Professional Documents

Culture Documents

VW Passat B5 Ignition Servicing (SERVICE)

Uploaded by

José Luis OrmeñoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VW Passat B5 Ignition Servicing (SERVICE)

Uploaded by

José Luis OrmeñoCopyright:

Available Formats

28-1

Ignition, servicing

Ignition system, general notes

Notes: This section deals especially with components having to do with ignition. Other components of the injection and ignition system.

Repair Group 24 The Engine Control Module (ECM) is equipped with an On Board Diagnostic (OBD) Components marked with * are checked via On Board Diagnostic (OBD). Page 01-28 , checking DTC memory For the electric components to work properly, a voltage of at least 11.5 V is required. It is possible that the control module will recognize a malfunction and store a DTC during some tests. Therefore, after all tests and repairs have been performed, DTC memory should be

checked and erased if necessary 28 , Checking DTC memory. Safety precautions Page 28-5 . Page 28-7

Page 01-

Test data, spark plugs

28-2

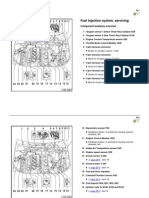

Ignition system components, removing and installing

A parts: Only for engine code ATW B parts: Only for engines AUG, AWM 1 - Connector Black, 4-pin 2 - Ignition coil with power output stage (-N70-, -N127, -N291-, -N292-) Checking Page 28-10

Tighten mounting bolts to 10 Nm Use T10094 removal tool to remove 3 - Seal Replace if damaged 4 - Spark plug, 30 Nm Remove and install with 3122 B Type and spark plug gap spark plugs Page 28-7 , test data,

28-3

5 - 3-pin harness connector Terminals are gold-plated Brown for Knock Sensor (KS) 1 -G61Black for Knock Sensor (KS) 2 -G666 - 20 Nm Tightening torque affects function of Knock Sensor (KS) 7 - Knock Sensor (KS) 1 -G61-* Terminals of sensor and connector are gold-plated Checking Page 28-14

8 - Knock Sensor (KS) 2 -G66-* Terminals of sensor and connector are gold-plated Checking Page 28-14

28-4

9 - Connector Black, 3-pin 10 - 10 Nm 11 - Camshaft Position (CMP) sensor -G163-* Checking 12 - 25 Nm 13 - Washer Conical 14 - Face plate For Camshaft Position (CMP) sensor 2 -G163Note position when installing 15 - Ground (GND) wire Do not loosen or tighten unless ignition is switched off. 16 - 10 Nm Do not loosen or tighten unless ignition is switched off. Page 28-8

28-5

Safety precautions

To reduce the risk of personal injury and/or damage to the fuel injection and ignition system, always observe the following: Do not touch or disconnect ignition wires when engine is running or turning at starting RPM. Only disconnect and reconnect wires for injection and ignition system, including test leads, when ignition is turned off. If engine is to be cranked at starting RPM without starting: - Remove fuses 29 and 32. Notes: By removing fuse 29, voltage supply to the ignition coils is interrupted. By removing fuse 32, voltage supply to the fuel injectors is interrupted.

28-6

If special testing equipment is required during road test, note the following: Test equipment must always be secured to the rear seat and operated from there by a second person. If test and measuring equipment is operated from the passenger seat, the person seated there could be injured in the event of an accident involving deployment of the passenger-side airbag.

28-7

Test Data, Spark Plugs

Engine identification Firing sequence Spark plugs1) VW/Audi Manufacturer code Spark plug gap Tightening torque

1)

ATW 1-3-4-2

AUG, AWM 1-3-4-2

101 000 063 AA 101 000 063 AA PFR 6 Q max. 0.8 mm 30 Nm PFR 6 Q max. 0.8 mm 30 Nm

Use 3122B spark plug removal tool to remove and install spark plugs

28-8

Camshaft Position (CMP) sensor, checking

Special tools and equipment VAG1598/31 adapter cable VAG1526 multimeter or VAG1715 multimeter VAG1594 connector test kit Wiring diagram Test requirement Battery voltage must be at least 11.5 volts. Test sequence - Disconnect 3-pin connector -1- from Camshaft Position (CMP) sensor -2-. - Use adapter cables from VAG1594 to connect multimeter to outer terminals of connector for voltage measurement. - Switch ignition on. Specification: at least 4.5 V

- Switch ignition off.

28-9

- Connect VAG1598/31 adapter cable to control module wiring harness. Engine Control Module (ECM) is not connected.

- Check for open circuits in wires between test box and connector according to wiring diagram. Terminal 1 + socket 98 Terminal 2 + socket 86 Terminal 3 + socket 108 Wire resistance: max: 1.5 - Check wires for shorts between one another. If no malfunctions are found in the wires and there was voltage between terminals 1 + 3: - Replace Camshaft Position (CMP) Sensor 2 -G163-. If no errors are found in wires and there was no voltage between terminals 1 + 3:

- Replace Engine Control Module (ECM)

Page 24-120 .

28-10

Ignition coils with power output stages, checking

Special tools and equipment VAG1598/31 adapter cable VAG1526 multimeter or VAG1715 multimeter VAG1594 connector test kit VAG1527 voltage tester Wiring diagram Test requirements Battery voltage must be at least 11.5 volts. Camshaft Position (CMP) sensor must be OK, checking Page 28-8 . Engine speed (RPM) sensor must be OK, checking Page 24-57 .

28-11

Test sequence I - Engine code ATW II - Engine codes AUG, AWM - Disconnect 4-pin connector -2- from ignition coil -1- to be checked. - Measure supply voltage between terminals 1 + 2 and 1 + 4 of disconnected connector using the multimeter and adapter cables from the VAG1594 connector test kit. - Switch ignition on. Specification: at least 11.5 V - Switch ignition off. If there is no voltage: - Check wire between 4-pin connector terminal 1 and relay carrier for open circuits according to wiring diagram. Wire resistance: max: 1.5 - Check wires between 4-pin connector and Ground (GND) for open circuits according to wiring diagram. Terminal 2 and Ground (GND) Terminal 4 and Ground (GND) Wire resistance: max: 1.5

28-12

If there is no malfunction in voltage supply: - Check activation Checking activation - Remove fuse 32. Note: By removing fuse 32, voltage supply to the fuel injectors is interrupted. I - Engine code ATW II - Engine codes AUG, AWM Page 28-12

- Use auxiliary wires from VAG1594 to connect diode test lamp VAG1527 to terminals 2 and 3 of disconnected connector. - Operate starter and test ignition signal from Engine Control Module (ECM). LED should flicker. - Switch ignition off.

28-13

If LED flickers and voltage supply is OK: - Replace ignition coils with power output stage If LED does not flicker: - Check wires Checking wiring - Connect VAG1598/31 adapter cable to control module wiring harness. Engine Control Module (ECM) is not connected. I - Engine code ATW II - Engine codes AUG, AWM Page 28-13 .

- Check wires between test box and 4-pin connector for open circuits according to wiring diagram. Cylinder 1 terminal 3 + socket 102 Cylinder 2 terminal 3 + socket 95

Cylinder 3 terminal 3 + socket 103 Cylinder 4 terminal 3 + socket 94 Wire resistance: max: 1.5 - Check wires for shorts among one another. If there is no malfunction in wire connections: - Replace Engine Control Module (ECM) Page 24-120 .

28-14

Knock sensors, checking

Notes: For the Knock Sensors to function properly, it is important for tightening torque to be exactly 20 Nm. Use only gold-plated terminals when servicing terminals in harness connector of knock sensors. Special tools and equipment VAG1598/31 adapter cable VAG1526 multimeter or VAG1715 multimeter VAG1594 connector test kit Wiring diagram Test requirement On Board Diagnostic (OBD) must have recognized a malfunction at one or both of

the Knock Sensors (KS).

28-15

Test sequence Engine code AWM - Connect V.A.G1551 scan tool (VAG1552). Start engine and select Engine Control Module (ECM) using address word 01. (connecting scan tool and selecting ECM Page 01-20 )

Rapid data transfer Select function XX HELP

Indicated on display: - Press buttons -0- and -4- to select "Basic Setting" function 04. Press -Q- button to confirm input.

Basic setting Enter display group number XXX

HELP

Indicated on display: - Press buttons -0-, -2- and -8- to select "Display group number 28". Press -Qbutton to confirm input.

System in basic setting 28 1 2 3 4

Indicated on display: - Use VAG1788/10 speed adjuster tool to adjust engine RPM to at least 2600 RPM: - Maintain engine speed until indication in display field 4 jumps from "Test OFF" to "Test ON".

28-16

- Continue to maintain engine speed until display field 4 indicates specified value:"Syst. OK". If specified values are obtained: - Press button.

- Press buttons -0- and -6- to select "End Output" function 06. Press -Q- button to confirm input. - Switch ignition off. If specified values are not obtained: - Check resistances and wiring: Checking resistances and wires I - Engine code ATW II - Engine codes AUG, AWM - Disconnect 3-pin harness connector to Knock Sensor (KS) 1 -G61- (green, item no. 1) and/or 3-pin harness connector to Knock Sensor (KS) 2 -G66- (blue, item no. 2). - Measure resistance between terminals 1 + 2, 1 + 3, and 2 + 3 at connectors to

knock sensors. Specification: If specified value is not obtained:

28-17

- Replace Knock Sensor(s) If specified value is obtained: - Connect VAG1598/31 adapter cable to control module wiring harness. Engine Control Module (ECM) is not connected. - Check wiring between test box and 3-pin connector for open circuit according to wiring diagram.

G61: Terminal 2 + socket Terminal 2 + socket Terminal 3 + socket Wire resistance: 106 99 108

G66: 107 99 108

max: 1.5

- Check wires for shorts between one another. If no malfunctions are found in wires:

- Loosen Knock Sensor (KS) and then retighten to 20 Nm. - Perform a road test. The following operating conditions must be obtained during road test: Coolant temperature must rise to above 80 C.

28-18

Once the temperature is reached, the operating conditions Idle Partial throttle Wide Open Throttle (WOT) Deceleration must be reached several times each. Engine speed must be increased to above 3500 RPM during Wide Open Throttle (WOT). - Check control module DTC memory again. If complaint persists: - Replace Knock Sensor(s)

28-19

Misfire recognition, checking

Special tools and equipment V.A.G1551 scan tool (or VAG1552 mobile scan tool) with VAG1551/3B cable Test sequence - Connect V.A.G1551 scan tool (VAG1552). Start engine and select Engine Control Module (ECM) using address word 01. (connecting scan tool and selecting ECM Page 01-20 )

Rapid data transfer Select function XX HELP

Indicated on display: - Press buttons -0- and -8- to select "Read measuring value block" function 08. Press -Q- button to confirm input.

Read measuring value block Enter display group number XXX

Indicated on display: - Press buttons -0-, -1- and -4- to select "display group number 14" and then press -Q- button to confirm input.

Read measuring value block 14 1 2 3 4

Indicated on display: (1 to 4

display fields)

- Check total number of misfires in display field 3:

Specification: 0 to 5

28-20

- Check status of misfire recognition in display field 4: Specification: activated If specified values are obtained: - Press button.

- Press buttons -0- and -6- to select "End Output" function 06. Press -Q- button to confirm input. - Switch ignition off. If specified values are not obtained: - Check spark plugs Page 28-2 , Parts of ignition, removing and installing - Check ignition coils with power output stage Page 28-10 - Check fuel injector Page 24-61

You might also like

- VW Passat B5 24 Fuel Injection Sys, ServicingDocument126 pagesVW Passat B5 24 Fuel Injection Sys, ServicingJosé Luis Ormeño100% (4)

- VW Passat b5 70-1 Instrument PanelDocument13 pagesVW Passat b5 70-1 Instrument PanelJosé Luis Ormeño75% (4)

- VW Passat B5 87-132 AC Refrigerant SysDocument9 pagesVW Passat B5 87-132 AC Refrigerant SysJosé Luis Ormeño100% (1)

- Climatronic Self DiagnosticsDocument7 pagesClimatronic Self Diagnosticsmuath007100% (1)

- VW Passat B5 57-32 Central LockingDocument10 pagesVW Passat B5 57-32 Central LockingJosé Luis Ormeño100% (2)

- VW Passat B5 21 (38) Charge Air SystemDocument47 pagesVW Passat B5 21 (38) Charge Air SystemJosé Luis OrmeñoNo ratings yet

- VW Passat b5 Door Lock Mechanism RepairDocument8 pagesVW Passat b5 Door Lock Mechanism RepairJosé Luis Ormeño67% (3)

- VW Passat B5 58-1 Rear DoorDocument26 pagesVW Passat B5 58-1 Rear DoorJosé Luis Ormeño100% (2)

- Manual Climatronic b5Document61 pagesManual Climatronic b5Muraru Dan91% (11)

- VW Passat B5 ATF Fluid & Filter ChangeDocument6 pagesVW Passat B5 ATF Fluid & Filter ChangeJosé Luis Ormeño100% (3)

- VW Passat B5 69-28 AirbagDocument40 pagesVW Passat B5 69-28 AirbagJosé Luis Ormeño67% (3)

- Running Gear SystemDocument35 pagesRunning Gear SystemMohammed Bin Jafarullah100% (2)

- Volkswagen Passat B5 Work ProceduresDocument182 pagesVolkswagen Passat B5 Work ProceduresJurek Ogórek100% (1)

- VW Passat B5.5 Service Light Reset ProceedureDocument1 pageVW Passat B5.5 Service Light Reset ProceedureJosé Luis Ormeño100% (1)

- Volkswagen Passat B5 VCDS InfoDocument3 pagesVolkswagen Passat B5 VCDS InfoAnthony Yao Hama100% (2)

- b5 45-06Document15 pagesb5 45-06Tanee BoonmalertNo ratings yet

- VW Climatronic Codes Service EngDocument24 pagesVW Climatronic Codes Service Engmegatron_vf50% (2)

- VW Passat B5 42-1 Rear Axle, FFDocument19 pagesVW Passat B5 42-1 Rear Axle, FFJosé Luis Ormeño100% (1)

- VW Passat Brake SystemsDocument100 pagesVW Passat Brake SystemsMihai Ioan100% (6)

- Repair ABS Unit PassatDocument13 pagesRepair ABS Unit Passatbars_winner100% (3)

- DIY Heated Seats RetrofitDocument27 pagesDIY Heated Seats RetrofitvalymadNo ratings yet

- b6 42 EngDocument159 pagesb6 42 EngepicenterrulezNo ratings yet

- Passat Fuse and Relay LocationsDocument10 pagesPassat Fuse and Relay Locationsgosa46100% (3)

- 2006 E320cdi E350 E500 E3505004matic E55amgDocument521 pages2006 E320cdi E350 E500 E3505004matic E55amgacer012006No ratings yet

- Timitng Belt Replacement Procedure For A VW Passat b5Document18 pagesTimitng Belt Replacement Procedure For A VW Passat b5forray_catalin2000100% (1)

- VW Passat b5 Motronic Injection 1 8 LTR EngDocument160 pagesVW Passat b5 Motronic Injection 1 8 LTR EngChiulafli FediaNo ratings yet

- MHH - Co+reset SBC w211Document1 pageMHH - Co+reset SBC w211هشام محمدNo ratings yet

- MK4 B5 ColorMFA Install GuideDocument17 pagesMK4 B5 ColorMFA Install GuideAbdelouahab TOUATINo ratings yet

- W211 Compressor (Turbo) Removal Install PDFDocument2 pagesW211 Compressor (Turbo) Removal Install PDFTiago SantosNo ratings yet

- 2,3l Motronic (AGZ) 1Document14 pages2,3l Motronic (AGZ) 1Bernardo Verber100% (2)

- b6 70 PDFDocument81 pagesb6 70 PDFVlad ZahiuNo ratings yet

- Passat Eletric Parking BrakeDocument36 pagesPassat Eletric Parking Brakedelbo101071% (7)

- Omegas Plus: Software ManualDocument40 pagesOmegas Plus: Software ManualВіктор ЛялькаNo ratings yet

- Front Suspension, ServicingDocument4 pagesFront Suspension, ServicingpabloNo ratings yet

- Remove E60 530d Turbo PDFDocument2 pagesRemove E60 530d Turbo PDFmassimo1983100% (2)

- VW Golf 5 - Electromechanical Steering Gear, Servicing (Generation I)Document43 pagesVW Golf 5 - Electromechanical Steering Gear, Servicing (Generation I)NPNo ratings yet

- A4 B8 Stereo RemovalDocument7 pagesA4 B8 Stereo RemovalMickyman123No ratings yet

- VCDS Mods-Tweaks Passat B7 NMSDocument7 pagesVCDS Mods-Tweaks Passat B7 NMSFelipe ZanellaNo ratings yet

- Webasto Telestart T90 Octavia Installation GuideDocument12 pagesWebasto Telestart T90 Octavia Installation GuidePavel CosminNo ratings yet

- E90 PDC PinoutDocument2 pagesE90 PDC PinoutkojcanNo ratings yet

- Schema Electrica VW PassatDocument160 pagesSchema Electrica VW Passatonuta780% (5)

- b5 Rear Drive ShaftDocument11 pagesb5 Rear Drive ShaftTanee BoonmalertNo ratings yet

- b5 Ign Serv AhaDocument41 pagesb5 Ign Serv AhacoronacoralineNo ratings yet

- Engine Speed (RPM) Sensor - G28-, Checking: Special Tools and EquipmentDocument6 pagesEngine Speed (RPM) Sensor - G28-, Checking: Special Tools and EquipmentSuksan SananmuangNo ratings yet

- NB 28 Ignition Eng BNDocument30 pagesNB 28 Ignition Eng BNCristian ManolacheNo ratings yet

- Transmission Electrical Testing On 096Document45 pagesTransmission Electrical Testing On 096Michelle KerriganNo ratings yet

- Ignition System, Servicing: 28-1, General Notes On Ignition System 28-1, Safety Precautions 28-1, Ignition, AssemblyDocument5 pagesIgnition System, Servicing: 28-1, General Notes On Ignition System 28-1, Safety Precautions 28-1, Ignition, AssemblyspikerowNo ratings yet

- Mercedes Benz Engine Fault Code GuideDocument37 pagesMercedes Benz Engine Fault Code GuideAda Paloma Soto Brambila90% (40)

- Diagram Encend Transporter t4Document27 pagesDiagram Encend Transporter t4juventinocoronapNo ratings yet

- VW Passat B5 Exhaust System 1,8 Aug AwmDocument14 pagesVW Passat B5 Exhaust System 1,8 Aug AwmNPNo ratings yet

- 28-21 Engine Speed Sensor Checking and AdjustingDocument0 pages28-21 Engine Speed Sensor Checking and AdjustingMuhammad Nico PermanaNo ratings yet

- MSB 97e17 502 PDFDocument10 pagesMSB 97e17 502 PDFAutof FerreiraNo ratings yet

- Engine Control System: General InformationDocument47 pagesEngine Control System: General InformationاحمدميدوNo ratings yet

- A4 18T AEB Cam Sensor CheckDocument2 pagesA4 18T AEB Cam Sensor CheckVolker Traudt100% (1)

- VW Golf 4 Secondary Air Injection System - Engines: Aeg Avh AzgDocument22 pagesVW Golf 4 Secondary Air Injection System - Engines: Aeg Avh AzgNPNo ratings yet

- Bentley Audi A6 C5 IgnitionDocument82 pagesBentley Audi A6 C5 Ignitiontjonkka100% (3)

- RAPTORDocument16 pagesRAPTORp.motortechNo ratings yet

- 2008 Chevrolet HHR DTCDocument6 pages2008 Chevrolet HHR DTCTal Benyamin100% (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- VW Passat b5 Door Lock Mechanism RepairDocument8 pagesVW Passat b5 Door Lock Mechanism RepairJosé Luis Ormeño67% (3)

- VW Passat B5.5 Service Light Reset ProceedureDocument1 pageVW Passat B5.5 Service Light Reset ProceedureJosé Luis Ormeño100% (1)

- VW Passat B5 ATF Fluid & Filter ChangeDocument6 pagesVW Passat B5 ATF Fluid & Filter ChangeJosé Luis Ormeño100% (3)

- VW Passat B5 1998 System Wiring Diagrams, Schematy by - Chytry - KlechaDocument74 pagesVW Passat B5 1998 System Wiring Diagrams, Schematy by - Chytry - KlechaJosé Luis Ormeño100% (1)

- VW Passat B5 Aeb - Timing - BeltDocument3 pagesVW Passat B5 Aeb - Timing - BeltJosé Luis Ormeño100% (1)

- VW Passat B5 70-14 Door TrimDocument13 pagesVW Passat B5 70-14 Door TrimJosé Luis Ormeño100% (1)

- VW Passat B5 48-15 Steering ColumnDocument23 pagesVW Passat B5 48-15 Steering ColumnAleksandar Kovačević100% (1)

- VW Passat B5 58-1 Rear DoorDocument26 pagesVW Passat B5 58-1 Rear DoorJosé Luis Ormeño100% (2)

- VW Passat B5 69-28 AirbagDocument40 pagesVW Passat B5 69-28 AirbagJosé Luis Ormeño67% (3)

- VW Passat B5 42-1 Rear Axle, FFDocument19 pagesVW Passat B5 42-1 Rear Axle, FFJosé Luis Ormeño100% (1)

- VW Passat B5 21 (38) Charge Air SystemDocument47 pagesVW Passat B5 21 (38) Charge Air SystemJosé Luis OrmeñoNo ratings yet

- SSP 191 - VW Passat B5 '97 - Construction & OperationDocument47 pagesSSP 191 - VW Passat B5 '97 - Construction & OperationaleuzevaxNo ratings yet

- DYNAPAC Scc900-3enDocument180 pagesDYNAPAC Scc900-3enCuiNo ratings yet

- Engine Brake Flap MB 542.9Document2 pagesEngine Brake Flap MB 542.9GeorgeNo ratings yet

- ++++u30000 - Us Motor NameplateDocument2 pages++++u30000 - Us Motor NameplatevuongNo ratings yet

- 2 Gears PDFDocument67 pages2 Gears PDFPushkar TaralekarNo ratings yet

- Boots Do TremDocument4 pagesBoots Do TremBiblioteca Brasil AviationNo ratings yet

- ABB Synchronous MotorsDocument20 pagesABB Synchronous Motorsidontlikeebooks0% (1)

- Ecofard 700 Aa MB PDFDocument25 pagesEcofard 700 Aa MB PDFMichael George100% (1)

- Perkins Engine 1306C-E87TAG6 SERIES SPARE PARTSDocument2 pagesPerkins Engine 1306C-E87TAG6 SERIES SPARE PARTSIbrahim YunusNo ratings yet

- 349 F Esquema ElectricoDocument46 pages349 F Esquema ElectricoBASILIO JARA HUERTA100% (1)

- Service Manual Trucks: Anti-Lock Brake System (ABS) Meritor Wabco With E Version Ecu VN/VHDDocument66 pagesService Manual Trucks: Anti-Lock Brake System (ABS) Meritor Wabco With E Version Ecu VN/VHDjose luis100% (5)

- Indonesia RTGC Retrifit 22 Unit - NewDocument189 pagesIndonesia RTGC Retrifit 22 Unit - NewMechatronic EngineeringNo ratings yet

- 3 SyllabusDocument2 pages3 SyllabusVel MuruganNo ratings yet

- Double Acting Hacksaw Using Scotch Yoke Mechanism: Project Report 2016Document38 pagesDouble Acting Hacksaw Using Scotch Yoke Mechanism: Project Report 2016JEFFRY ANTO PRAKASH VNo ratings yet

- Grashof's Law Explained - Four-Bar Linkage MechanismsDocument3 pagesGrashof's Law Explained - Four-Bar Linkage MechanismsSyed Faiz QuadriNo ratings yet

- Volvo EC210C Specs SheetDocument1 pageVolvo EC210C Specs SheetShlomo AbrarNo ratings yet

- Induction MotorDocument20 pagesInduction MotorC V VIJAY KUMASRNo ratings yet

- Diagrama Motor Cummins Qsb5, Qsb7 12v, y Qsl9 24vDocument6 pagesDiagrama Motor Cummins Qsb5, Qsb7 12v, y Qsl9 24vsticortesNo ratings yet

- NKE Bearings For Industrial GearboxesDocument4 pagesNKE Bearings For Industrial GearboxesAdrian Rodrigo Jofre AlvarezNo ratings yet

- 6M170AP-5 SeriesDocument2 pages6M170AP-5 SeriesTruong Nguyen ThanhNo ratings yet

- Kverneland OPTIMA HD-09322-11 PDFDocument307 pagesKverneland OPTIMA HD-09322-11 PDFJUAN C48No ratings yet

- Drawing PackageDocument150 pagesDrawing PackageRafael Paixao100% (1)

- Sangamo TimerDocument12 pagesSangamo TimerAmil KariemNo ratings yet

- EPG Electrically Powered Governors With Single Phase Droop: Installation and Operation ManualDocument32 pagesEPG Electrically Powered Governors With Single Phase Droop: Installation and Operation ManualInter Home AguinzaNo ratings yet

- Knocking and Knock Rating of FuelsDocument8 pagesKnocking and Knock Rating of FuelsShivananda BhatNo ratings yet

- SBC AlternatorDocument4 pagesSBC Alternatormalik budi sNo ratings yet

- 03 Mechanism SynthesisDocument124 pages03 Mechanism SynthesisEric ChowNo ratings yet

- KOM Torque Converter Catalogue For Web PDFDocument345 pagesKOM Torque Converter Catalogue For Web PDFChristopher Tedeschi Mattar100% (1)

- REPOWER MM92 UkDocument2 pagesREPOWER MM92 Ukscuderia_f147No ratings yet

- GROUP 4 STEERING DISASSEMBLY AND ASSEMBLYDocument31 pagesGROUP 4 STEERING DISASSEMBLY AND ASSEMBLYGustavo Alonso Cappa SalasNo ratings yet

- SRP1515FP Ultrag12+13+14+15Document669 pagesSRP1515FP Ultrag12+13+14+15Ruben RodriguezNo ratings yet