020 IOP Conf. Ser. Mater. Sci. Eng. 963 012027Document10 pagesEdreis 2020 IOP Conf. Ser. Mater. Sci. Eng. 963 012027Dewi ApaNo ratings yet

- Ch.2.Regenerative Rankine Cycle With Closed Feed Water HeaterDocument55 pagesCh.2.Regenerative Rankine Cycle With Closed Feed Water Heaterlayanalfar0No ratings yet

- 1.LIB. SPEC - Temperature Humidity Calibration Chamber THC-50ADocument11 pages1.LIB. SPEC - Temperature Humidity Calibration Chamber THC-50Avijay.victorysolutions01No ratings yet

- Poeb94 LohDocument10 pagesPoeb94 LohTina RinNo ratings yet

- B. Biology DiscussionDocument26 pagesB. Biology Discussionaltika pNo ratings yet

- A1hex Lu6v8Document24 pagesA1hex Lu6v8andremaxwelNo ratings yet

- ATTACHMENT 3 Start-Up and Operational Manual For Steam TurbineDocument116 pagesATTACHMENT 3 Start-Up and Operational Manual For Steam TurbineMuhammad Junaid KhanNo ratings yet

- Boost Boiler Efficiency with Thermal Utility AssessmentsDocument15 pagesBoost Boiler Efficiency with Thermal Utility AssessmentsVishal ShitoleNo ratings yet

- CSSDDocument90 pagesCSSDNikhil MohananNo ratings yet

- Department of Labor and Employment RULE 1160 RULE 1170: Gimarangan Saldo Loquinario Pobreza Sano IndinoDocument43 pagesDepartment of Labor and Employment RULE 1160 RULE 1170: Gimarangan Saldo Loquinario Pobreza Sano IndinoJinky Mae PobrezaNo ratings yet

- Sru Heat ExchangerDocument29 pagesSru Heat ExchangerJordan Young100% (1)

- Steam Turbine ManualDocument261 pagesSteam Turbine ManualShivam Kumar67% (3)

- Atmospheric Flash TankDocument3 pagesAtmospheric Flash TankBlitz Xyrus100% (2)

- CHE 510 Pulp and Paper Technology Lecture 1 IntroductionDocument12 pagesCHE 510 Pulp and Paper Technology Lecture 1 IntroductionChristian Nweke100% (2)

- Changes of State and the Water CycleDocument22 pagesChanges of State and the Water CycleAgnes LinNo ratings yet

- SSC JE Mechanical Syllabus BreakdownDocument4 pagesSSC JE Mechanical Syllabus BreakdownAbhishek DadhwalNo ratings yet

- Plan & Organiz HospitalDocument119 pagesPlan & Organiz HospitalJobykrishna100% (1)

- Boiler SpecificationsDocument34 pagesBoiler SpecificationsHenry CoronadoNo ratings yet