Professional Documents

Culture Documents

Multi Pull Belts

Uploaded by

Erman KILICOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multi Pull Belts

Uploaded by

Erman KILICCopyright:

Available Formats

MULTI - PULL POLY - V BELTS

Standards : ISO 9982, RMA IP-26, DIN 7867

FENNER MULTI-PULL POLY-V BELTS

The name Fenner has been synonymous with quality and reliability in Mechanical Power Transmission Products for over 140 years. Fenner V-belts, Pulleys, Couplings and Gear Boxes have become the industry bench marks over the years manufactured in state-of-art facilities conforming to quality standards ISO-9001:2000 & ISO/TS-16949:2002 along with ISO 14001:1996 for Environmental Management System. Fenner has the unique distinction of being the only company in India to be accredited with API certification. Multi-Pull Ribbed belts offer high power capacity in a single flexible low stretch belt. The continuous high tensile synthetic cord makes maximum utilization of the face width and ensures a uniform tension throughout the belt. There are five sections available: PHFractional Horse Power belt for very light duty applications.

(No. of Ribs X P) 40o

FEATURES

COMPACT DRIVE POLY-V belt is highly flexible and hence can be used with smaller pulley diameters to give a lighter and compact drive. HIGHER POWER 40% higher power rating per unit width compared to conventional V-belts. ZERO SLIPPAGE Almost eliminates the slippage due to maximum wedge contact on the pulleys. ENERGY SAVING Maximum returns with energy saving upto 6%. REAR SIDE DRIVE

PJ - Low cost belt for light duty applications. PK - Designed specifically for the automotive industry, it is also suitable for Machine Tool drives etc. PL - Medium duty drive belt covering a wide range of applications. PM - High performance makes this belt unrivalled for heavy duty applications. Polychloroprene Rib Rubber High Modulus Polyester Cord Polychloroprene adhesion compound Polyester cotton fabric

Being thinner the rear side can be used to drive additional accessories / idlers without affecting life. HIGHER BEARING LIFE Lesser static tension gives higher bearing life. SILENT DRIVE Gives vibration and noise free power transmission in every application. SINGLE BELT Eliminates the necessity to use multiple / matched set belts. HIGHER SPEED Can be used at higher speed more than 40 m/sec.

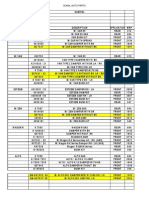

SECTION PH PJ PK PL PM

PITCH(P) THICKNESS(T) MAX .NO OF (mm) (mm) RIBS/SLEEVE 1.60 2.34 3.56 4.70 9.40 2.90 3.80 4.50 7.00 13.50 24 96 24 50 40

LONGER LIFE Gives lesser wear and longer life to the pulleys due to lesser static tension and belt slippage. LOW DOWNTIME & REPLACEMENT COST Reduces downtime and also belt replacement cost.

FENNER MULTI-PULL POLY-V BELTS

STANDARD BELT LENGTHS

PH Effective Length mm inch 1321 1346 1372 1397 1422 1473 1549 1588 1664 1753 1854 1892 1905 1930 1956 1969 1981 1994 2007 2032 2057 2083 2108 2134 2159 2184 2210 2235 2261 2286 2311 2337 2362 2388 2413 2438 2464 2489 2515 2540 52 53 54 55 56 58 61 62.5 65.5 69 73 74.5 75 76 77 77.5 78 78.5 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 PJ Effective Length mm inch 483 508 559 584 610 660 711 724 762 813 864 914 940 965 1016 1054 1092 1105 1118 1130 1143 1168 1194 1219 1232 1245 1270 1283 1295 1308 1321 1346 1372 1397 1422 1473 1549 1588 1651 1664 1753 1854 1892 1905 1956 1969 1994 2083 2210 2261 2286 2337 2388 2438 2489 2540 19 20 22 23 24 26 28 28.5 30 32 34 36 37 38 40 41.5 43 43.5 44 44.5 45 46 47 48 48.5 49 50 50.5 51 51.5 52 53 54 55 56 58 61 62.5 65 65.5 69 73 74.5 75 77 77.5 78.5 82 87 89 90 92 94 96 98 100 PK Effective Length mm inch 610 24 660 26 673 26.5 686 27 699 27.5 711 28 739 29.1 762 30 775 30.5 790 31.1 818 32.2 841 33.1 871 34.3 884 34.8 902 35.5 914 36 927 36.5 940 37 955 37.6 970 38.2 991 39 1016 40 1031 40.6 1054 41.5 1080 42.5 1110 43.7 1146 45.1 1166 45.9 1194 47 1229 48.4 1257 49.5 1295 51 1334 52.5 1359 53.5 1387 54.6 1425 56.1 1461 57.5 1496 58.9 1529 60.2 1560 61.4 1626 64 1659 65.3 1681 66.2 1725 67.9 1760 69.3 1796 70.7 1829 72 1862 73.3 1900 74.8 1930 76 1948 76.7 1961 77.2 1981 78 2050 80.7 2101 82.7 2144 84.4 2205 86.8 2258 88.9 2329 91.7 2385 93.9 2441 96.1 2479 97.6 2522 99.3 2586 101.8 2611 102.8 2680 105.5 2835 111.6 2845 112 2896 114 2921 115 2997 118 PL Effective Length mm inch 1270 1334 1372 1397 1422 1473 1562 1613 1664 1715 1803 1842 1943 1981 2019 2070 2096 2134 2197 2235 2324 2362 2477 2515 2705 2743 2845 2896 2921 2997 3086 3124 3289 3327 3493 3696 4051 4191 4470 4623 5029 5385 6096 6121 6883 7645 8407 9169 9931 10693 12217 13741 13970 13995 50 52.5 54 55 56 58 61.5 63.5 65.5 67.5 71 72.5 76.5 78 79.5 81.5 82.5 84 86.5 88 91.5 93 97.5 99 106.5 108 112 114 115 118 121.5 123 129.5 131 137.5 145.5 159.5 165 176 182 198 212 240 241 271 301 331 361 391 421 481 541 550 551 PM Effective Length mm inch 2311 2388 2515 2692 2832 2921 3010 3124 3327 3531 3734 4089 4191 4470 4648 5029 5410 6121 6883 7645 8407 9169 9931 10693 12217 13741 13970 13995 91 94 99 106 111.5 115 118.5 123 131 139 147 161 165 176 183 198 213 241 271 301 331 361 391 421 481 541 550 551

Sizes not listed can also be supplied subject to minimum order quantity. Consult Fenner

1N 28 FENNER MU LTI - PULL 1N 28 FENNER MUL TI - PULL 21PL 1900 1N 28 FENNER MULTI - PULL 21PL 1900 1N 28 FENNER M ULTI -P ULL 21PL 1900 1N 28 FENNER MULTI - PULL 21PL 1900 1N 28 FENNER MU LTI -PU LL 21PL 1900 1N 28 FENNER MULTI - PULL 21PL 1900 1N 28 FENNER MULTI - PULL 21PL 1900 21PL 1900

FENNER MULTI-PULL POLY-V BELTS

DESIGNATION OF BELTS

METRIC : No.of ribs Belt profile Effective length (mm) IMPERIAL : Effective length (51.5 Inches) Belt profile No.of ribs 515 PJ 6 6 PJ 1308 The take-up allowance given in the same table should be added on to the calculated centre distance to allow for belt stretch. Rotate the drive while tightening the belt in order to equalize the tension. The belt should be run under load and observed during the first few hours. After several hours running re-check the tension, it may be necessary to take up adjustment to compensate for normal drop in tension during the running in period. 4. GUARDS Where guards are necessary it is desirable to use the mesh type to permit adequate ventilation.

INSTALLATION INSTRUCTIONS

1. PULLEYS Before assembling the drive, check the pulley grooves are free from scores or sharp edges, and are dimensionally correct. 2. ALIGNMENT Good alignment of pulleys prior to belt installation is important. The pulleys may be aligned by placing a straight edge or cord along the edges. The shafts must also be parallel and in the same plane. 3. BELTS When pulleys have been correctly positioned on the shafts, the belts can be installed to complete the drive. The drive centre distance should be reduced prior to the installation of the belts so that they may be fitted without the use of force. Under no circumstances must belts be prised into the grooves. Belt and pulley grooves can easily be damaged by using sharp tools to stretch the belts over the pulley rim. The installation allowance given in the table below is the minimum recommended reduction in centre distance for the various belt section and lengths to allow for correct fitting.

Section PJ PK PL PM Minimum Diameter (mm) Idler on Inside 20 38 100 224 Idler on Outside 40 75 200 375

5. IDLER PULLEYS If idler pulleys are used it is recommended that they be as large a diameter as practical. All idlers should be located on the slack side of the drive. When used on the inside the idler should have the same groove profile as the driver and driven pulleys. The pulley should be positioned as close as possible to the large pulley. Minimum pitch diameters are listed in the table below. When using on the outside, the idler should be flat (not crowned) and positioned as close as possible to the small pulley.

Minimum effective diameter of Pulley (mm) PH 13 PJ 20 PK 50 PL 75 PM 180

SERPENTINE DRIVES For selection Consult Fenner Multi-Pull is a flexible belt and can be reverse bent round a pulley. The outside of the belt can be used to drive. This enables Multi-Pull to be used on MultiPulley or Serpentine Drives.

FENNER MULTI-PULL POLY-V BELTS

TENSIONING INSTRUCTIONS

DEFLECTION METHOD Multi-Pull Drives will be sufficiently tensioned if the deflection force 'F' applied perpendicular at midspan to produce a deflection equal to 16 mm per metre of span distance falls within the range given in the table below. Mark two reference lines on the back of the belt, at To improve tensioning accuracy the drive should be run briefly to seat the belt before making final measurement. A new belt should be tensioned to the higher value. Re-tensioning how-ever should be toward the lower value. A straight edge should be placed across the pulleys to act as datum for measuring the amount of deflection. Calculate the deflection in mm on a basis of 16 mm per metre of centre distance.

PJ

The above tensioning forces are for average drive conditions. A precise belt tensioning force can be calculated - contact Fenner Technical Services Although this is the preferred method of tensioning it may prove impractical. In this case the elongation method can be used. ELONGATION METHOD

approximately 80% of the span length, tighten the belt until the extension of the reference lines correspond with values given in the table below. New belts should be installed with an elongation towards the higher value and re-tensioned towards the lower value.

Belt Section Pulley Diameter Range mm Below 45 45 - 66 67 - 125 below 160 160 - 224 below 355 355 - 560 Elongation mm / metre 3-4 4-6 6-7 5-7 7-9 4-5 5-7

Belt Tension Indicator applied to Mid-span

CE NT RE

PL PM

16 CE pe m m sp r 1 m def an etr lect e o io n f

Fo rce

DIS TA N

SHAFT ALIGNMENT

1. Shafts are not parallel to one another. 2. Shafts are not in correct alignment although they appear parallel when seen from above.

TENSIONING FORCES

Force required to deflect belt 16 mm per metre of span

End view of the above.

Belt Section Small Pulley Newton (N) Kilogram force Diameter (mm) (kgf) per rib per rib Below 45 PJ 45 - 66 67 - 125 below 160 PL 160 - 224 below 355 PM 355 - 560 35 to 60 3.5 to 6.0 12 to 20 30 to 45 1.2 to 2.0 3.0 to 4.5 1.6 to 3.0 3.0 to 5.0 4.0 to 7.0 10 to 15 0.16 to 0.30 0.30 to 0.50 0.40 to 0.70 1.0 to 1.5

3. Shafts are parallel and in alignment but pulleys are not in alignment.

4. Correct installation both shafts and pulleys are parallel and in alignment

The dotted lines emphasize the faults by indicating the correct position.

FENNER MULTI-PULL POLY-V BELTS

Pulleys should be mounted as close as possible to the bearings to reduce overhung load. The maximum axial misalignment allowed is 3 mm per metre centre distance ( maximum 15 mm ).

1000 mm

Shaft parallelism must be kept within 2 degree. TENSIONING THE BELT Fenner Multipull Belts must be tensioned correctly and with great care. The under or over tensioning can cause functional problems and lead to premature belt failure. We recommend the elongation method, which is simple and requires no special equipment. 1.Fit the belt on the pulleys with no tension. 2.Draw two lines perpendicularly across the back of the belt about 80% of the belt span apart (or one metre apart for very long spans). 3.Increase the distance between the two lines by 0.5 to 0.75% i.e. by 5mm to 7.5mm for an initial spacing of 1000 mm. 4.Run the drive under load for about 10 minutes. 5.Check the tension of the belt (i.e. the spacing between the two lines) and readjust if necessary. Generally the tensioning values for each section are maintained as under:

PJ 0.5% PK 0.6% PL 0.6% PM 0.6% Centre Distance Adjustment : Fitting and Take-Up Recommendations Belt Length (mm) < 750 750 - 1200 1200 - 2000 2000 - 3500 3500 - 6000 > 6000 PJ M -10 -10 -15 -20 T +10 +15 +20 +30 PK T M -11 +13 -12 +16 -16 +22 -23 +32 PL M -15 -20 -30 -40 T +20 +25 +35 +50 M PM T M T

1007.5 mm

C after Take-up Calculated C C For Fitting

-40 +50 -50 +70 -100 +130

C. L. Shah & Co.

137, Canning Street, Kolkata - 700 001 Phone: 2243 1198 / 3363, Fax: 2230 2678 Mobile: 98300 42037, Email: shiv_chopra@vsnl.net

You might also like

- Multiplication TableDocument1 pageMultiplication TableHarish BishtNo ratings yet

- Judgement - 05 Mar 2020Document46 pagesJudgement - 05 Mar 2020Harish BishtNo ratings yet

- The Dashboard WarningDocument2 pagesThe Dashboard WarningsenthilanviewNo ratings yet

- 07 Science Key Notes ch15 Light PDFDocument2 pages07 Science Key Notes ch15 Light PDFanitaNo ratings yet

- The Dashboard WarningDocument2 pagesThe Dashboard WarningsenthilanviewNo ratings yet

- Congratulations PDFDocument10 pagesCongratulations PDFHarish BishtNo ratings yet

- What NextDocument10 pagesWhat NextbalajiNo ratings yet

- Delhi HC Judgement On DA Freezing 01.06.2020 PDFDocument8 pagesDelhi HC Judgement On DA Freezing 01.06.2020 PDFHarish BishtNo ratings yet

- Free Look Period:: Life Insurance Corporation of IndiaDocument2 pagesFree Look Period:: Life Insurance Corporation of IndiaDebendra nayakNo ratings yet

- CL - Price List Dale Filter Systems Private Limited PDFDocument15 pagesCL - Price List Dale Filter Systems Private Limited PDFBharti Puratan100% (1)

- InTech-Lubrication and Lubricants PDFDocument22 pagesInTech-Lubrication and Lubricants PDFHarish BishtNo ratings yet

- 2301 0600 (Honorary Secretary) No. 5 (20) /2018/D (SSC) 2301 2938 (Under Secretary) 2301 1498 (Inspecting Officer)Document3 pages2301 0600 (Honorary Secretary) No. 5 (20) /2018/D (SSC) 2301 2938 (Under Secretary) 2301 1498 (Inspecting Officer)srinivas mudgalaNo ratings yet

- InTech-Lubrication and Lubricants PDFDocument22 pagesInTech-Lubrication and Lubricants PDFHarish BishtNo ratings yet

- Jeevan Shanti EnglishDocument2 pagesJeevan Shanti EnglishPadmanabhan SwaminathanNo ratings yet

- All India Sainik School Entrance Exam 2018 Question PaperDocument17 pagesAll India Sainik School Entrance Exam 2018 Question PaperD KabipranavNo ratings yet

- Gabrielprice List W.E.F 01.6.2015Document8 pagesGabrielprice List W.E.F 01.6.2015Deepak SiwalNo ratings yet

- 530create Blog PDFDocument25 pages530create Blog PDFHarish BishtNo ratings yet

- DM Civil Paper-1 PDFDocument20 pagesDM Civil Paper-1 PDFHarish BishtNo ratings yet

- Thermal Overload Relays: MN1 To MN5 MN12 To MN12 LDocument12 pagesThermal Overload Relays: MN1 To MN5 MN12 To MN12 LHarish Bisht100% (1)

- L&T MN RelaysDocument6 pagesL&T MN RelaysYogeshJaiswalNo ratings yet

- CC Policy-Document LIC-s Tech-Term With-LogoDocument16 pagesCC Policy-Document LIC-s Tech-Term With-LogoDebendra nayakNo ratings yet

- Apollo Curb-Paver-Slip-Form-Type-Kp-1200-SfDocument4 pagesApollo Curb-Paver-Slip-Form-Type-Kp-1200-SfHarish BishtNo ratings yet

- Kent Super Plus Product Brochure EnglishDocument2 pagesKent Super Plus Product Brochure EnglishHarish BishtNo ratings yet

- ThreadsDocument1 pageThreadsTai Kuei LeeNo ratings yet

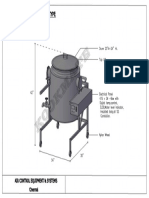

- Electric Bulk Cooker DiagramDocument1 pageElectric Bulk Cooker DiagramHarish BishtNo ratings yet

- Hanuman 40Document4 pagesHanuman 40Braham sharmaNo ratings yet

- CC Policy-Document LIC-s Tech-Term With-LogoDocument16 pagesCC Policy-Document LIC-s Tech-Term With-LogoDebendra nayakNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hoek Cell & Pressurisation System: Biaxial ChamberDocument2 pagesHoek Cell & Pressurisation System: Biaxial ChamberNguyễn Văn MinhNo ratings yet

- Saturn Guidance Navigation and TargettingDocument8 pagesSaturn Guidance Navigation and TargettingkbenceNo ratings yet

- Basic Electronics - Activity 1Document3 pagesBasic Electronics - Activity 1Coreene Alva Mana-ay PradoNo ratings yet

- Joseph Rendall 2021Document13 pagesJoseph Rendall 2021Fábio A. BodnarNo ratings yet

- Eigenvalue ProblemsDocument17 pagesEigenvalue ProblemsCivil Engineer PKNo ratings yet

- Detect methane with low-power SB-12A-00 gas sensorDocument2 pagesDetect methane with low-power SB-12A-00 gas sensorPABLO ANTONIO ESTEVEZ RUEDANo ratings yet

- Extracts ASCE 7 4chapter 18 Design of Damped StructuresDocument6 pagesExtracts ASCE 7 4chapter 18 Design of Damped Structuresrehan7421No ratings yet

- Mcpa-Kac Data SheetDocument2 pagesMcpa-Kac Data SheetAdrian OprisanNo ratings yet

- Mechanics Chap 3-parts1-2+TD-2021Document34 pagesMechanics Chap 3-parts1-2+TD-2021Mat MatttNo ratings yet

- EPQ Full Project Version 2Document52 pagesEPQ Full Project Version 2nsjNo ratings yet

- ESE Questions Bank CE BMCDocument10 pagesESE Questions Bank CE BMCahiNo ratings yet

- DLS A Practical Guide and Applications PDFDocument19 pagesDLS A Practical Guide and Applications PDFJoel Cisneros YupanquiNo ratings yet

- Debye Specific Heat TheoryDocument3 pagesDebye Specific Heat TheoryJuly T Widya R100% (1)

- Ac Substation Equipment Failure Report Nerc ComDocument51 pagesAc Substation Equipment Failure Report Nerc ComPaikoNo ratings yet

- Service Manual: Eleganza SmartDocument30 pagesService Manual: Eleganza Smartpm4002100% (1)

- Cayenne 5Document17 pagesCayenne 5Marcelo AndradeNo ratings yet

- EN9 Technical Data: Print Friendly Text Only Site MapDocument1 pageEN9 Technical Data: Print Friendly Text Only Site MapMari selvamNo ratings yet

- Molecular Geometry and PolarityDocument15 pagesMolecular Geometry and Polaritysincerely reverieNo ratings yet

- Basic Electronics Important Expected MCQ With SolutionDocument11 pagesBasic Electronics Important Expected MCQ With SolutionAbhay ShuklaNo ratings yet

- Internal Pipe Distributor Design ProcedureDocument5 pagesInternal Pipe Distributor Design Proceduresenthil kumarNo ratings yet

- 3RW40271BB14 Datasheet enDocument7 pages3RW40271BB14 Datasheet enRodrigo RiveraNo ratings yet

- 2019 Sec 4 Pure Chemistry SA2 Geylang MethodistDocument32 pages2019 Sec 4 Pure Chemistry SA2 Geylang MethodistErOn TaNNo ratings yet

- B Quantum Physics - 1Document104 pagesB Quantum Physics - 1Ujjwal RajpalNo ratings yet

- Heat Transfer CHE0301 LECTURE 2 Basics of Heat TransferDocument21 pagesHeat Transfer CHE0301 LECTURE 2 Basics of Heat TransfermiraNo ratings yet

- Seismic System Factors and System OverstrengthDocument51 pagesSeismic System Factors and System OverstrengthBenjamin EdwardNo ratings yet

- Speed Time Distance Questions AnswersDocument12 pagesSpeed Time Distance Questions Answersmeyyappan saravanan100% (1)

- Doosan Powertrain ManualDocument54 pagesDoosan Powertrain Manualian armstrong100% (1)

- Engg Mechanics Exercise Problems Apr 2024 1Document5 pagesEngg Mechanics Exercise Problems Apr 2024 1Sharmaine FajutaganaNo ratings yet

- Common Lab TechniquesDocument6 pagesCommon Lab TechniquesQueen Alyana BernabeNo ratings yet

- (Canto Classics) Erwin Schrödinger - 'Nature and The Greeks' and 'Science and Humanism'-Cambridge University Press (2014) PDFDocument186 pages(Canto Classics) Erwin Schrödinger - 'Nature and The Greeks' and 'Science and Humanism'-Cambridge University Press (2014) PDFJack Bravo100% (4)